Ball screw assembly precision retaining testing apparatus with characteristics of precise pre tightening and loading

A ball screw pair, precision maintenance technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effect of ensuring the loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

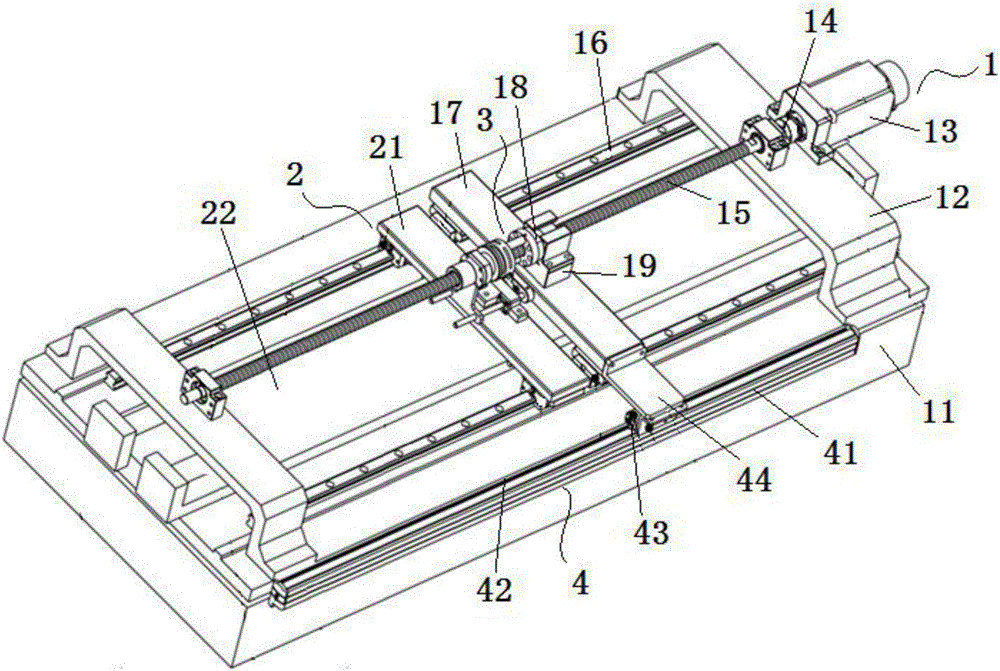

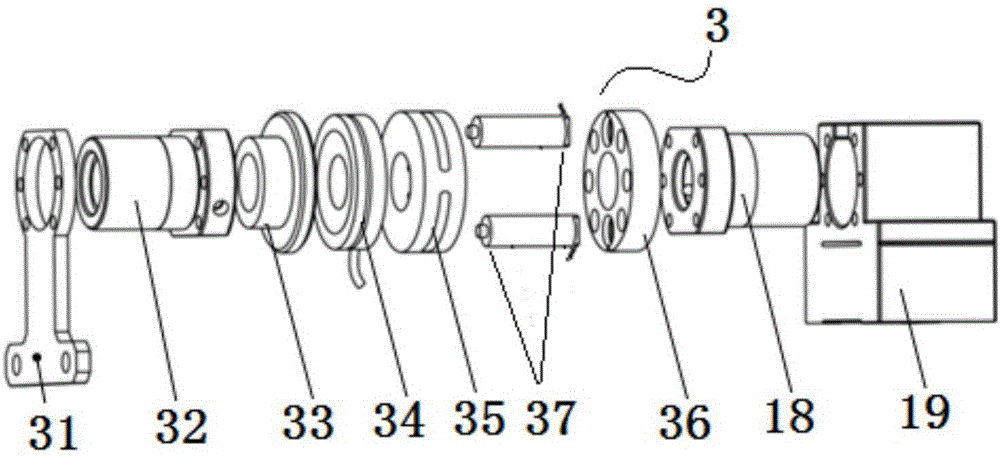

[0016] like figure 1 As shown, the present invention consists of five parts: a linear feed system 1, a load force simulation system 2, a preload force adjustment system 3, a measurement system 4 and a control system.

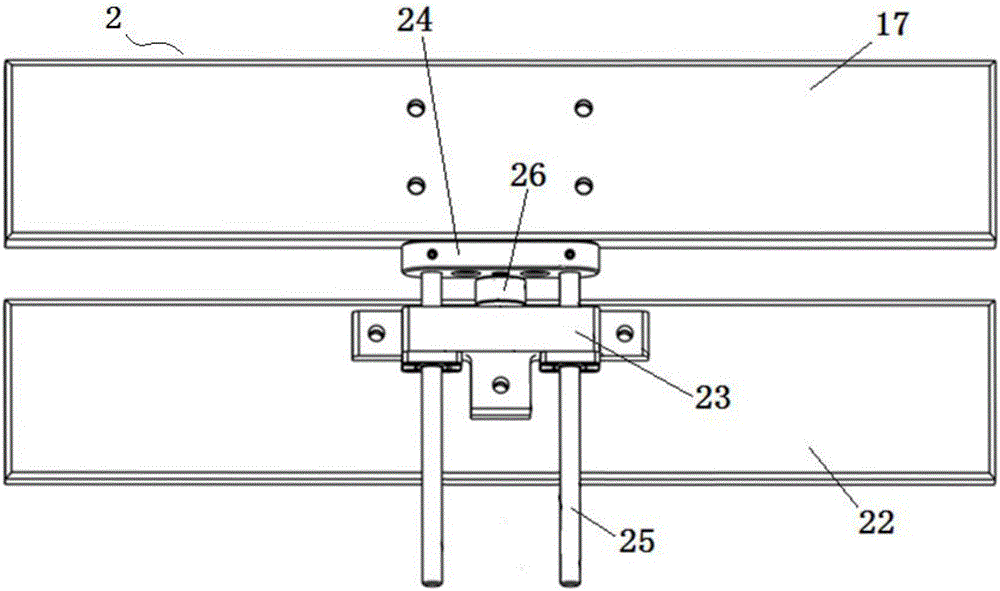

[0017] The linear feed system 1 includes a base 11 , and brackets 12 are fastened and connected to the top ends of the base 11 relatively oppositely, and a servo motor 13 is arranged on one of the brackets 12 , and the output shaft of the servo motor 13 is connected with the coupling 14 . One end of the ball screw 15 , which is rotatably connected between the two brackets 12 , is fastened and connected to drive the ball screw 15 to rotate. On both sides of the top of the base 11 parallel to the axis of the ball screw 15 are respectively fastened guide rails 16 , and a worktable 17 is slidably connected to the two guide rails 16 . A firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com