Hydraulic loading system

A hydraulic loading and hydraulic cylinder technology, applied in fluid pressure actuators, servo motors, mechanical equipment, etc., can solve problems such as loading platform 4 inclination, affecting the service life of control accuracy equipment, wear and other problems, to ensure loading accuracy and prolong Longevity and wear-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

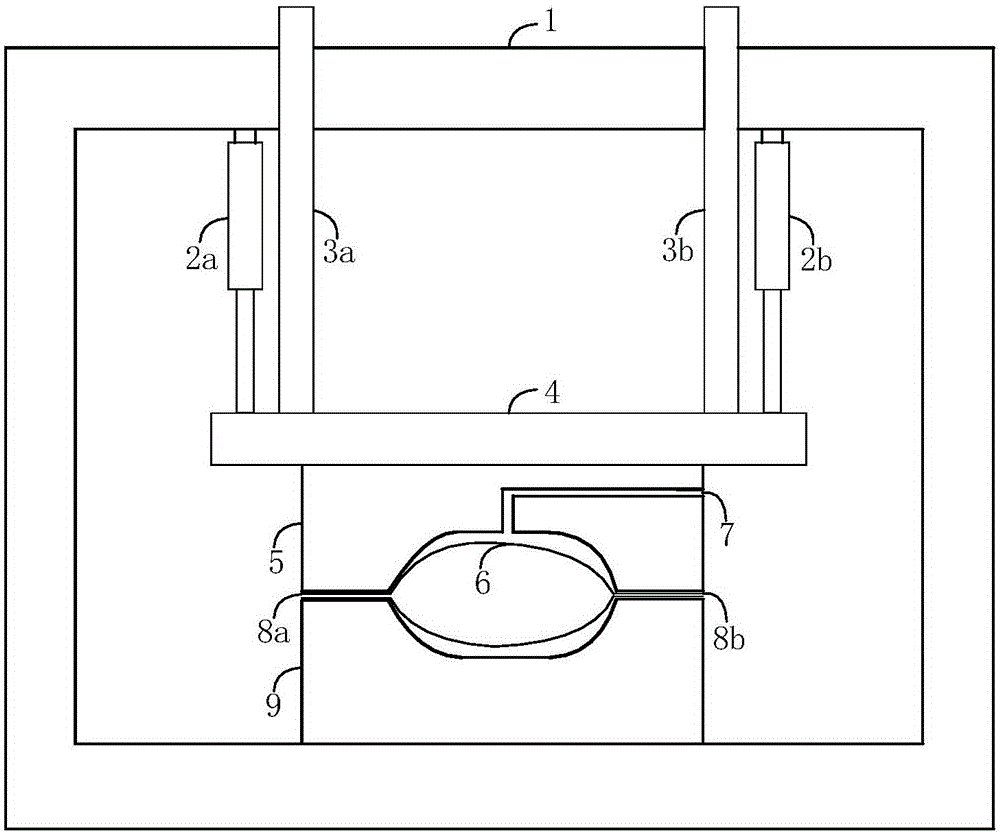

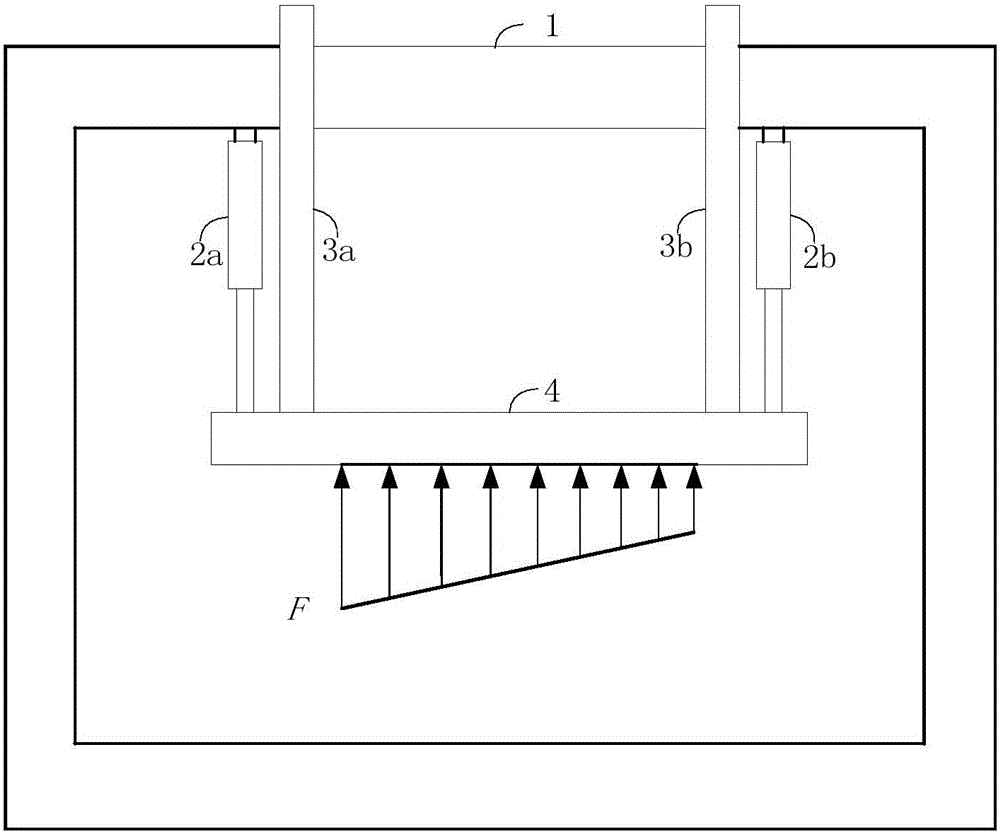

[0018] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

[0019] Such as Figure 4 Shown is a schematic structural diagram of a hydraulic loading system according to an embodiment of the present invention, Figure 5 It is a connection diagram of the control components in the hydraulic loading system of the present application and other components in the hydraulic loading system.

[0020] The following will combine Figure 4 , Figure 5 The hydraulic loading system of this embodiment will be described....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com