Indoor available comprehensive tubing string mechanics experiment platform

A technique of pipe string mechanics and experimental platform, applied in the direction of using stable torsion to test material strength, using stable bending force to test material strength, and using stable tension/pressure to test material strength, etc. It can improve the stability of the whole machine, reduce the cost and scale, and simplify the processing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention will be further described:

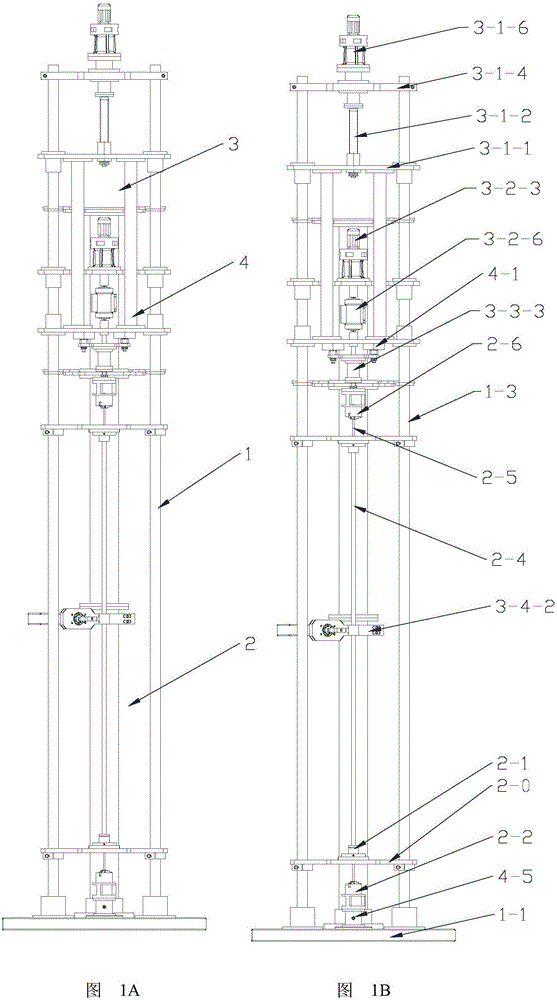

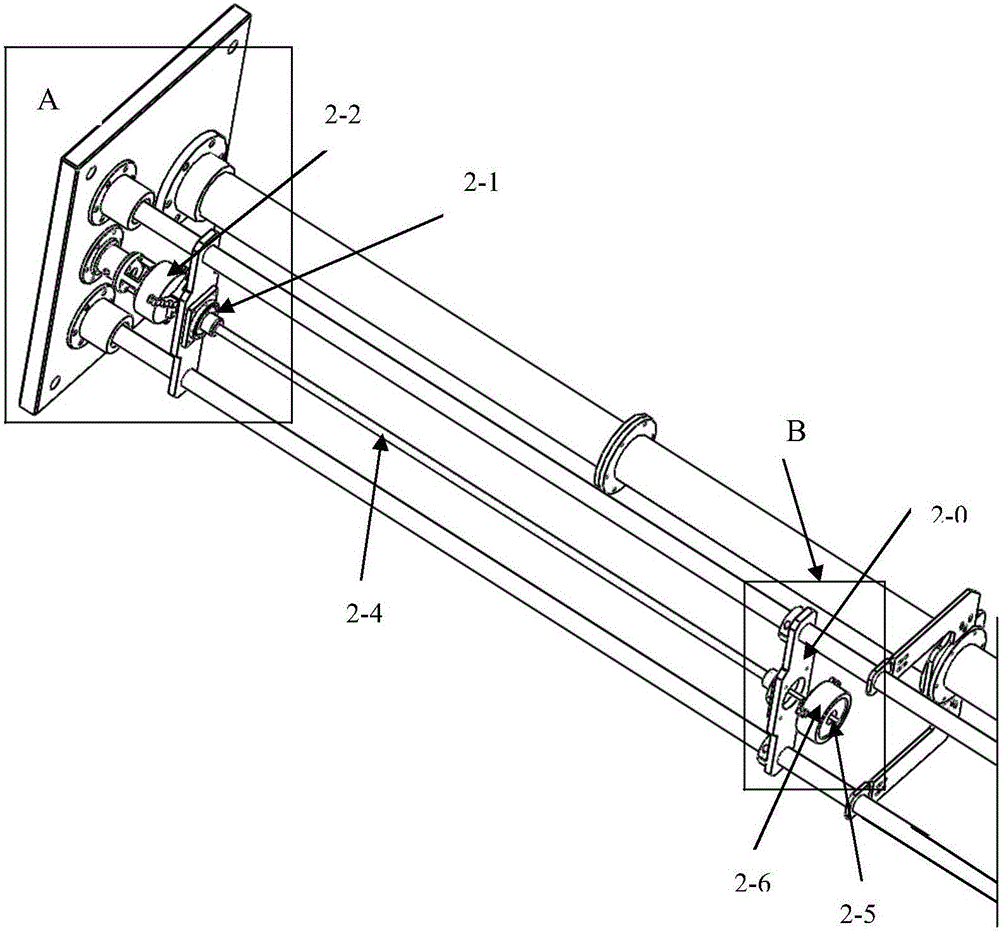

[0040] Depend on Figure 1A Shown: a comprehensive pipe mechanics experiment platform available indoors, including frame 1, specimen and its sealing system 2, loading and transmission system 3 and control system 4.

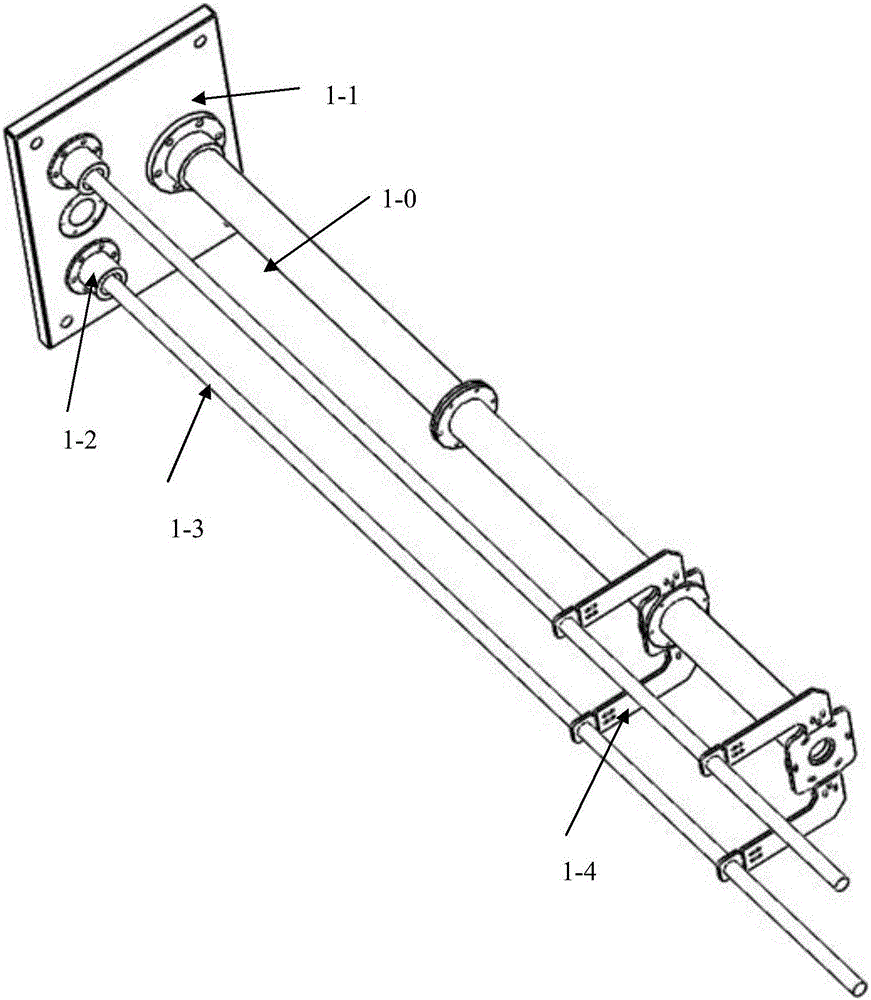

[0041] Depend on figure 2 As shown: the frame 1 includes the main stress column 1-0, two auxiliary guide columns 1-3 and the lower platform 1-1, the main force column 1-0 and the two auxiliary guide columns 1-3 pass through The torsion support frame 1-4 is connected to form a tripod structure, in which the main force column 1-0 adopts a three-stage structure, and is fixed by straight positioning and flange connection. The main force column 1-0 and the lower platform 1- 1 adopts straight mouth positioning and flange connection, and the auxiliary guide column 1-3 is fixedly connected to the lower table 1-1 by using the expansion sleeve 1-2, so the whole machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com