The load loading system and the selection method of the disc spring group used in the reliability test device of the cabin door lock

A test device and loading system technology, which is applied in the direction of spring components, springs, and measuring devices composed of several springs, can solve the problems of large changes in the load of the lock ring and the inability to ensure the loading accuracy of the lock hook, and achieve high loading accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

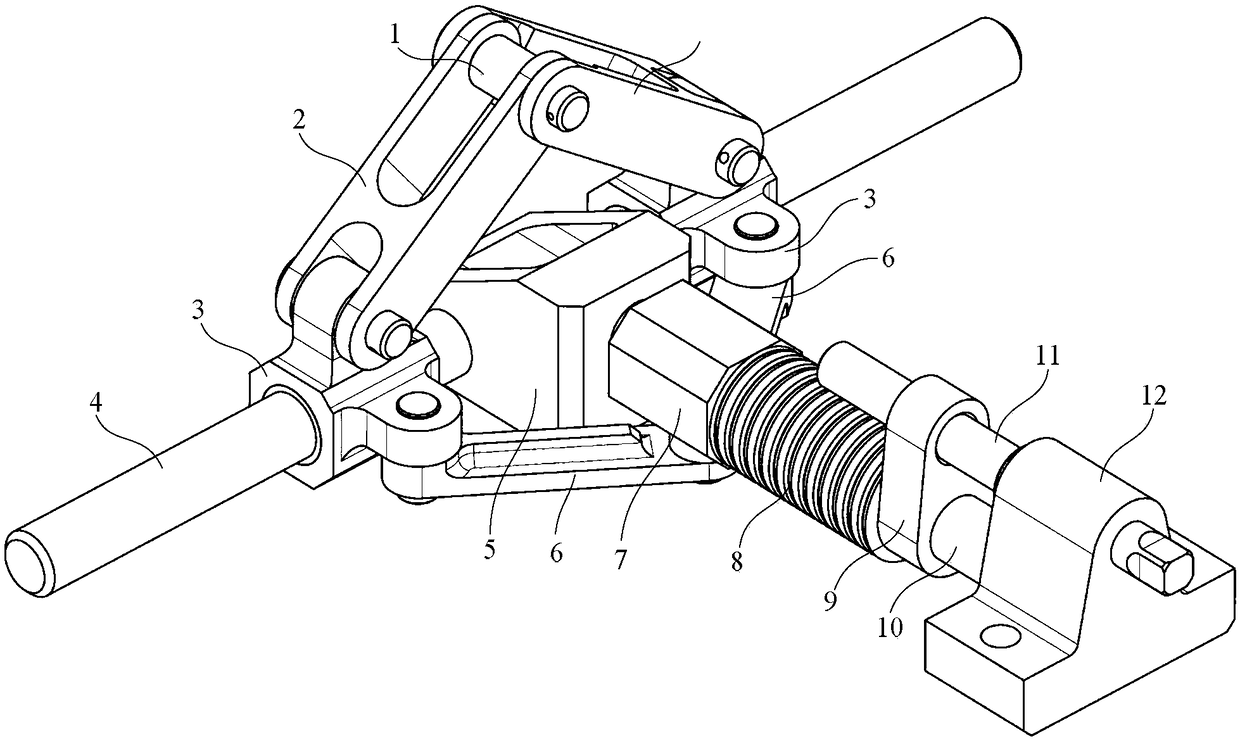

[0048] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the load loading system used for the hatch door lock reliability test device described in this embodiment, it includes a lock ring 1, two No. 1 connecting rods 2, two No. 1 sliders 3, and No. 1 guide rails 4 , No. 1 guide rail intermediate joint 5, two No. 2 connecting rods 6, No. 2 slider 7, disc spring group 8, load adjustment block 9, No. 2 guide rail 10, load adjustment lever 11 and No. 2 guide rail joint 12,

[0049] The middle of the No. 1 guide rail 4 is fixedly connected to the No. 1 guide rail intermediate joint 5, and the two No. 1 sliders 3 are arranged on both sides of the No. 1 guide rail intermediate joint 5, and are slidably connected to the No. 1 guide rail 4; One end of the rod 2 is rotatably connected with the lock ring 1 at the same time, the lock ring 1 is located directly above the middle joint 5 of the No. 1 guide rail, and the other ends of ...

specific Embodiment approach 2

[0059] Specific implementation mode two: the following combination Figure 1 to Figure 7 Describe this implementation mode, this implementation mode is realized based on Embodiment 1, and it comprises the following four steps:

[0060] The first step is to determine the initial elastic coefficient k of the disc spring group 8 TH for:

[0061]

[0062] In the formula, F HK2,2 is the load on the second slider 7 when the lock ring 1 is at the highest position; F HK2,1 is the load on the second slider 7 when the lock ring 1 is at the lowest position; V HK2,2 When the lock ring 1 is at the highest position, the distance between the axis of the second slider rotation pair and the axis of the first guide rail; V HK2,1 is the distance between the axis of the No. 2 slider rotating pair and the No. 1 guide rail axis when the lock ring 1 is at the lowest position;

[0063] When the locking ring 1 is in the lowest position, F HK2,1 and the load F on the disc spring group at this ...

specific Embodiment

[0090] Concrete embodiment: in the test process, the ideal load F that lock ring 1 is subjected to SH It is 1500N, and the load error limit in engineering practice is generally 5%. The determination method and process of the relevant parameters of the load loading system are as follows:

[0091] (1) Determine the length L of the No. 1 connecting rod 2 LG1 . According to the movement principle and size parameters of the cabin door lock, the upward movement distance of the lock ring 1 during the locking process is 20mm, that is, V SH,2 -V SH,1 = 20mm. According to the allowable height of the test device, determine the distance V between the axis of the locking ring 1 and the axis of the No. 1 guide rail 4 when it is at the lowest position SH,1 40mm, then V SH,2 is 60mm. According to the position parameters of the bolt holes on the vibrating table surface, determine the left and right width H of the middle joint 5 of the No. 1 guide rail JT is 60mm, the length L of the No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com