Patents

Literature

42results about How to "Guaranteed loading accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

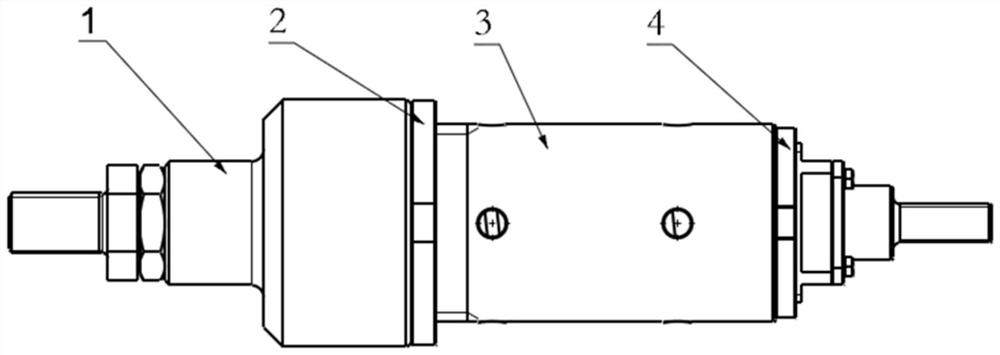

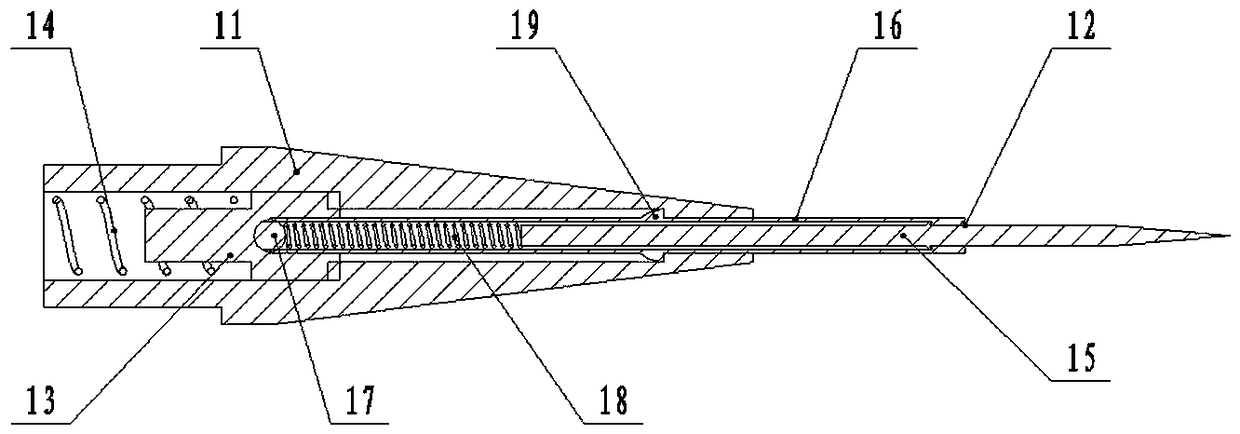

Ball screw assembly precision retaining testing apparatus with characteristics of precise pre tightening and loading

InactiveCN106017915AGuaranteed accuracyGuaranteed a high degree of matchingMachine gearing/transmission testingUltrasound attenuationElectricity

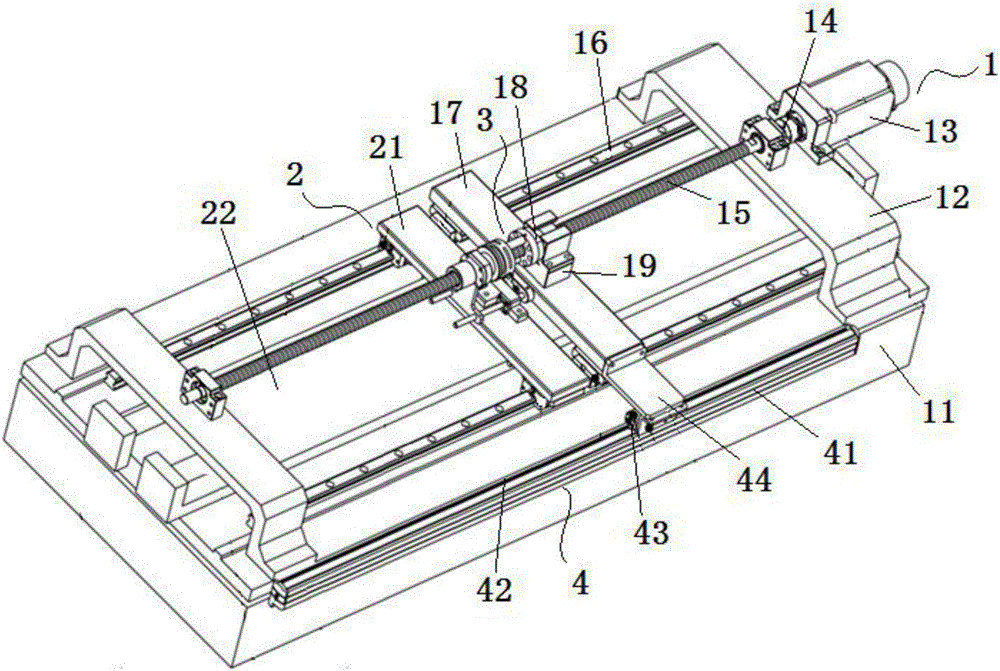

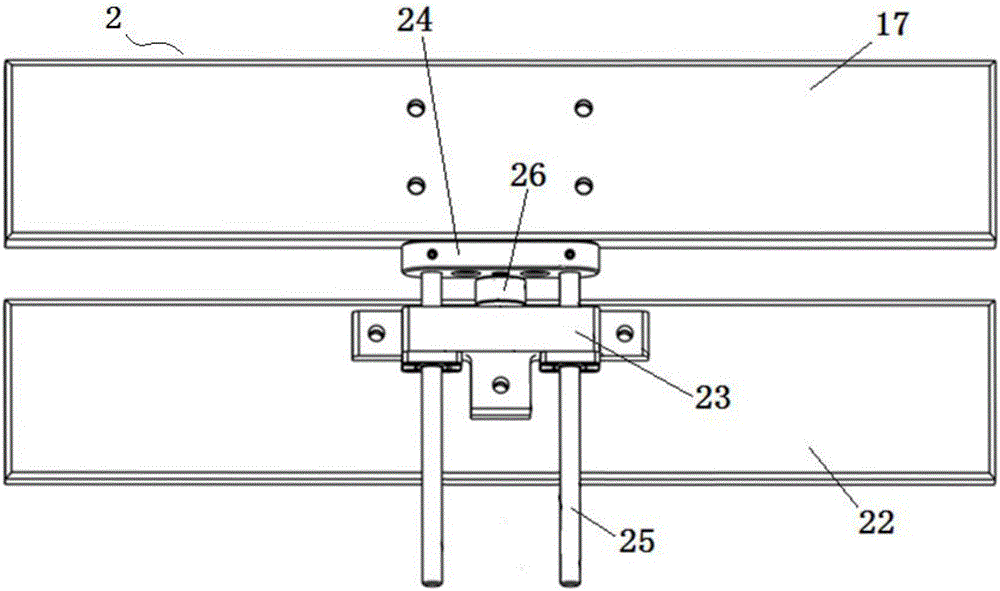

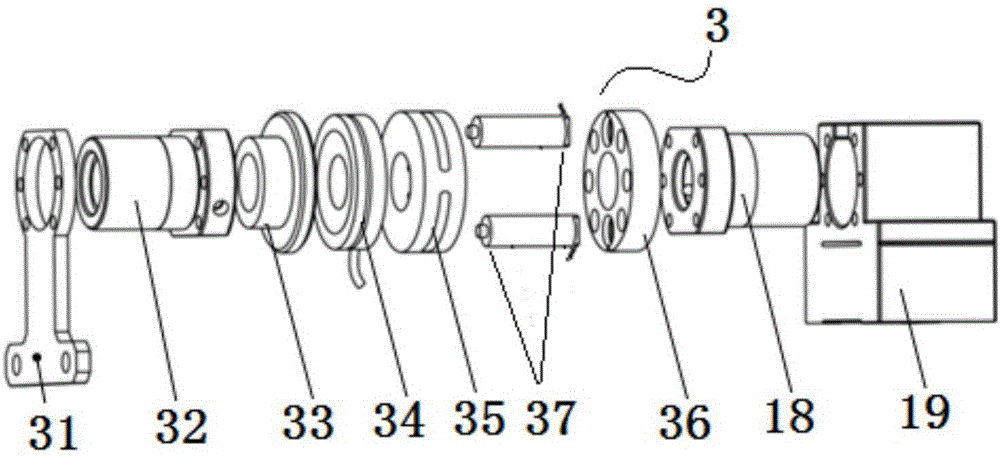

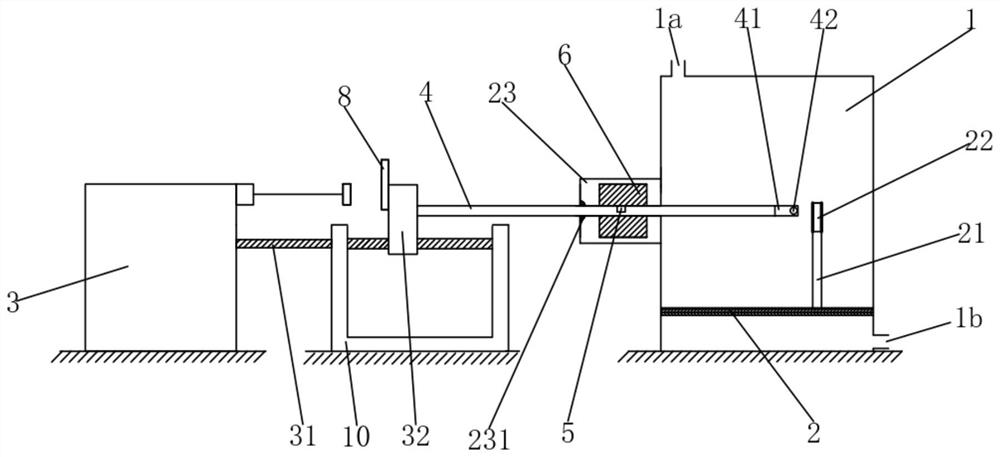

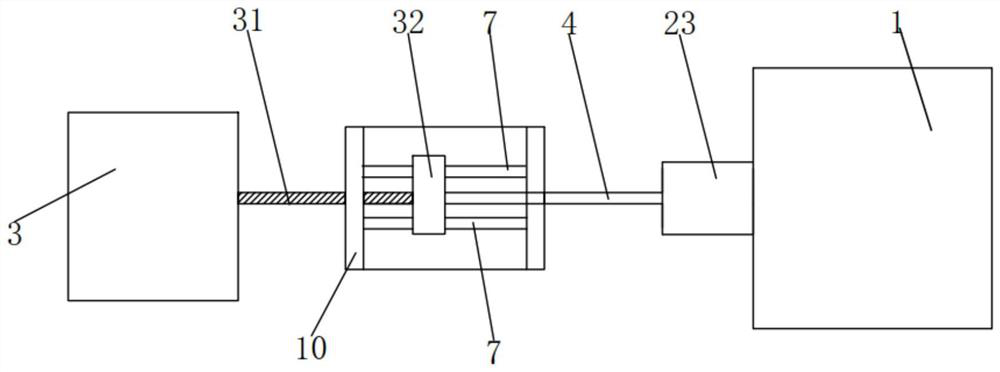

The invention provides a ball screw assembly precision retaining testing apparatus. A linear feeding system comprises a pedestal; supports are arranged at the two ends of the pedestal; a servo motor is arranged at one support and is connected with a ball screw; guide rails are fastened and connected to the two sides of the pedestal; and a work bench is connected on the two guide rails in a sliding mode. A lead screw nut sleeves the ball screw and is connected with the work bench by the lead screw nut firmly. A loading force simulation system consists of a linear motor platform mechanism fixed on the pedestal; and a sliding platform of the linear motor platform mechanism is connected with the sliding rails in a sliding mode. A pull pressure sensor is arranged between the sliding platform and the work bench. A pre-tightening adjusting system includes a lead screw nut, a sleeve, a pressure sensor, a support ring, and a fixed ring, wherein the units sleeve the ball screw in sequence; and a piezoelectric ceramic actuator is arranged between the support ring and the fixed ring. According to the invention, the pre-tightening force of the lead screw nut is controlled precisely based on the expansion value of the piezoelectric ceramic actuator, so that automatic compensation for attenuation of the pre-tightening force during the operation process of the ball screw assembly can be guaranteed.

Owner:TSINGHUA UNIV

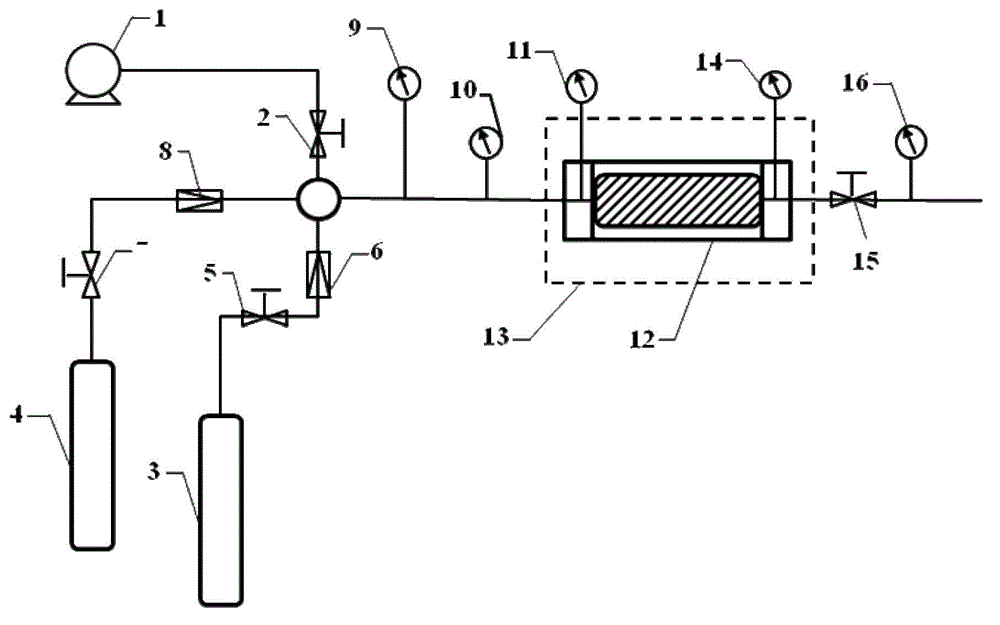

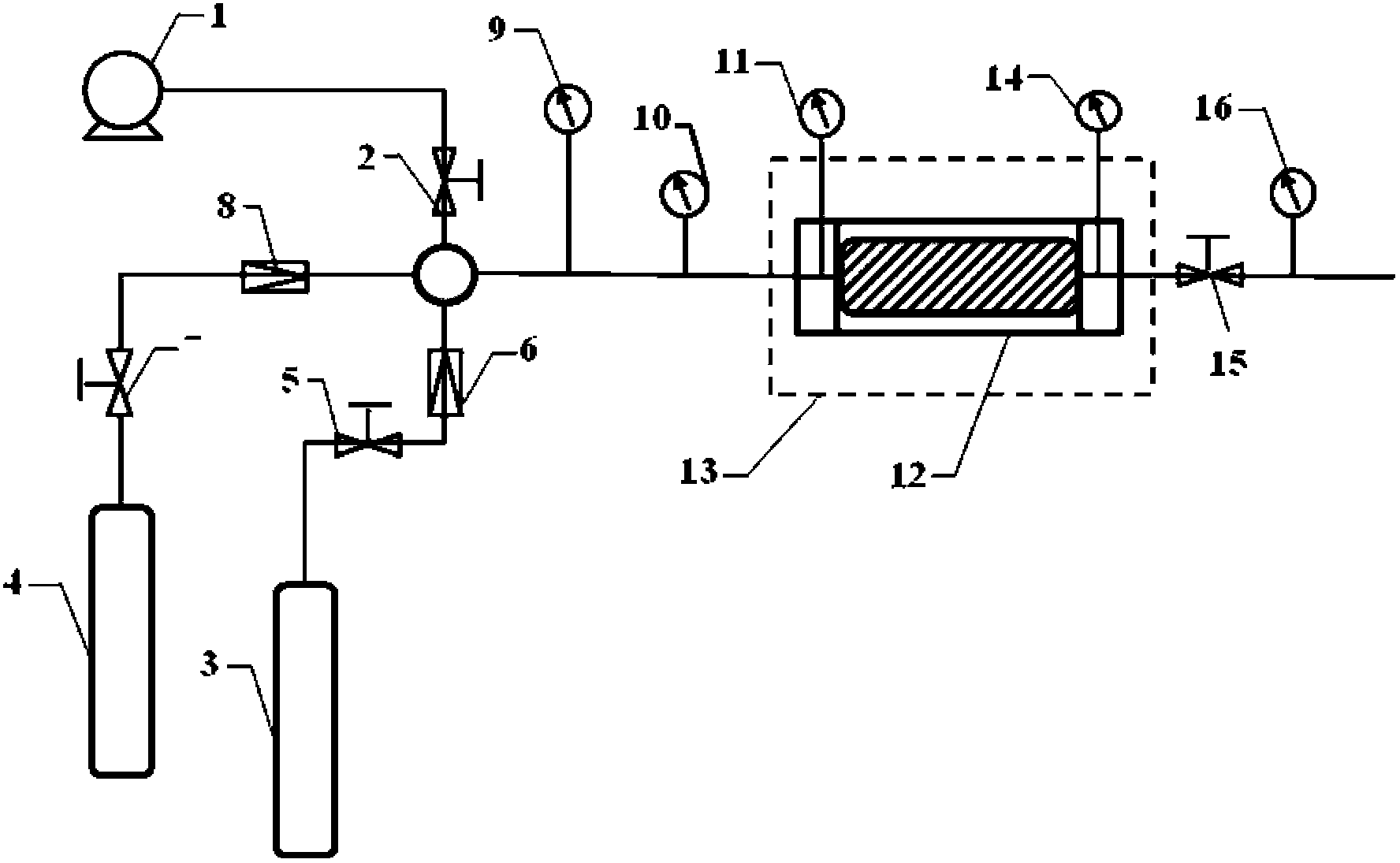

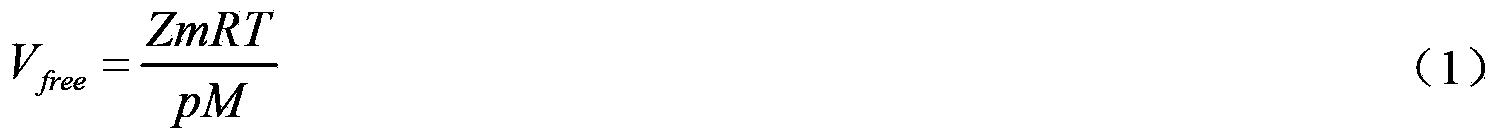

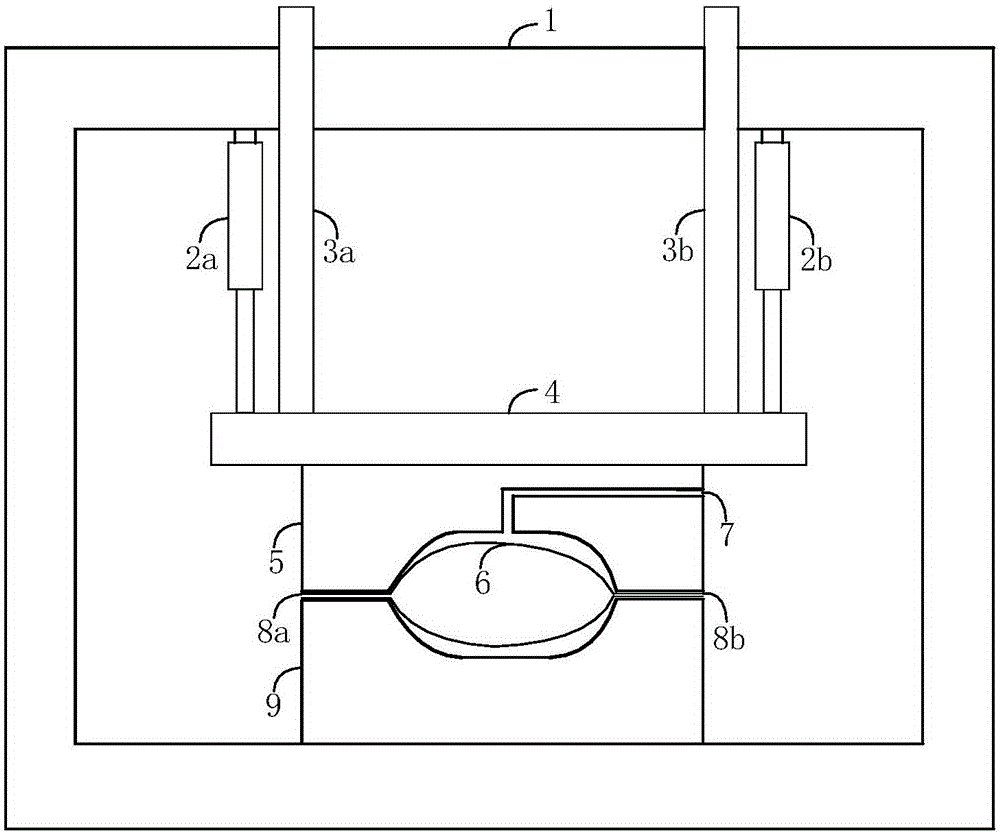

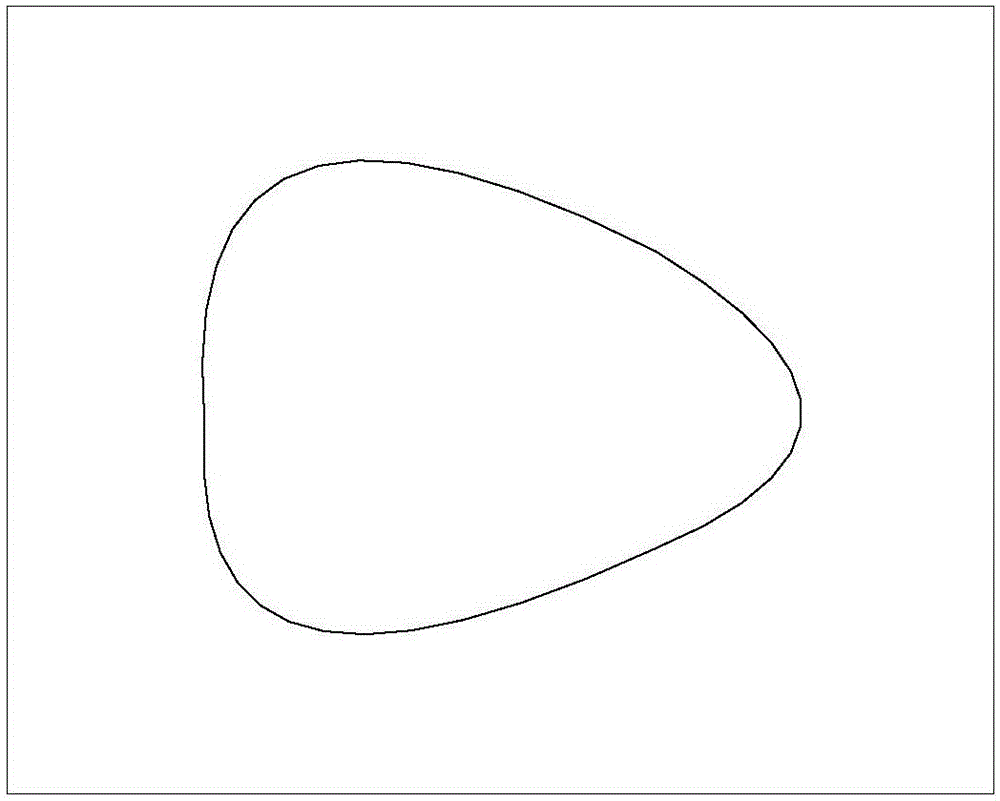

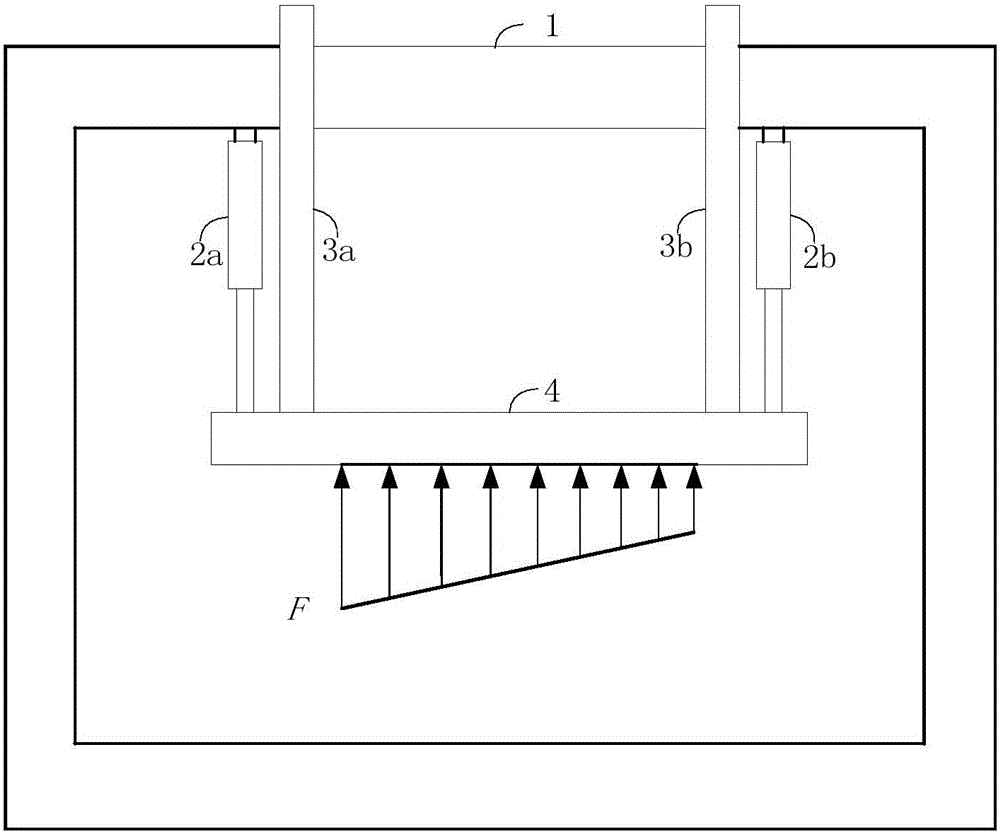

Carbonaceous shale isothermal adsorption/desorption experimental device

The invention provides an experimental device for testing adsorption / desorption amounts of gas on carbonaceous shale and adsorption / desorption curves. The device is mainly composed of real triaxial core clamping and compression system, a system pressure sensor, a system temperature sensor, an inlet end high-grade pressure gauge, an inlet end high-precision gas mass flow meter, an outlet high-precision gas mass flow meter, a vacuum pump, a high pressure helium tank, a high pressure to-be-measured gas cylinder, a thermostat, a corresponding pipeline and a valve. A carbonaceous shale test piece is placed in the real triaxial core clamping and compression system. An initial measuring condition of the test piece is set according to a real formation condition. After free pore volume is set, an adsorption / desorption test of the test piece is performed. According to a gas cumulative discharge value and a balanced system pressure value which are measured and recorded by the inlet end high-precision gas mass flow meter or the outlet end high-precision gas mass flow meter end and the system pressure sensor, adsorbed gas volume is calculated so that the isothermal adsorption / desorption curve of the carbonaceous shale test piece is drawn.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

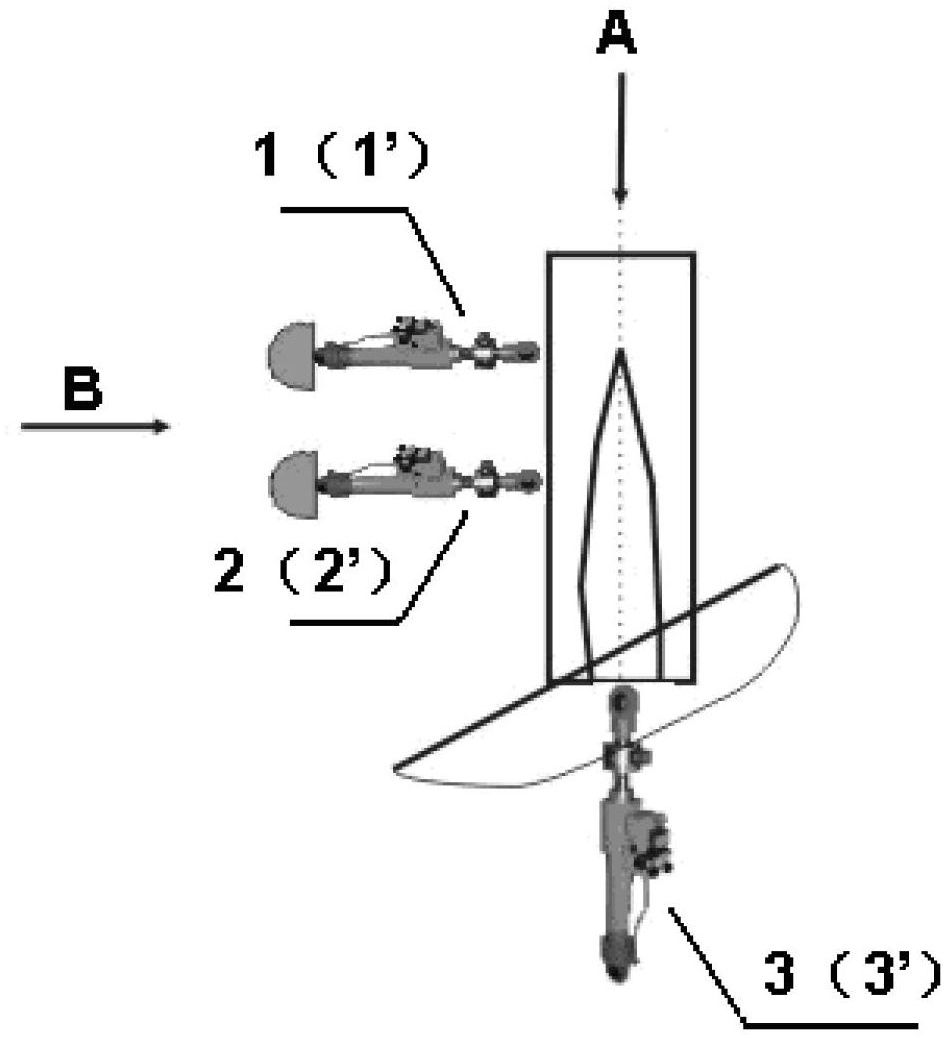

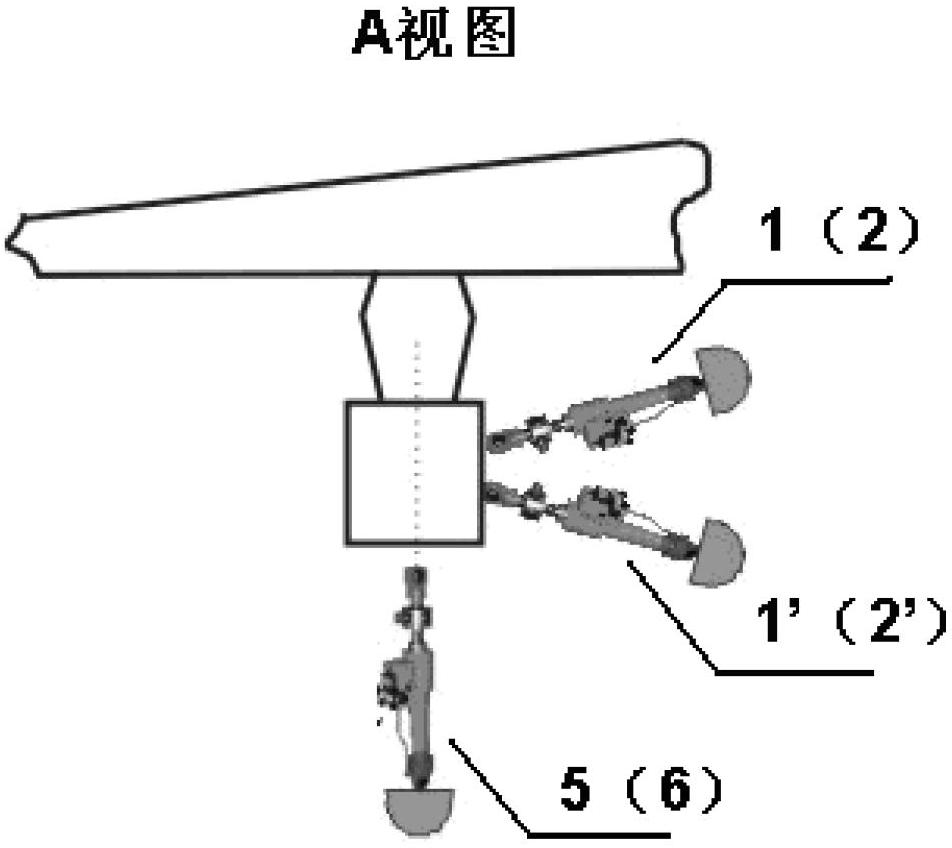

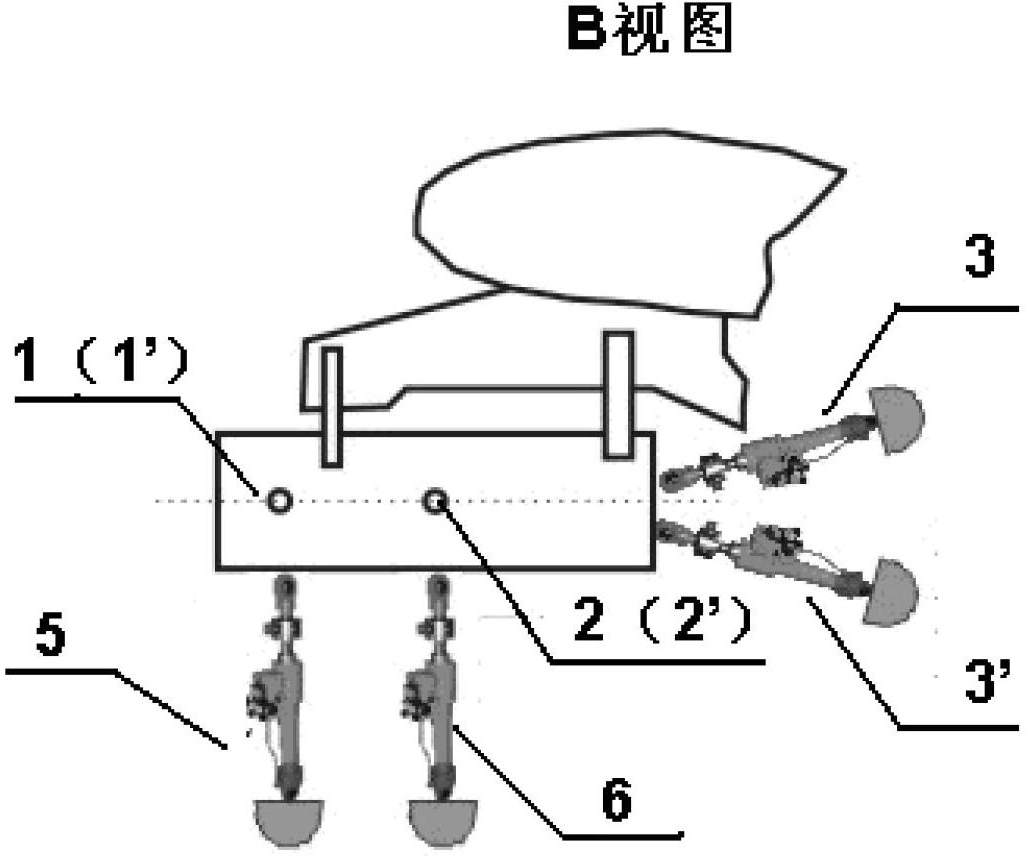

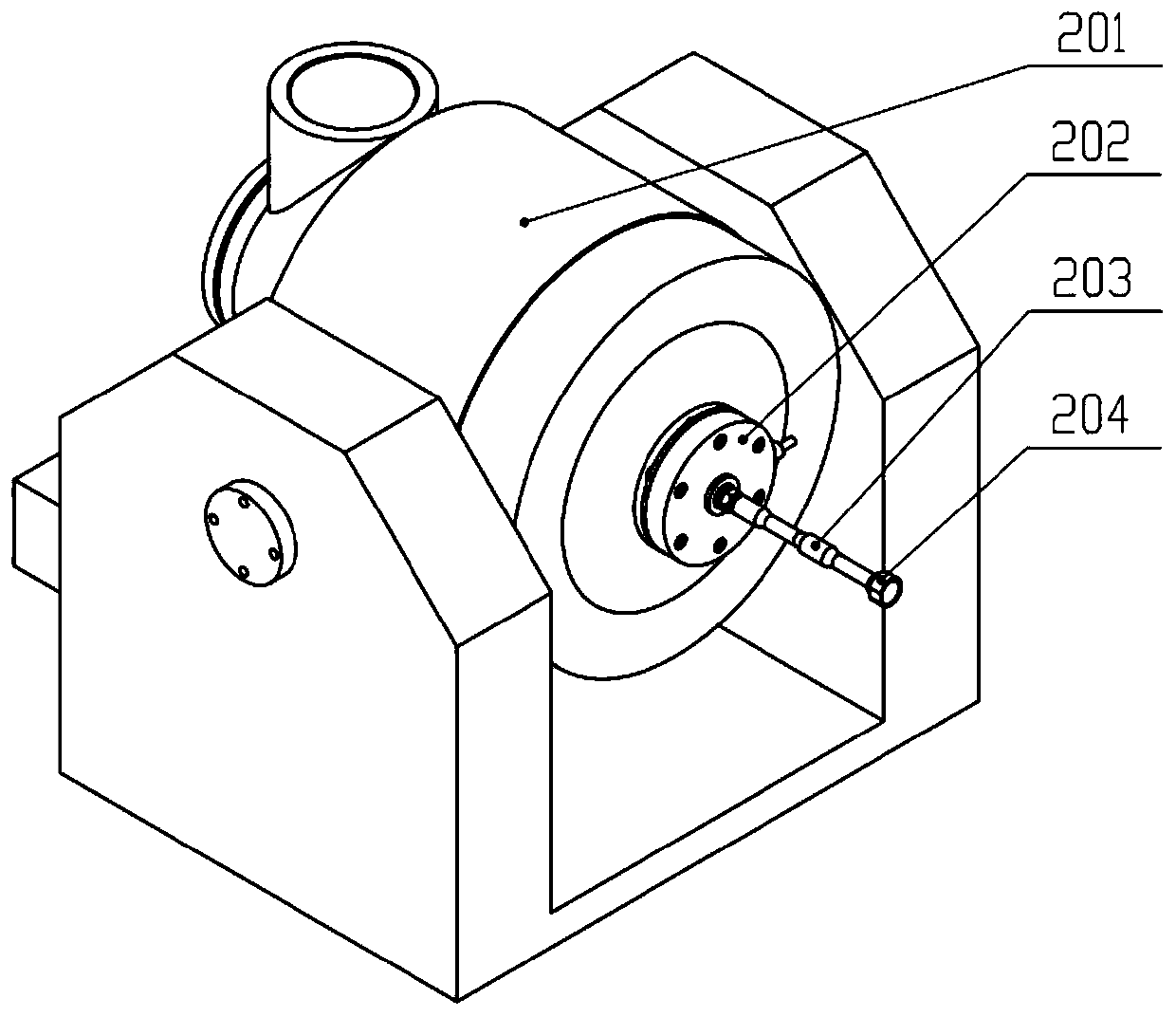

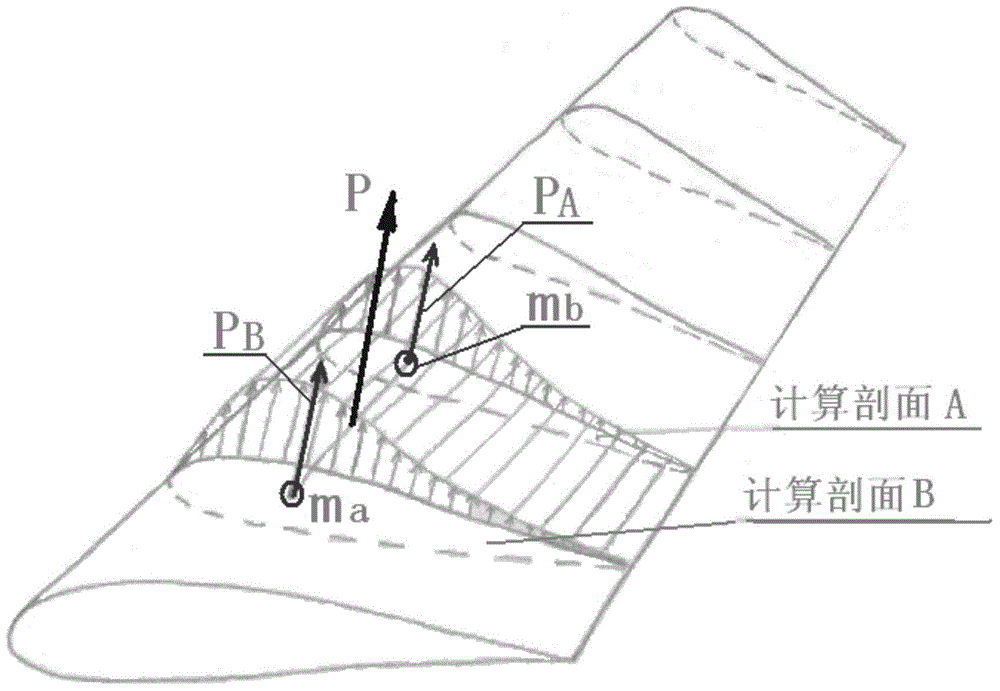

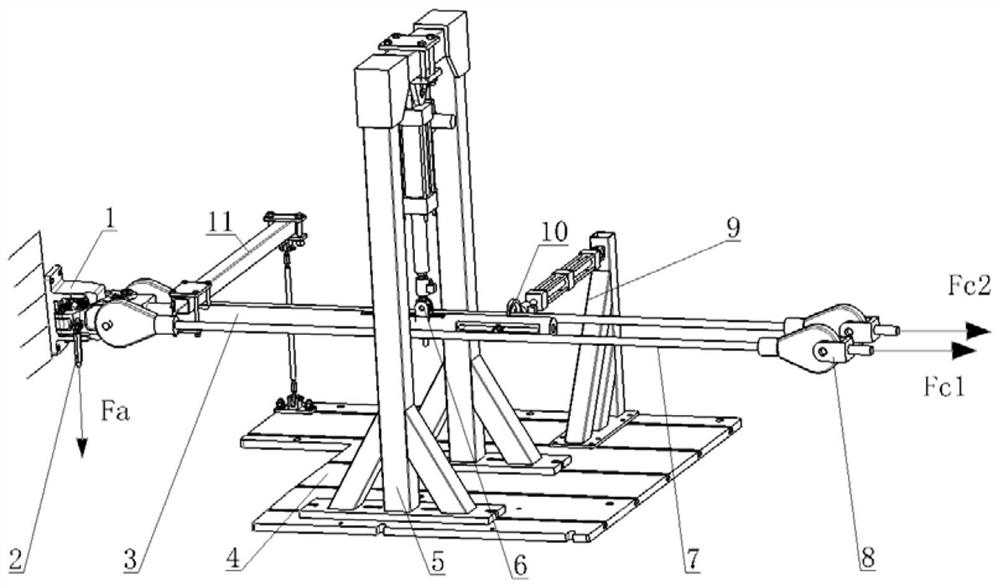

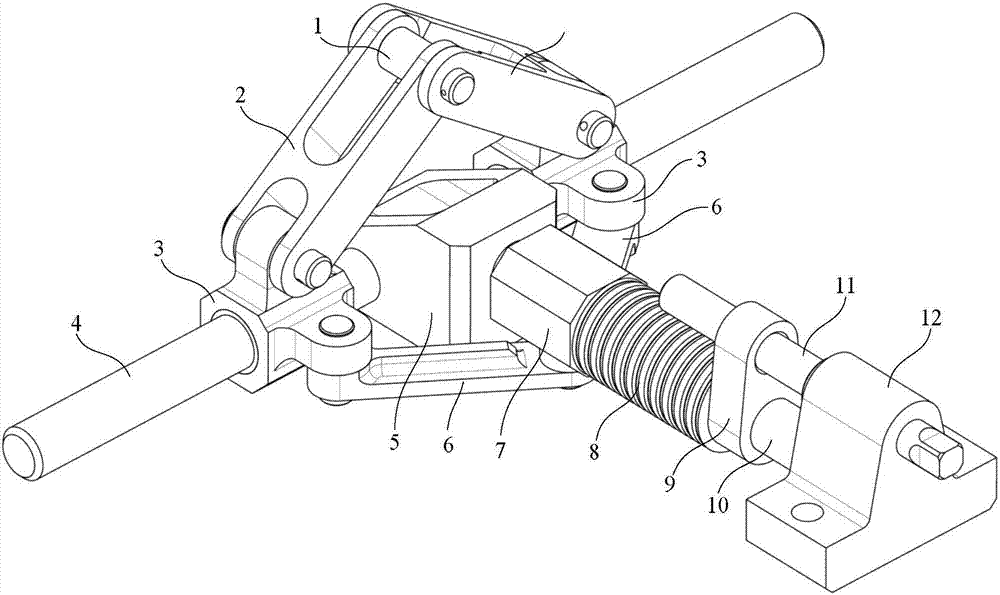

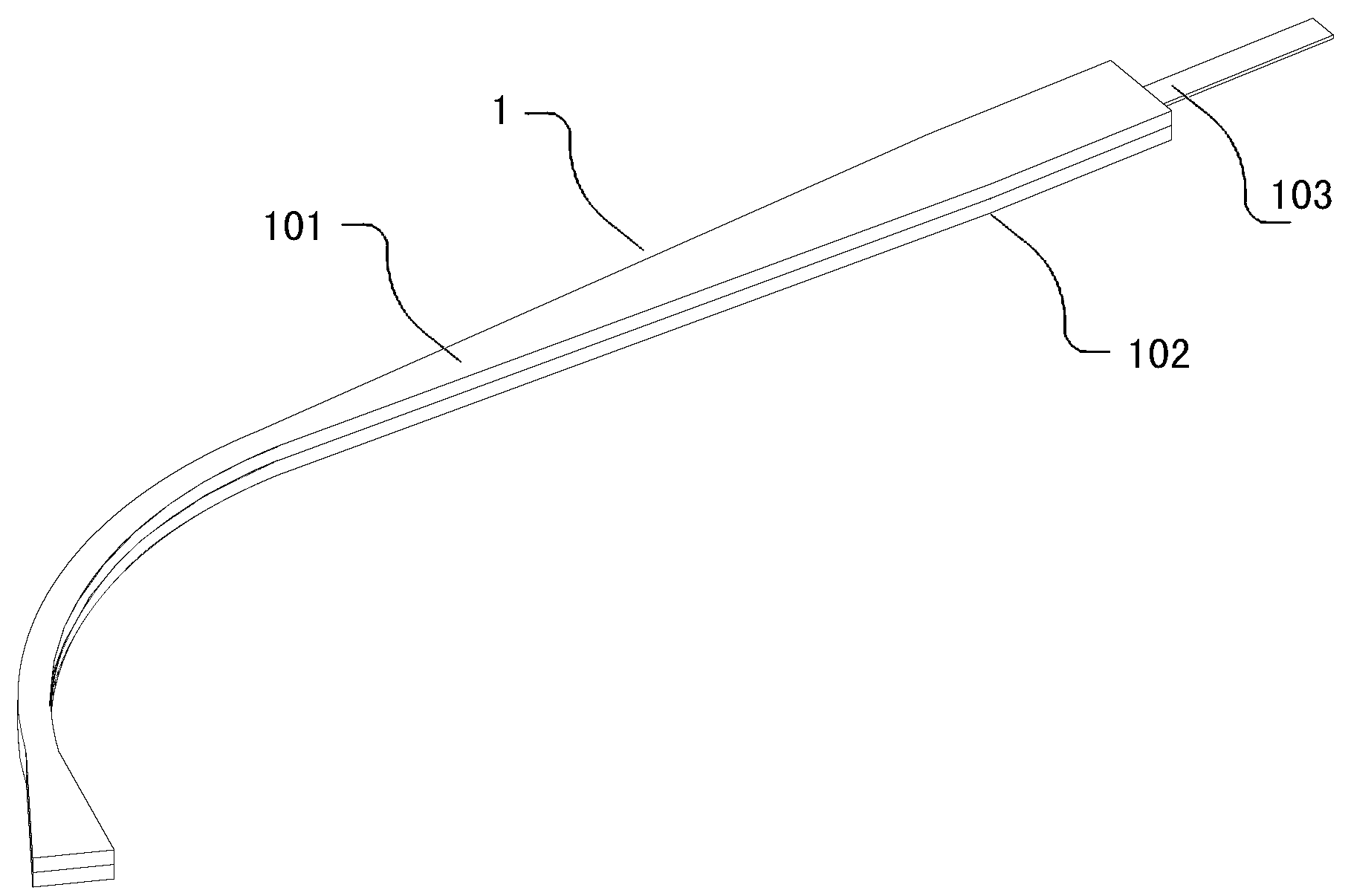

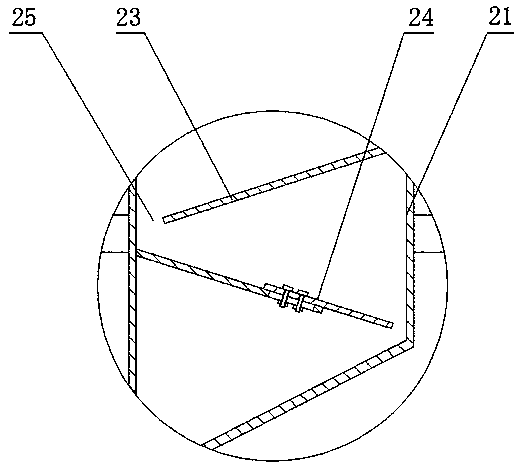

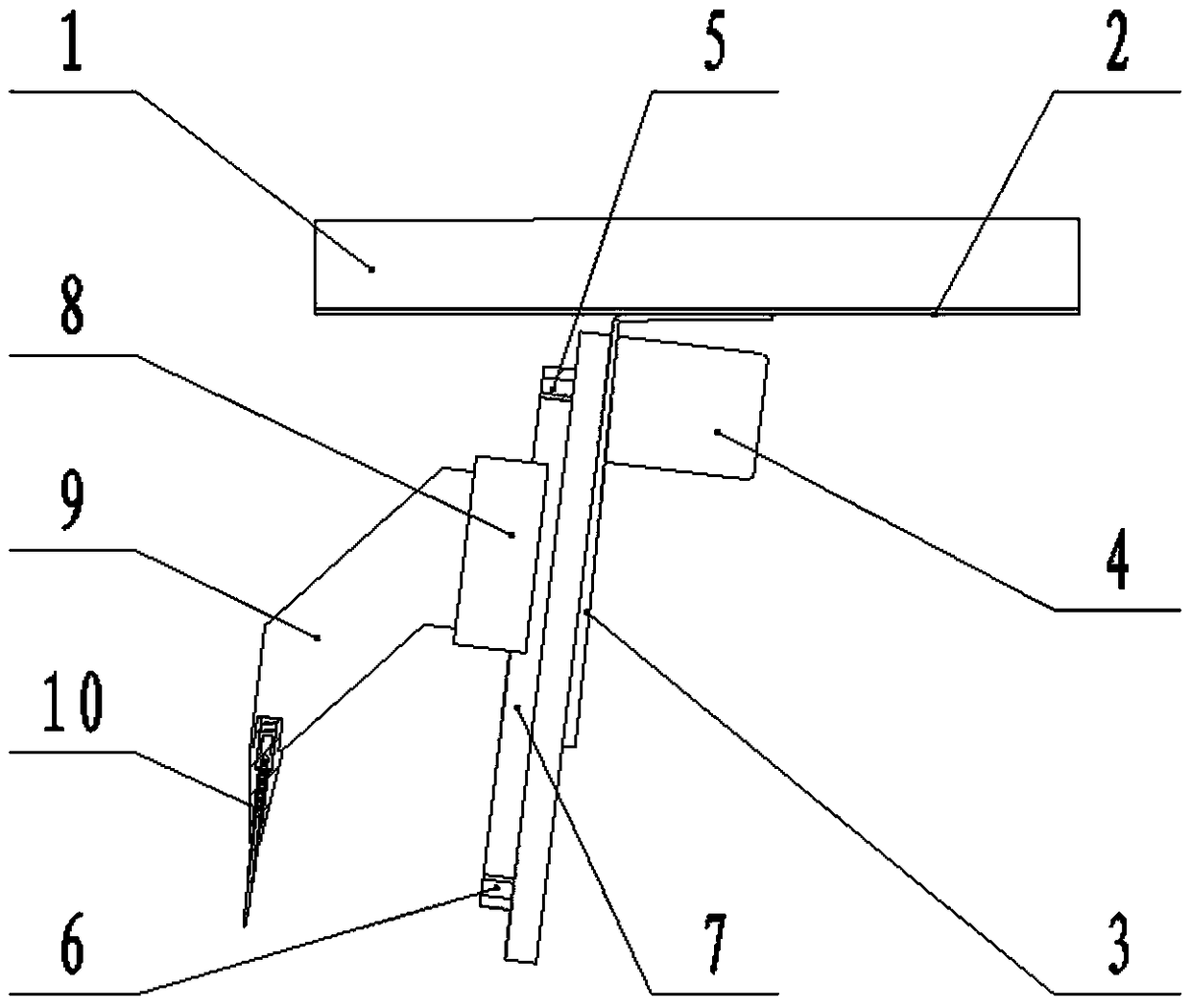

Structural strength test loading device for aircraft wing-mounted engine

ActiveCN102680236AAccurate and reliable assessment resultsGuaranteed loading accuracyEngine testingAirplaneFront loading

The invention belongs to an aircraft strength testing technology and relates to a structural strength test loading device for an aircraft wing-mounted engine. The structural strength test loading device comprises side front loading actuating cylinders, side rear loading actuating cylinders, front actuating cylinders and lower actuating cylinders, and is characterized in that the loading device comprises the two side front loading actuating cylinders, the two side rear loading actuating cylinders, the two front actuating cylinders and the lower actuating cylinders. According to the loading device disclosed by the invention, a course load of the engine is applied through a pair of the actuating cylinders which mutually form the angle, so that the loading device can ensure that the course load can be always positioned along the direction of the axial line of the engine under the condition that the deformation of airfoils occurs during testing; a lateral load of the engine can be applied through the pair of the actuating cylinders which mutually form the angle, so that the loading device can ensure that the lateral load can be always positioned in the horizontal direction under the condition that the deformation of the airfoils occurs; and a hanging lateral load of the engine is applied by the pair of the actuating cylinders which mutually form the angle, so that the loading device can ensure that the lateral load can be always positioned in the horizontal direction under the condition that the deformation of the airfoils occurs. The loading device can ensure the loading precision of the loads of the wing-mounted engine under the condition that the deformation of the airfoils occurs so as to enable a testing check result to be more accurate and reliable.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

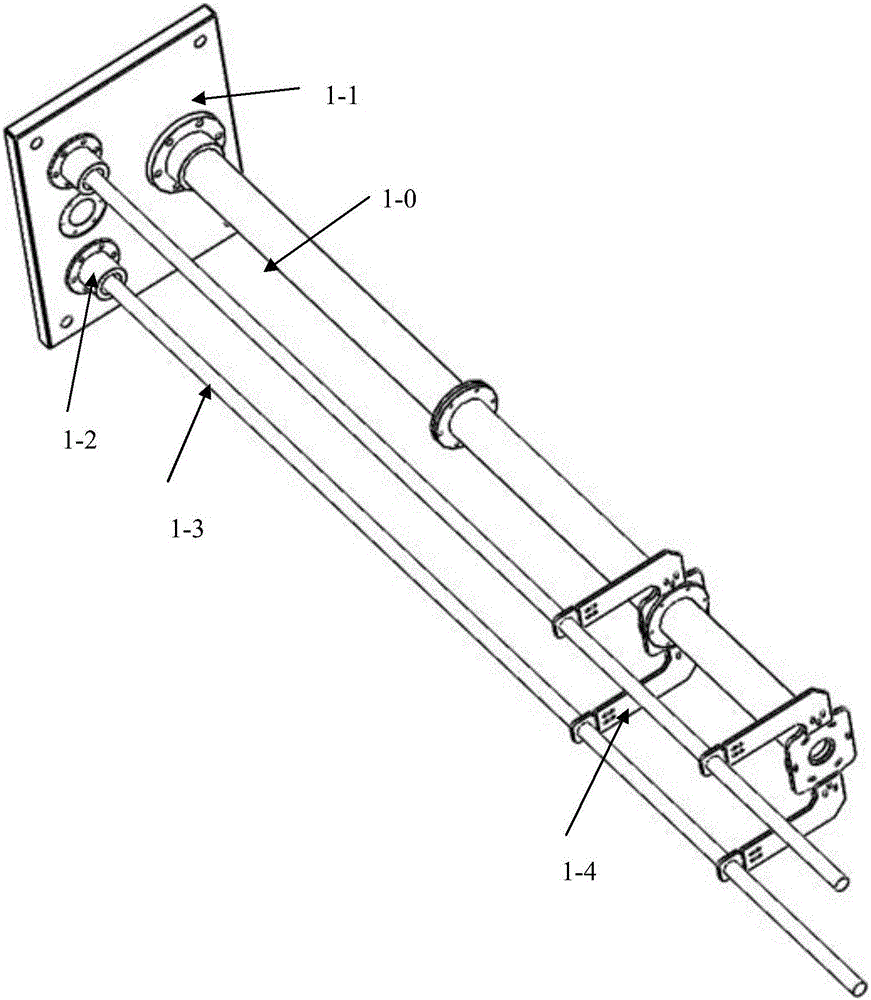

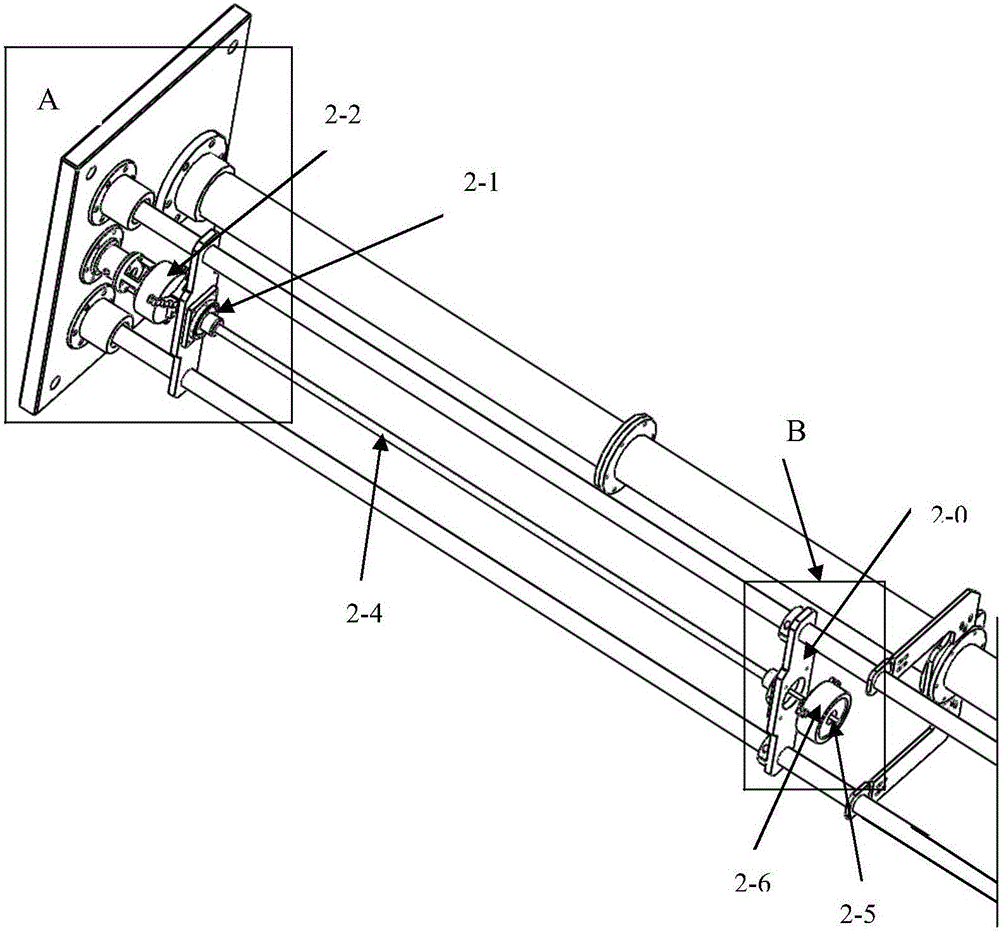

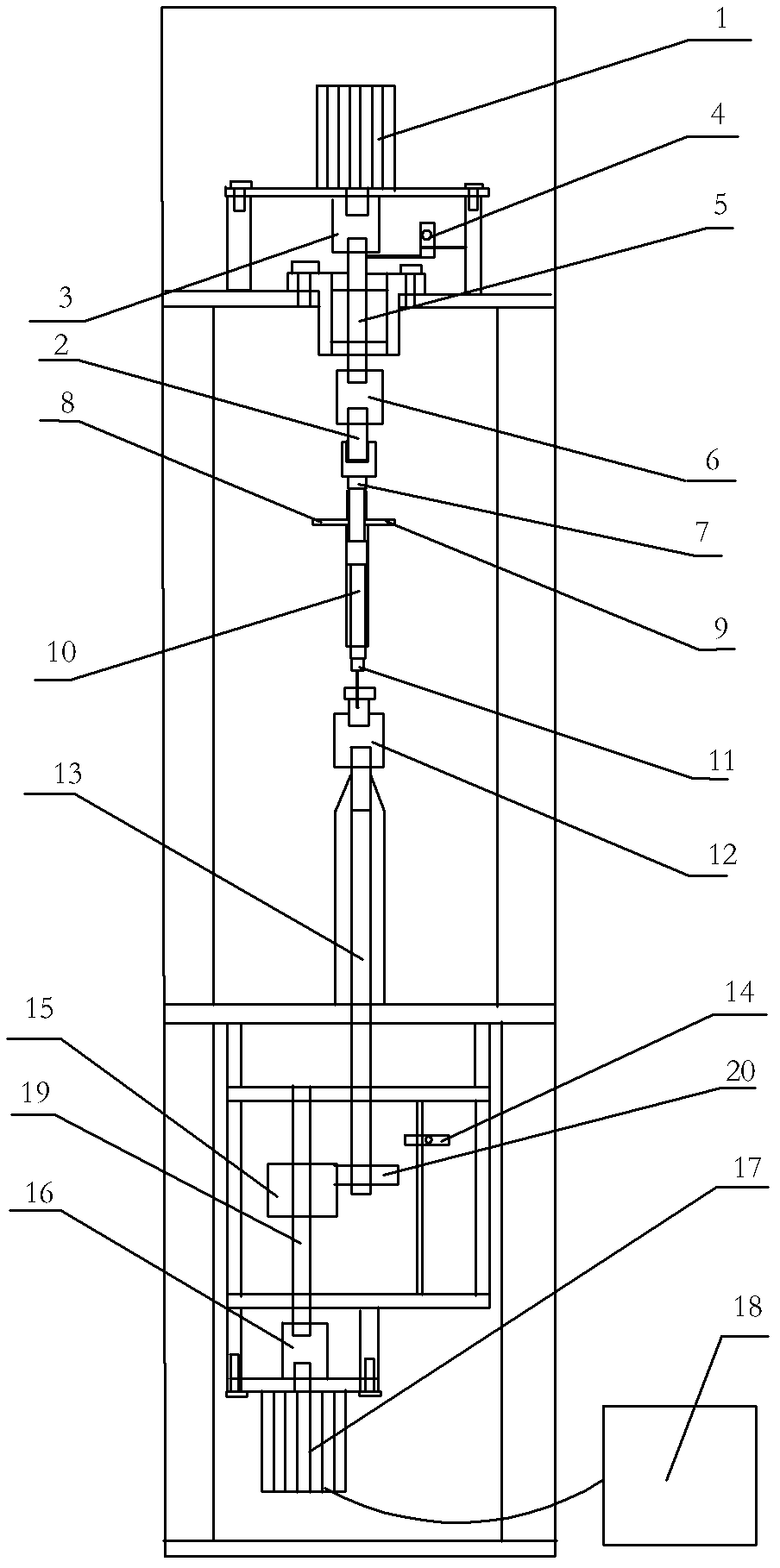

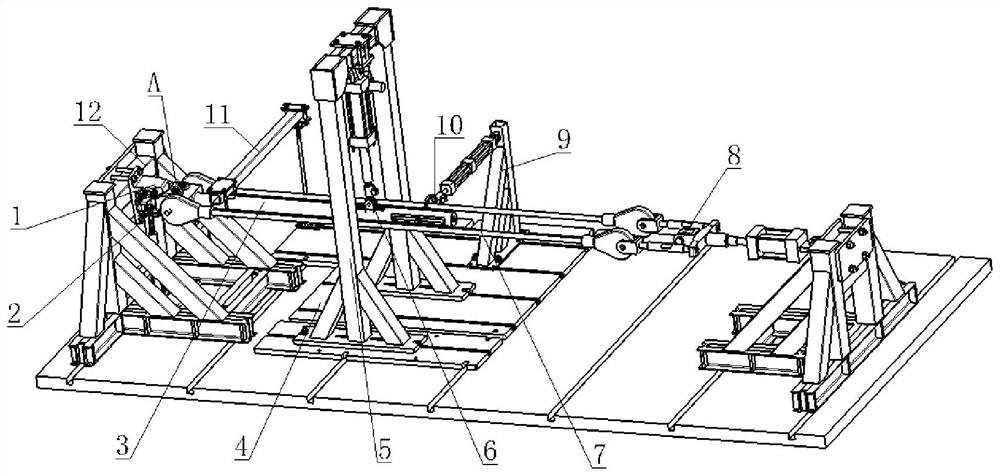

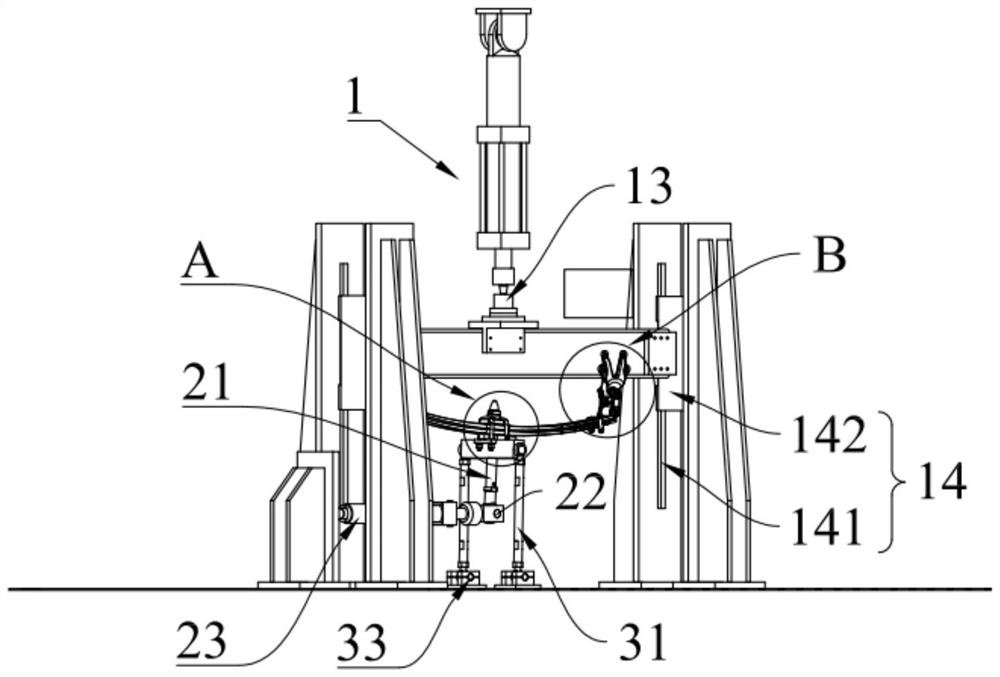

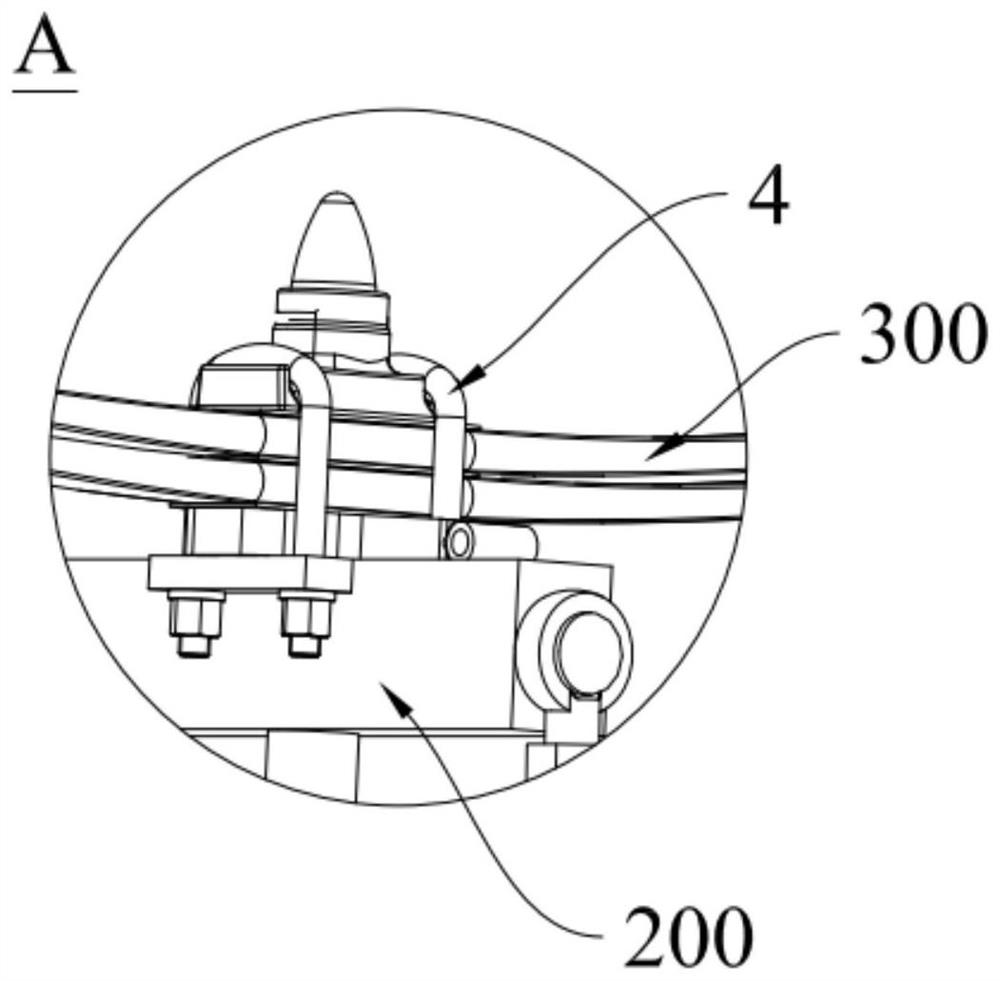

Indoor available comprehensive tubing string mechanics experiment platform

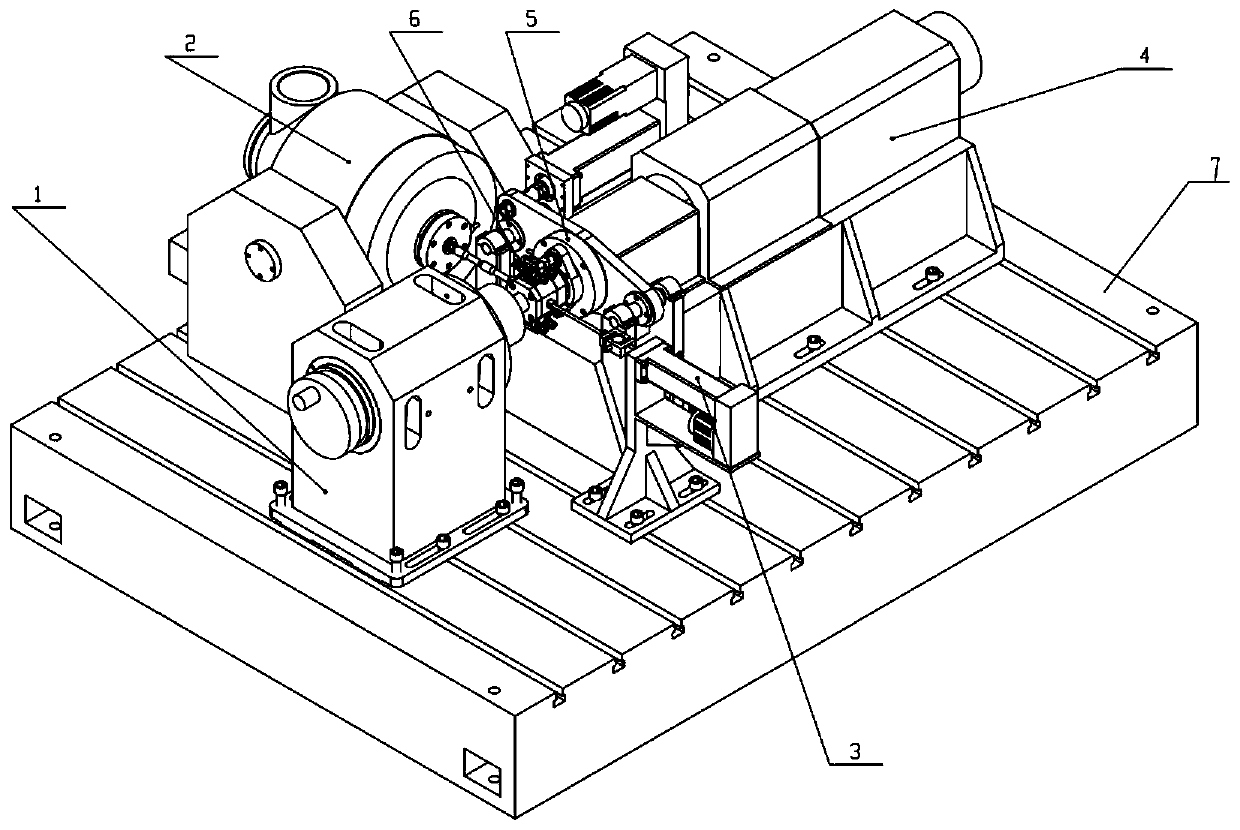

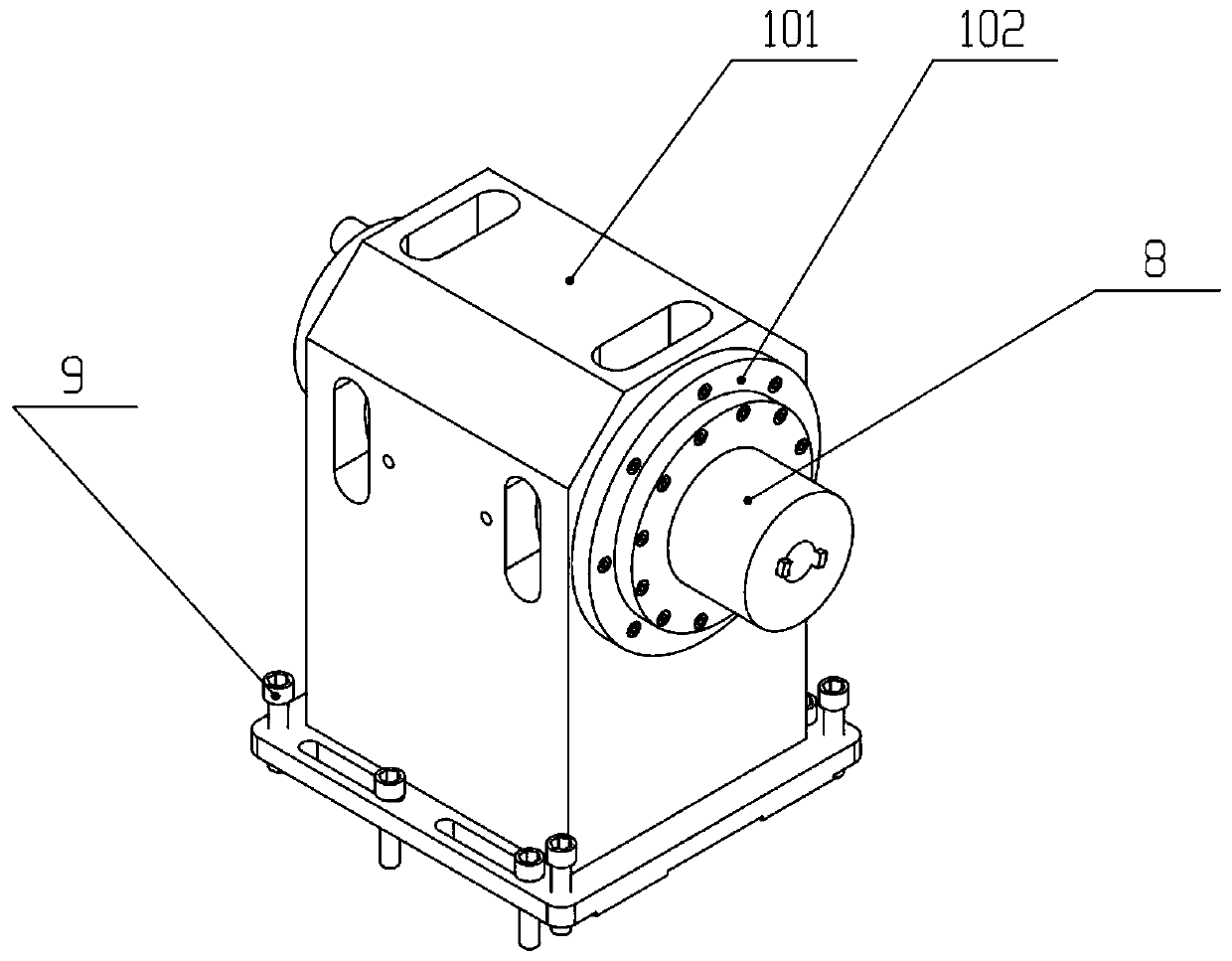

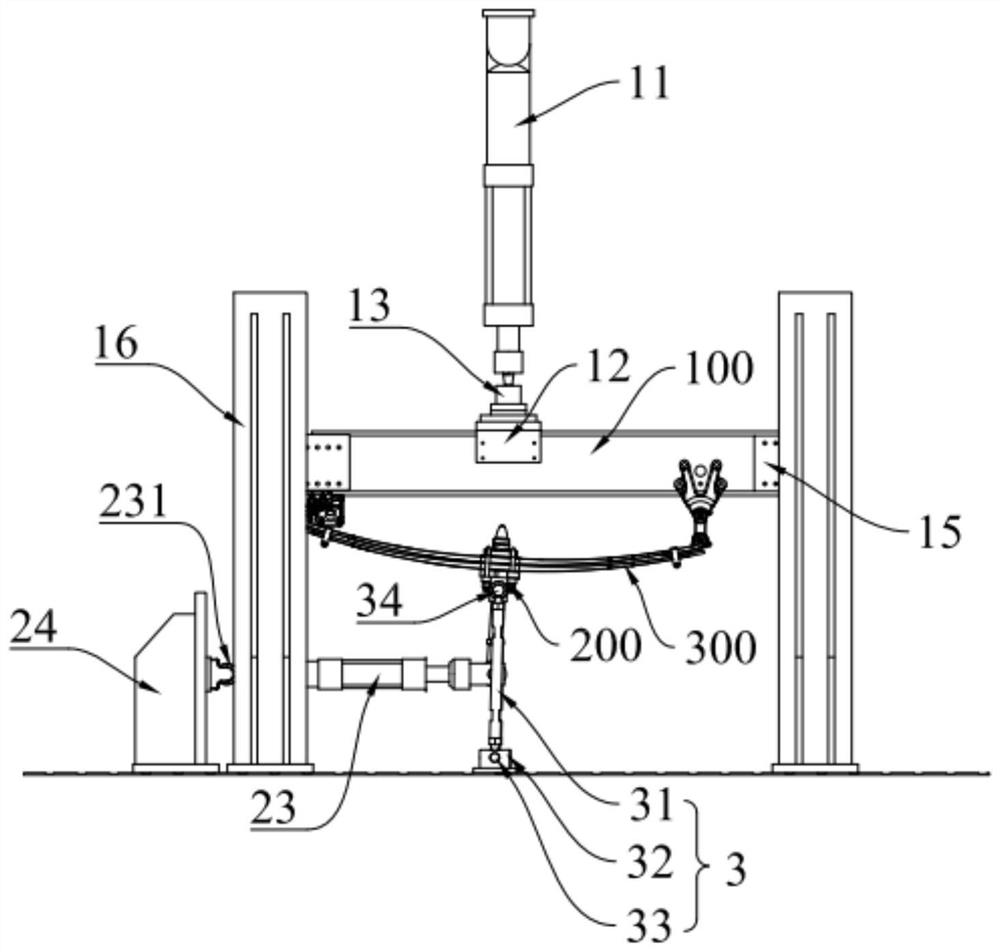

ActiveCN105928789AReduce cost and scaleLow driving torqueMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMutual influenceEngineering

The invention discloses an indoor available comprehensive tubing string mechanics experiment platform to solve the problem of unable accurate synchronous application of pulling, pressing, bending, twisting and other loads of present indoor experiment devices. The platform integrates loading and test mechanisms of pulling, pressing, bending, twisting and other different loads, and eliminates mutual influences of pulling and twisting combination load in a bearing isolation manner, and a test terminal collects and processes a pulling and twisting load signal in a double-sensor merging output mode. The platform can realize synchronous loading and testing of pulling, bending, twisting and other loads, and allows the real deformation of an oilfield tubing string under a given load condition to be obtained through scaling all parts of the oilfield tubing string in the practical use process.

Owner:NORTHEAST GASOLINEEUM UNIV

High-viscosity liquid precise subpackaging device

ActiveCN102633006APrecise positioningImprove continuityLiquid fillingPackaging automatic controlAutomatic controlElectronic control system

The invention relates to the field of a biological and chemical machine, and particularly discloses a high-viscosity liquid precise subpackaging device which comprises an electronic control system, an electrical system, a mechanical transmission system and a piston pump, wherein the electronic control system comprises a programmable logic controller (PLC) and a touch control screen; the electrical system comprises a piston servo motor and a rotary valve servo motor; the mechanical transmission system comprises a rolling shaft screw rod, a screw rod sliding block and a concentric shaft; the piston pump is provided with a liquid outlet pipe and a liquid inlet pipe; and a pipe orifice of the liquid outlet pipe is provided with a liquid outlet needle. The high-viscosity liquid precise subpackaging device can be automatically controlled to run by the PLC, can manually change various parameters, and is simple and convenient in operation and high in degree of mechanization. The servo motors are accurate in location and high in accuracy, so that the accuracy is high and the performance is stable when subpackaging is carried out on the liquid. The liquid outlet needle is arranged at a liquid outlet hole, so that the pressure in a pipeline can be reduced; and due to the small-hole design of the needle, the charging and measuring accuracy can be guaranteed. The high-viscosity liquid precise subpackaging device can be used for subpackaging in a laboratory and large-scale industrial charging, and is low in cost and suitable for large-scale popularization.

Owner:BEIJING SAISHENG PHARMA

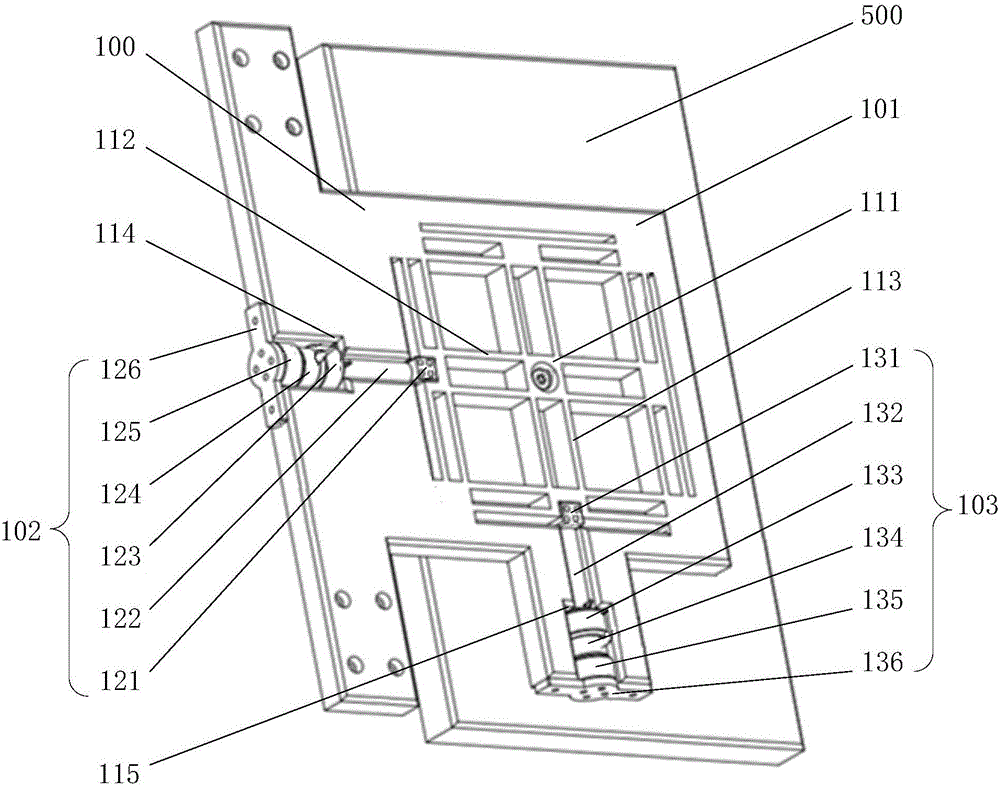

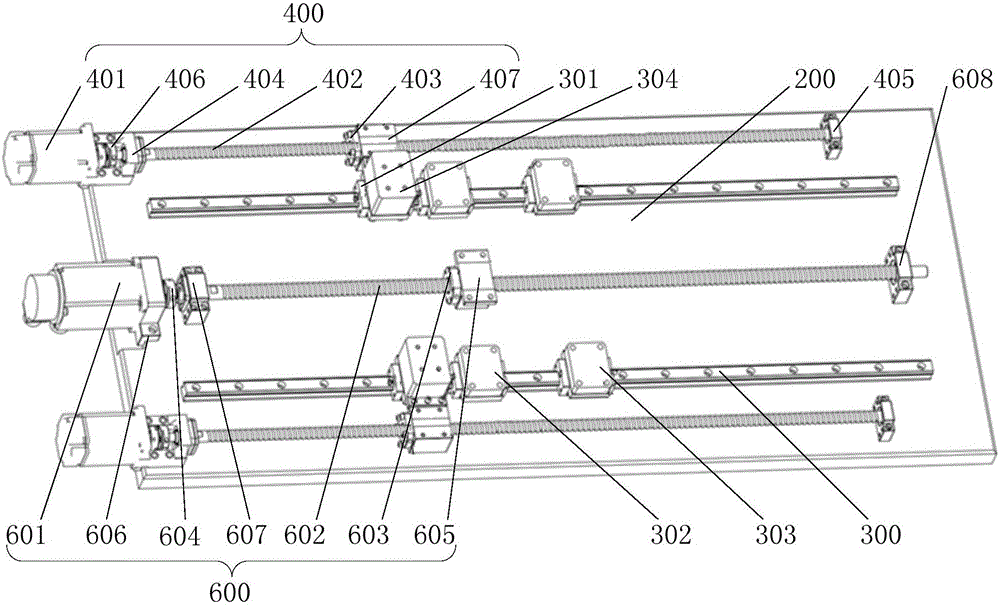

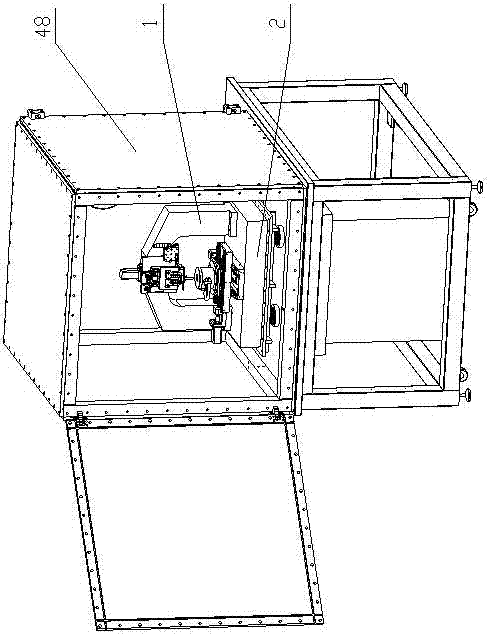

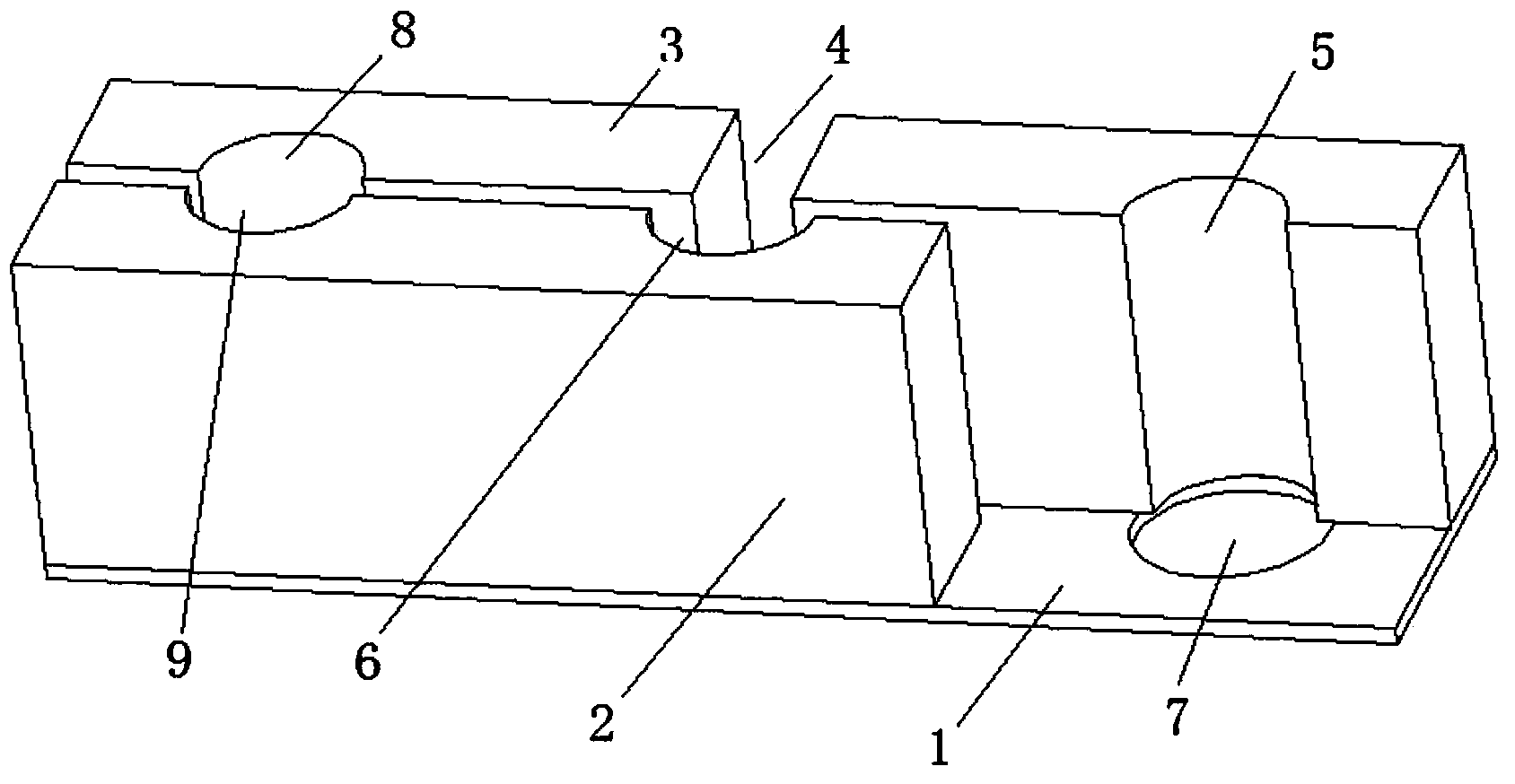

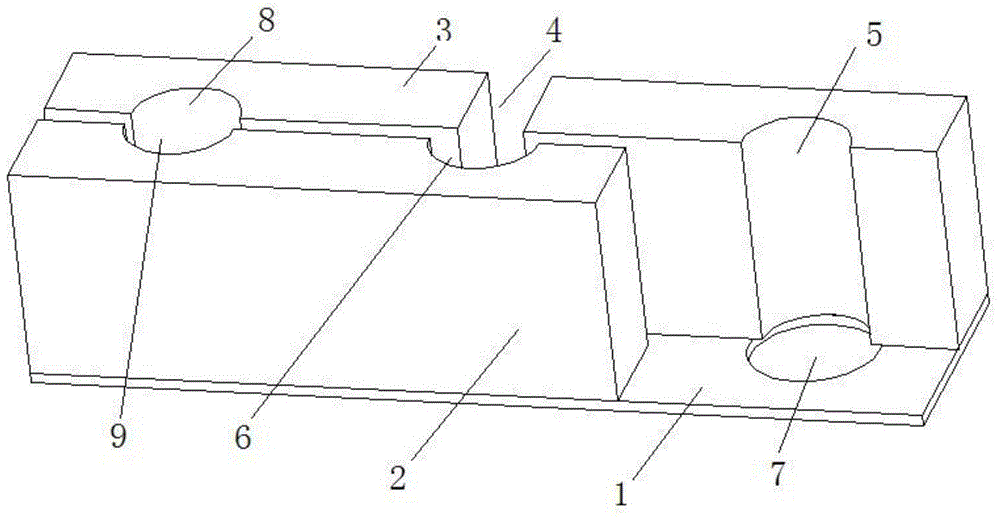

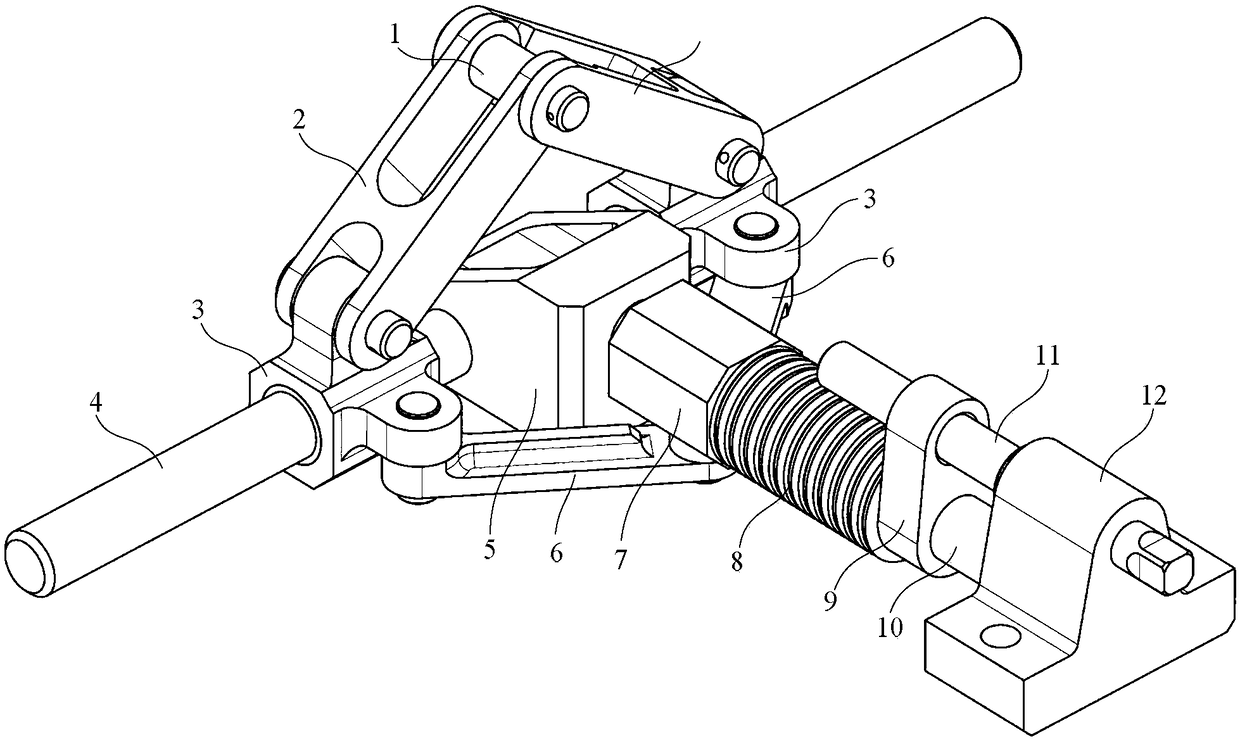

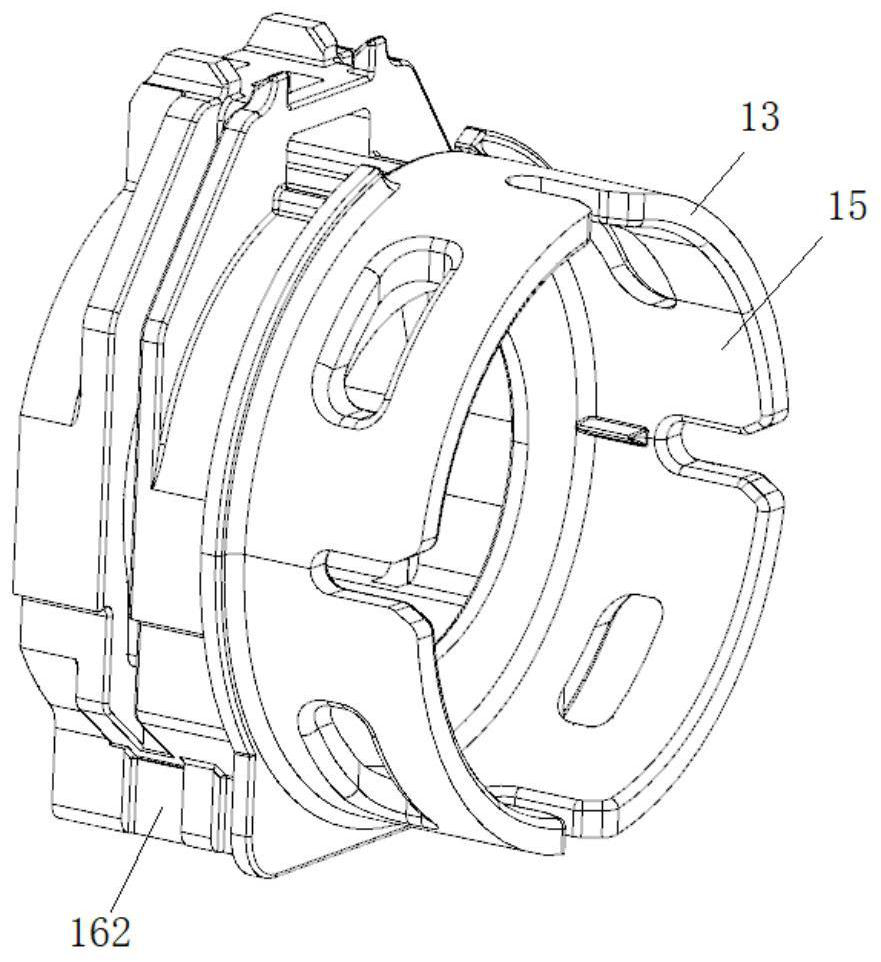

Planar two-degree-of-freedom high-frequency loading device and testing platform for ball screw pair

InactiveCN106092563AGuaranteed loading accuracySimple controlMachine gearing/transmission testingHinge angleTwo degrees of freedom

The invention relates to a planar two-degree-of-freedom high-frequency loading device and testing platform for a ball screw pair. The planar two-degree-of-freedom high-frequency loading device for a ball screw pair comprises a flexible hinge parallel mechanism basic body, a first driving branched chain, and a second driving branched chain. The center of the flexible hinge parallel mechanism basic body is equipped with a rigid moving platform. A first flexible branched chain and a second flexible branched chain are disposed along two vertical directions through the center of the rigid moving platform, and are symmetrically and fixedly connected with the rigid moving platform. A first installing groove and a second installing groove which reach side end faces are disposed on the flexible hinge parallel mechanism basic body along the extending line of the first flexible branched chain and the extending line of the second flexible branched chain, respectively. The first driving branched chain comprises a first driver connector, a first piezoelectric ceramic brake, and a first tension and pressure sensor which are installed in the first installing groove. The second driving branched chain comprises a second driver connector, a second piezoelectric ceramic brake, and a second tension and pressure sensor which are installed in the second installing groove.

Owner:TSINGHUA UNIV

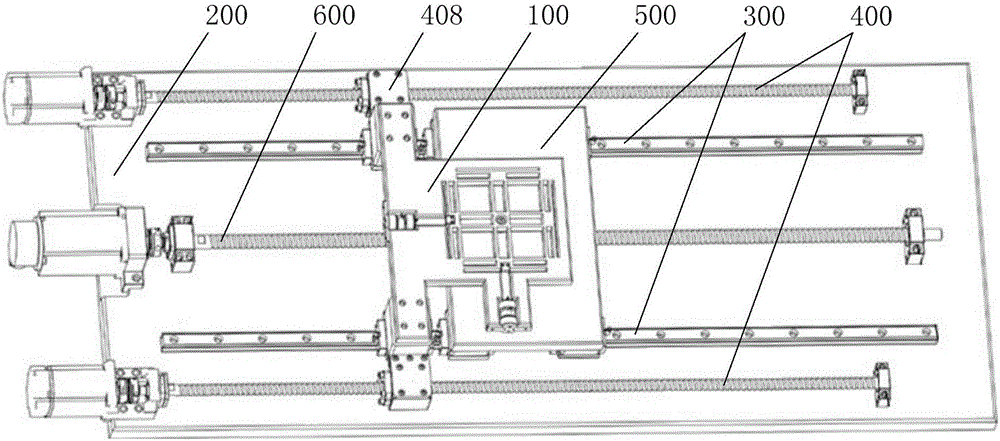

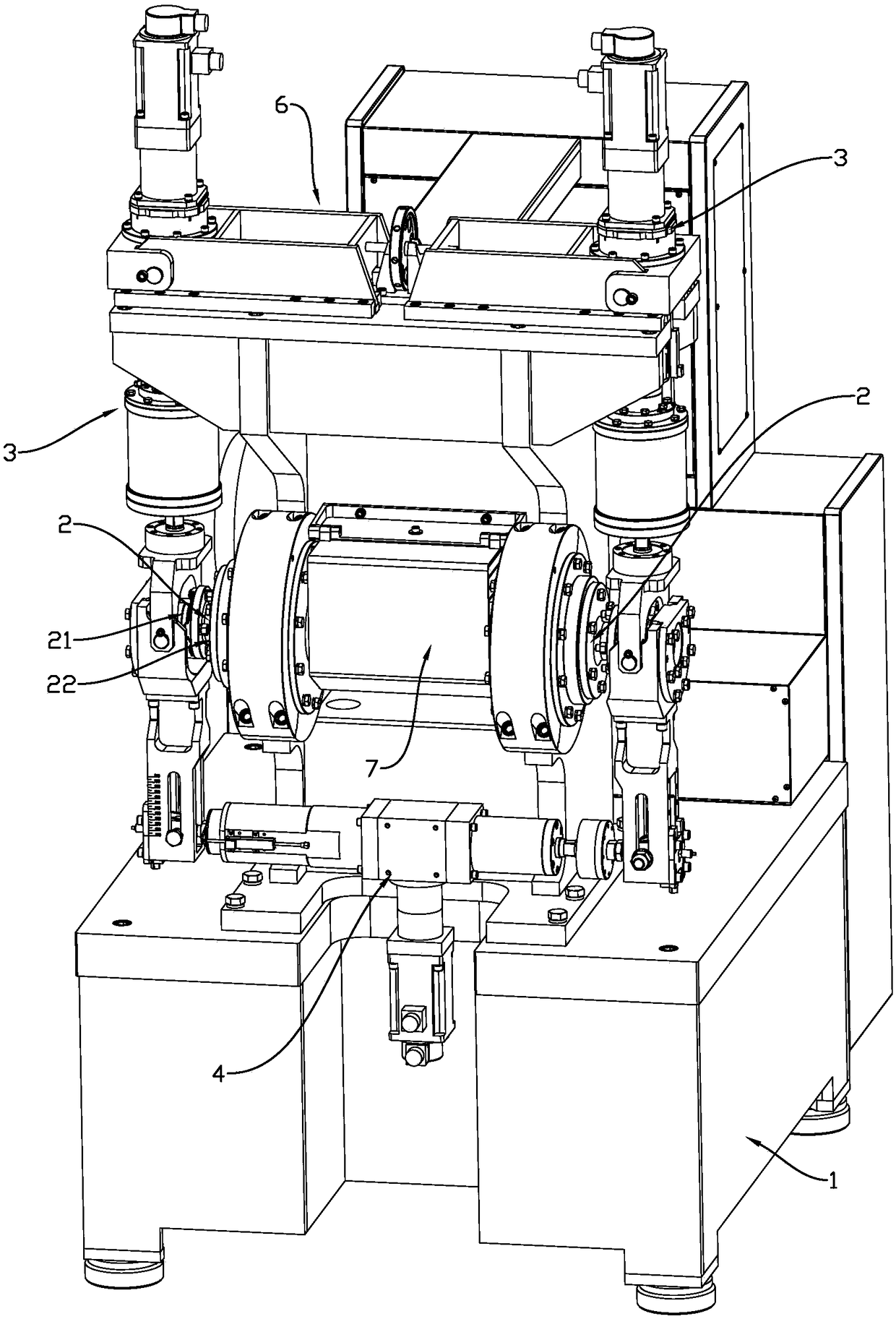

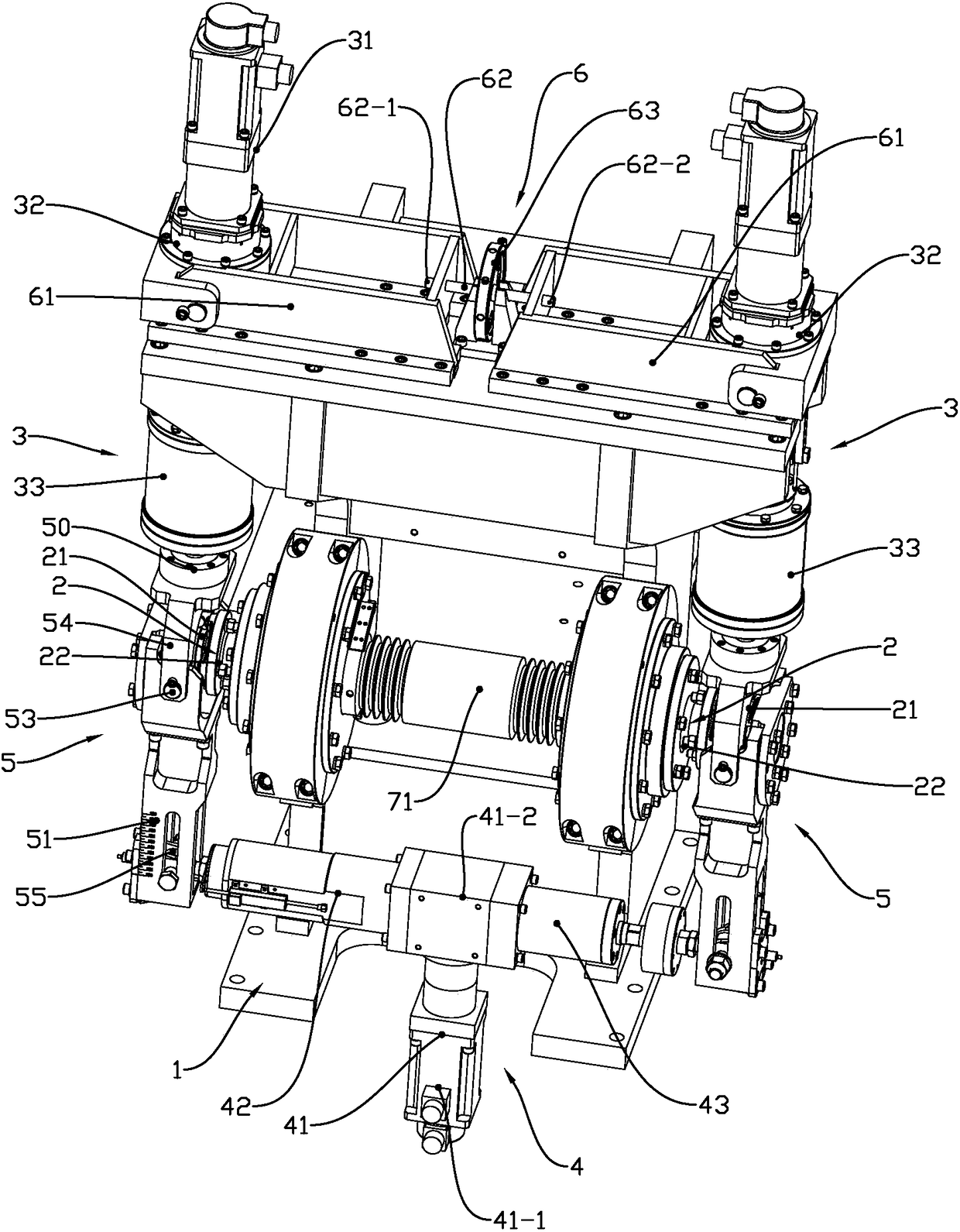

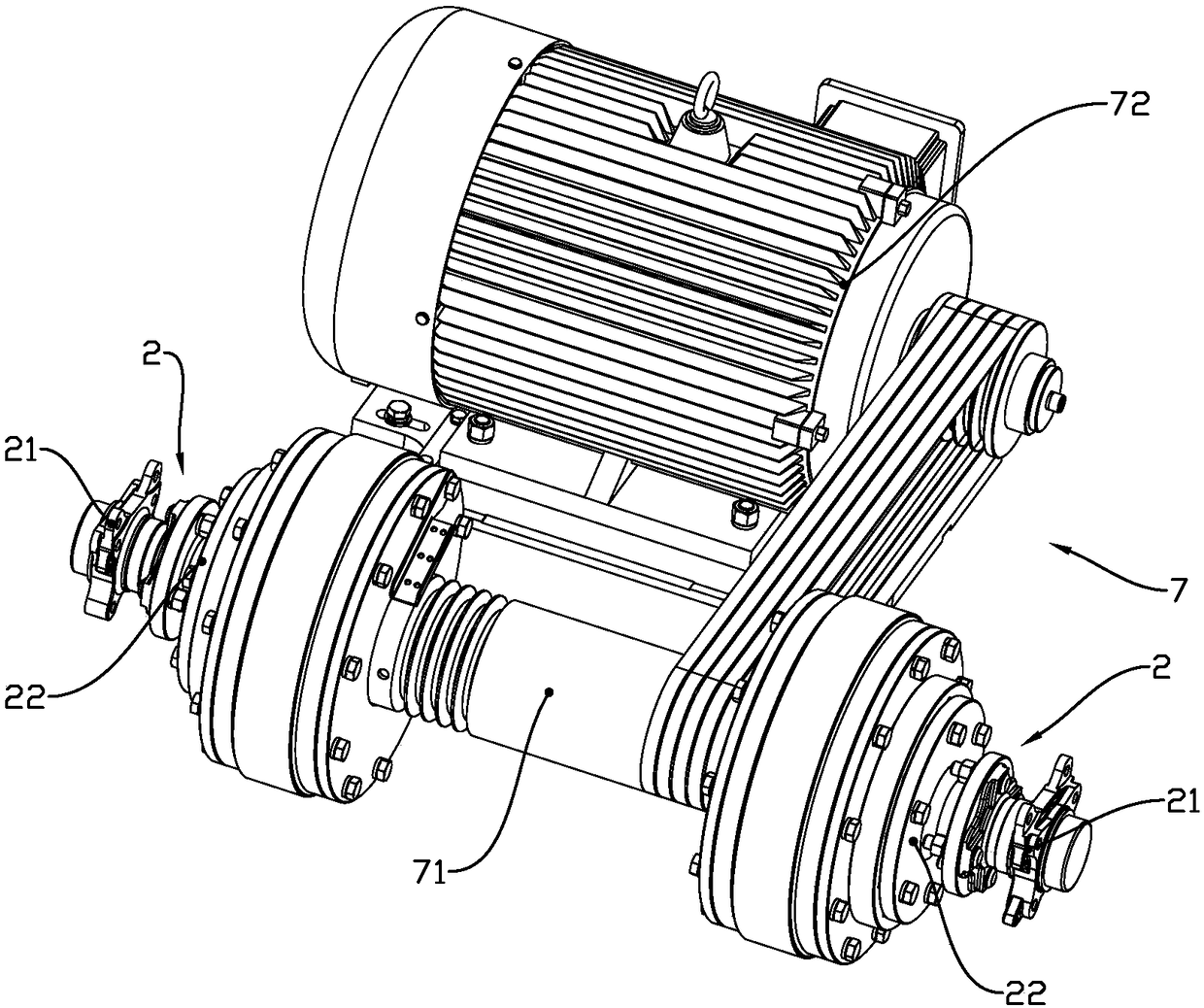

Electric main shaft reliability loading testbed for load comprehensive decoupling

PendingCN110542550AIncrease loading frequencyTwo-way loading implementationMachine part testingElectricityCoupling

The invention belongs to the technical field of the test of mechanical test equipment, and relates to an electric main shaft reliability loading testbed for load comprehensive decoupling. The testbedcomprises an electric main shaft clamping module, a radial force amplitude loading module, a radial force mean loading module, a cutting torque loading module, an axial force loading module and a loading unit module; the electric main shaft clamping module, the radial force amplitude loading module, the radial force mean loading module and the cutting torque loading module are fixed on horizontaliron; one end of a simulated handle in the loading unit module is connected with a bellows coupling in the cutting torque loading module, and the other end is matched with a main shaft conical surfacethrough a simulated real handle conical surface; the axial force loading module are connected with two sides of a front end of a dynamometer base in the cutting torque loading module through bracketsat two ends. The loaded state under a main shaft real working status is simulated by adopting the collaborative loading of an electrodynamics vibration generator and an electric cylinder, the load comprehensive decoupling is realized by adopting the flexible loading structure, and the loading accuracy is improved.

Owner:JILIN UNIV

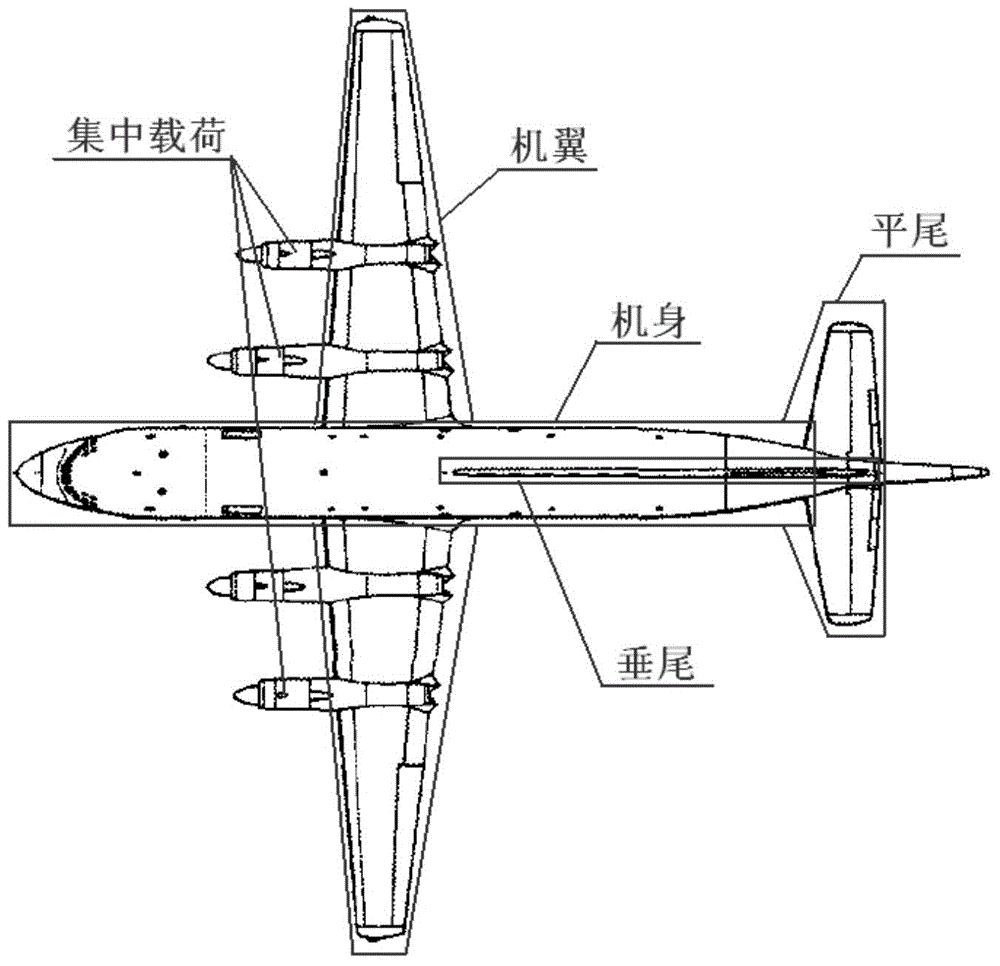

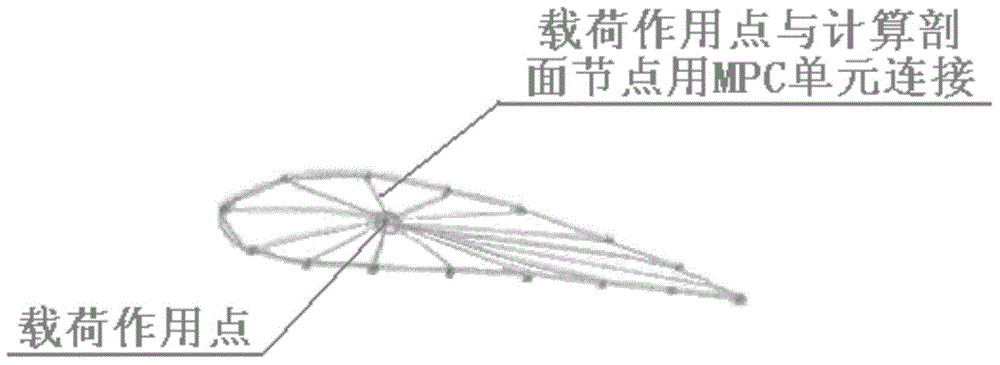

Finite element load application method

ActiveCN103984803AGuaranteed loading accuracySimplified load application processSpecial data processing applicationsJoint ImplementationBatch processing

The invention, which belongs to the field of aircraft designs, relates to a finite element load application method. The finite element load application method is characterized by comprehensively taking the affection of the simplification or distribution of various loads on calculation results and the difficulty level of loading implementation into consideration, the finite element load application method divides aircraft loads into concentrated loads and distributed loads and divides the distributed loads into subareas; nodes to be loaded are chosen from a finite element model and divided into subareas according to the pattern of the distributed load subareas; the concentrated loads and the distributed loads are respectively applied. When the method is adopted to carry out finite element model loading, the precision of engineering calculation can be met, and moreover, computers can be conveniently used for batch processing.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Measuring method for isothermal adsorption/desorption curve of coaly shale

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

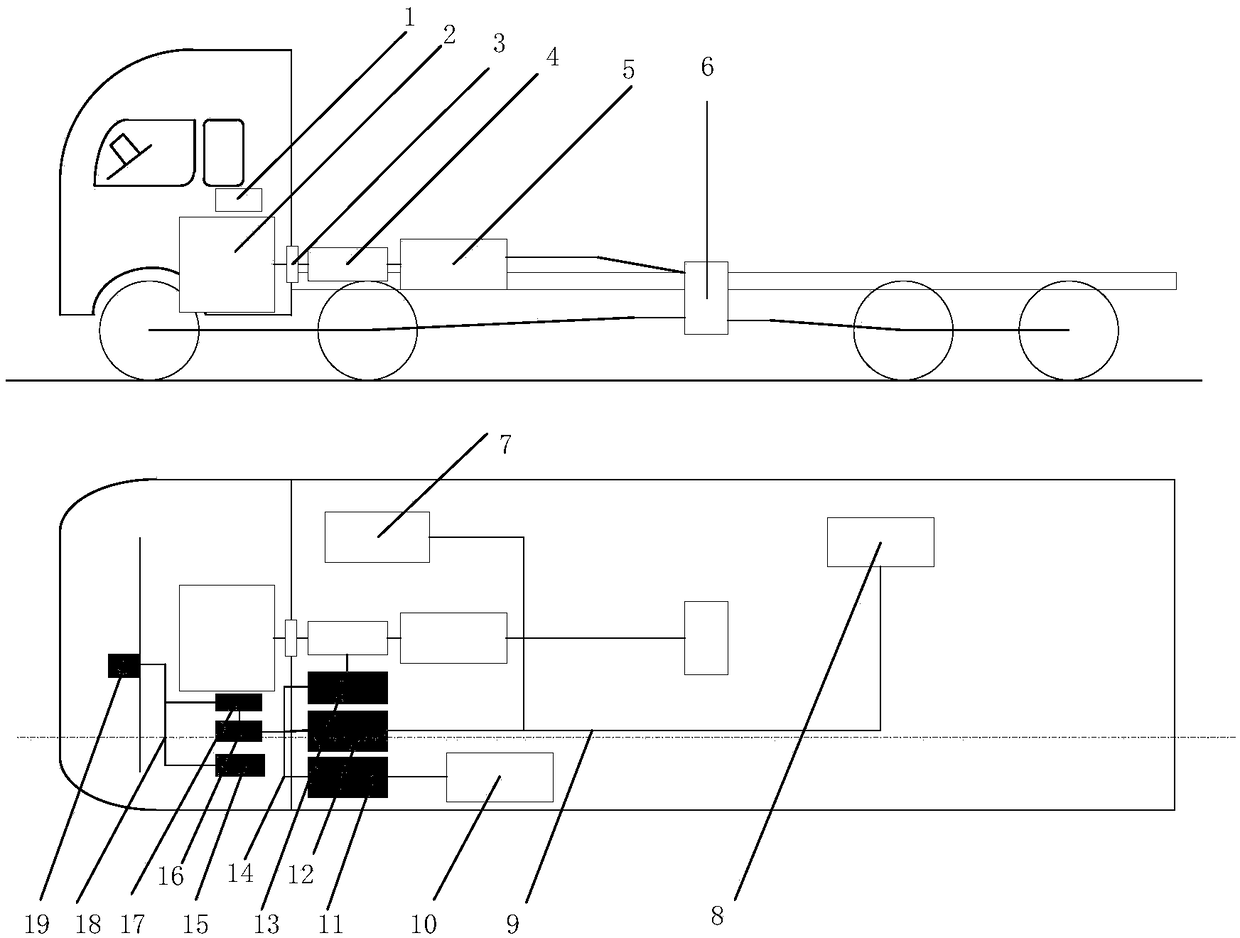

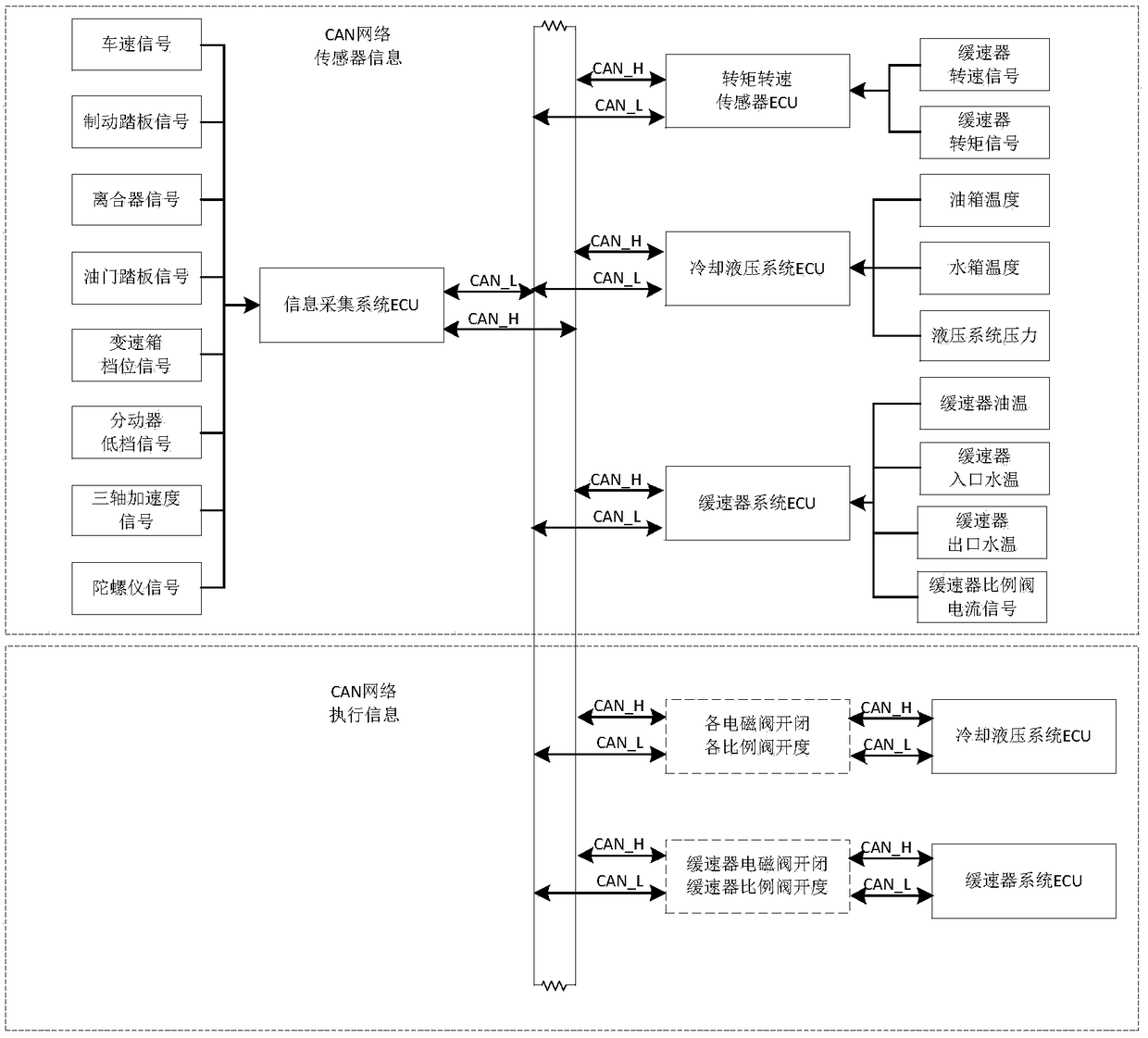

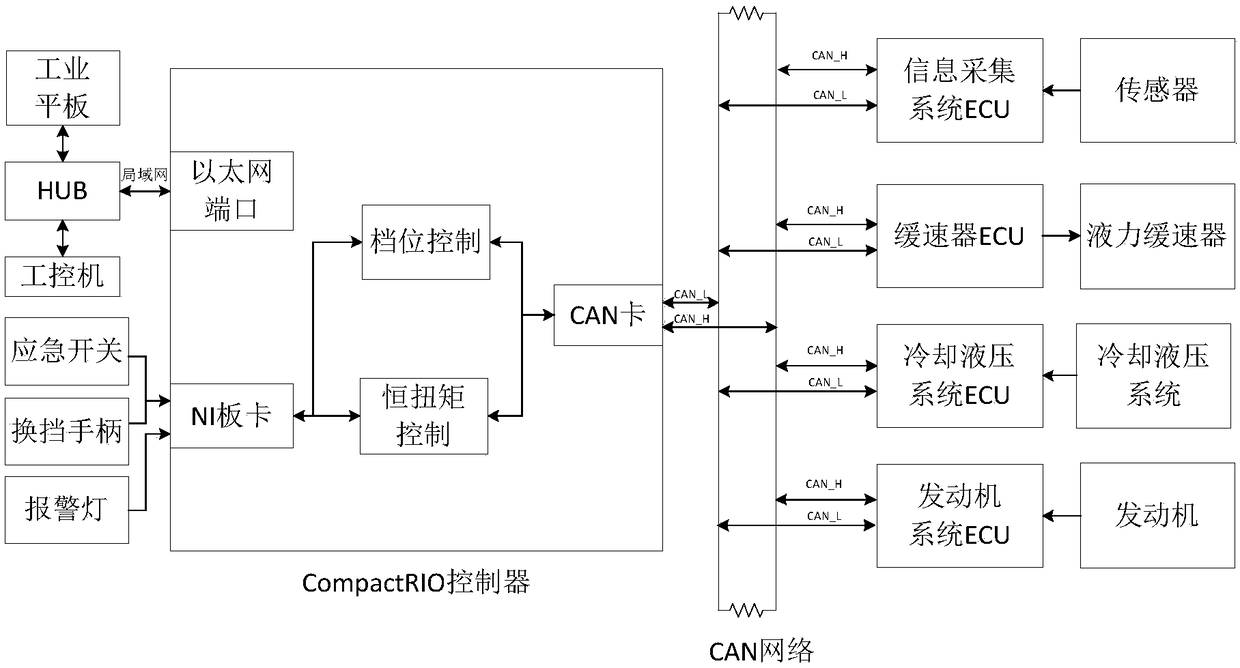

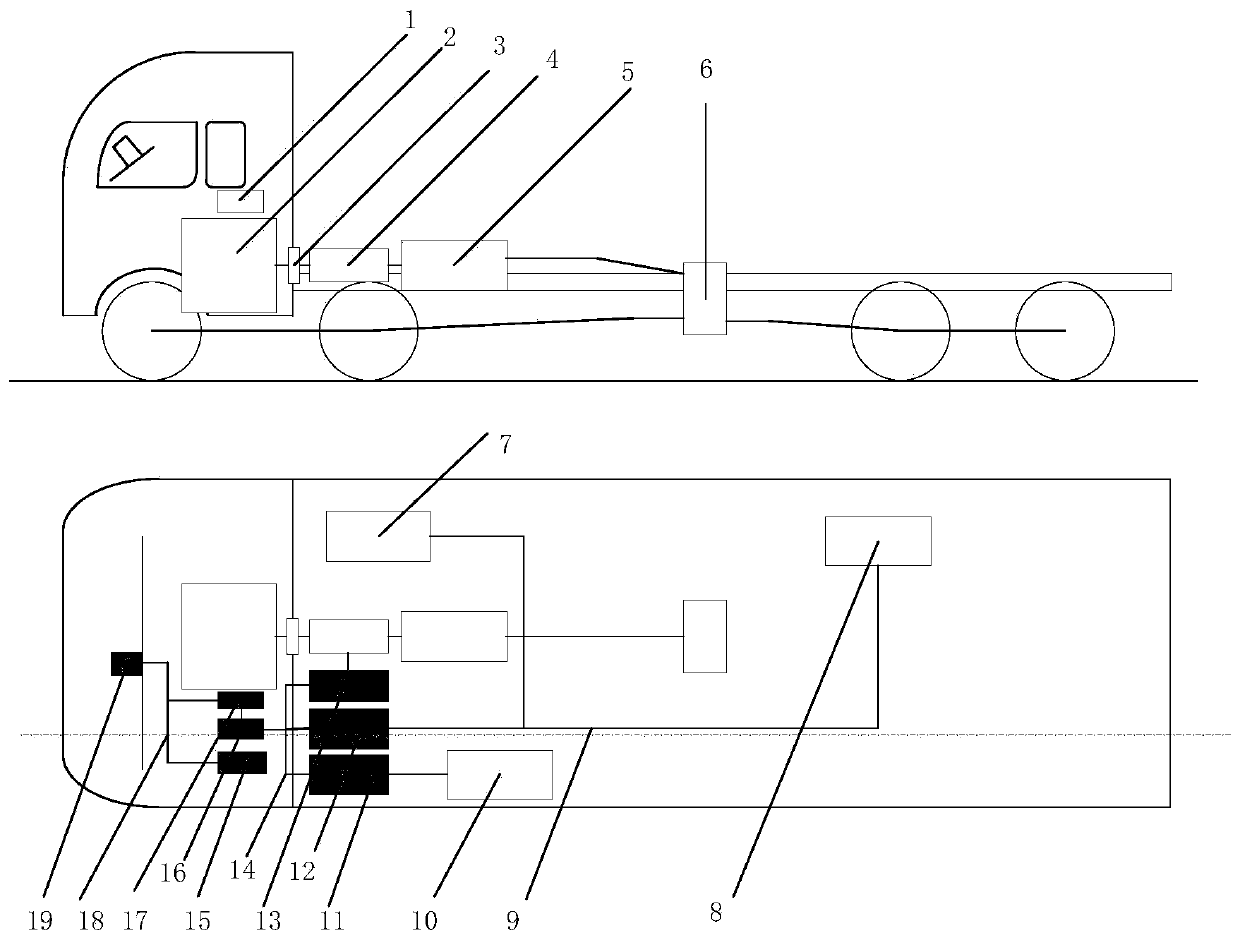

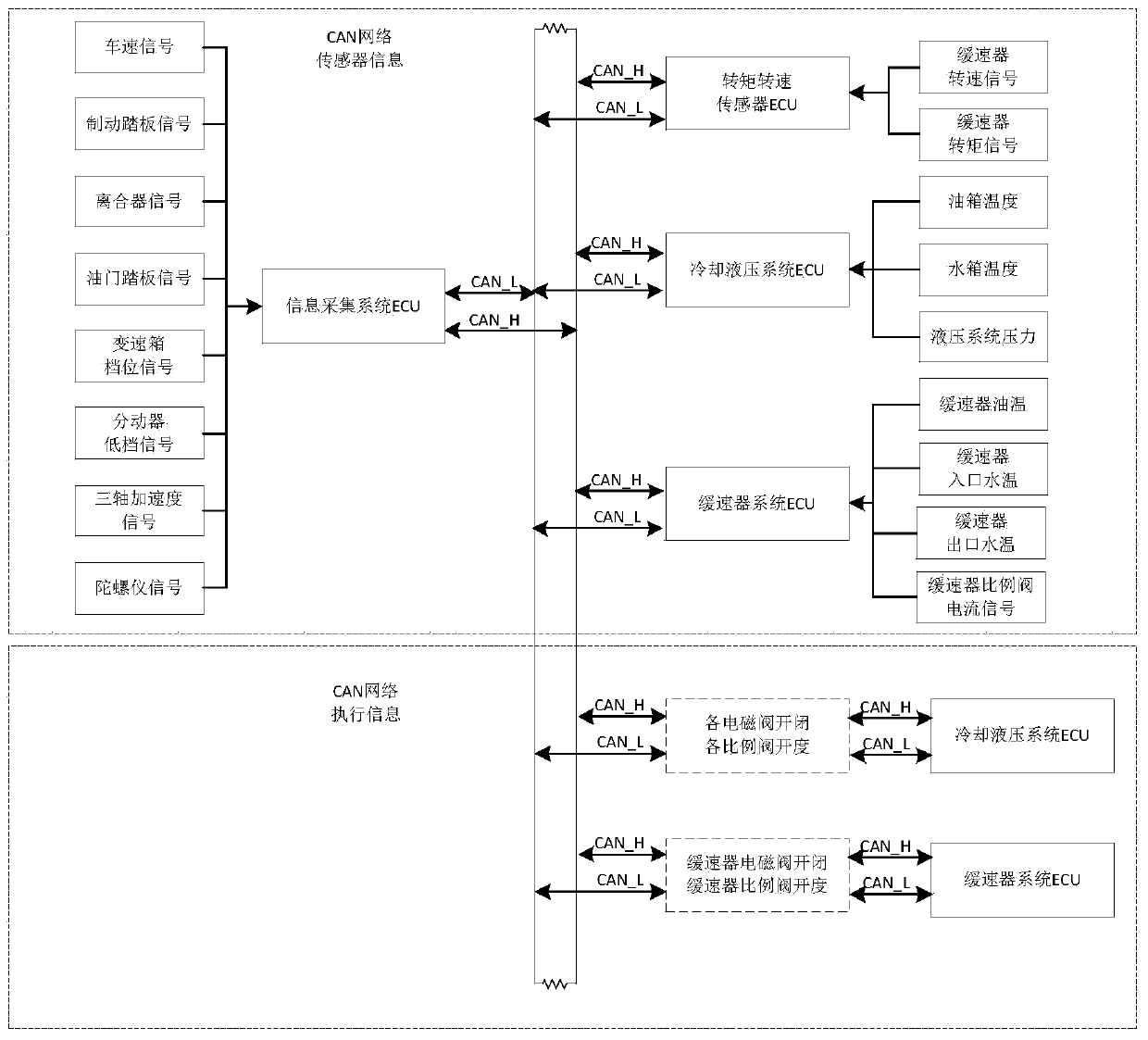

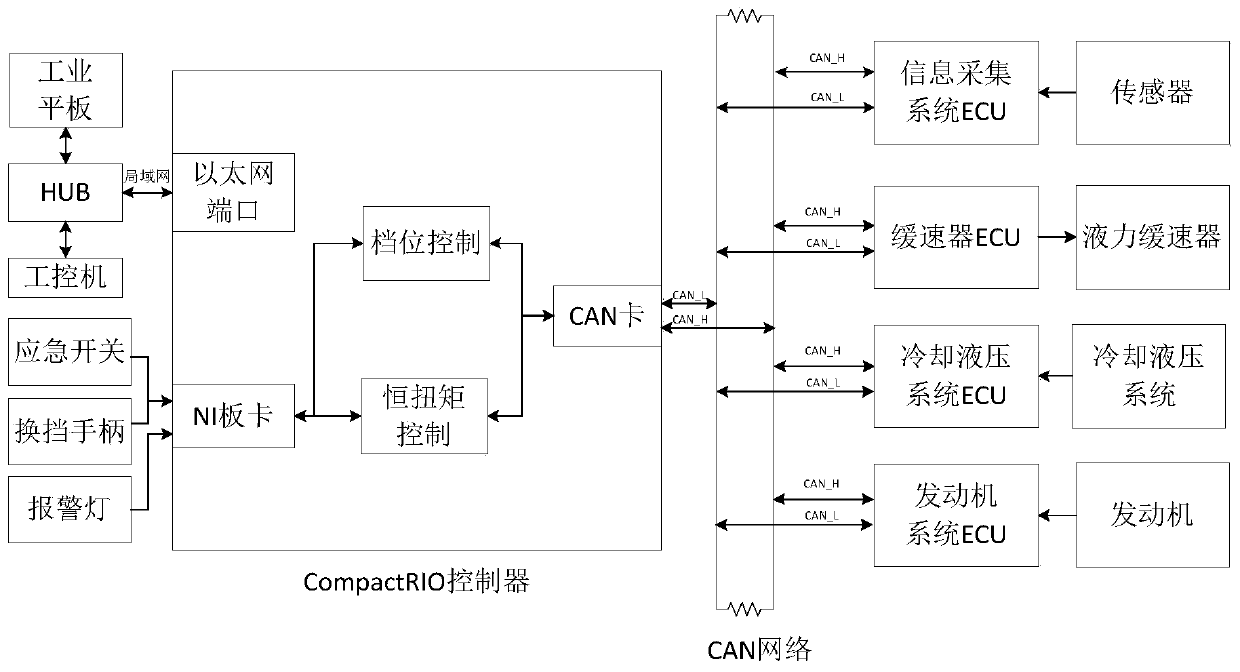

Hydraulic retarder type analog loading system

ActiveCN108918156AGuaranteed loading accuracyEnsure system stabilityVehicle testingTransfer caseClosed loop

The invention discloses a hydraulic retarder type analog loading system. The hydraulic retarder type analog loading system comprises a torque sensor used for measuring the torque and the rotating speed of an input shaft of a retarder, the hydraulic retarder used for applying a load to an engine, a transmission used for changing the transmission ratio, a transfer case used for transmitting motion and the torque, a cooling system used for cooling and heat dissipation of the hydraulic retarder and the engine, a hydraulic system used for changing the rotating speed of a fan and the water flow of the cooling system, a hydraulic retarder ECU used for controlling the hydraulic retarder, a cooling and hydraulic system ECU used for controlling the cooling system and the hydraulic system, an information collecting system used for collecting the vehicle operation states such as the three-axis acceleration and the slope inclination, and a vehicle controller used for controlling a vehicle electronic control system. According to the hydraulic retarder type analog loading system, through a closed-loop control algorithm for the hydraulic retarder and the cooling and hydraulic systems, the loadingprecision for the analog load and system stability under different test conditions are ensured, and stepless regulation and control of the analog load are realized.

Owner:WUHAN UNIV OF TECH

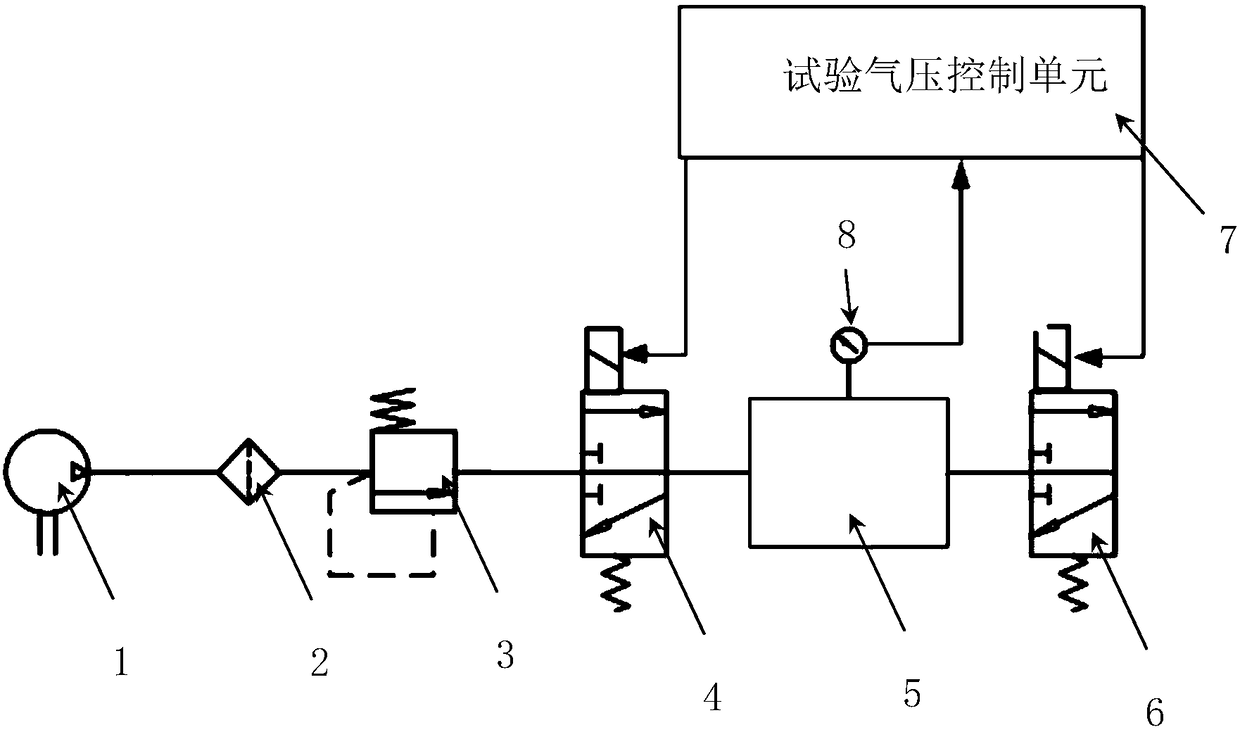

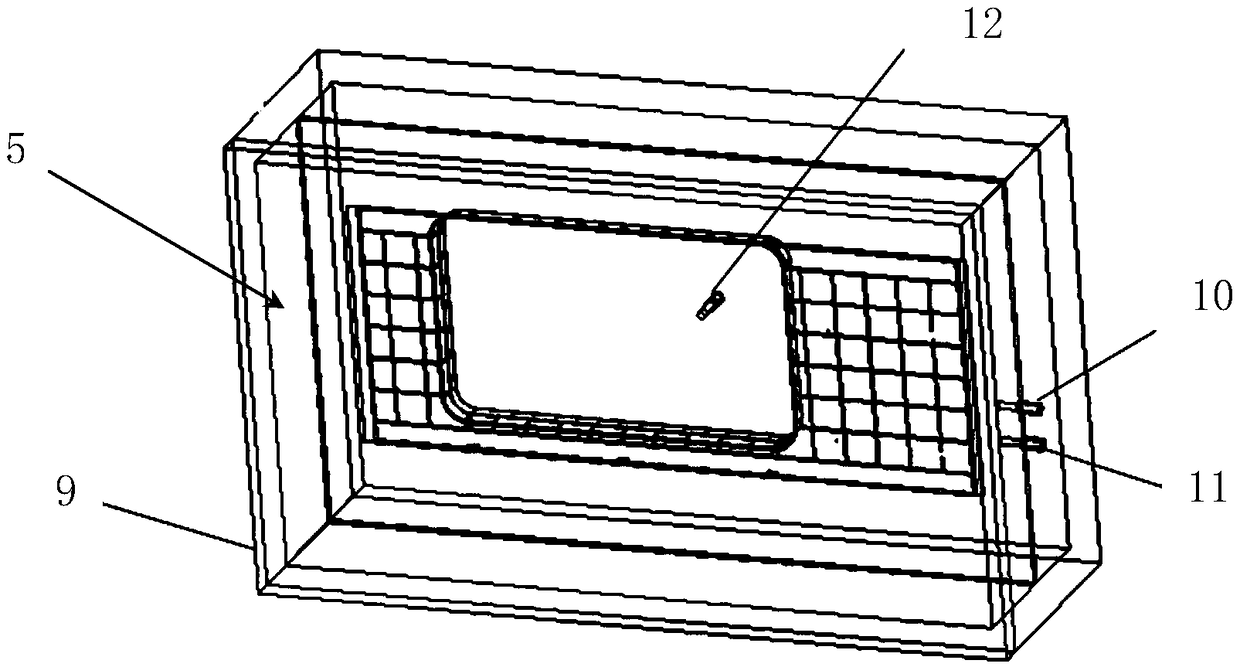

Static pressure test system for rail transit product

InactiveCN109186970AReduce labor costsGuaranteed loading accuracyMachine part testingControl signalAtmospheric pressure

The invention discloses a static pressure test system for a rail transit product, comprising a test box (5). The test box (5) is provided with a preset rail transit product that needs to be subjectedto a static pressure test. The test box (5) is connected with a pressurizing system configured to input air with a preset pressure to the inside of the test box (5). The test box (5) is in communication with a pressure relief system for discharging the air inside the test box (5) to decompress the air pressure inside the test box (5). A test air pressure control unit (7) is respectively connectedto the pressurizing system and the pressure relief system for respectively transmitting control signals to the pressurizing system and the pressure relief system so as to correspondingly control the opening and closing states of the pressurizing system and the pressure relief system. According to the static pressure test system for the rail transit product, the air pressure applied to the productcan be automatically adjusted, the labor cost of the test is saved, and the loading precision of the load during static pressure intensity testing of the product is guaranteed.

Owner:TIANJIN AEROSPACE RELIA TECH +1

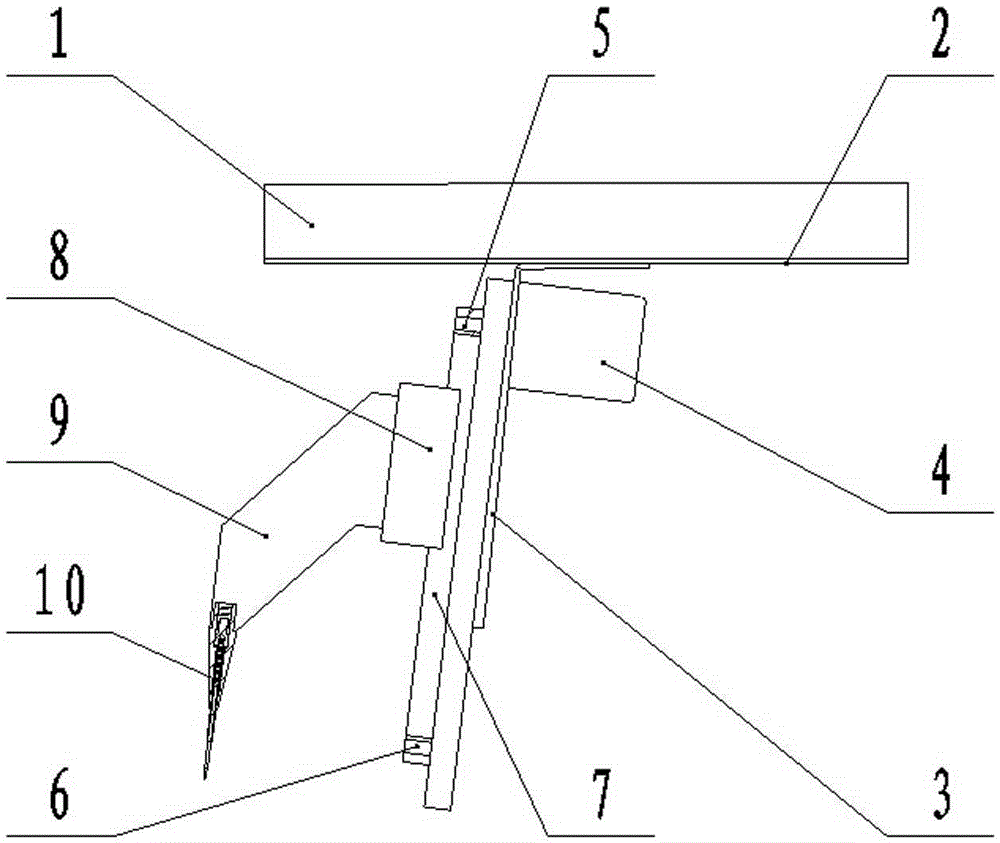

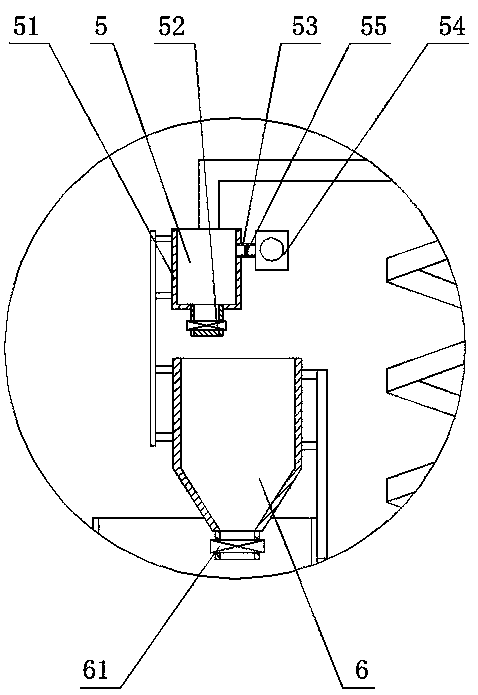

High-precision probe loading device used for PCB automatic testing device

ActiveCN105353179ALoading pressure adjustmentGuaranteed Loading Accuracy IndexElectrical measurement instrument detailsPrinted circuit testingDrive wheelSteel ball

The invention specifically provides a high-precision probe loading device used for a PCB automatic testing device and solves the problems that an existing probe loading device is complex in mechanical structure, small in probe stroke and probe pressure adjusting range and low in loading precision. A support is arranged on the surface of a mover body. A linear motor is fixed at one side of the support. The other side of the support is provided with a driving wheel and a driven wheel. A transmission belt is arranged between the driving wheel and the driven wheel. A sliding block is arranged on the transmission belt. The sliding block is provided with an insulating block. The lower end of the insulating block is provided with a probe assembly. The probe assembly comprises a sleeve. A probe is arranged in the sleeve in a penetrating manner. The tail part of the probe is abutted against a stepped positioning block. The tail part of the stepped positioning block is sleeved by a buffering spring. The probe is composed of a probe body and a probe sleeve, and the probe sleeve is internally provided with a steel ball. A probe buffering spring is arranged between the steel ball and the tail part of the probe body. The probe body and the side wall of the probe are respectively provided with an anti-falling boss. By adopting the high-precision probe loading device, a loading precision index of a tested point is ensured.

Owner:ZHONGBEI UNIV

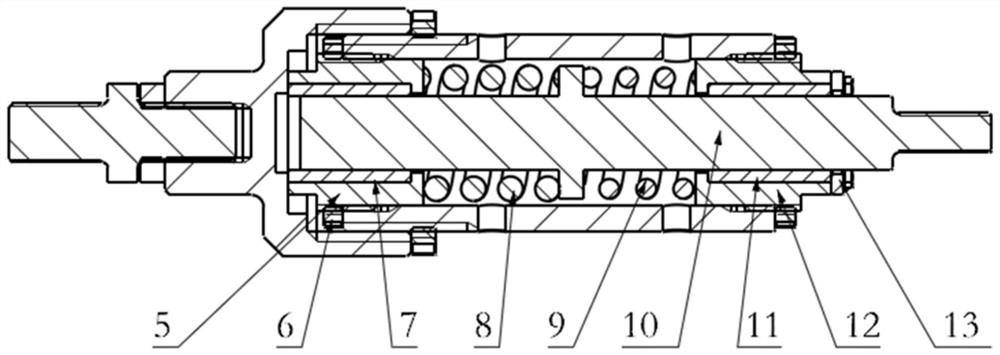

Asymmetric load buffer and parameter determination method

ActiveCN112484972AReduce stiffnessAvoid commutation shockMachine part testingFlight vehicleSlider bearing

The invention belongs to the technical field of aircraft strength test loading, and discloses an asymmetric load buffer and a parameter determination method, and the asymmetric load buffer comprises aforce transmission end cover, a locking large nut, an outer cylinder, a locking small nut, a sliding bearing bracket, a locking small nut, a sliding bearing, a large spring, a small spring, a loadingmandrel, a sliding bearing, a sliding bearing bracket and an end cover. Through the application of the invention, the rigidity of the loading system can be reduced, a lag recovery area of the servo loading system is avoided, the loading command curve and the feedback command curve are highly superposed, the loading precision is ensured, and meanwhile, the reversing impact on the loading of a testpiece is avoided. The stroke requirements of actuators of different load levels can be met by adjusting the compression amount of the spring.

Owner:HARBIN

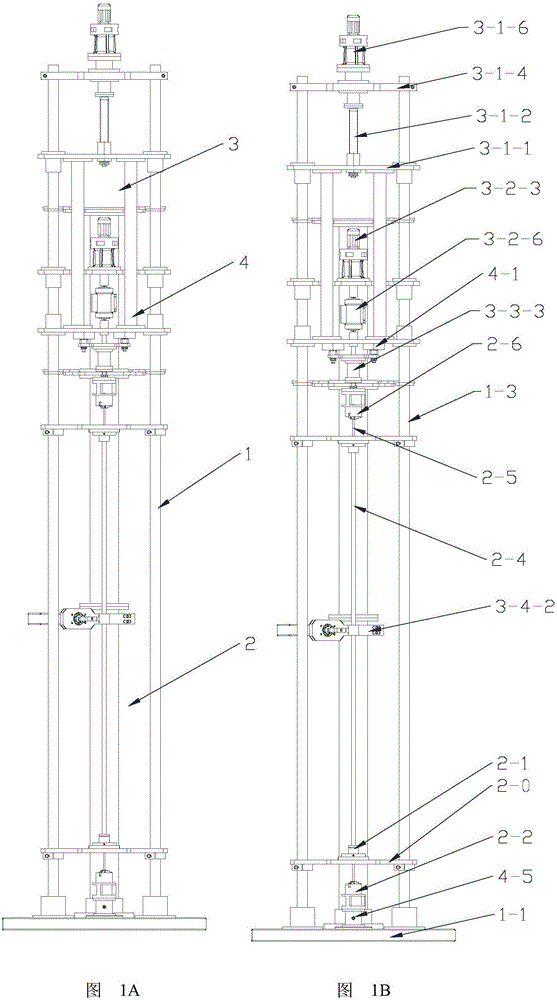

Loading test device for rigid main propeller hub connecting piece

ActiveCN114166489AAvoid unloadingReduced commissioning timeMachine part testingSustainable transportationPropellerStructural engineering

The invention provides a loading test device for a rigid main propeller hub connecting piece. The loading test device comprises a propeller hub fake piece, a variable-pitch pull rod loading joint, a propeller blade fake piece, a steel cable, a propeller hub mounting bracket, a waving loading mechanism, a shimmy loading mechanism, a centrifugal force loading mechanism and a variable-pitch pull rod force loading mechanism. According to the fatigue test device and method for the rigid main propeller hub connecting piece, the blade false piece is designed, and the four loading actuators are adopted to apply test loads in four directions, so that the real boundary condition and the loaded state of the rigid main propeller hub connecting piece are simulated, and a real and accurate fatigue test assessment environment for the rigid main propeller hub connecting piece is provided; therefore, the fatigue dangerous part and the corresponding damage mode of the rigid main propeller hub connecting piece can be accurately determined, the fatigue characteristic of the rigid main propeller hub connecting piece is obtained, and an effective test basis is provided for the service life of the rigid main propeller hub connecting piece.

Owner:CHINA HELICOPTER RES & DEV INST

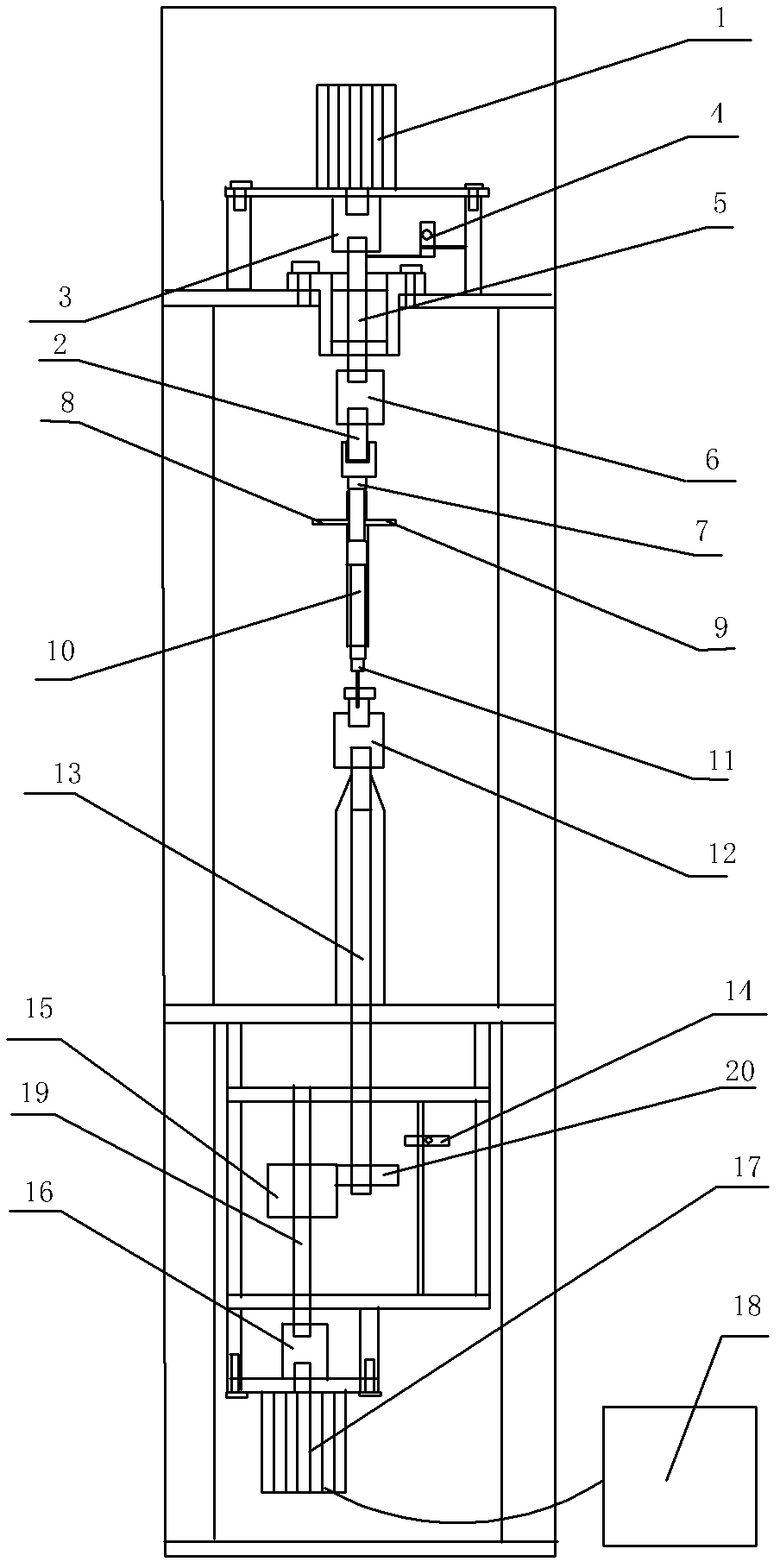

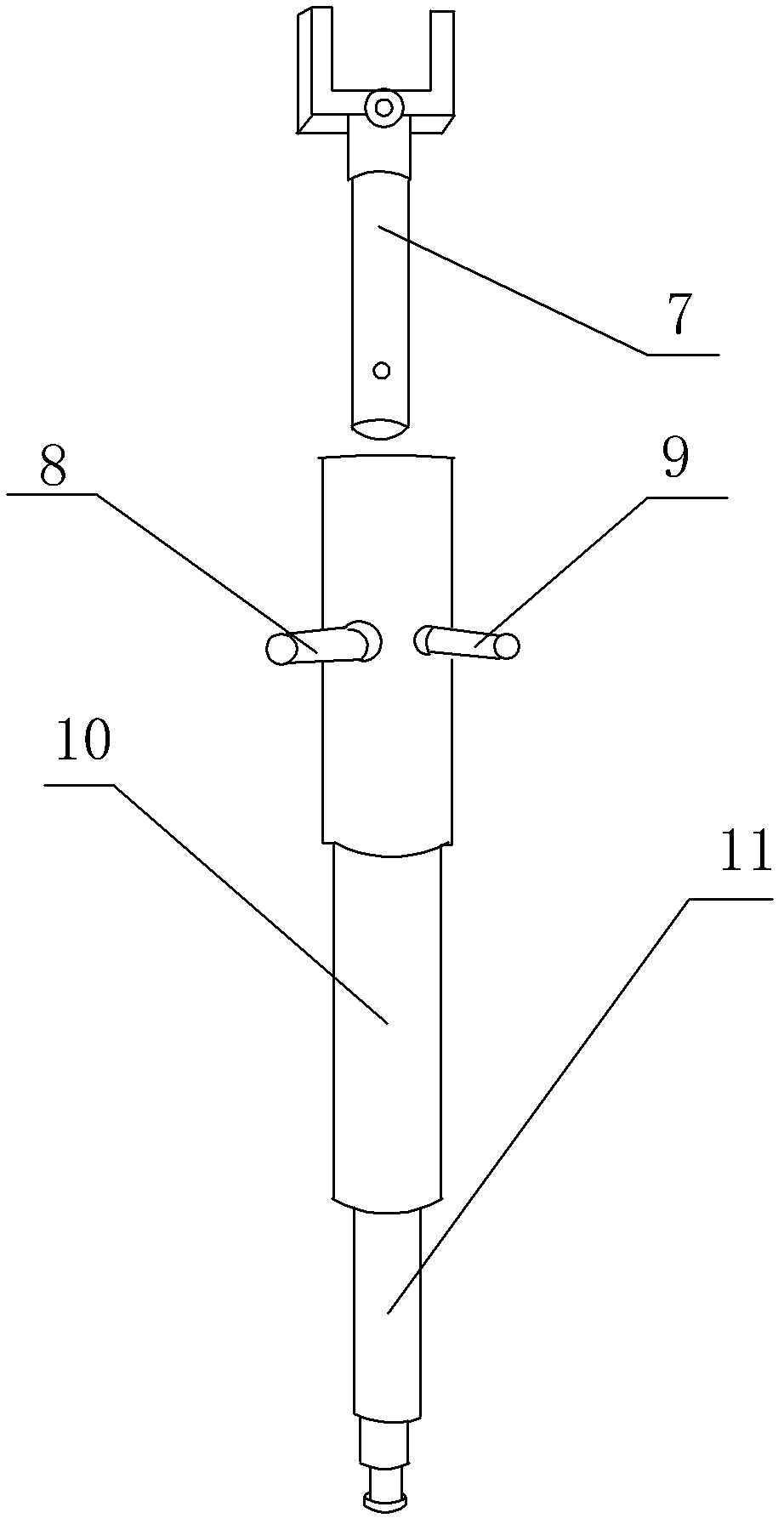

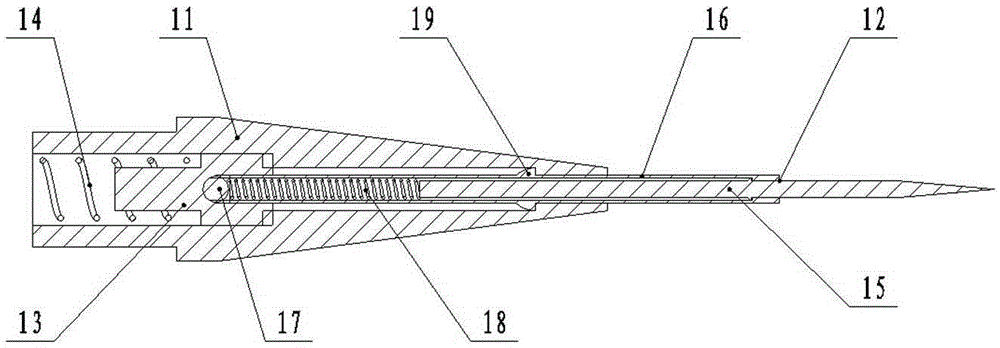

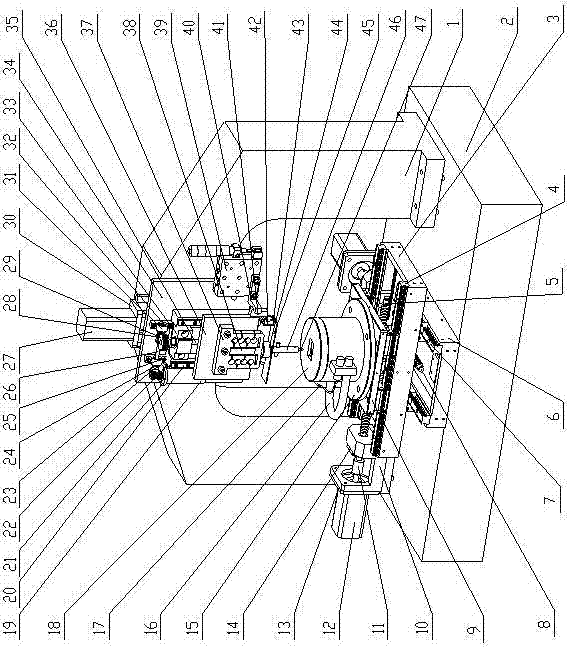

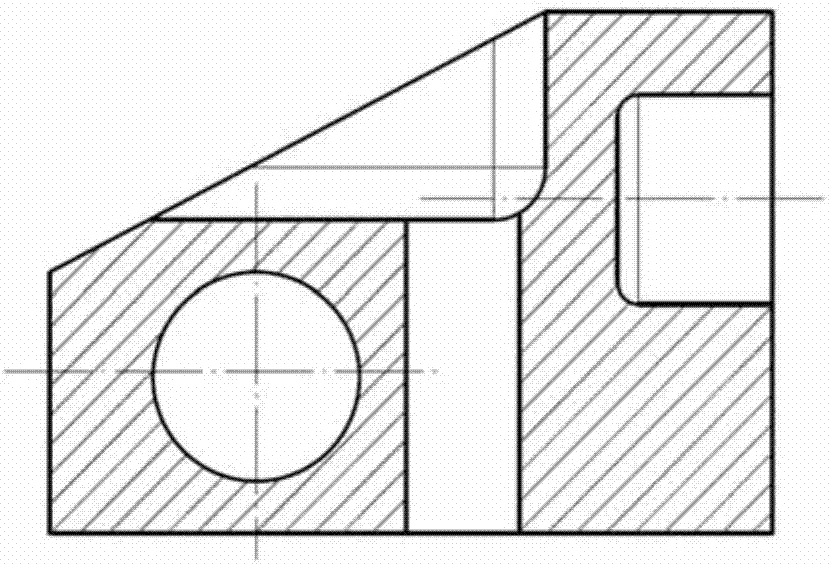

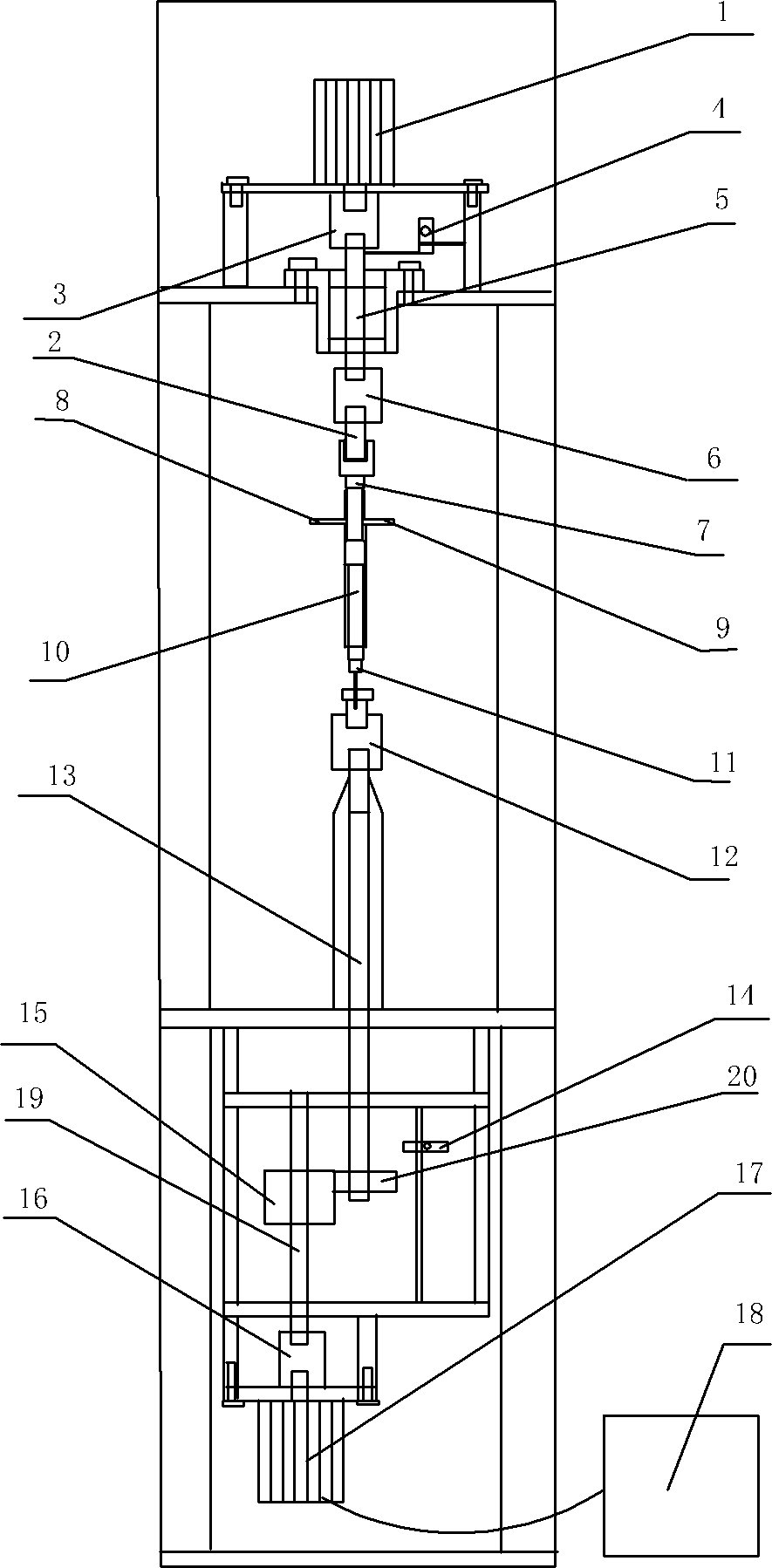

Variable temperature micro-nano indentation test method with vacuum protection

ActiveCN104596873BGuaranteed loading accuracyMeet the indentation requirements of large loading strokesInvestigating material ductilityInvestigating material hardnessElectricityMotor drive

The invention relates to a system for testing temperature-varying micro-nanometer indentations with vacuum protection characteristics and a method for testing the indentations, and belongs to the field of an optical mechanical and electrical integration precision science instrument. The system comprises a vacuum chamber system, a Z-shaft direction macro-adjusting mechanism, a Z-shaft long-stroke precision pressing-in drive unit, a Z-shaft short-stroke precision pressing-in drive unit, a pressing-in displacement signal detection unit, a pressing-in loading force signal detection unit, a temperature loading and detecting unit and an X-Y precision locating platform. The system is characterized that a high-temperature heating module and an indentation loading module are reasonably integrated so that the micro-nanometer indentations are tested at a temperature field; because vacuum environment is provided, the testing results cannot be affected by an oxidized specimen surface in a heating process; two driving methods such as motor drive and piezoelectric drive are adopted, so that the loading precision of the short-stroke indentation is ensured in test, and the requirement for largely loading the stroke indentations of a special material is also met. Thus the system and the method have the wide development prospect and application value in fields such as material science, aerospace and defense military industry.

Owner:JILIN UNIV

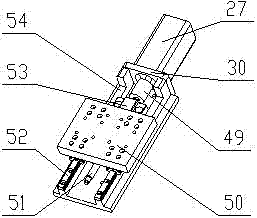

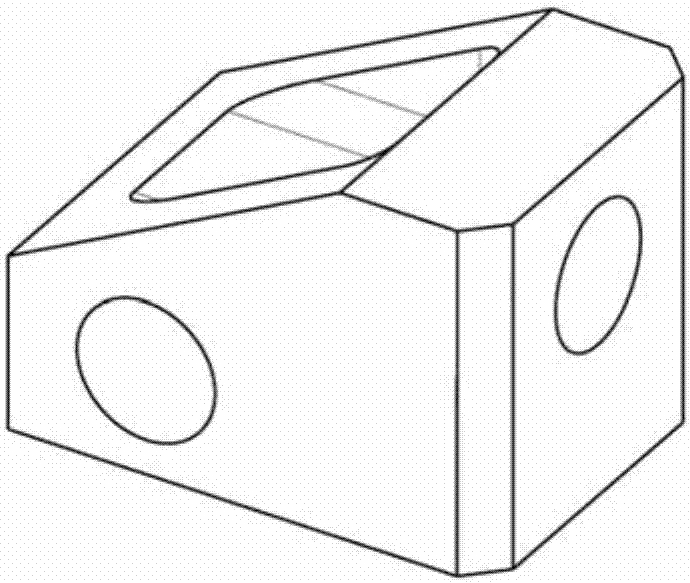

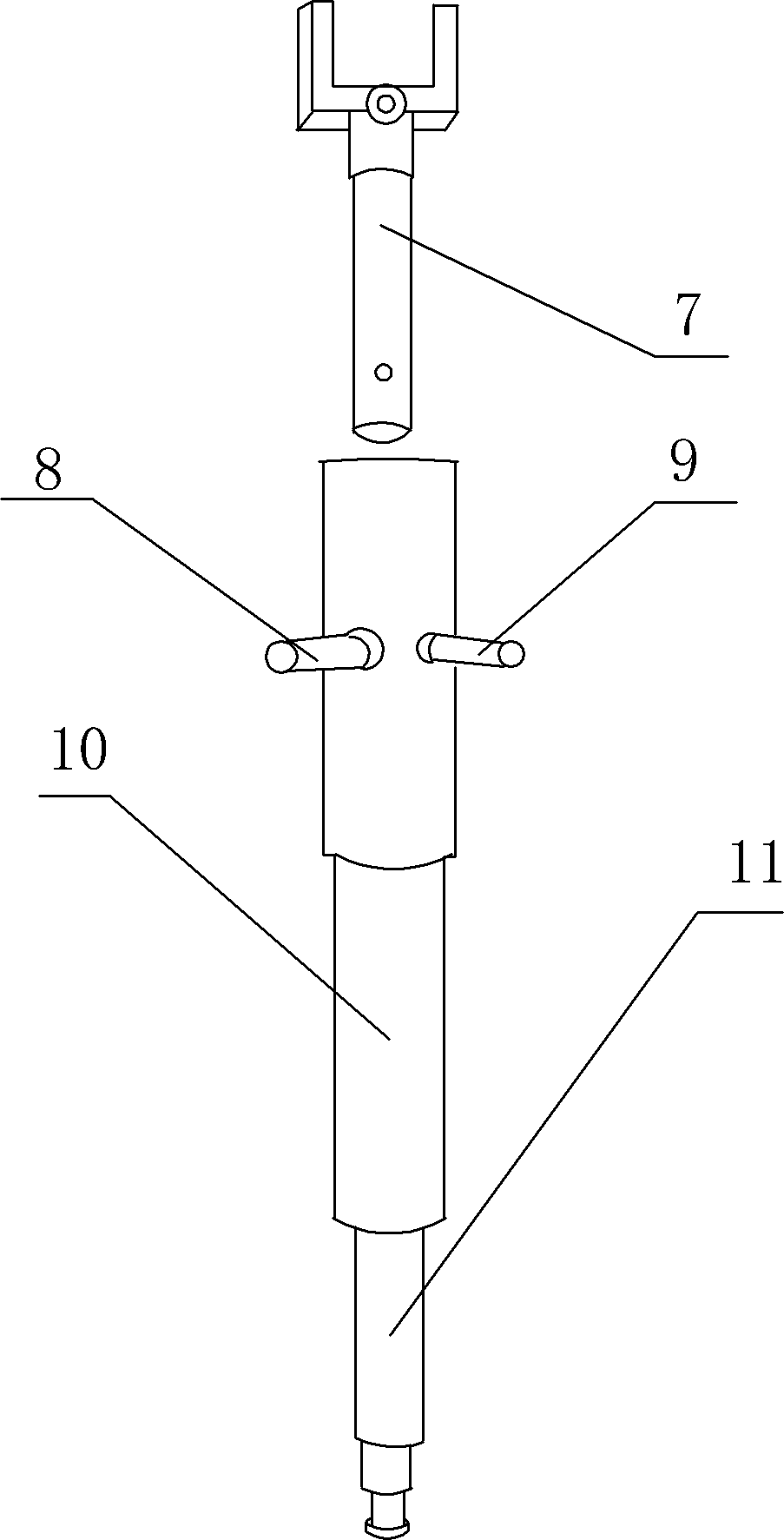

Sliding type loading mechanism applied to automatic pipettor tip loader

InactiveCN104354907AImprove work efficiencyGuaranteed loading accuracyPackaging automatic controlPipettePosition sensor

The invention discloses a sliding type loading mechanism applied to an automatic pipettor tip loader, which solves the technical problem of low loading efficiency due to the fact that the whole process of single material feeding, delivery and blanking of a loading mechanism in an automatic pipettor tip loader in the prior art is carried out by loading units alternately. The invention adopts the technical scheme that the sliding type loading mechanism comprises a bottom plate, a stationary block, a slide block, an incoming material position sensor, a first blanking position sensor and a second blanking position sensor, wherein the stationary block is arranged on the bottom plate; the slide block is arranged on the bottom plate in a sliding manner; the stationary block is parallel to the slide block; a feed groove is formed in the stationary block; the incoming material position sensor is arranged above the feed groove in the stationary block; a first blanking groove and a second blanking groove are formed in the stationary block; the first blanking position sensor is arranged above the first blanking groove in the stationary block; and the second blanking position sensor is arranged above the second blanking groove in the stationary block. The mechanism has the advantages that two materials are loaded alternately, gapless acquisition of tips and drippage of the tips are achieved; and the loading efficiency is improved.

Owner:李俊

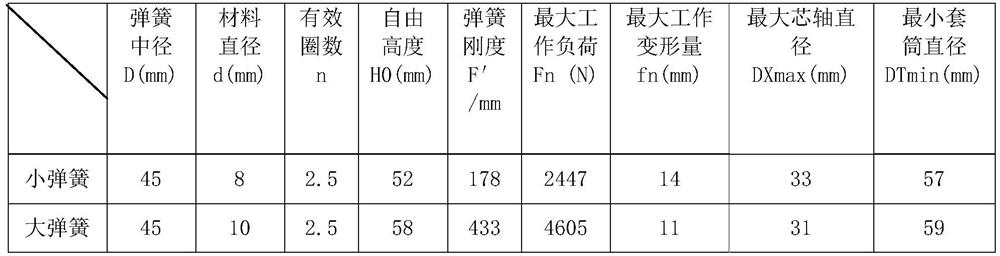

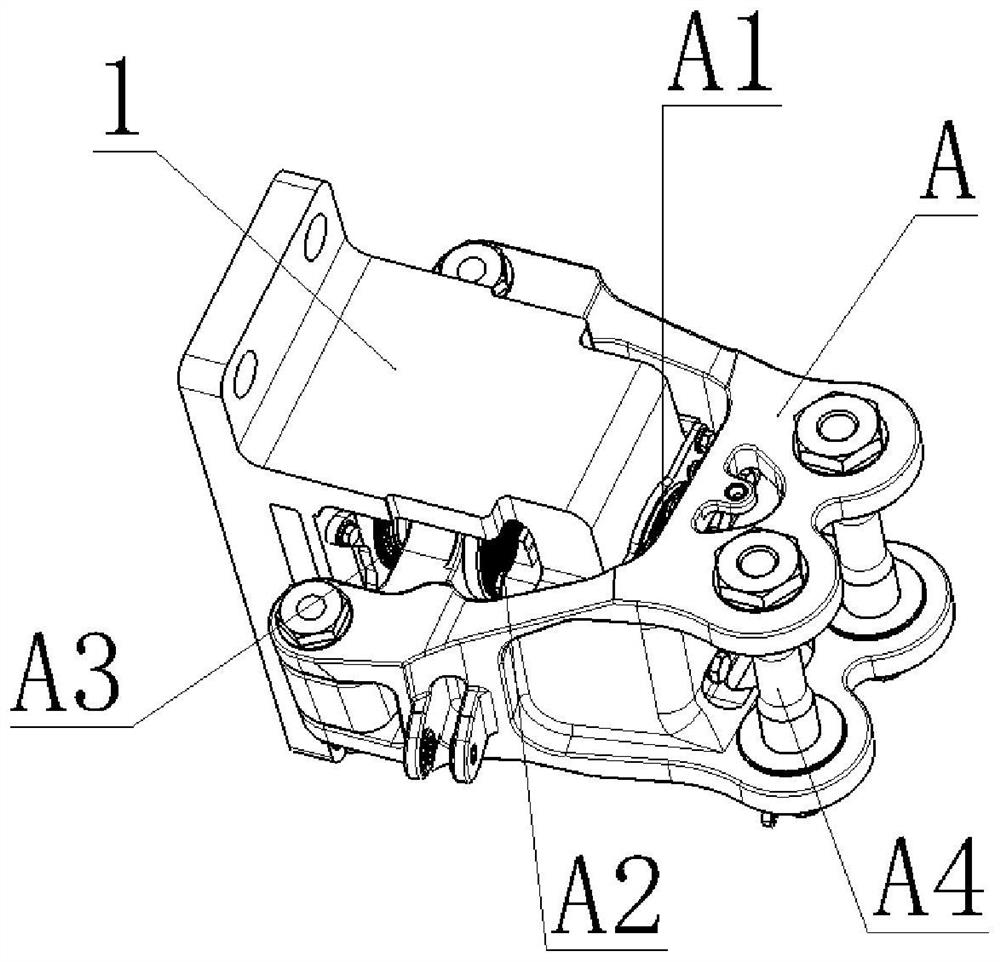

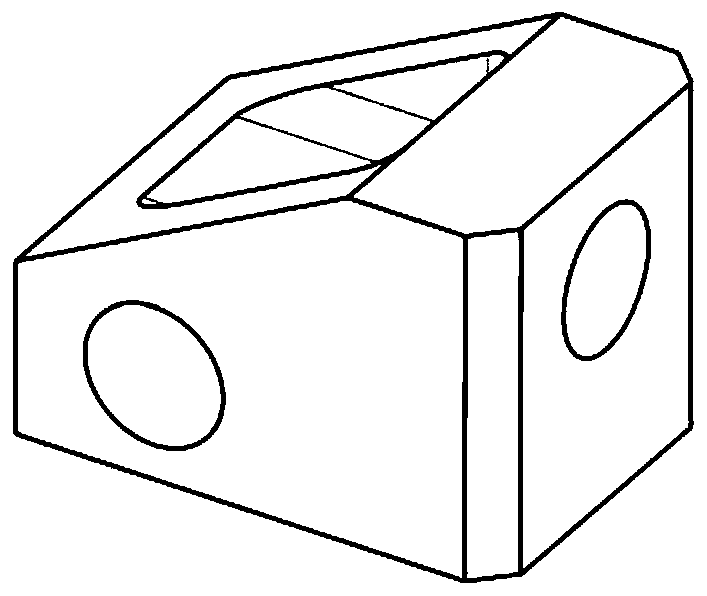

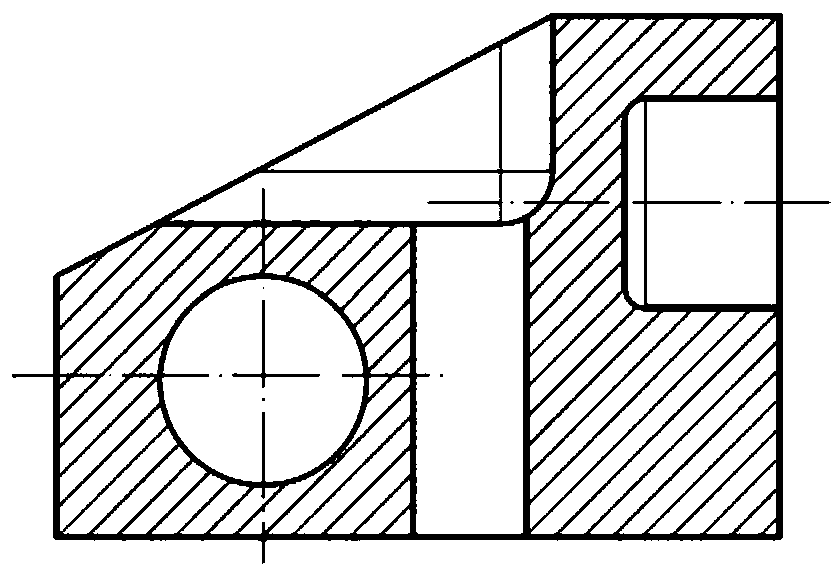

Load loading system for hatch lock reliability testing device and butterfly-shaped spring assembly selecting method of load loading system

ActiveCN106908234AOverall small sizeSmall weightMachine part testingMultiple spring combinationsLoading TechniqueMechanical engineering

The invention relates to a load loading system for a hatch lock reliability testing device and a butterfly-shaped spring assembly selecting method of the load loading system, belongs to load loading technologies of a hatch lock, and aims at solving the problems that a load born by a lock ring changes widely when a load loading spring of a present hatch lock reliability testing device is stretched or compressed. An intermediate joint of a first guide rail is fixedly connected to the middle of the first guide rail, two first slide blocks are arranged at the two sides of the intermediate joint of the first guide rail respectively, and first connecting rods are connected to the slide blocks and a lock ring; a second guide rail is vertical to the first guide rail, and a second slide block, a butterfly-shaped sprig assembly and a load adjusting block sleeve the second guide rail successively; and a load adjusting rod is positioned over the second guide rail. The butterfly-shaped spring assembly is determined by determining an initial elastic coefficient of the spring assembly, establishing an initial function relation between FTH and VHK2, determining a correcting elastic coefficient of the butterfly-shaped spring assembly, and determining the number of spring leaves. The system and method are used for load loading in hatch lock reliability test.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-temperature and high-pressure water environment normal fretting wear test device

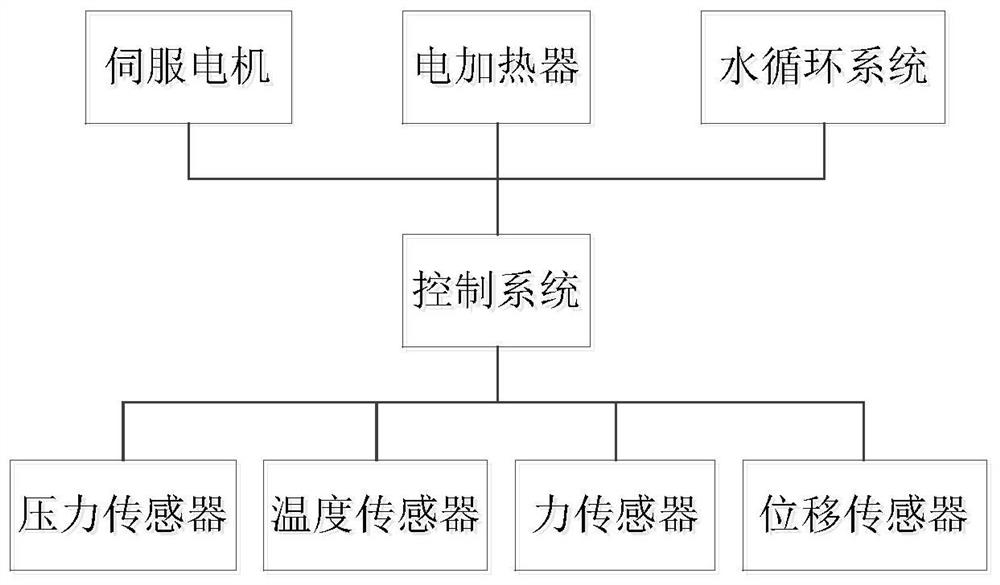

PendingCN112683650AGuaranteed loading accuracyGuaranteed validityInvestigating abrasion/wear resistanceControl systemEngineering

The invention provides a high-temperature and high-pressure water environment normal fretting wear test device, which comprises a kettle body with a high-temperature and high-pressure water environment, wherein a guide rail with a lock is transversely arranged in the kettle body, a first fixing seat used for fixing a first sample is arranged on the guide rail with the lock, a transverse driving mechanism is arranged outside the kettle body, a transmission rod is arranged on the transverse driving mechanism, the transmission rod is movably arranged on the side wall of the kettle body in a penetrating manner, the length direction of the transmission rod is parallel to the length direction of the guide rail with the lock, a second fixing seat for fixing a second sample is arranged at one end, far away from the transverse driving mechanism, of the transmission rod, a force sensor is arranged on the transmission rod and is positioned outside the kettle body, the transverse driving mechanism and the force sensor are both electrically connected to a control system, a normal fretting wear test in a high-temperature and high-pressure water environment can be simulated, fretting wear test parameters are adjusted in real time according to data obtained by the sensor in the test process, and the test accuracy is improved.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Two-degree-of-freedom loading bench test equipment for steel plate spring

ActiveCN113029783ARealize the stress situationGuaranteed loading accuracyMachine part testingMaterial strength using tensile/compressive forcesVehicle frameClassical mechanics

The invention discloses two-degree-of-freedom loading bench test equipment for a steel plate spring, which belongs to the technical field of automobile part tests. The two-degree-of-freedom loading bench test equipment for the steel plate spring comprises a frame clamp, an axle clamp and a steel plate spring, the axle clamp is fixedly connected to the steel plate spring, and the steel plate spring is movably connected to the frame clamp. The two-degree-of-freedom loading bench test equipment for the steel plate spring further comprises a vertical loading mechanism, a longitudinal loading mechanism and a vertical fixing mechanism, the vertical loading mechanism is used for loading a vertical load to the frame clamp so as to load the vertical load to the steel plate spring, and the longitudinal loading mechanism is used for loading a longitudinal load to the axle clamp so as to load the longitudinal load to the steel plate spring. One end of the vertical fixing mechanism is rotationally connected to the axle clamp, and the other end of the vertical fixing mechanism is rotationally arranged. According to the loading bench test equipment, vertical and longitudinal motion interference is effectively decoupled, and the loading accuracy in two directions is ensured.

Owner:FAW JIEFANG AUTOMOTIVE CO

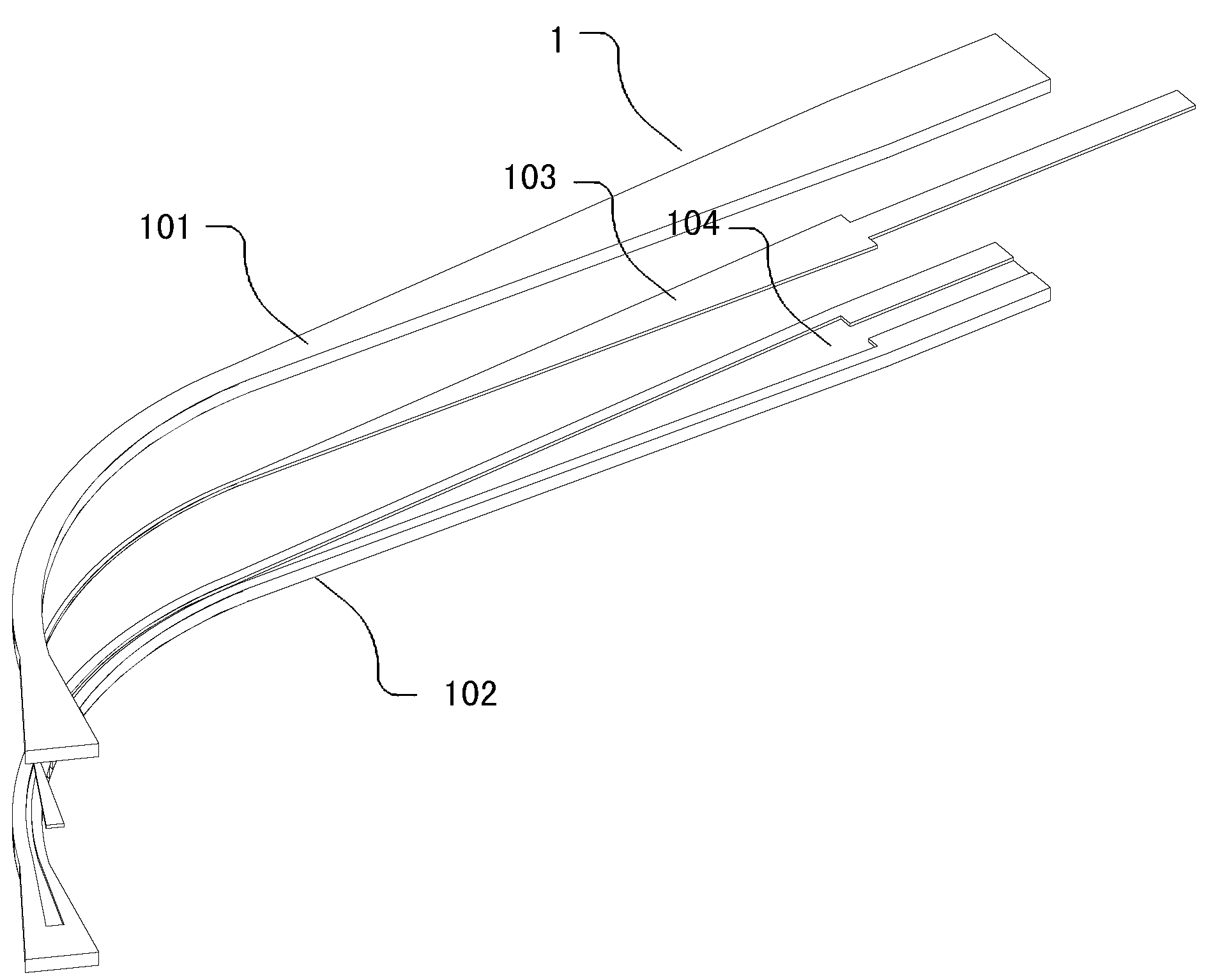

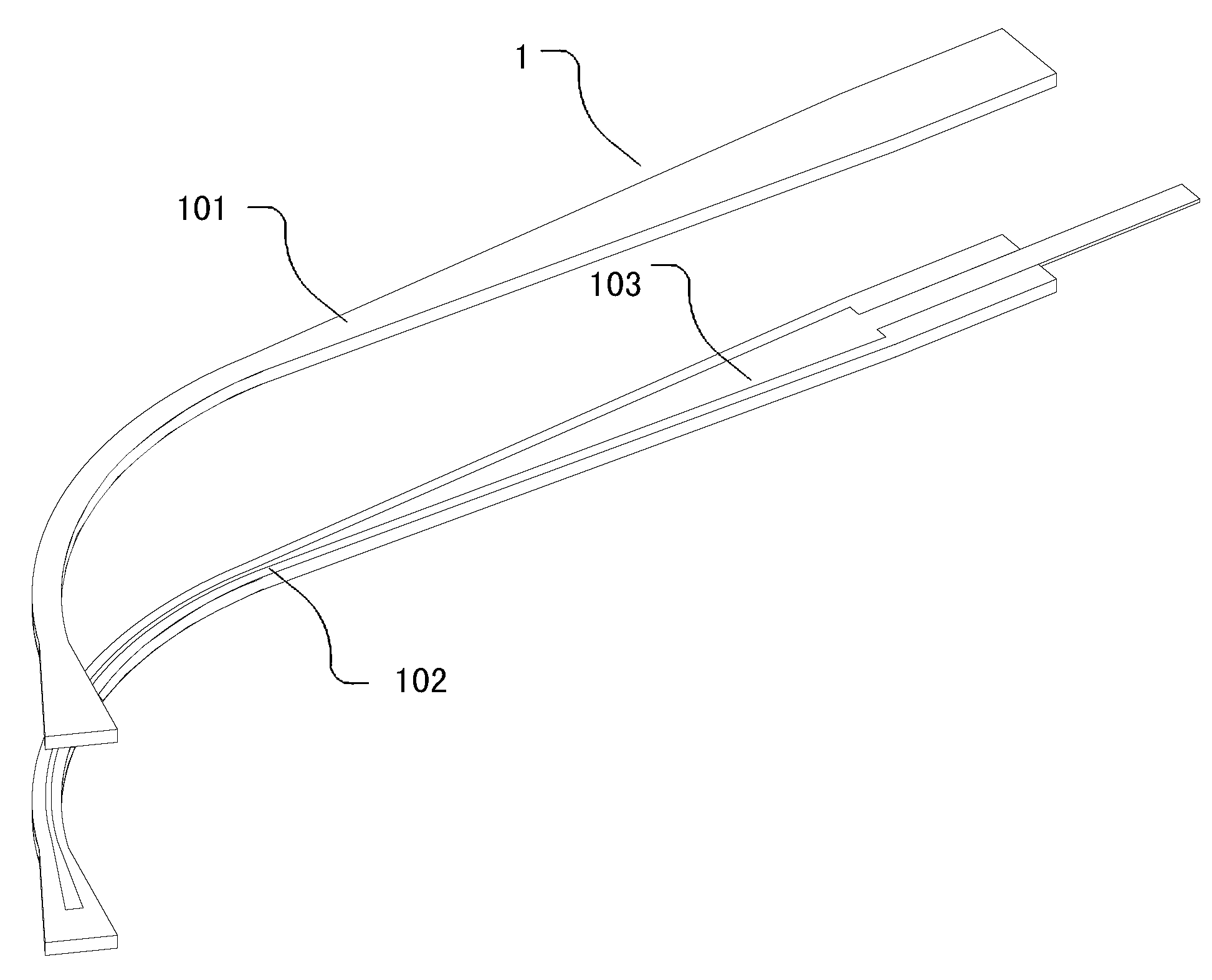

Improved glasses legs, colloid injection manufacturing method and die equipment

The invention discloses improved glasses legs, a colloid injection manufacturing method and die equipment. Each improved glasses leg is characterized by comprising a glasses leg upper sheet and a glasses leg lower sheet, and also comprising a leg wire containing cavity, wherein the leg wire containing cavity consists of leg wire containing grooves of the glasses leg upper sheet and / or the glasses leg lower sheet; a leg wire is positioned in the leg wire embedding containing cavity; the glasses leg upper sheet and the glasses leg lower sheet are integrated through an adhesive layer; the die equipment comprises the glasses leg containing cavity, a liquid colloid injection channel and a vacuumizing channel; the method comprises the following steps of: injecting liquid colloid, vacuumizing the liquid colloid injection channel, and solidifying the liquid colloid by a liquid colloid solidifying technology. According to the invention, the problems of complex production technology and low yield of conventional glasses legs in the prior art are solved.

Owner:宏懋金属制品(深圳)有限公司

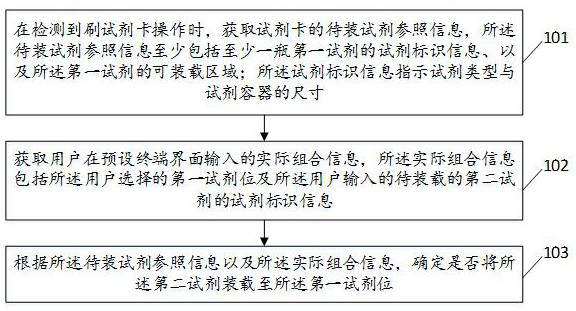

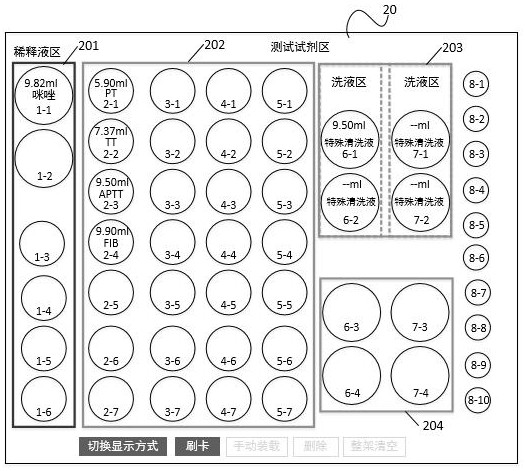

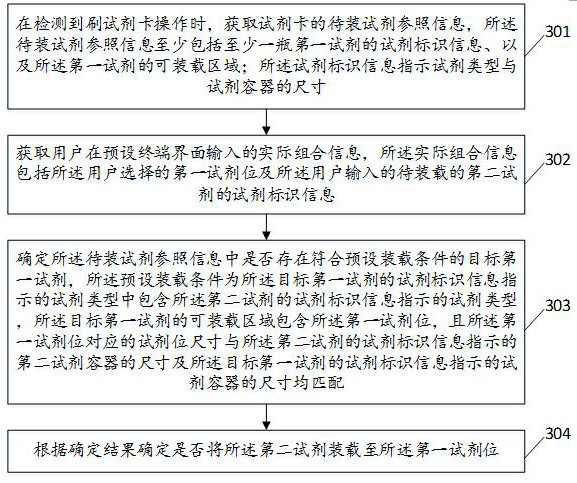

Reagent loading control method and device, computer equipment and storage medium

ActiveCN114093444AGuaranteed loading accuracyImprove loading efficiencyCo-operative working arrangementsLaboratory analysis dataComputer hardwareSimulation

The embodiment of the invention discloses a reagent loading control method and device, computer equipment and a storage medium, and the method comprises the steps: when reagent card swiping operation is detected, obtaining to-be-loaded reagent reference information of a reagent card, and the to-be-loaded reagent reference information at least comprising reagent identification information of at least one bottle of first reagent and a loadable area of the first reagent; the reagent identification information indicating the reagent type and the size of the reagent container; acquiring actual combination information which is input by a user on a preset terminal interface and comprises a first reagent position selected by the user and reagent identification information of a to-be-loaded second reagent input by the user; and determining whether the second reagent is loaded to the first reagent position or not according to the reference information of the to-be-loaded reagent and the actual combination information. By means of the method, whether the second reagent is loaded to the first reagent position or not can be comprehensively judged based on the reference information of the reagent to be loaded and the actual combination information, manual subjective judgment is reduced, reagent loading accuracy is guaranteed, and reagent loading efficiency is improved.

Owner:SHENZHEN DYMIND BIOTECH

Automobile hub bearing testing machine

ActiveCN106017934BAccurate and reliable application of loading forceLow machining accuracy requirementsMachine bearings testingLoading armEngineering

Owner:C&U CO LTD +2

High-viscosity liquid precise subpackaging device

ActiveCN102633006BPrecise positioningImprove continuityLiquid fillingPackaging automatic controlAutomatic controlElectronic control system

The invention relates to the field of a biological and chemical machine, and particularly discloses a high-viscosity liquid precise subpackaging device which comprises an electronic control system, an electrical system, a mechanical transmission system and a piston pump, wherein the electronic control system comprises a programmable logic controller (PLC) and a touch control screen; the electrical system comprises a piston servo motor and a rotary valve servo motor; the mechanical transmission system comprises a rolling shaft screw rod, a screw rod sliding block and a concentric shaft; the piston pump is provided with a liquid outlet pipe and a liquid inlet pipe; and a pipe orifice of the liquid outlet pipe is provided with a liquid outlet needle. The high-viscosity liquid precise subpackaging device can be automatically controlled to run by the PLC, can manually change various parameters, and is simple and convenient in operation and high in degree of mechanization. The servo motors are accurate in location and high in accuracy, so that the accuracy is high and the performance is stable when subpackaging is carried out on the liquid. The liquid outlet needle is arranged at a liquid outlet hole, so that the pressure in a pipeline can be reduced; and due to the small-hole design of the needle, the charging and measuring accuracy can be guaranteed. The high-viscosity liquid precise subpackaging device can be used for subpackaging in a laboratory and large-scale industrial charging, and is low in cost and suitable for large-scale popularization.

Owner:BEIJING SAISHENG PHARMA

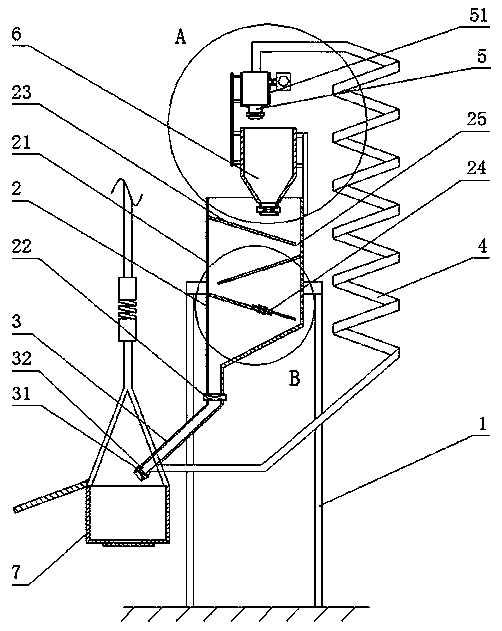

An adjustable counterweight device for building construction and its working method

ActiveCN111005566BFlexible useMeet different counterweight needsWindow cleanersBuilding material handlingArchitectural engineeringPipe

The invention discloses an adjustable counterweight device for building construction and a working method thereof, comprising a bracket, a drainage mechanism is connected to the bracket, openings are arranged above and below the drainage mechanism, and a guide material is connected to the lower opening There is an electric switch B at the junction of the trough, the drainage mechanism and the material guide trough, an electric switch C is installed at the lower opening of the material guide trough, a sensor is installed above the electric switch C, and a return pipe is connected to the opening below the material guide trough. There is a return mechanism under the other end of the return pipe, and a feeding mechanism is arranged under the return mechanism. There are openings above and below the feeding mechanism. An electric switch E is arranged at the opening below the feeding mechanism. It is filled with flowable substances; the purpose of this invention is to solve the difficulty in handling the current construction counterweight due to its large weight. A question of precision.

Owner:LUDONG UNIVERSITY

Slide Loading Mechanism Applied to Automatic Pipette Tip Loader

InactiveCN104354907BImprove work efficiencyGuaranteed loading accuracyPackaging automatic controlPipetteEngineering

The invention discloses a sliding type loading mechanism applied to an automatic pipettor tip loader, which solves the technical problem of low loading efficiency due to the fact that the whole process of single material feeding, delivery and blanking of a loading mechanism in an automatic pipettor tip loader in the prior art is carried out by loading units alternately. The invention adopts the technical scheme that the sliding type loading mechanism comprises a bottom plate, a stationary block, a slide block, an incoming material position sensor, a first blanking position sensor and a second blanking position sensor, wherein the stationary block is arranged on the bottom plate; the slide block is arranged on the bottom plate in a sliding manner; the stationary block is parallel to the slide block; a feed groove is formed in the stationary block; the incoming material position sensor is arranged above the feed groove in the stationary block; a first blanking groove and a second blanking groove are formed in the stationary block; the first blanking position sensor is arranged above the first blanking groove in the stationary block; and the second blanking position sensor is arranged above the second blanking groove in the stationary block. The mechanism has the advantages that two materials are loaded alternately, gapless acquisition of tips and drippage of the tips are achieved; and the loading efficiency is improved.

Owner:李俊

Hydraulic loading system

The application relates to a hydraulic loading system. The hydraulic loading system comprises a loading platform and at least two hydraulic loading components used for exerting pressure onto the loading platform, as well as a control component, wherein the control component adjusts the pressure output by each hydraulic loading component based on the corresponding relationship between the pressure output by the hydraulic loading components and displacement of the position, at which the hydraulic loading components on the loading platform exert pressure on the loading platform and a predetermined point. By adoption of the hydraulic loading system, the hydraulic loading components are prevented from action of a lateral force, and accordingly, abrasion of the hydraulic loading components is avoided.

Owner:BEIHANG UNIV

The load loading system and the selection method of the disc spring group used in the reliability test device of the cabin door lock

ActiveCN106908234BOverall small sizeSmall weightMachine part testingMultiple spring combinationsMechanical engineeringLoading Technique

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A hydraulic retarder type simulation loading system

ActiveCN108918156BGuaranteed loading accuracyEnsure system stabilityVehicle testingTransfer caseLoop control

The invention discloses a hydraulic retarder type analog loading system. The hydraulic retarder type analog loading system comprises a torque sensor used for measuring the torque and the rotating speed of an input shaft of a retarder, the hydraulic retarder used for applying a load to an engine, a transmission used for changing the transmission ratio, a transfer case used for transmitting motion and the torque, a cooling system used for cooling and heat dissipation of the hydraulic retarder and the engine, a hydraulic system used for changing the rotating speed of a fan and the water flow of the cooling system, a hydraulic retarder ECU used for controlling the hydraulic retarder, a cooling and hydraulic system ECU used for controlling the cooling system and the hydraulic system, an information collecting system used for collecting the vehicle operation states such as the three-axis acceleration and the slope inclination, and a vehicle controller used for controlling a vehicle electronic control system. According to the hydraulic retarder type analog loading system, through a closed-loop control algorithm for the hydraulic retarder and the cooling and hydraulic systems, the loadingprecision for the analog load and system stability under different test conditions are ensured, and stepless regulation and control of the analog load are realized.

Owner:WUHAN UNIV OF TECH

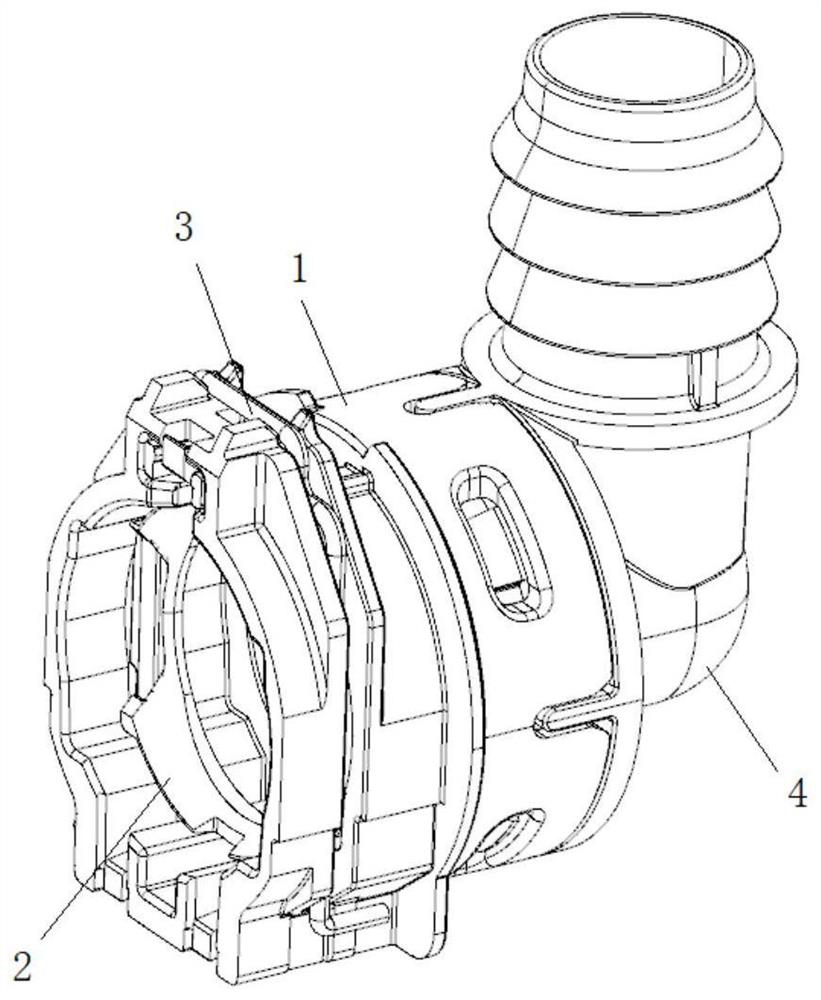

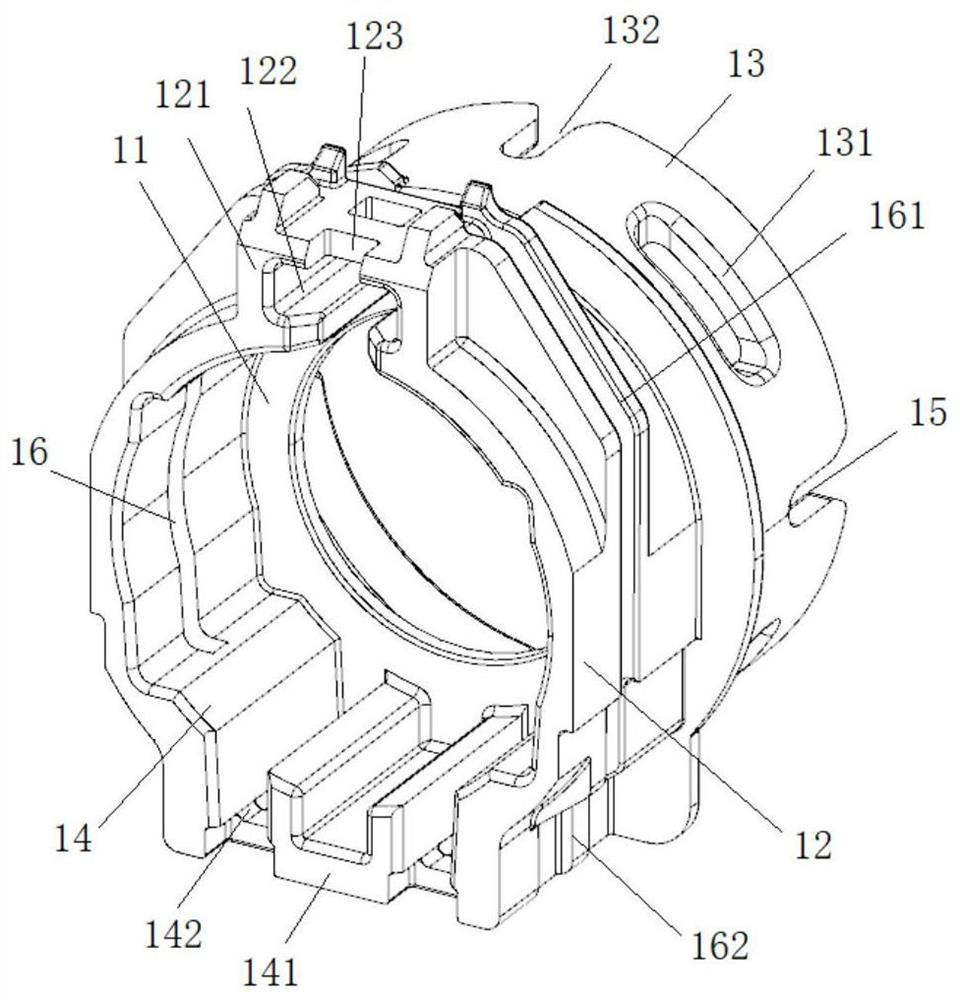

Quick connector adaptive to multi-angle mounting positions

The invention discloses a quick connector adaptive to multi-angle mounting positions. The quick connector comprises a main pipe body, a guide ring horizontally embedded into the front end of the main pipe body, an elastic retainer vertically embedded into the main pipe body and used for limiting the guide ring to prevent the guide ring from being separated, and a bent pipe body capable of covering and being inserted into the rear end of the main pipe body in a multi-angle manner. By means of the quick connector, a quick connector structure capable of adjusting the adaptive direction from multiple angles is achieved, and the application range is wide.

Owner:COOPER STANDARD AUTOMOTIVE SUZHOU CO LTD

A high-precision probe loading device for pcb automatic test equipment

ActiveCN105353179BLoading pressure adjustmentGuaranteed Loading Accuracy IndexElectrical measurement instrument detailsPrinted circuit testingAutomatic test equipmentEngineering

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com