Permanent magnet motor

A permanent magnet type, motor technology, applied in the direction of magnetic circuit, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of reduced driving torque, larger magnetic pole offset, and higher short-circuit magnetic flux ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

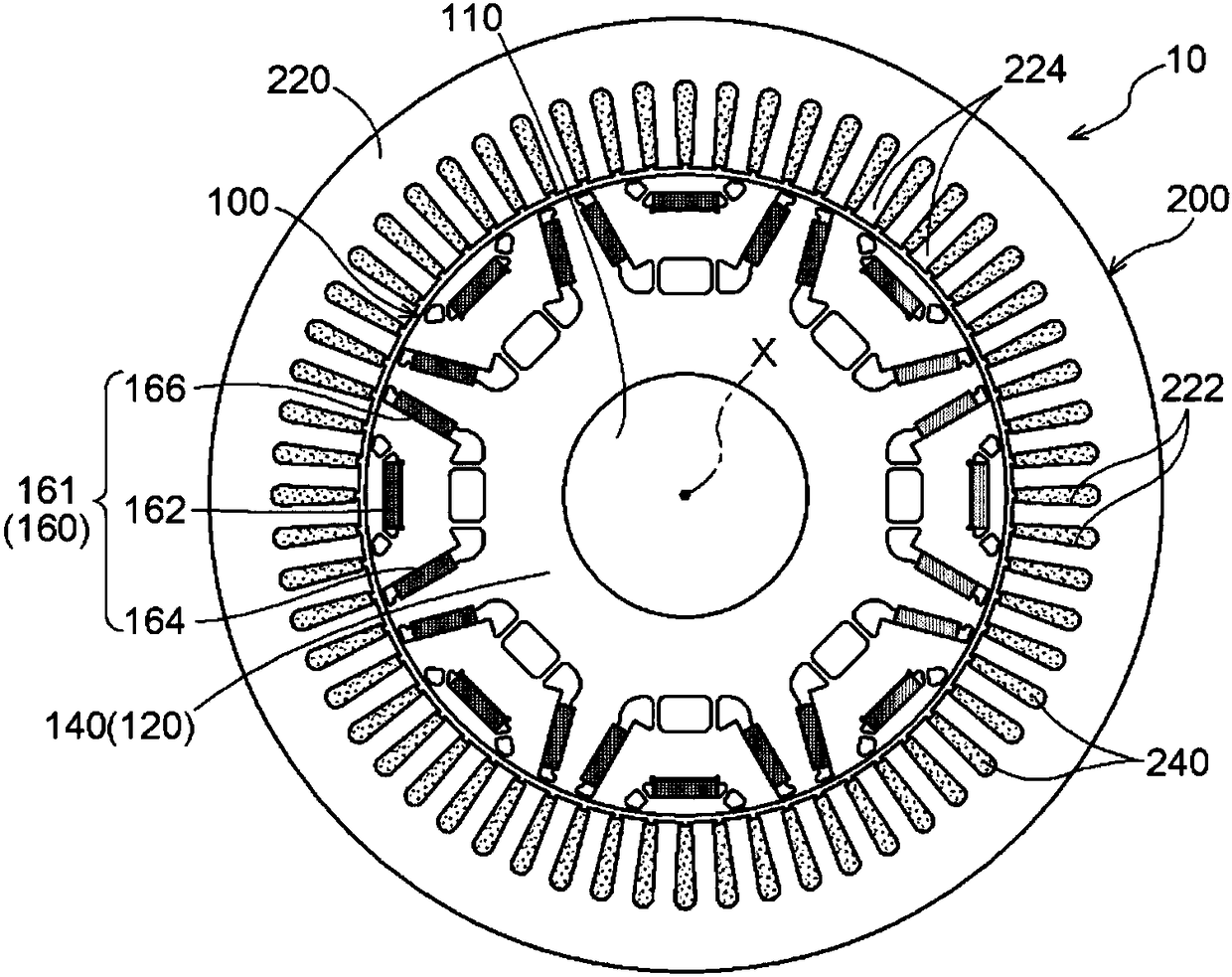

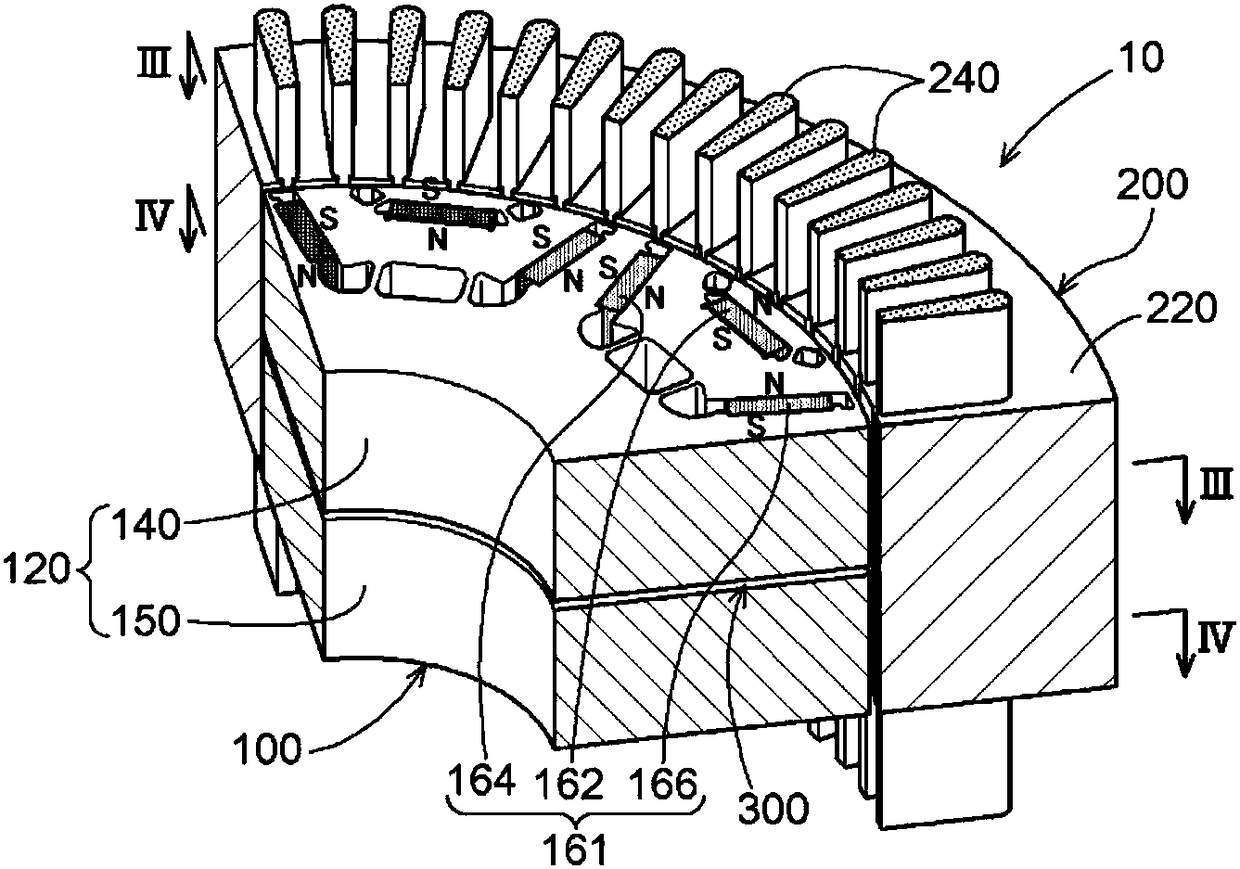

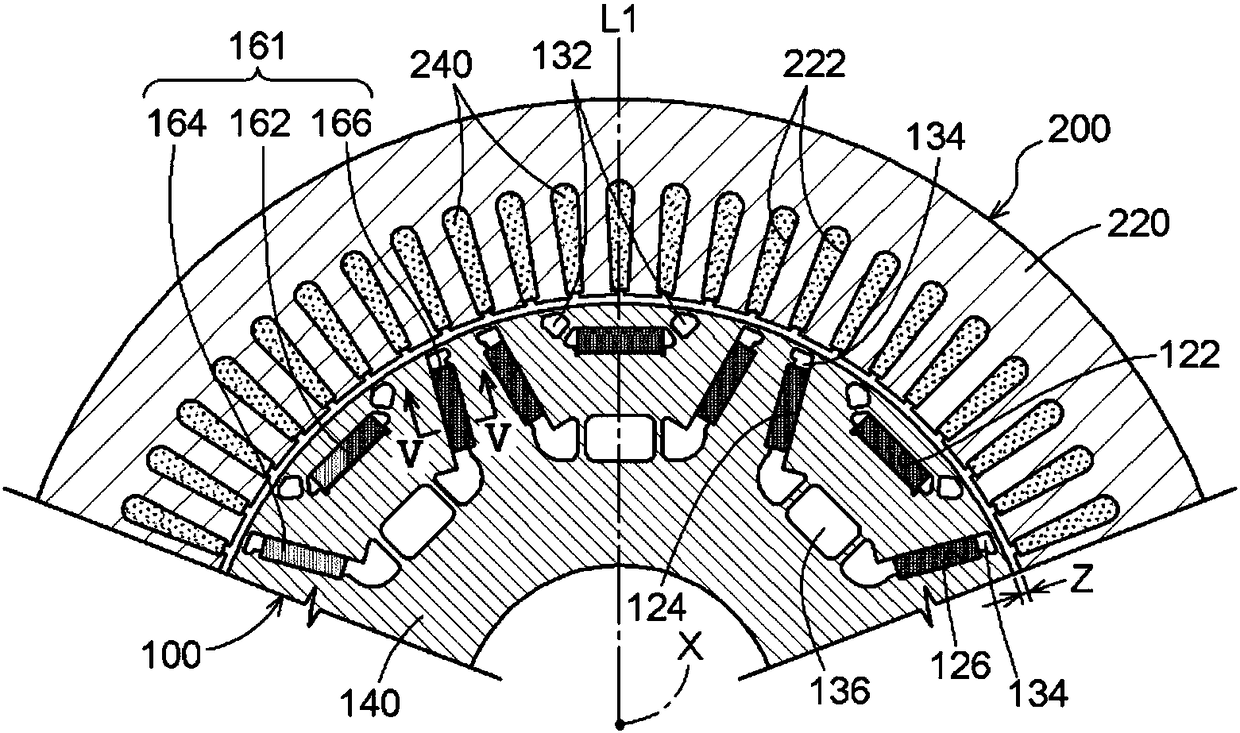

[0039] figure 1 It is a plan view of the embedded permanent magnet (IPM) motor 10 according to the first embodiment of the present invention viewed from the direction along the rotation axis. Such as figure 1 As shown, the IPM motor 10 has a rotor 100 and is coaxial with the axis X of the rotor 100 and has a gap Z on the radially outer side (refer to image 3 ) ground configuration of the stator 200. In addition, the IPM motor 10 is an example of a permanent magnet motor, and the gap Z is an example of the second gap.

[0040] The stator 200 has a stator core 220 and a coil 240 wound around a slot 222 of the stator core 220 . Stator core 220 is formed by laminating electromagnetic steel sheets and has a cylindrical shape.

[0041] The rotor 100 has a cylindrical rotor core 120 formed by laminating electromagnetic steel plates, a shaft 110 fixed through a through hole formed in the center of the rotor core 120 , and a cubic-shaped rotor core 120 accommodated inside the roto...

no. 2 approach

[0057] Hereinafter, an IPM motor 20 according to a second embodiment of the present invention will be described in detail with reference to the drawings. In the description of the present embodiment, the same reference numerals are attached to the positions of the same structures as those of the first embodiment, and the related description of the same structures will be omitted.

[0058] The IPM motor 20 is different from the first embodiment in that the first magnetic body 320 is inserted at the position of the gap 300 of the IPM motor 10 , and the other structures are the same as those of the first embodiment. The first magnetic body 320 is an example of a plate member, and the thickness of the first magnetic body 320 is an example of a first gap.

[0059] The first magnetic body 320 is formed by laminating one or more electromagnetic steel sheets constituting the rotor core 120 . The first magnetic body 320 is in contact with the lower surface of the upper iron core 140 a...

no. 3 approach

[0070] Hereinafter, an IPM motor 30 according to a third embodiment of the present invention will be described in detail with reference to the drawings. In the description of the present embodiment, the positions of the same configurations as those of the first embodiment and the second embodiment are assigned the same reference numerals, and related descriptions of the same configurations are omitted.

[0071] The IPM motor 30 is different from the second embodiment in that the second magnetic body 340 is inserted instead of the first magnetic body 320 that the IPM motor 20 has, and the other structures are the same as those of the second embodiment. The second magnetic body 340 is an example of a plate member, and the thickness of the second magnetic body 340 is an example of a first gap.

[0072] The second magnetic body 340 is formed by laminating one or more electromagnetic steel sheets. Such as Figure 10 As shown, compared with the first magnetic body 320, the charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com