Quick connector adaptive to multi-angle mounting positions

An installation position, multi-angle technology, applied in the direction of pipes/pipe joints/fittings, elbows, siphons, etc., can solve problems such as insufficient connection, inability to adapt to quick joints, and inability to install and arrange pipeline space. , to achieve the effect of ensuring the accuracy of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

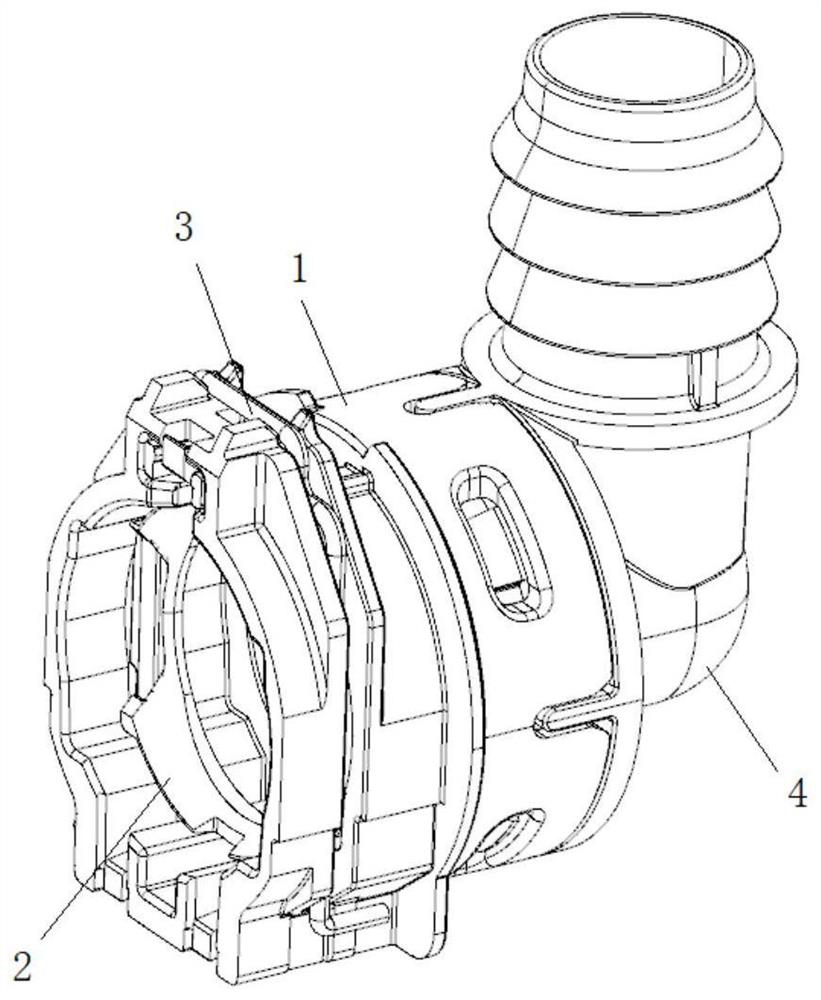

[0031] refer to Figure 1-8 As shown, this embodiment is a quick joint adaptable to multi-angle installation positions, including a main pipe body 1, a guide ring 2 embedded horizontally in the front end of the main pipe body 1, and an elastic retainer that is vertically embedded in the main pipe body 1 and limits the guide ring 2 to prevent it from detaching. Part 3, and the elbow body 4 that can cover and insert the rear end position of the main body 1 at multiple angles.

[0032] The front end of the main body 1 is correspondingly plugged and matched with the butt joint pipe 5, and the butt joint pipe 5 is guided by the guide ring 2 to be loaded and fixed in position.

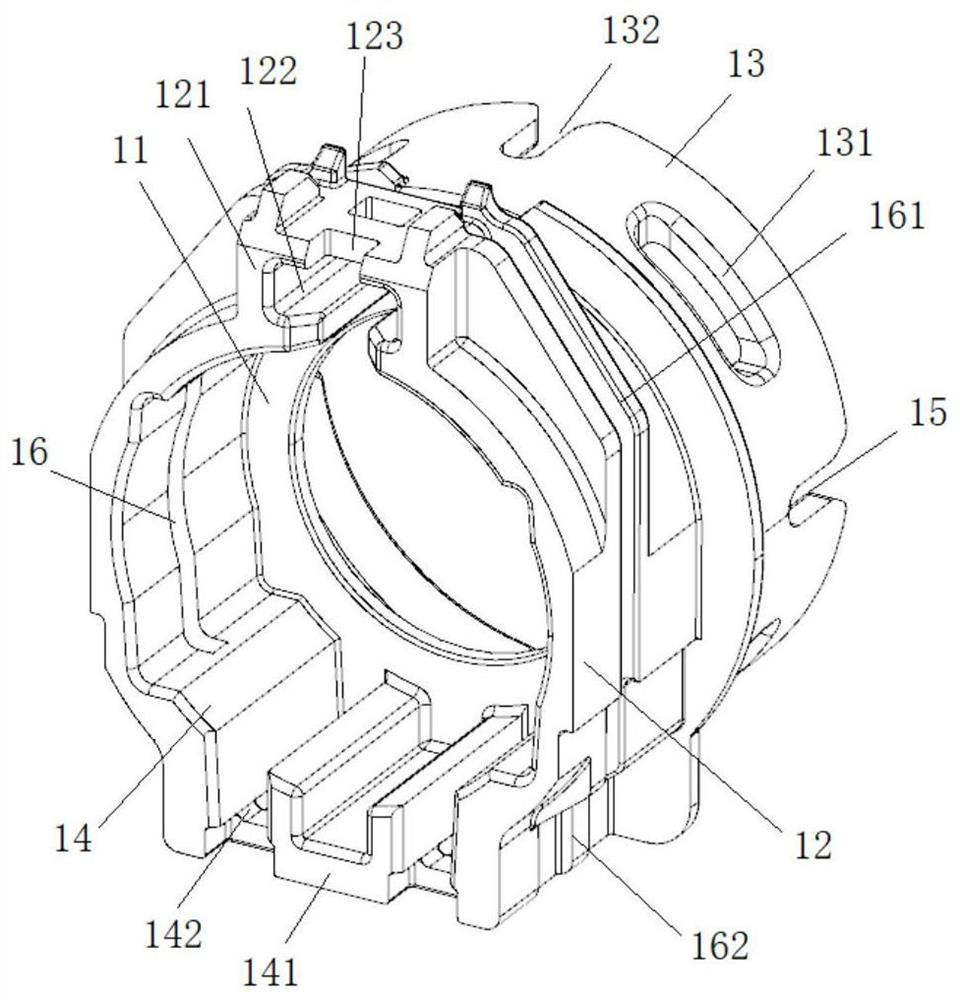

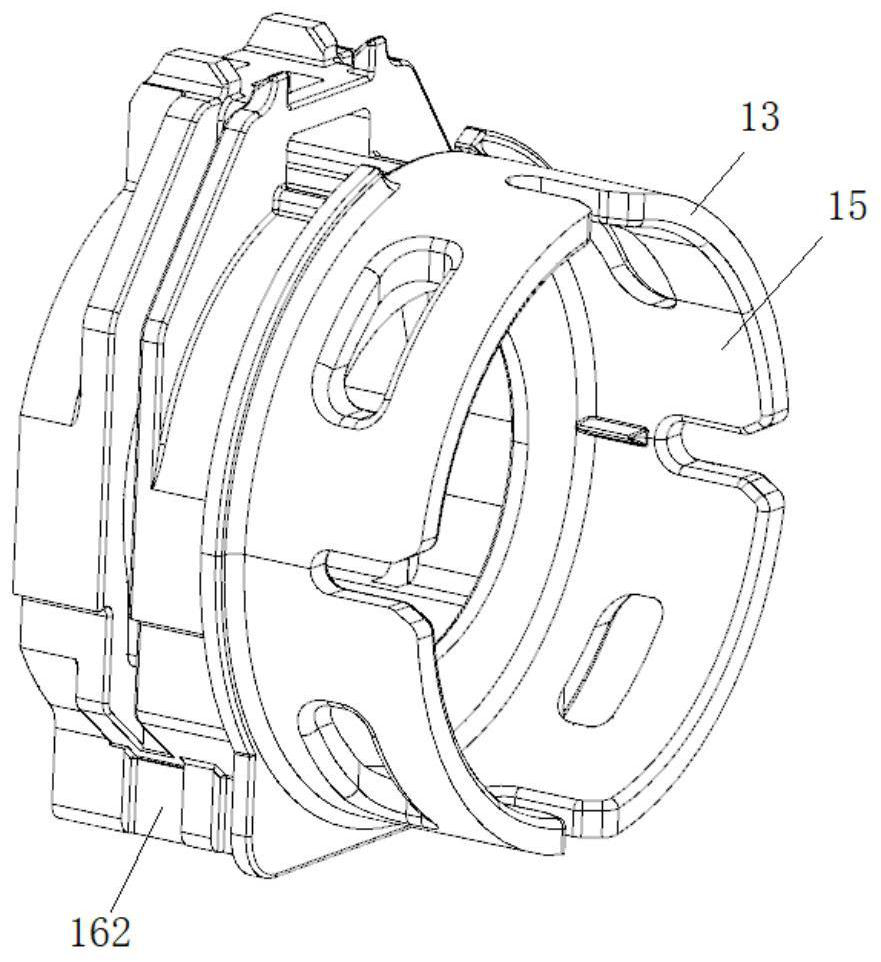

[0033] The main body 1 includes an annular portion 11, a first inserting portion 12 connecting one side of the annular portion 11, and a second inserting portion 13 connecting the other side of the annular portion 11; the inside of the first inserting portion 12 is provided with a first cavity The cavity bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com