Patents

Literature

85results about How to "Avoid unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Safe memory scanning

ActiveUS7216367B2Safely scanningAvoid unloadingMemory loss protectionUnauthorized memory use protectionOperational systemComputerized system

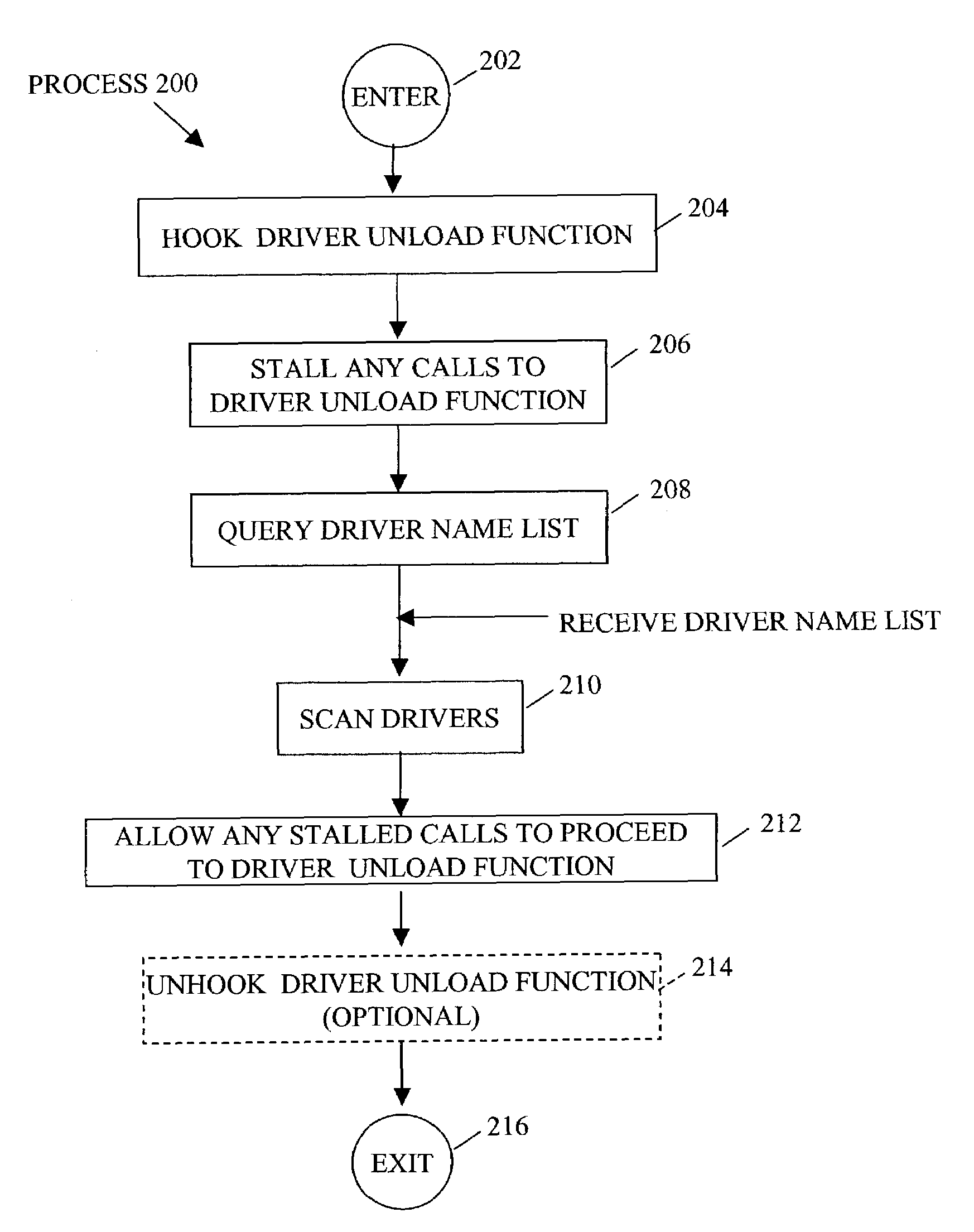

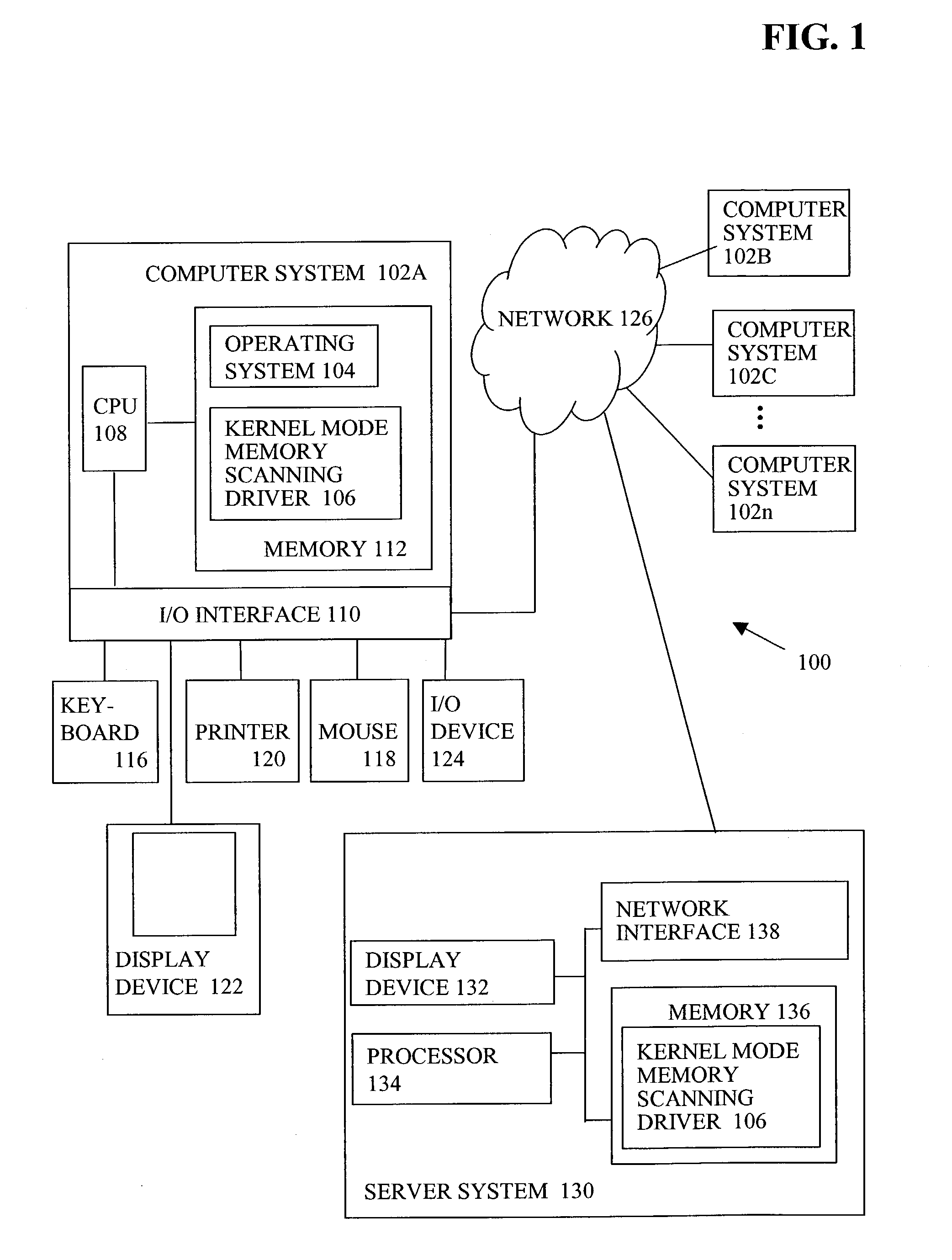

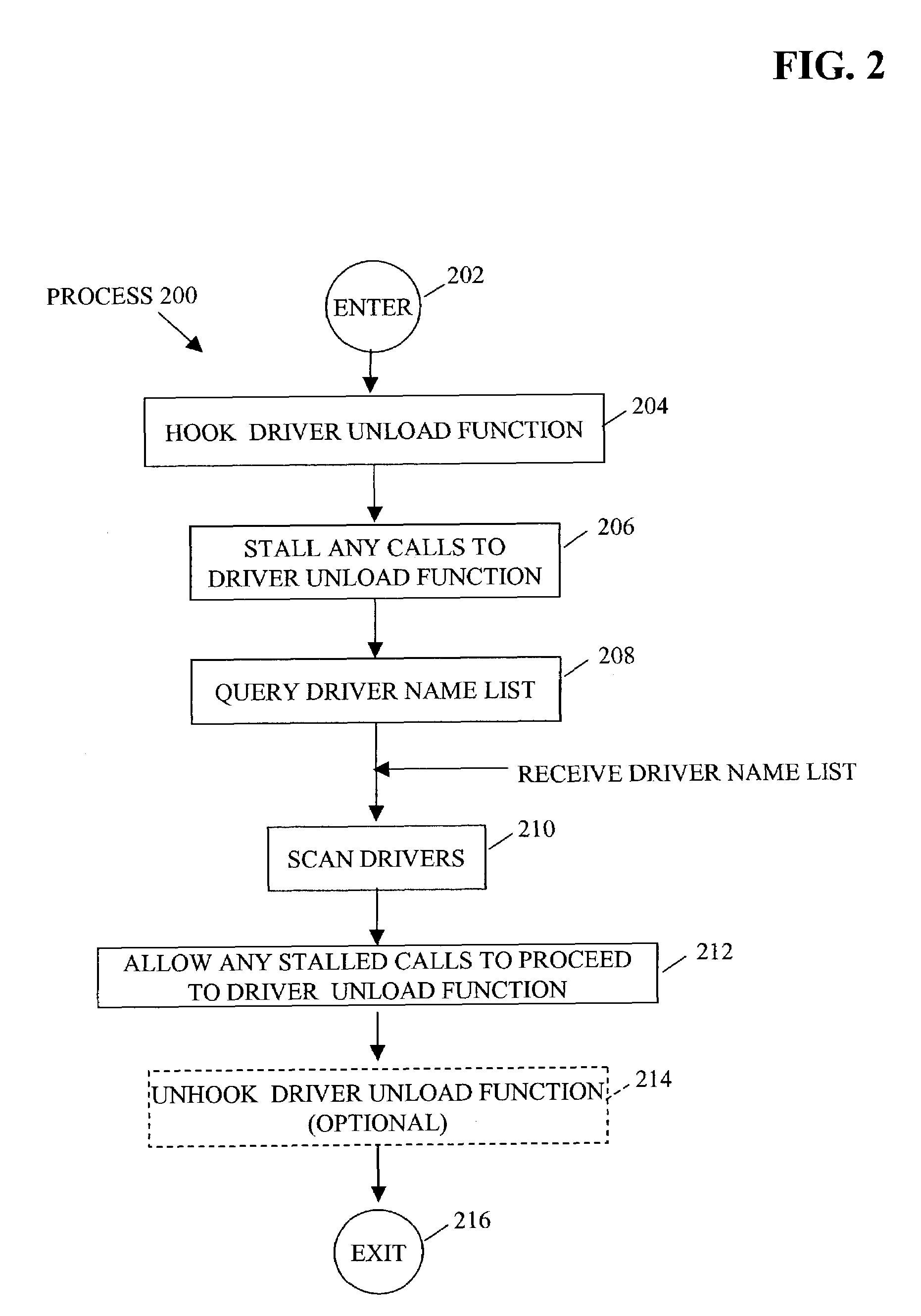

A kernel mode memory scanning driver for use in safely scanning loaded drivers in the memory of computer systems utilizing Windows® NT based operating systems, such as Windows® 2000, Windows® XP, and other operating systems utilizing the Windows® NT kernel base, for viruses. Prior to scanning the loaded drivers for viruses, the kernel mode memory scanning driver hooks a driver unload function of the operating system, and stalls any calls to the driver unload function to prevent the loaded drivers from being unloaded during scanning. After scanning is complete, any stalled calls to the driver unload function are released. In one embodiment, the kernel mode memory scanning driver is implemented as a Windows® NT 4.0 kernel mode memory scanning driver, and thus can be used on computer systems utilizing Windows® 2000 or Windows® NT without platform specific code.

Owner:CA TECH INC

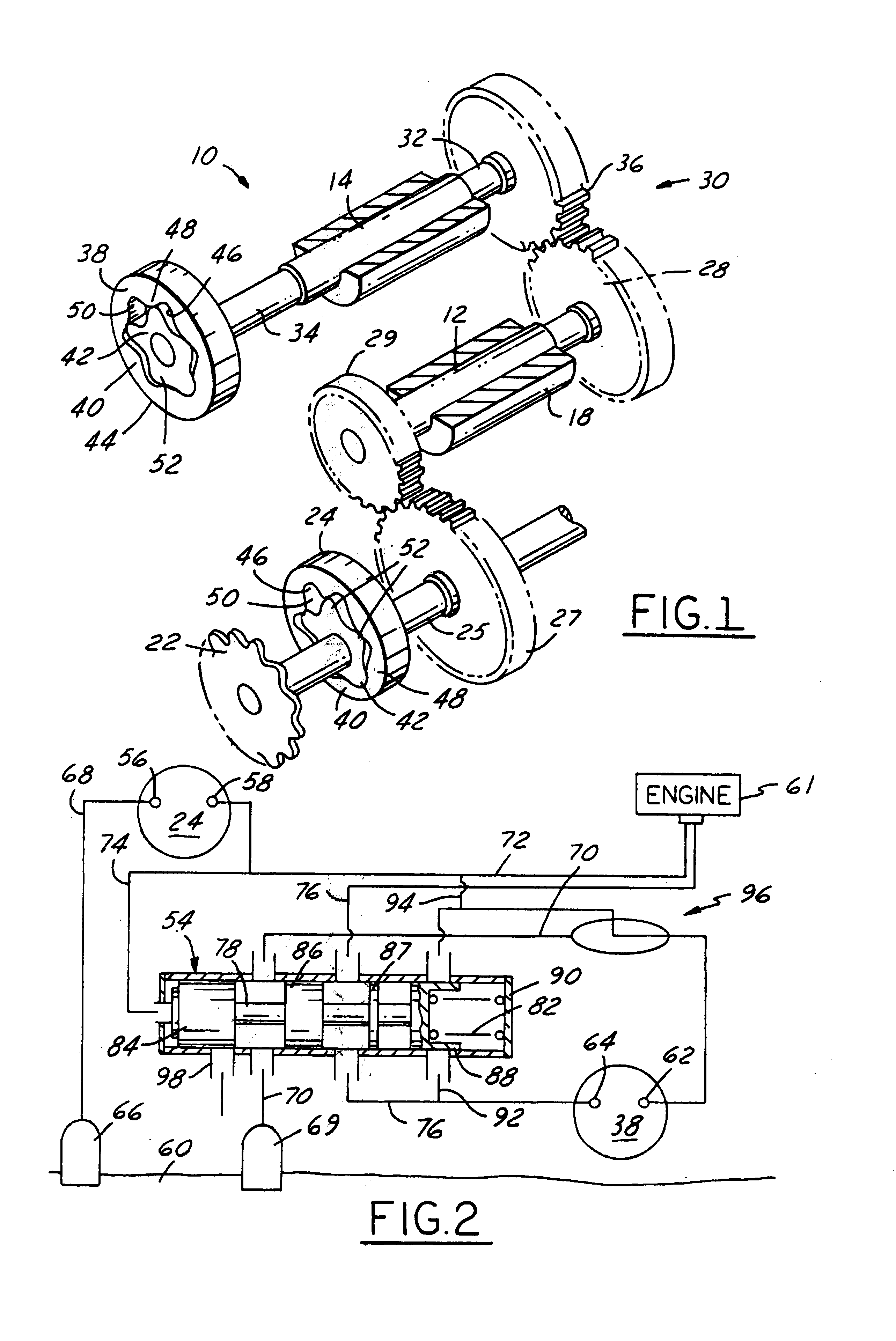

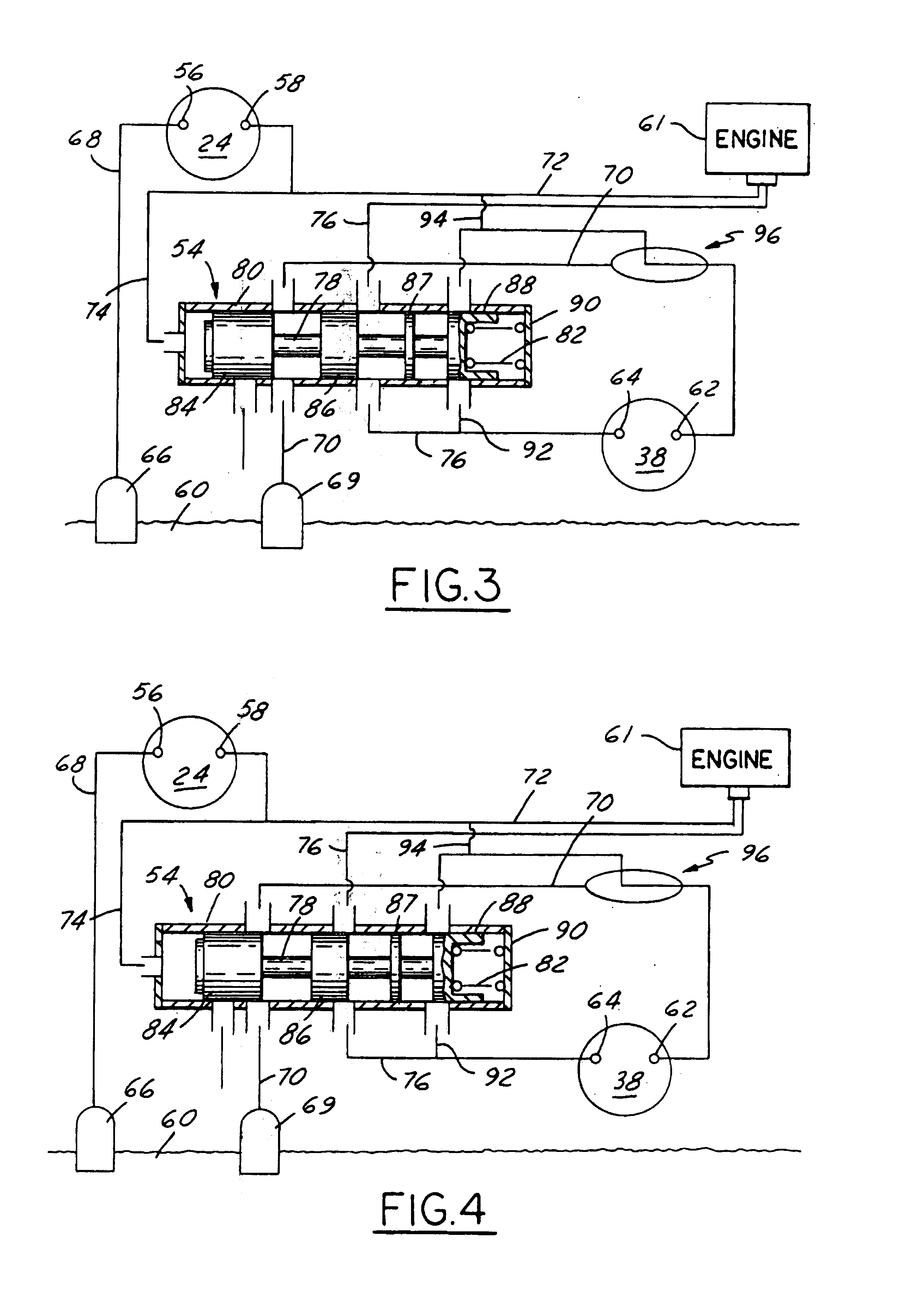

Energy efficient fluid pump

InactiveUS7086366B1Reduce noiseImprove efficiencyMachines/enginesPressure lubrication with lubrication pumpLow speedCavitation

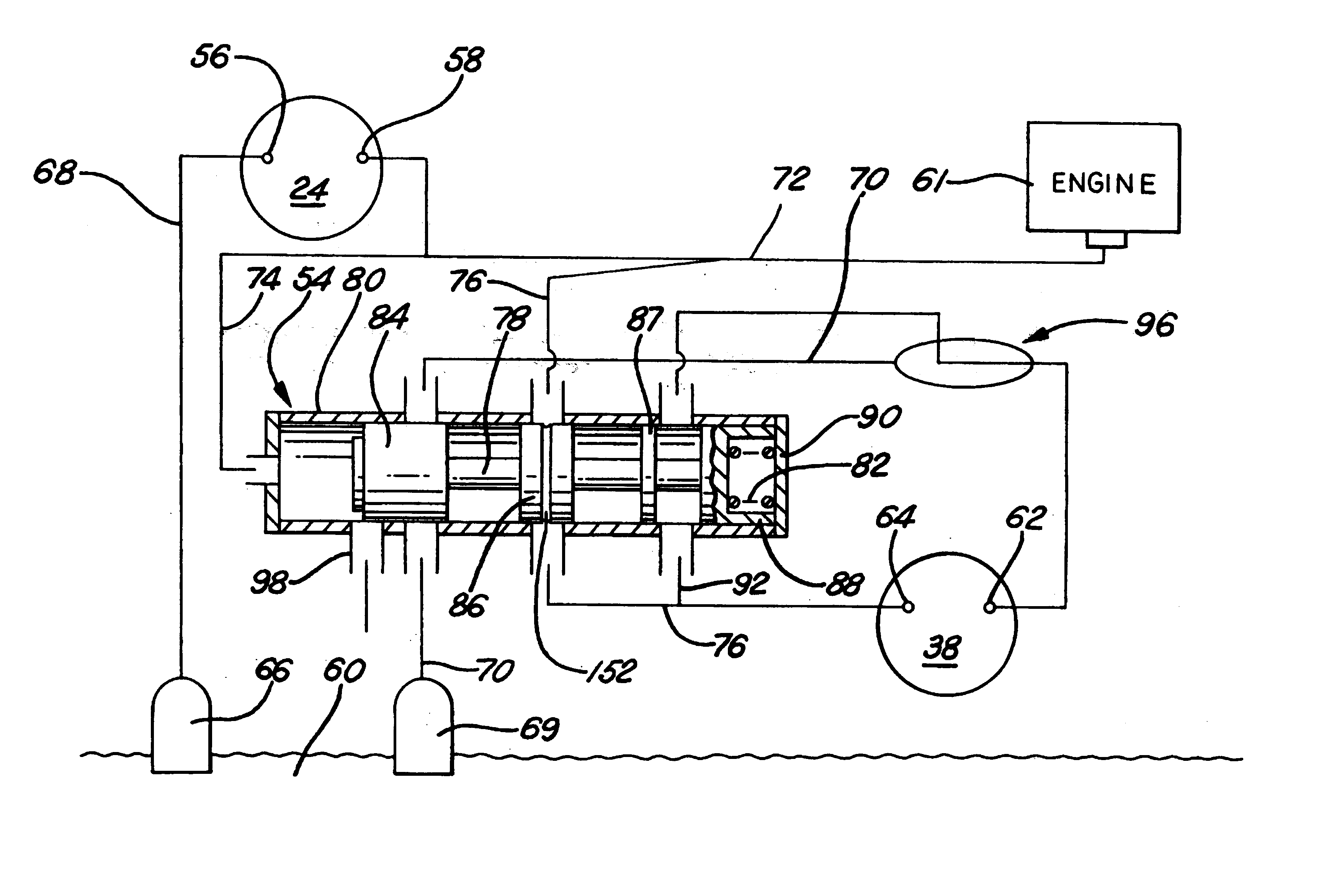

A dual pumping element fluid system for an engine or other system which reduces the driving power consumption by unloading one pumping element through the use of recirculation when a fluid pressure target value is achieved. A cross-over port fluid system prevents cavitation of the unloaded pump. A pressure-activated flow control valve mechanism is utilized to open and close the passageways from the secondary pump. The fluid system works in conjunction with an engine balance shaft system to control gear rattle at low speeds without adding undue gear loads at high speeds.

Owner:METALDYNE BSM

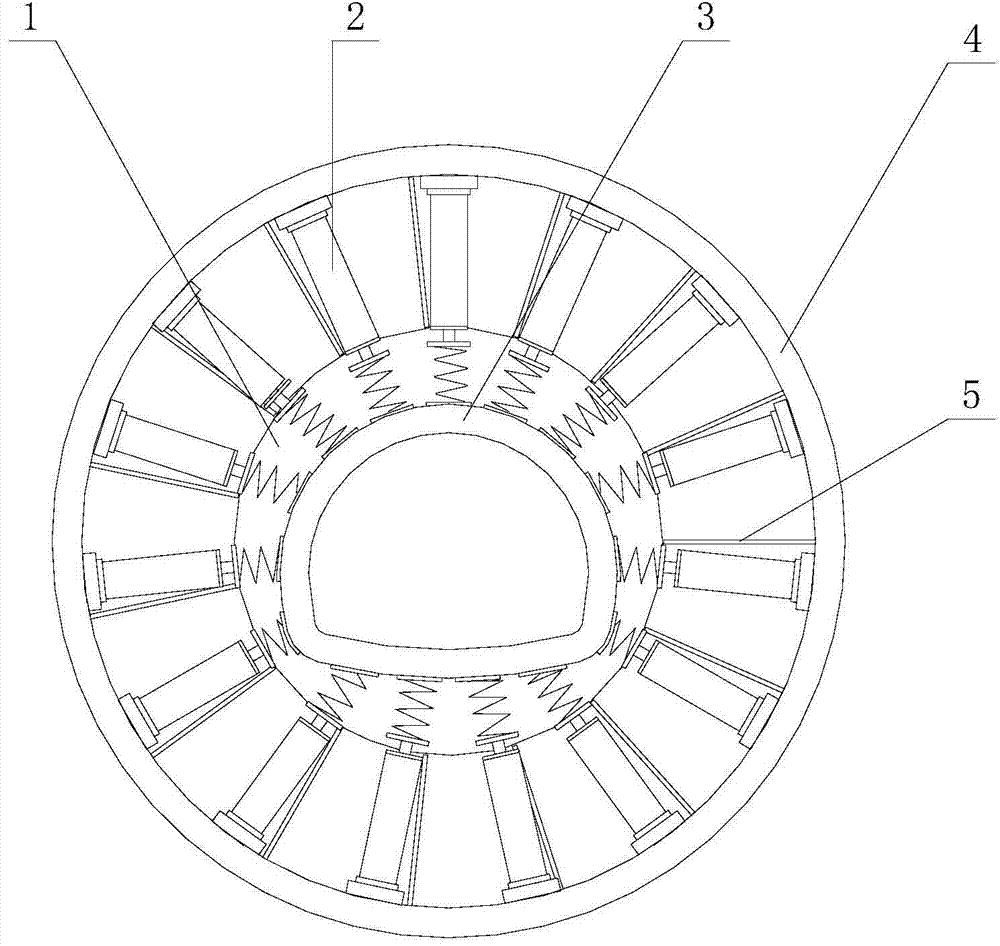

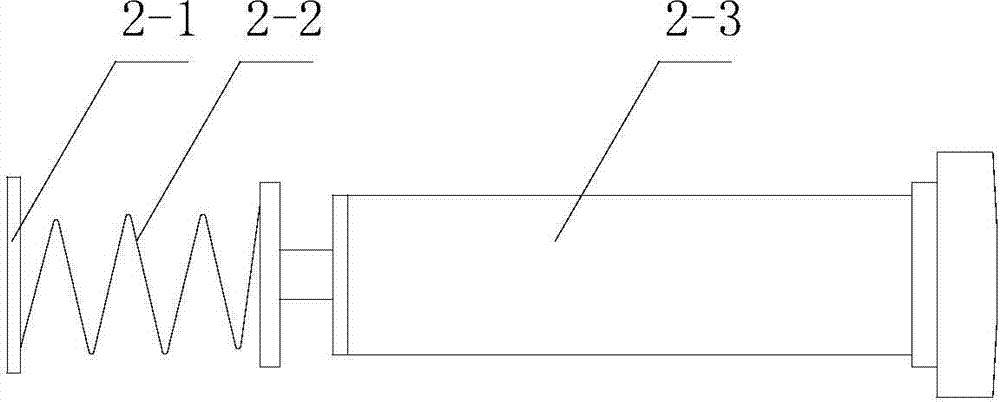

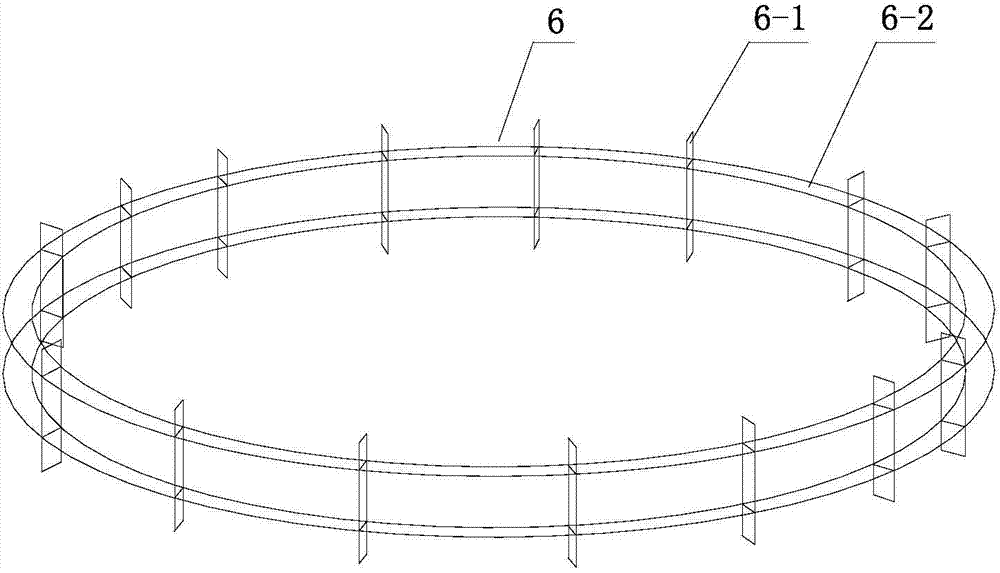

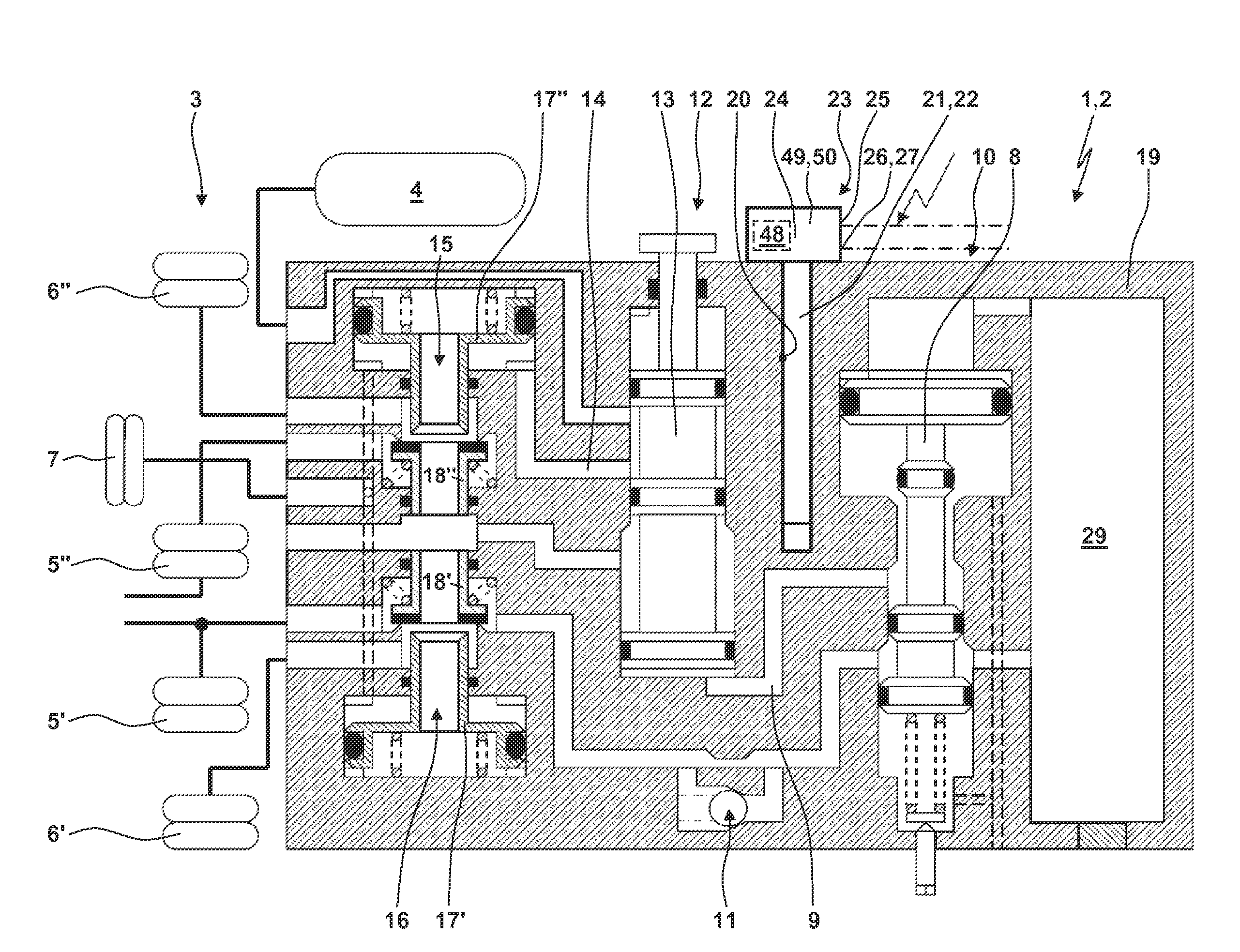

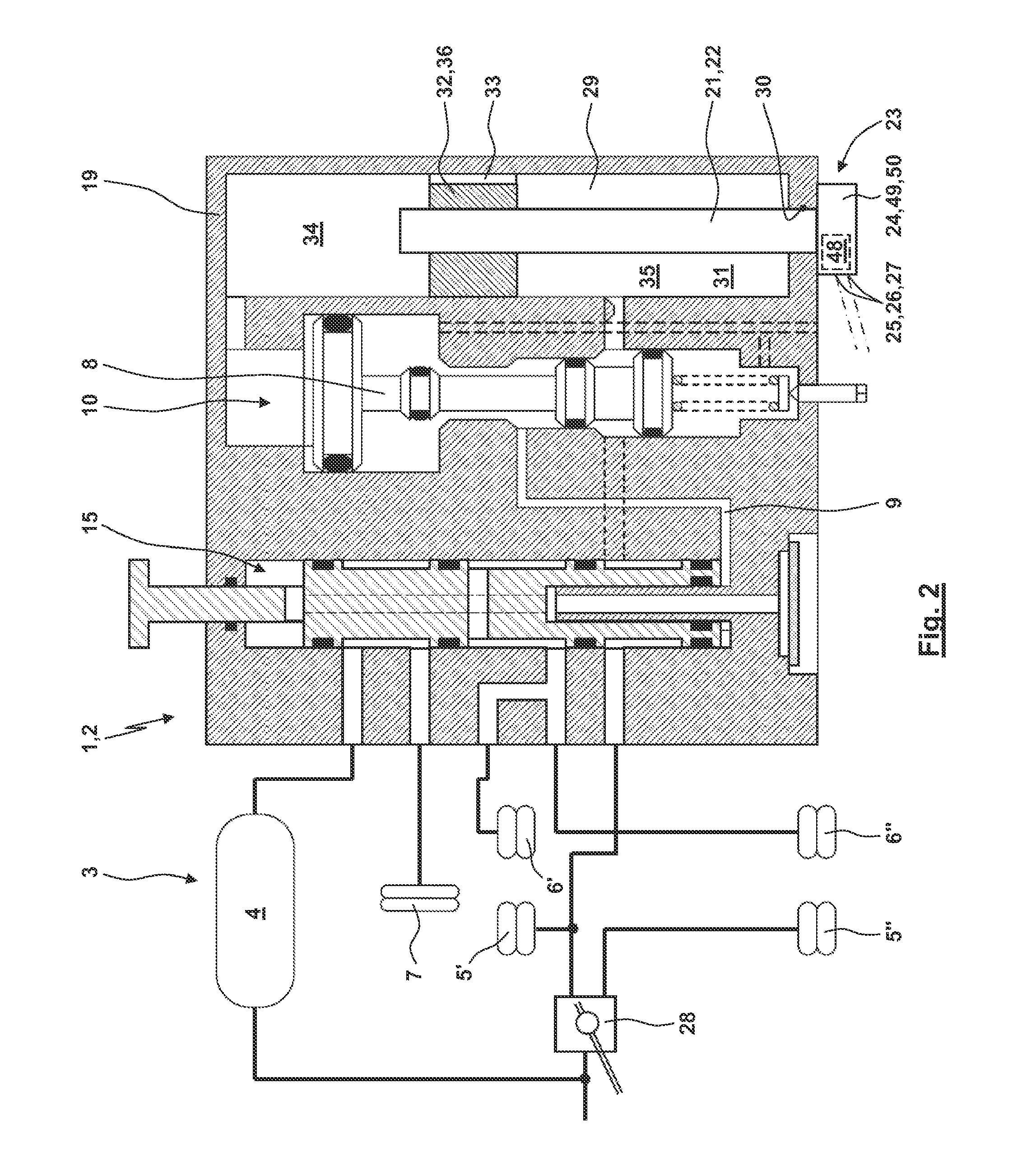

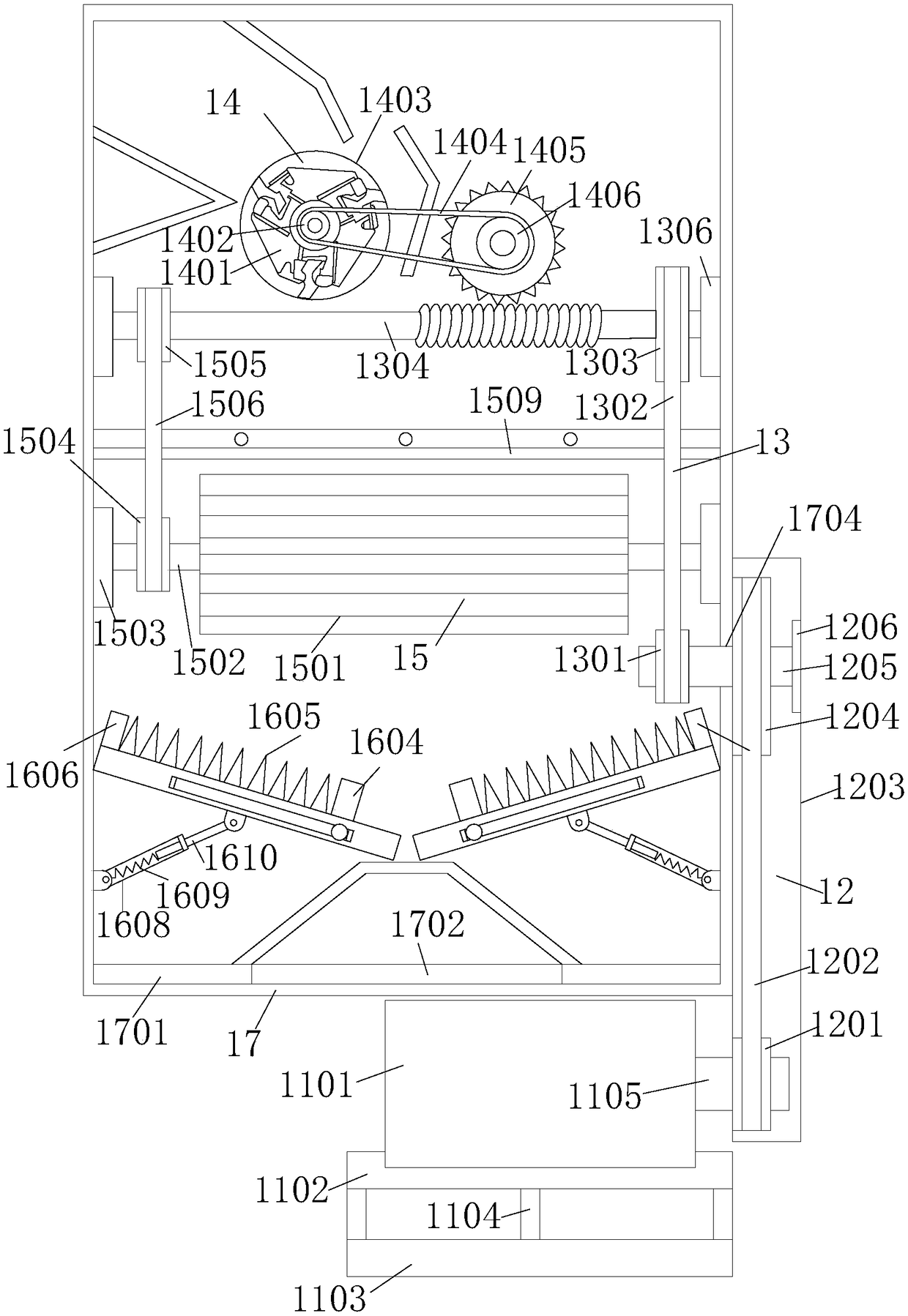

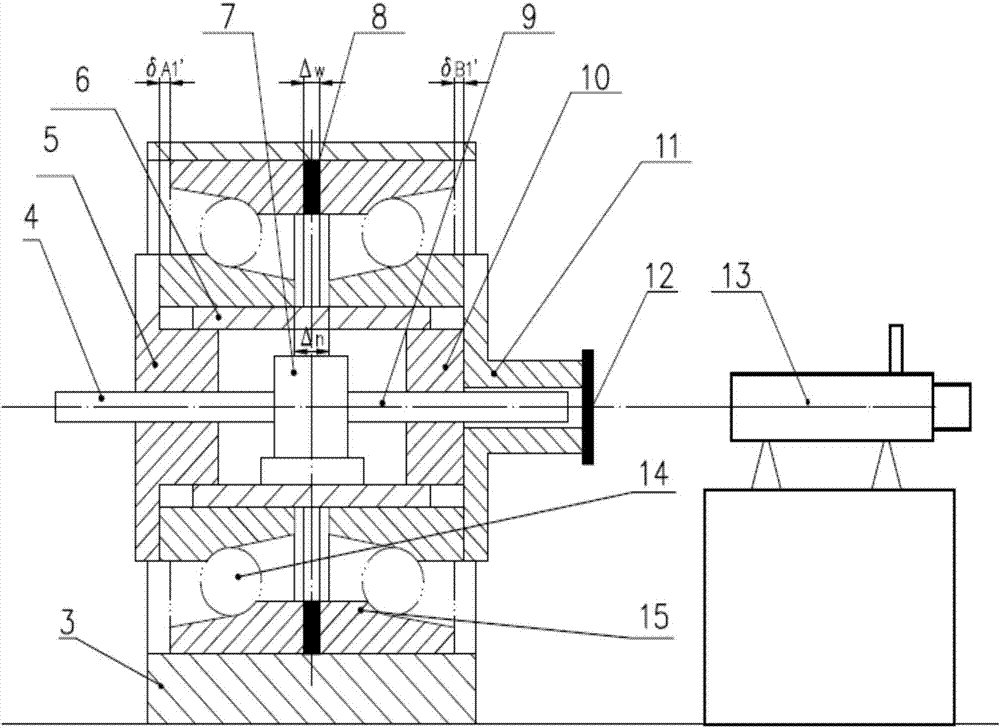

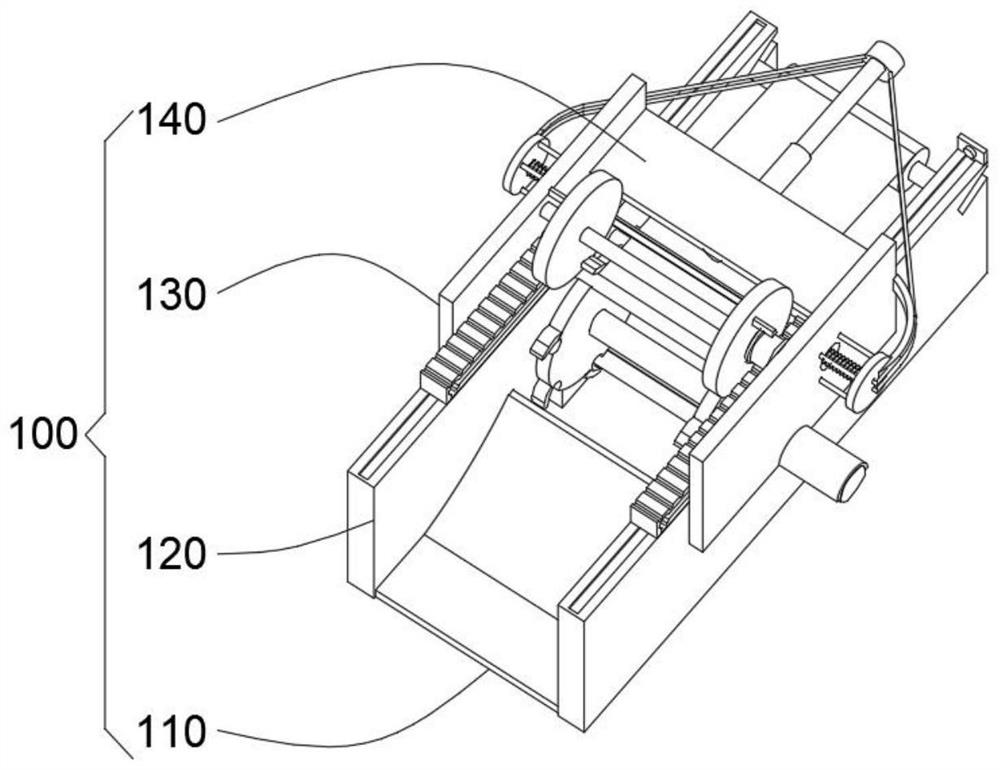

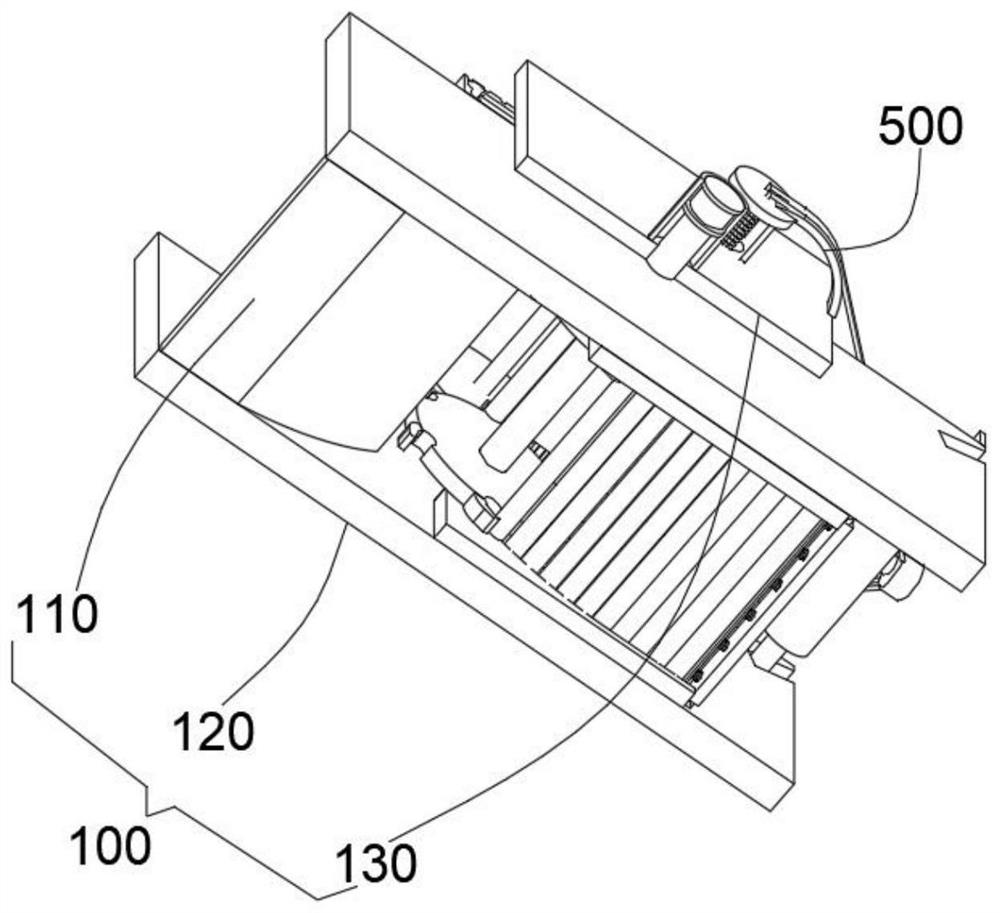

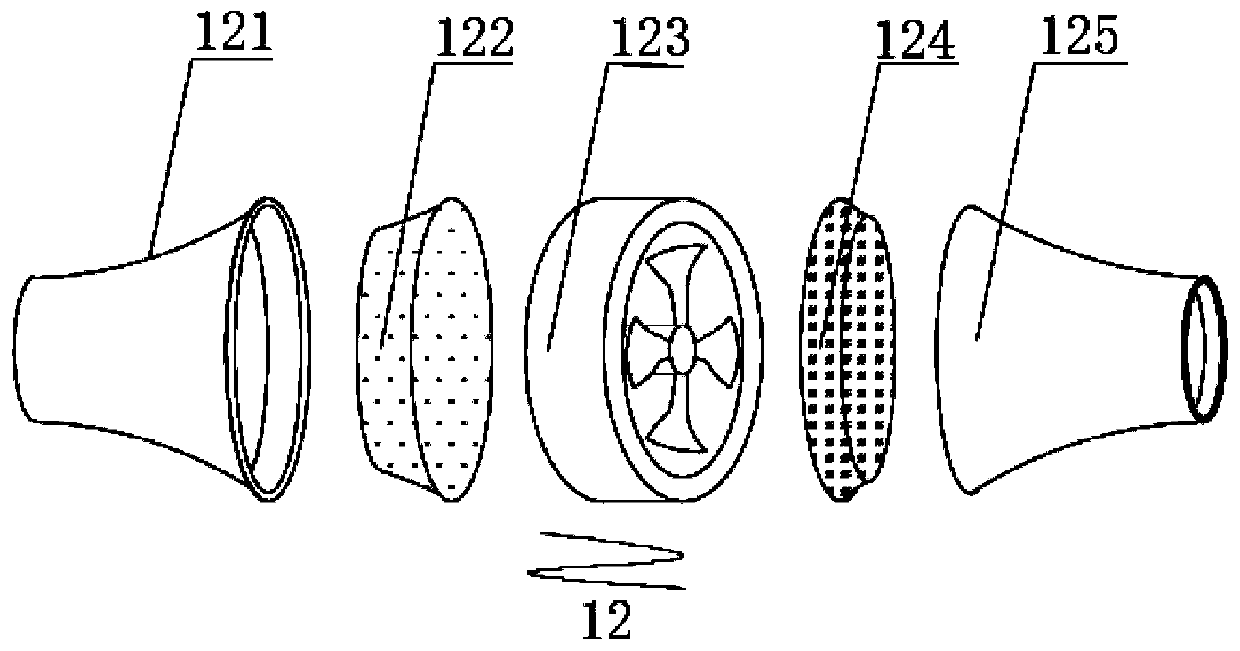

Load equipment of tunnel lining structural mechanics property simulation test device

InactiveCN104748993ALoad accuratelyMeet the test requirementsStructural/machines measurementNumerical controlStress conditions

The invention relates to load equipment of a tunnel lining structural mechanics property simulation test device. According to the arrangement, a tunnel lining is arranged on a displacement limitation face plate, a load mechanism is radially arranged on the outer surface of the tunnel lining, and the other end of the load mechanism is fixed on an outer retainer plate; the load mechanism is composed of cushion plates, springs and hydraulic jacks, the cushions are arranged along the outer wall of the tunnel lining, the springs are radially arranged on the outer walls of the cushion plates and allow the cushion plates to be connected with the hydraulic jacks, the hydraulic jacks are normally arranged on the outer surface of the tunnel lining, and cylinders of the hydraulic jacks are fixed on the inner wall of the outer retainer plate; under variable work conditions such as different lining types and thickness and different stress conditions, mechanics property simulation is effectively achieved; during the loading, the numerical control hydraulic jacks are adopted to ensure strength and position of stress applied to the lining, bringing convenience to the following data analysis and research, and accordingly the tunnel lining structural mechanics property changes are effectively simulated.

Owner:CHANGAN UNIV

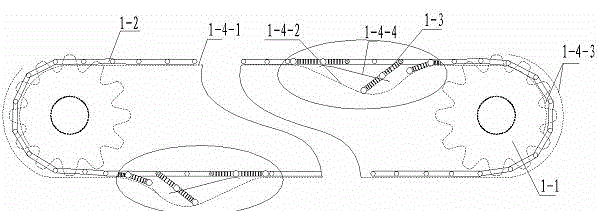

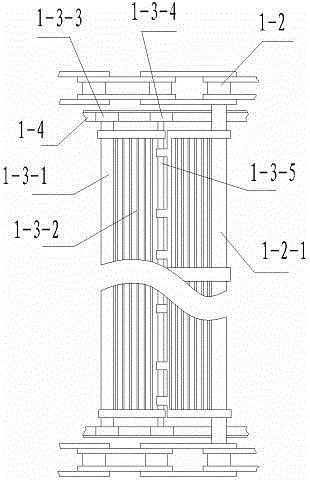

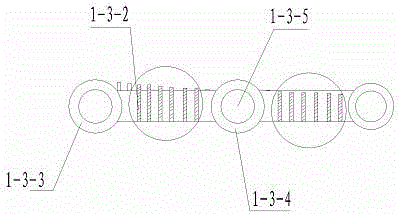

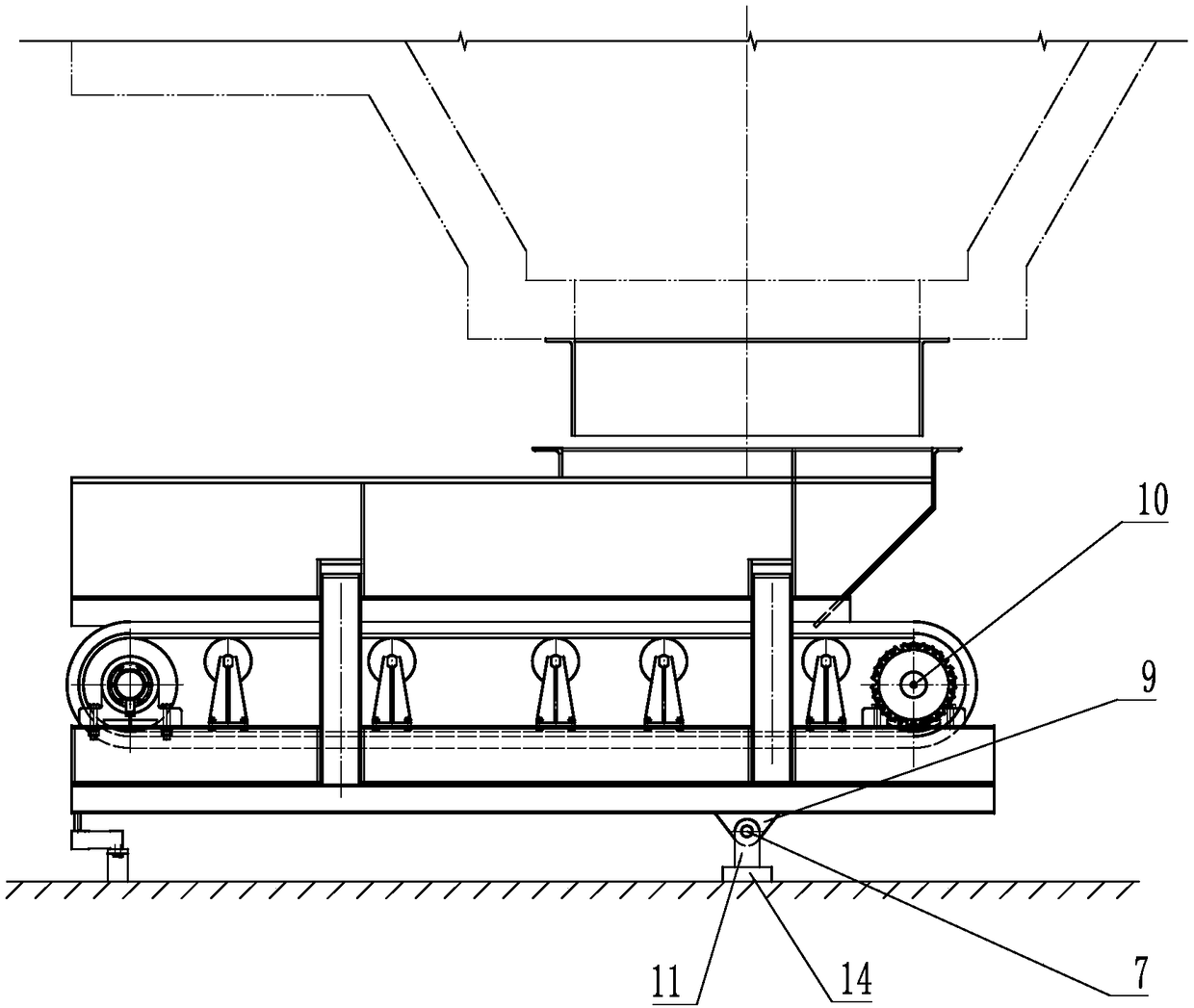

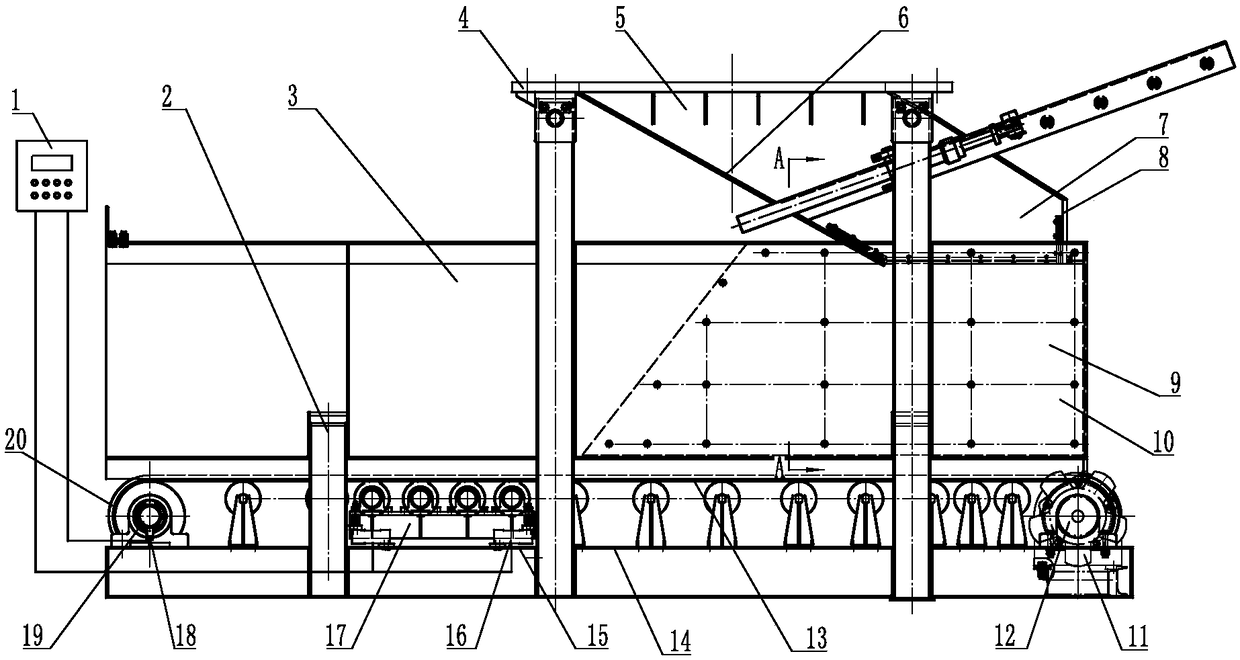

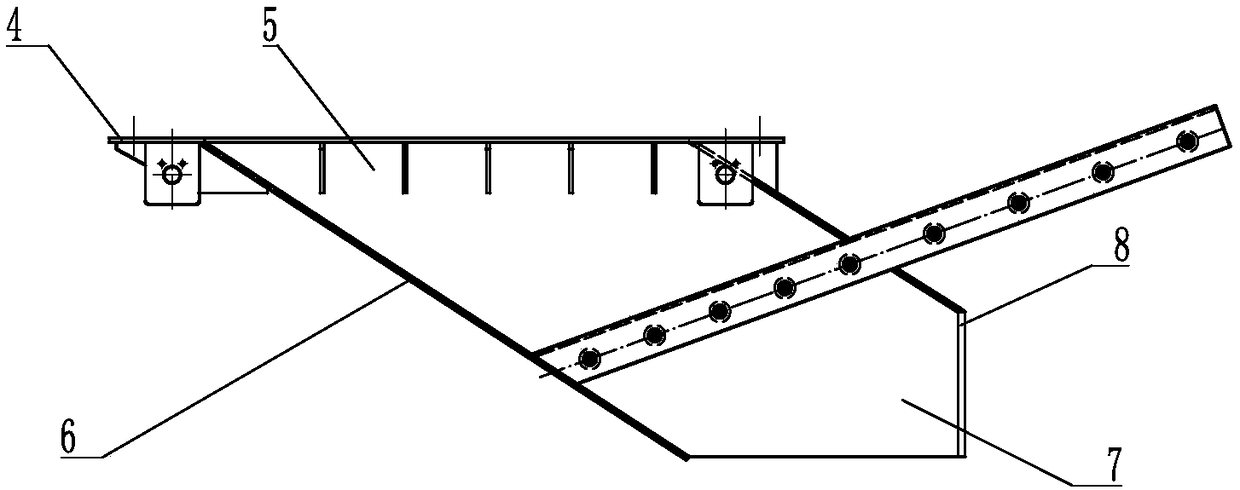

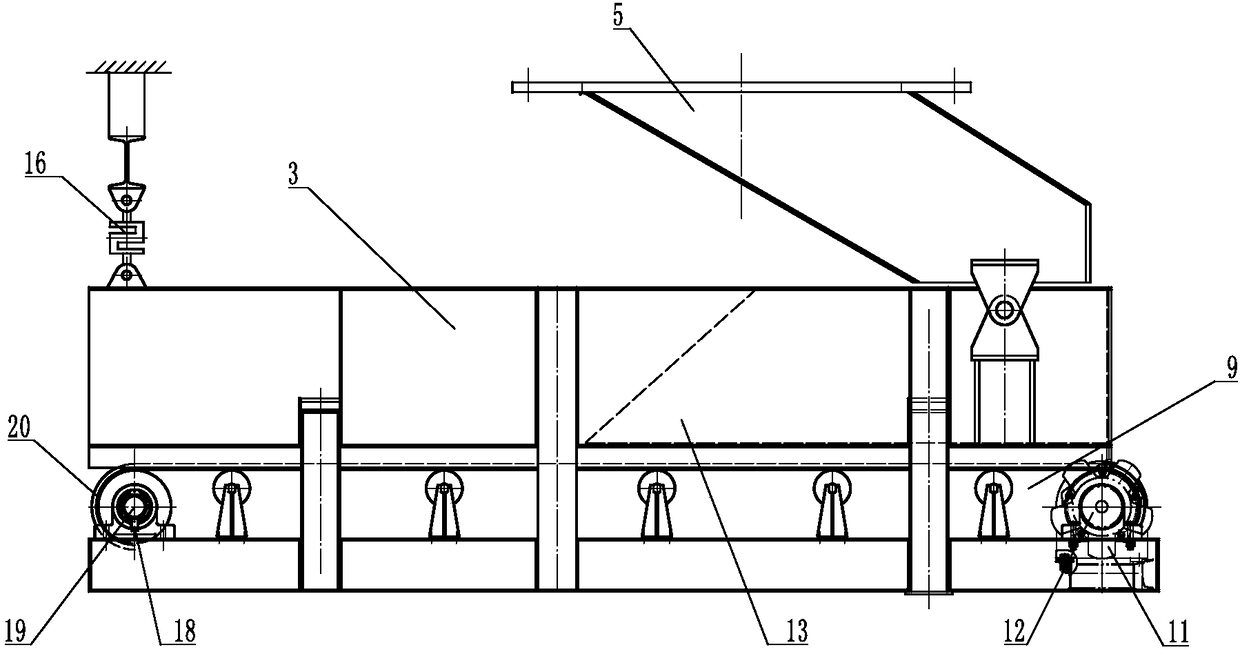

Chain plate conveying coal ball heat conduction oil dryer

ActiveCN104154728AUse diameter reductionImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsChain structureHeating effect

A chain plate conveying coal ball heat conduction oil dryer belongs to the field of drying equipment. The chain plate conveying coal ball heat conduction oil dryer comprises a heat insulation outer shell, a chain plate conveying mechanism, a feeding conveying belt, a discharging opening, a heating device and a waste heat using device. The chain plate conveying mechanism comprises a double-driving chain structure, a matched chain wheel, a bearing chain plate and a guiding sliding track. The bearing chain plate is a hollow-out structure formed by a frame and a grid bar and is located on a chain shaft in a hinge mode. The guiding sliding track is divided into an upper sliding track part and a lower sliding track part which have the same structure sequence. Each part is divided into a horizontal section, a V-shaped blanking section and an arc groove-shaped turning section which are connected in sequence. A falling zone corresponds to a lowering edge section of each V-shaped blanking section of the guiding sliding part. The heating device is connecting heat conduction oil furnace heat conduction calandrias which are distributed above and below a conveying interface formed by the bearing chain plate. An improved double-chain strip plate type conveyor is used, a high-efficiency heat conduction oil furnace is used as a heat source, a controllable heat conduction oil pipe composite layer distribution structure is used for improving the heating effect, and the effects of small space size, energy saving and environment protection are achieved.

Owner:HEBEI GOLD BANGZI BOILER

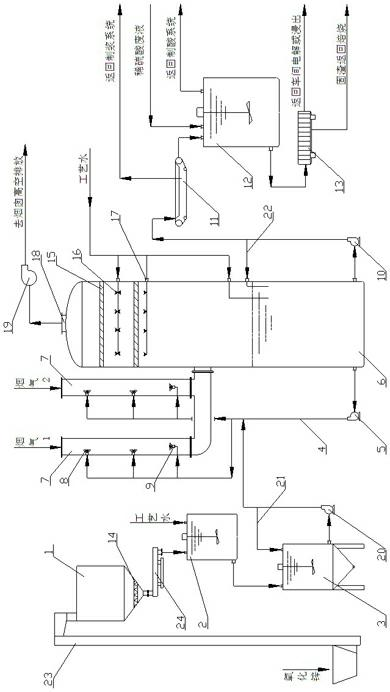

Novel zinc oxide desulfurization method and device

The invention relates to a desulfurization method, and in particular relates to a novel zinc oxide desulfurization method and device. The invention mainly solves the technical problems of the prior art that the zinc oxide desulfurization absorption rate is unstable, the pipeline is easy in blockage, the concentration of by-products is low, reuse is difficult, etc. The method comprises the following steps of: adding zinc oxide powder in a slurry-preparing trough to prepare zinc oxide slurry, then pumping the zinc oxide slurry in a circulating pipeline which is communicated with a washing tower, sending the zinc oxide slurry into a washing pipe through the circulating pipeline, injecting the flue gas to be treated in the upper part of the washing pipe, respectively spraying the zinc oxide slurry to a flue gas position at 90 degree and 180 degree reversedly to mix, conveying the slurry from the washing tower to a belt filter to filter, then performing an acid decomposition reaction in an acid decomposition reaction kettle, and finally sending the product into a filter press for filter pressing and roasting.

Owner:ZHEJIANG NANHUA ANTICORROSION EQUIP

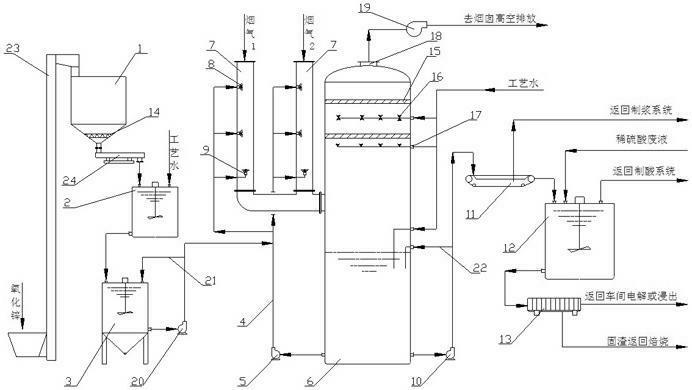

Splitting control method of large-scale regional power grids

ActiveCN103337859AImprove coordinationAvoid unloadingSystems intergating technologiesInformation technology support systemPower gridMaster station

The invention relates to a splitting control method of large-scale regional power grids. The splitting control method comprises steps as follows: (1) a control master station collects an out-of-step message of each transmission node in the power grids through a PMU (phasor measurement unit); (2) when the control master station judges that one section requires splitting according to the out-of-step message uploaded by the PMU, the control master station sends a splitting control command to a splitting terminal unit in a section substation; (3) the splitting terminal unit receives the splitting control command for splitting and simultaneously broadcasts a splitting locking command to other splitting terminal units located on the same electric transmission line passageway; and (4) after other splitting terminal units on the same electric transmission line passageway receive the splitting locking command, the splitting terminal units don't perform splitting no matter whether the splitting terminal units receive the splitting control command sent by the control master station. Compared with the prior art, the splitting control method has the advantages of good harmony, high self-adaptive ability and the like.

Owner:STATE GRID CORP OF CHINA +2

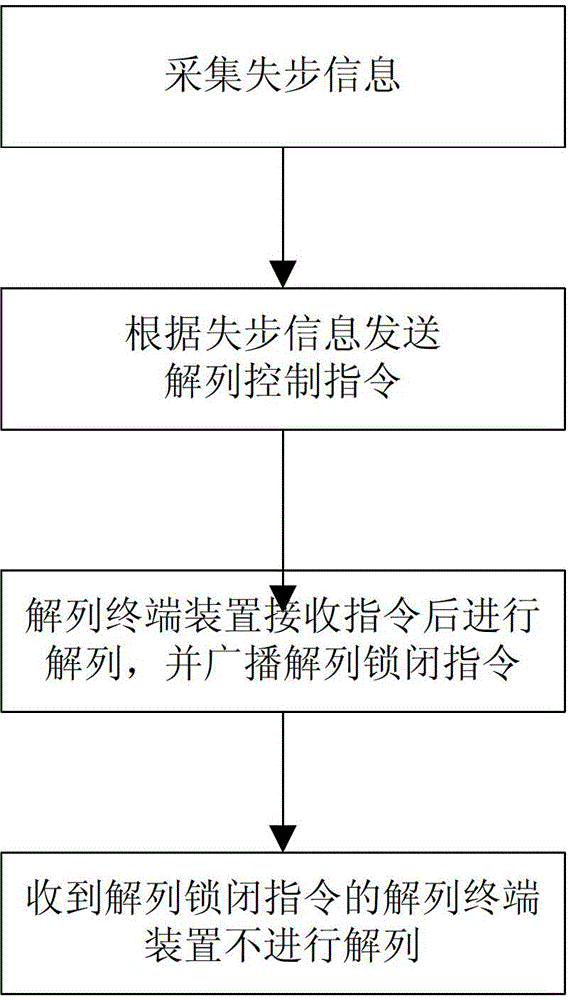

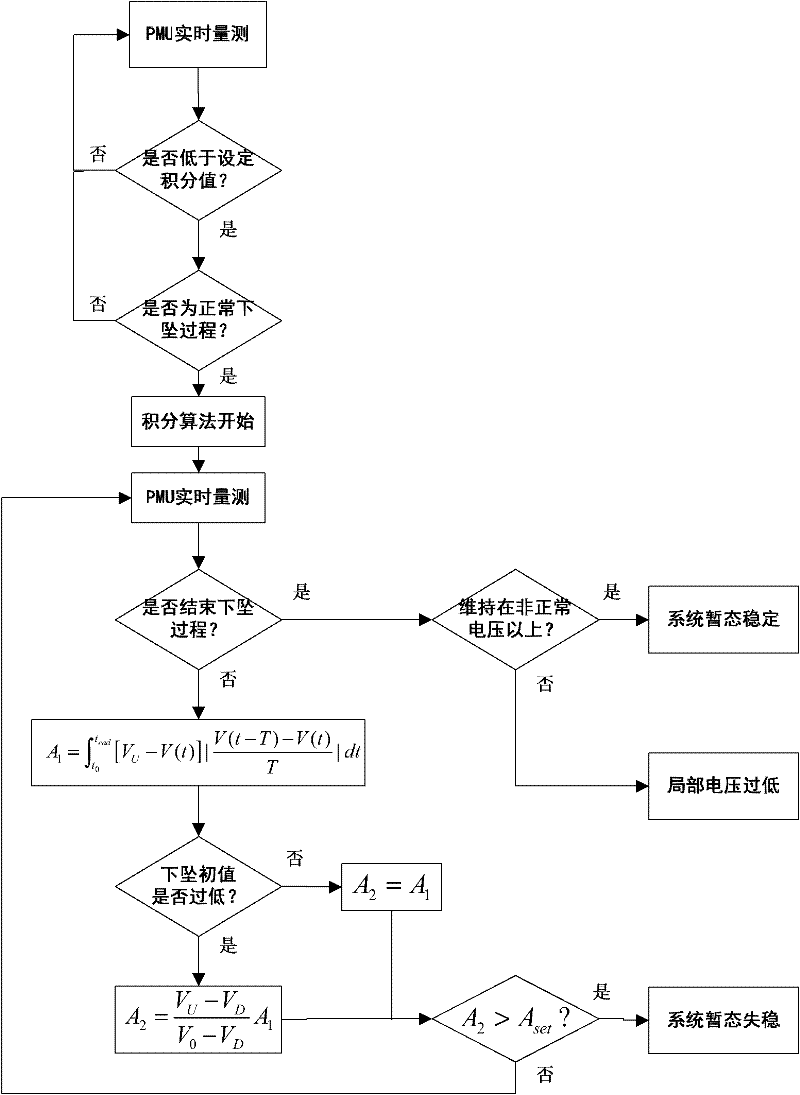

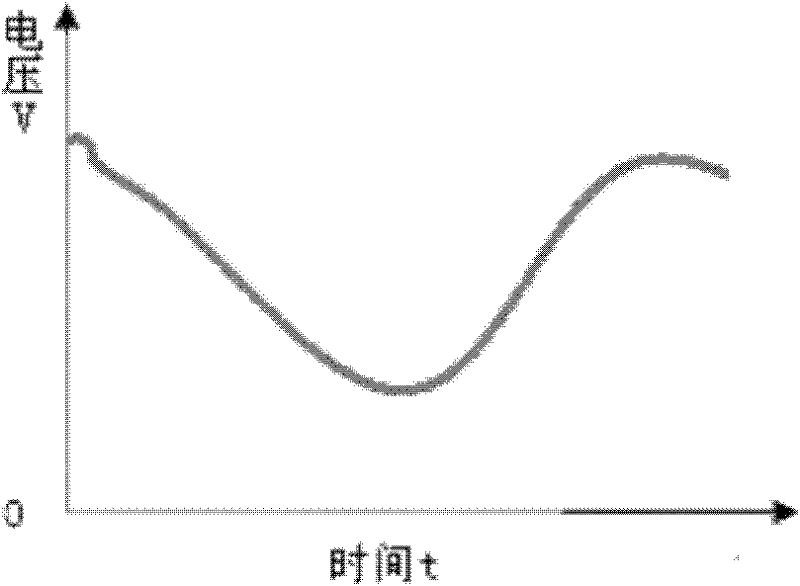

Method for distinguishing transient state instability of electric power system in real time based on voltage track after disturbance

ActiveCN102522759AResolve transient instabilityAvoid unloadingPower oscillations reduction/preventionWide areaTransient state

The invention relates to the technical field of fault distinguishment in an electric power system, in particular to a method for distinguishing transient state instability of the electric power system in real time based on voltage track after disturbance. The method comprises five steps, namely, selecting a voltage observation node, identifying voltage drop after fault clearance, complexly integrating the voltage track, distinguishing the transient state instability of the electric power system and identifying the fact that local voltage is over-low. The method for distinguishing the transient state instability of the electric power system in real time based on the voltage track after disturbance, disclosed by the invention, aims to solve a problem of system transient state instability caused by large disturbance out of a two-defense-line control range based on a measurement configuration of the existing phasor measurement unit ( PMU ) and a wide area measurement system ( WAMS ) in a power grid, and has the advantages of simple algorithm, low calculated quantity, less dependence on data precision and high reliability.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

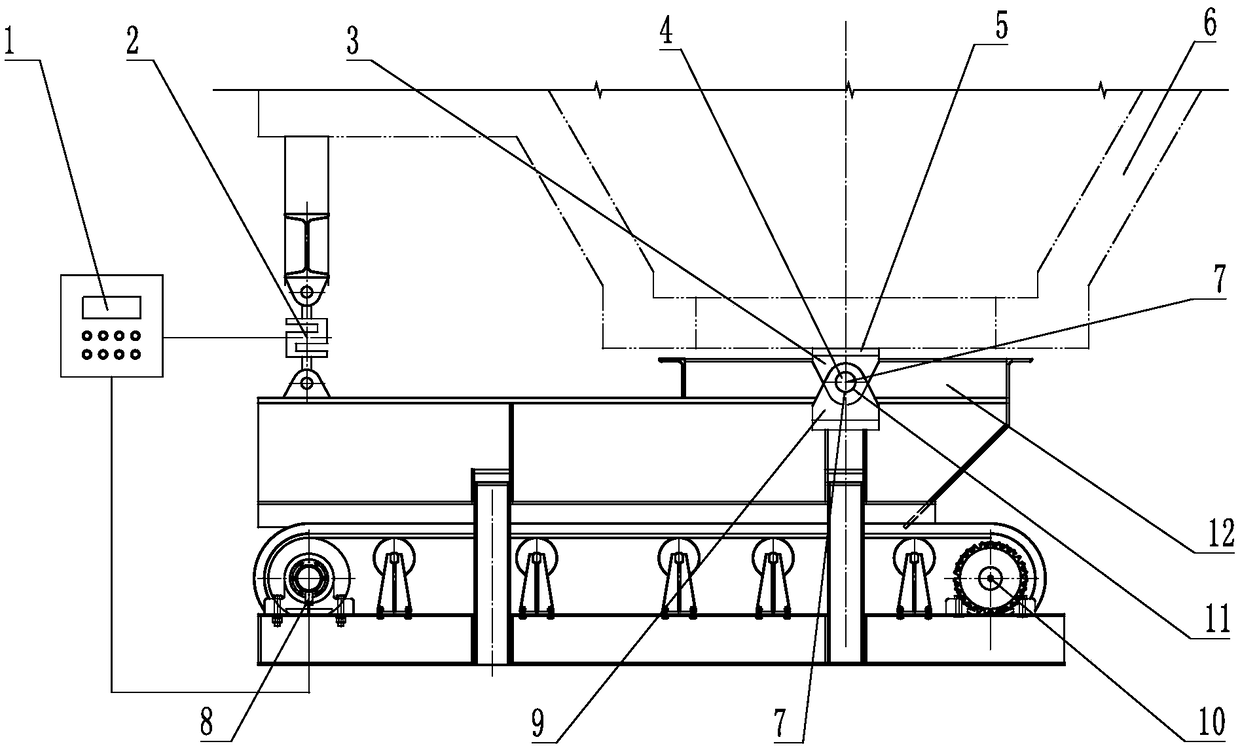

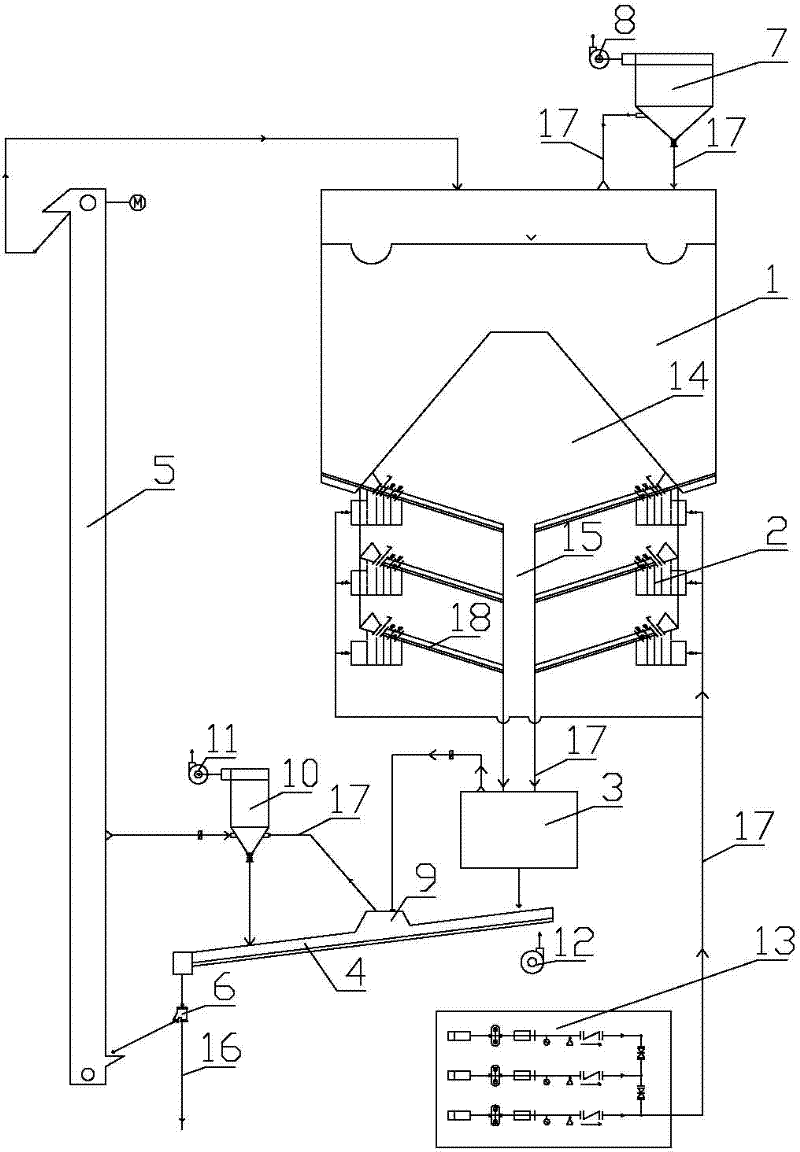

Method of rotary-connection cabin pressure removing of metering feeder and rotary-connection cabin pressure removing dynamic weighing and feeding machine

PendingCN108861659AEliminate the effects ofAvoid interferenceConveyorsCleaningQuality of workMaterial resources

The invention belongs to the field of machinery, and particularly relates to a method of rotary-connection cabin pressure removing of a metering feeder and a rotary-connection cabin pressure removingdynamic weighing and feeding machine. The weighing and feeding machine comprises a rotary-connection hanging frame, a rotary-connecting material receiving device, a hinge shaft, a rotary-connection weighing and material conveying device, a weighing sensor, a speed sensor and an arithmetic unit, wherein the weighing sensor is arranged at the end part, far away from a feeding machine supporting hinge point, of the rotary-connection weighing and material conveying device, the weighing sensor senses the change of the applied force of the rotary-connection weighing and material conveying device, the weighing sensor cooperates with the speed sensor to calculate the weight of a material conveyed by the rotary-connection weighing and material conveying device through the arithmetic unit. Accordingto the method and the machine, manpower and material resources are saved, a dirty, disorder, bad and abominable labor scene is changed into an environment which is clean, order, free of leaking material, and free of dust, so that the long-term stability and reliability of the weighing are ensured, and the working efficiency and the working quality are improved.

Owner:刘素华

Fault ride-through implementation method and system for direct-driven draught fan

ActiveCN105515052AImprove securityImproved fault ride-through capabilitySingle network parallel feeding arrangementsWind energy generationFlywheel energy storageElectric network

The embodiment of the invention discloses a fault ride-through implementation method and system for a direct-driven draught fan. The direct-driven draught fan is connected with the direct-current side of a grid connection converter, and the line side of the grid connection converter is connected with a grid system. The method comprises the steps that the grid connection point voltage of the line side of the grid connection converter is detected; whether the grid connection point voltage is in a preset grid voltage limit value interval or not is judged; if the grid connection point voltage is not in the preset grid voltage limit value interval, the direct-current bus voltage of the direct-current side of the grid connection converter is calculated; according to the relation between the direct-current bus voltage of the direct-current side of the grid connection converter and a preset direct-current bus voltage limit value, electric energy discharged by the direct-driven draught fan is absorbed from the direct-current bus through a flywheel energy storage converter connected to a direct-current bus in parallel or electric energy is discharged to the grid system connected to the line side of the grid connection converter through the direct-current bus. According to the fault ride-through implementation method and system for the direct-driven draught fan, the direct-current bus voltage can be balanced, the fault ride-through capacity of the direct-driven draught fan is improved, and the safety and stability of operation of the grid system are improved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

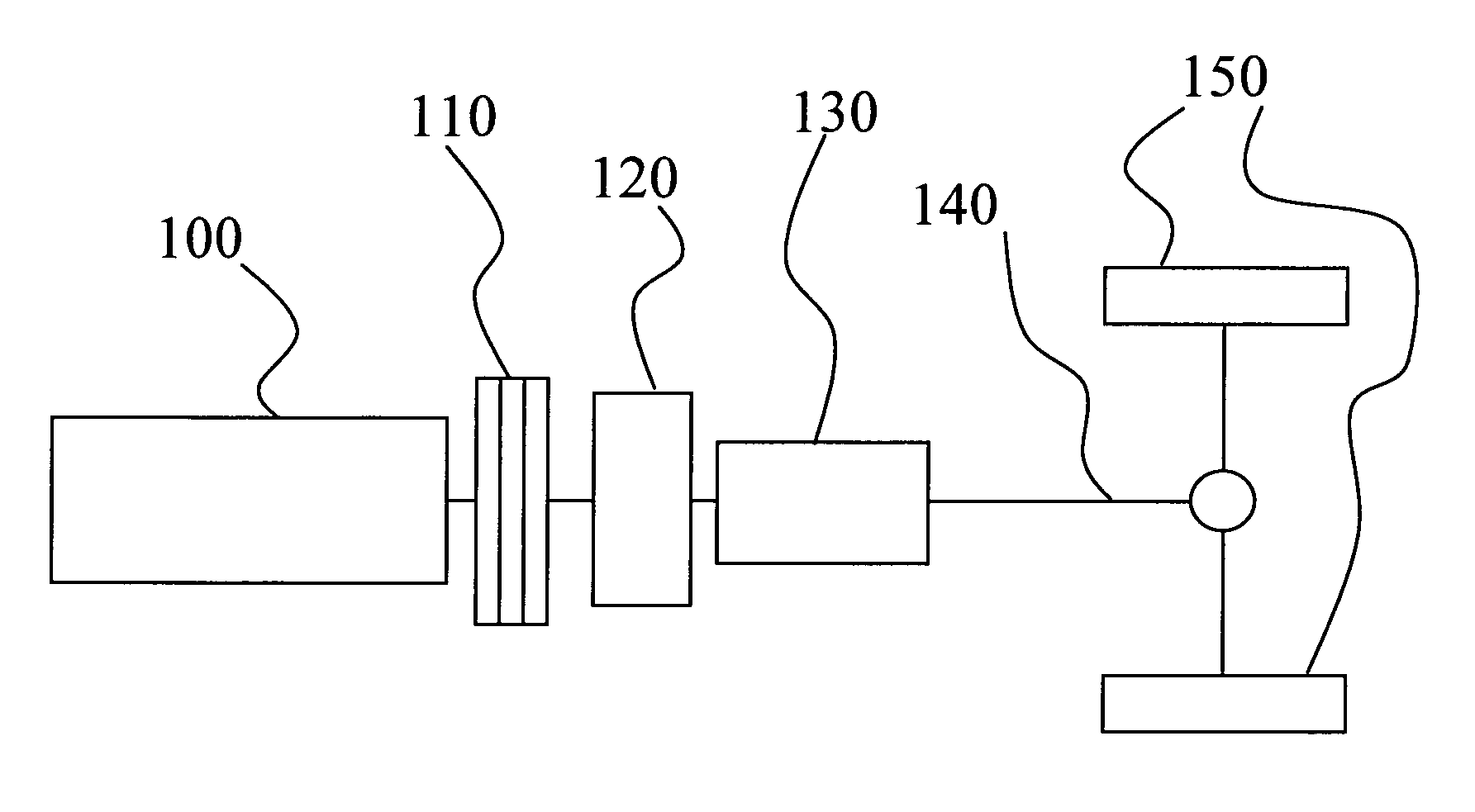

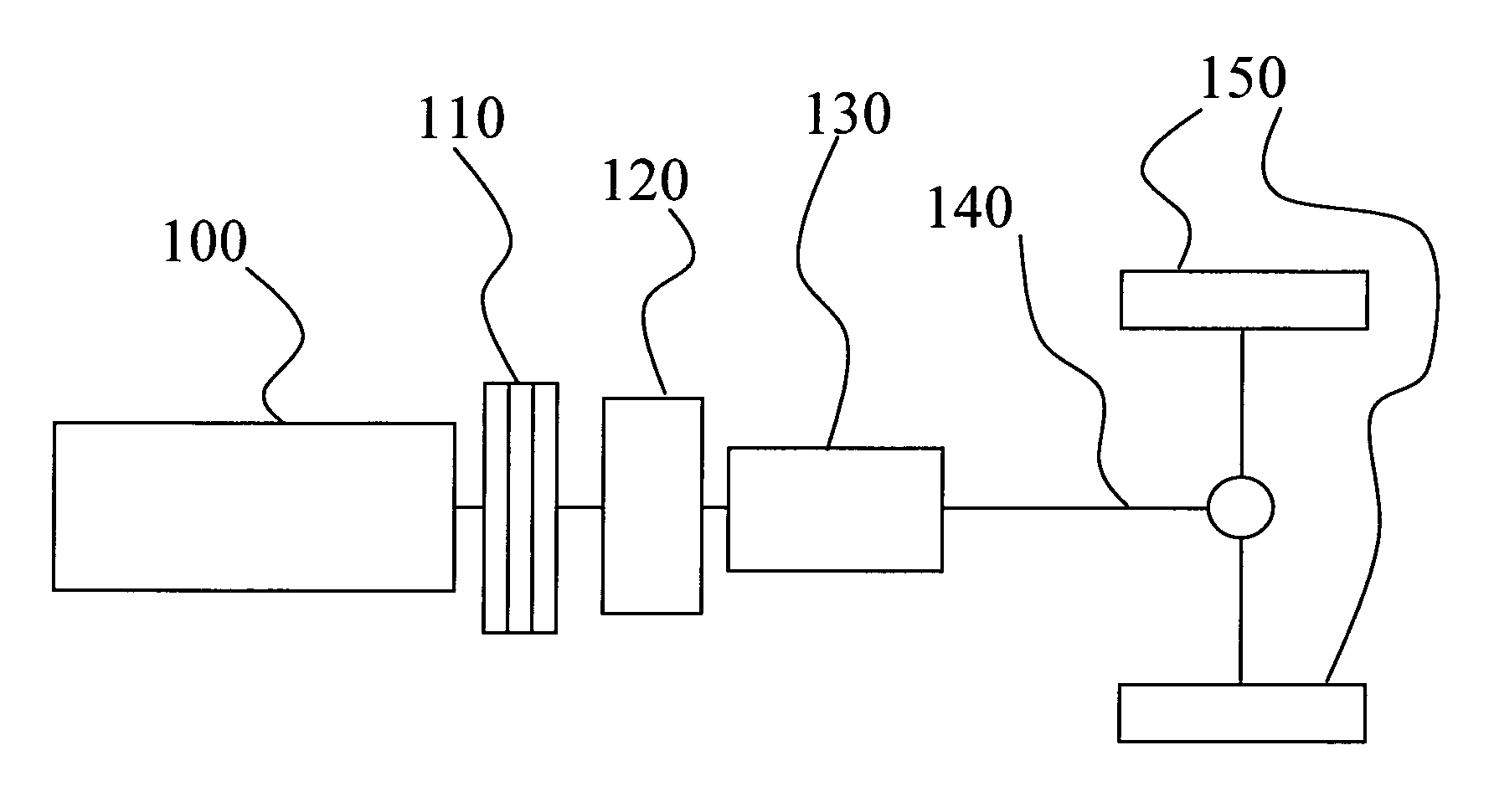

Method and drive train for performing a gear shift in a vehicle

ActiveUS8608617B2Reducing torque lossReduce outputElectric propulsion mountingGas pressure propulsion mountingElectrical batteryDrivetrain

Owner:VOLVO LASTVAGNAR AB

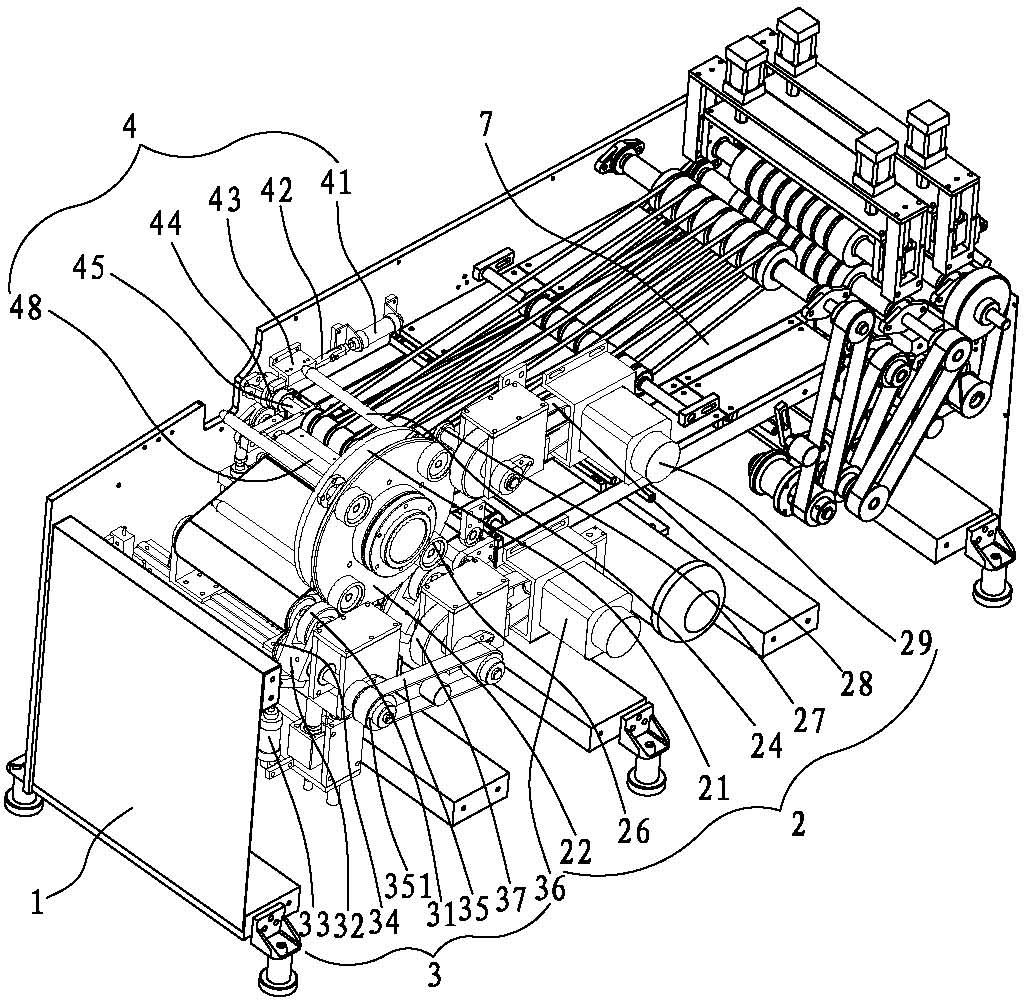

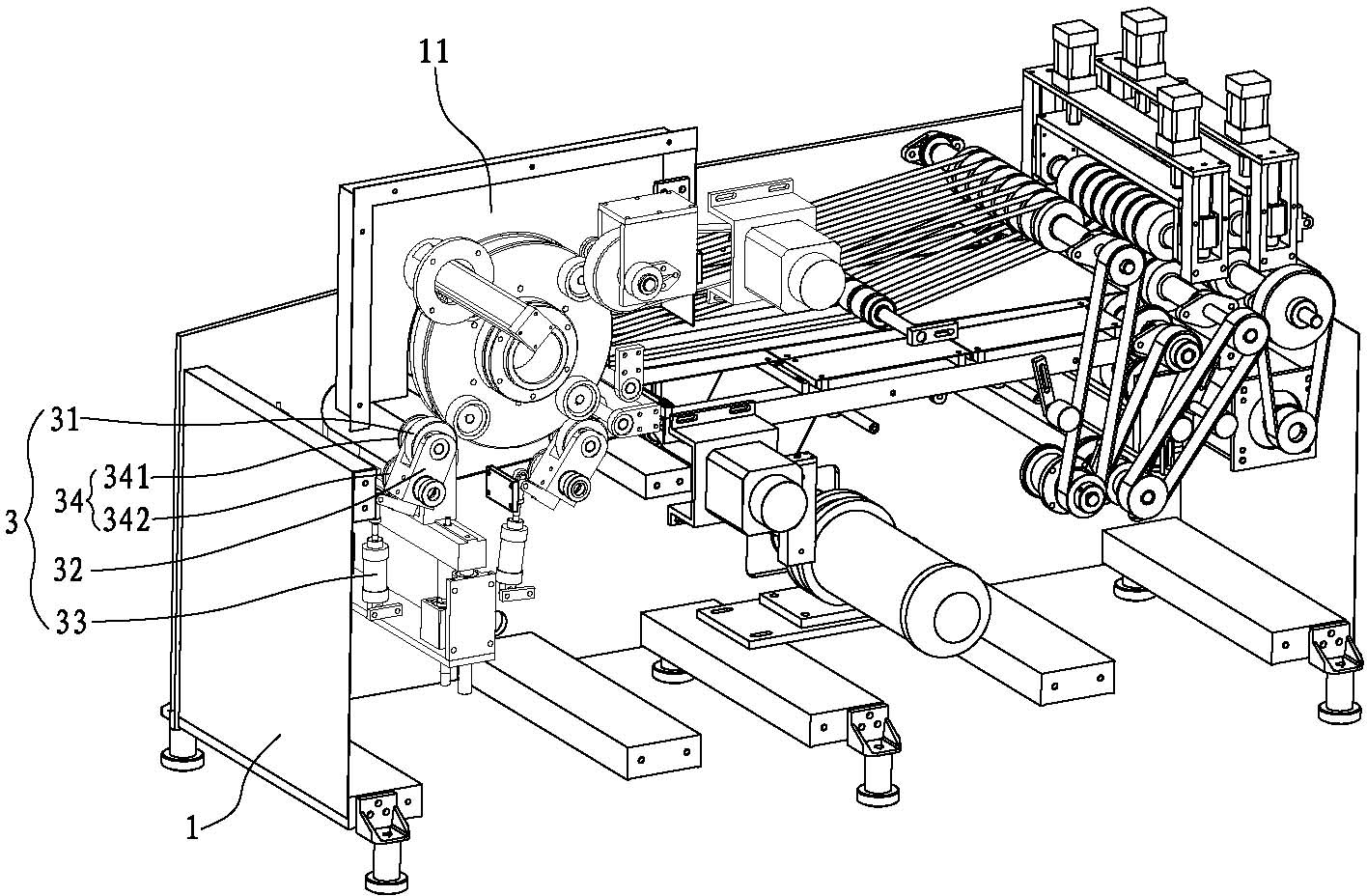

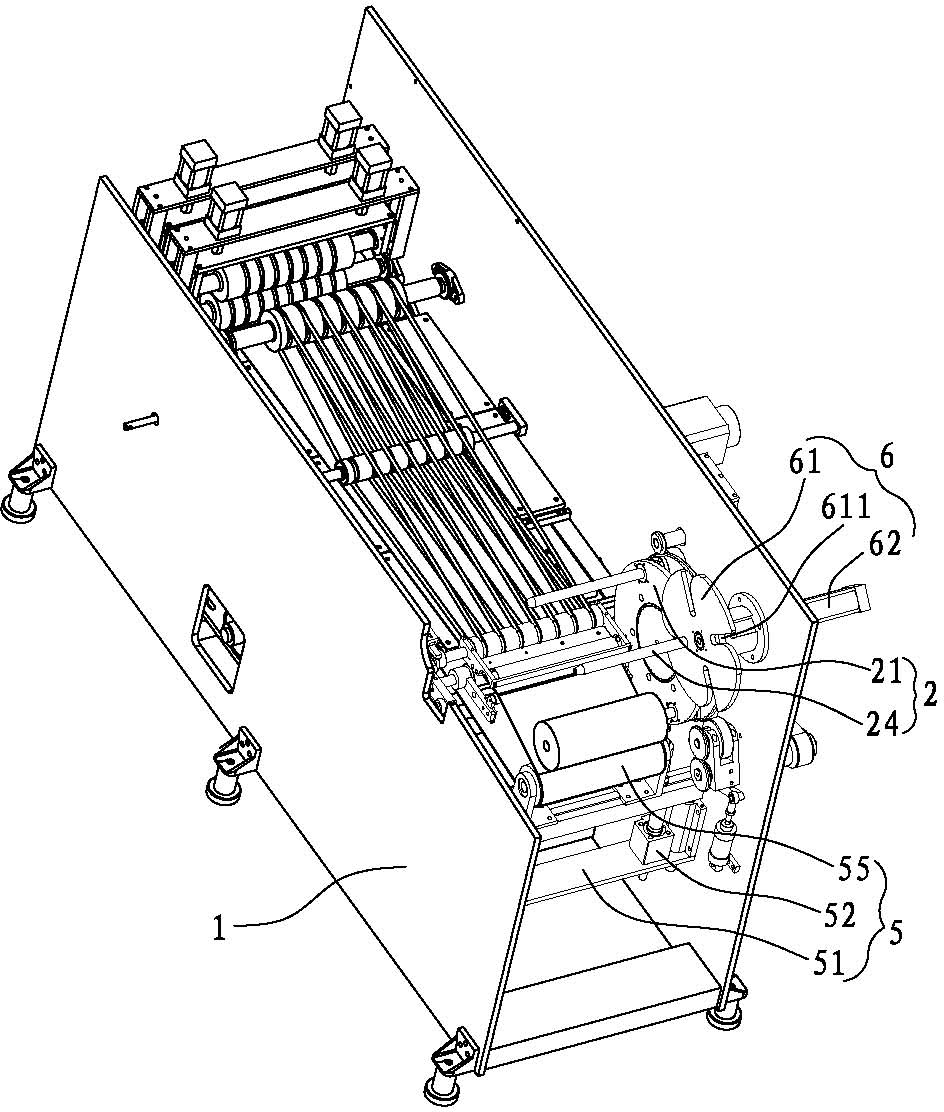

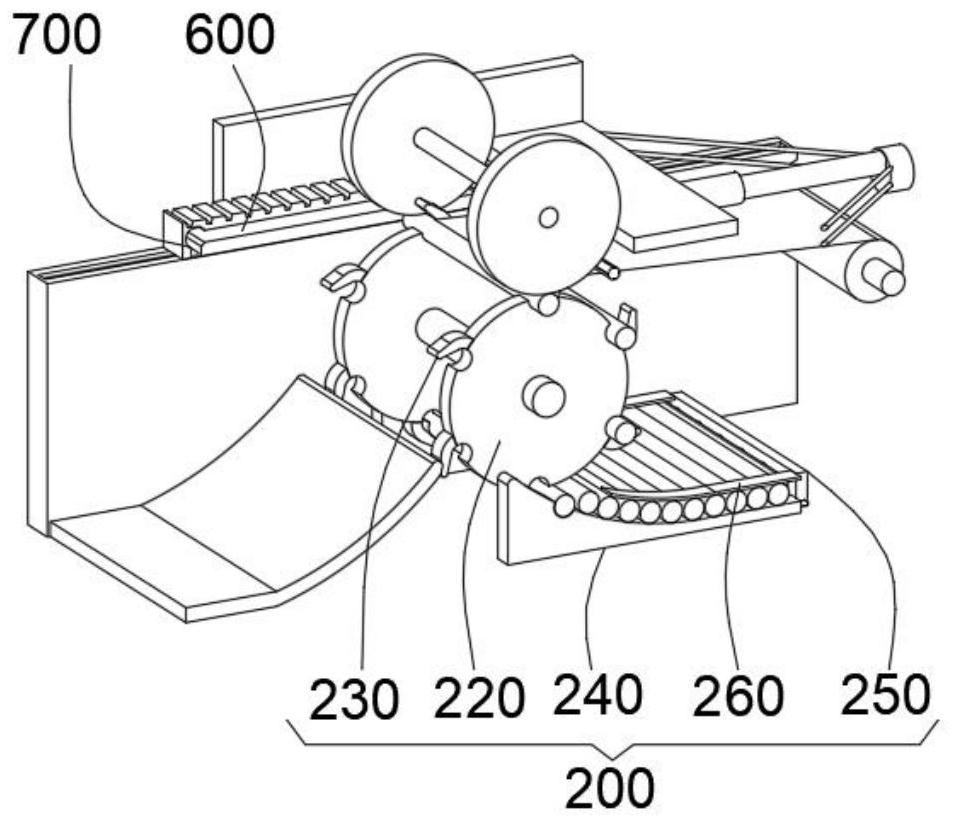

Separated roll-up device for plastic bags

InactiveCN102180369ASimple structure and principleStrong production applicabilityWebs handlingGear driveEngineering

The invention discloses a separated roll-up device for plastic bags, which mainly consists of a frame, a four-position rotary table device, a roll-up driving device, a roll-up conversion device, an ejector roller device and a partial position rotary table mechanism. In the rolling process, the roll-up conversion device drives a rack by a rack driving cylinder and a gear drives an overturning cover to overturn. The number of the rolled bags can be controlled simply by setting overturning moment of the overturning cover. The number of the rolled bags is simple and convenient to control. In the whole rolling process, the flexibility is high. The overturning structure principle is simple. The separated roll-up device is easy to manufacture. Moreover, the ejector roller device of the separatedroll-up device adopts an ejector roller cylinder as a power source, so that the situation that due to an excessively high pressure of the ejector roller, the whole roll of bags are excessively compact and are difficult to discharge or cannot be discharged after the bags are rolled up can be avoided. Due to the four-position rotary table device, a roll-up machine is ensured to work continuously inthe whole rolling process, so that a great amount of time is saved and the production efficiency is improved.

Owner:厦门亚太创新机器有限公司

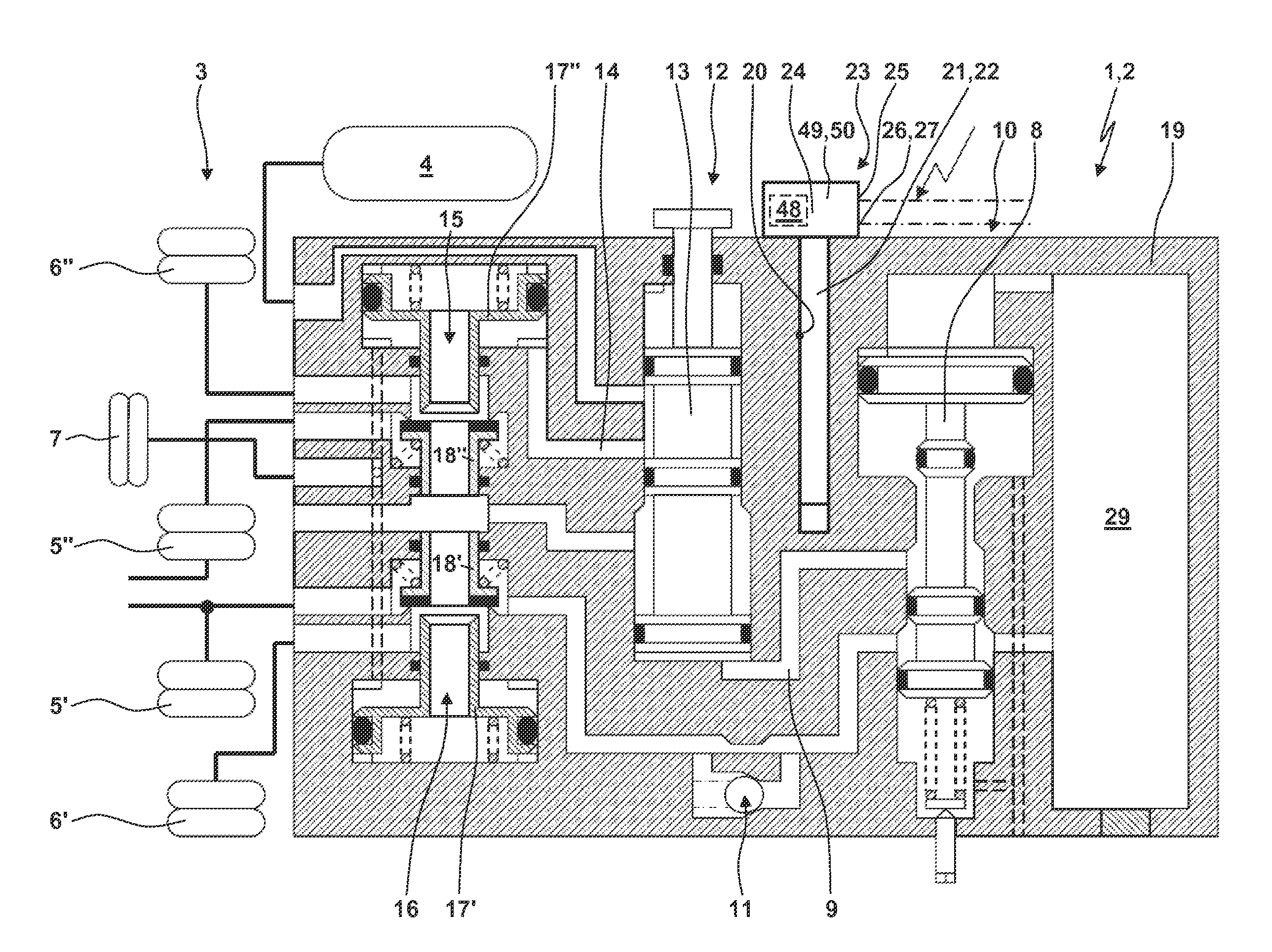

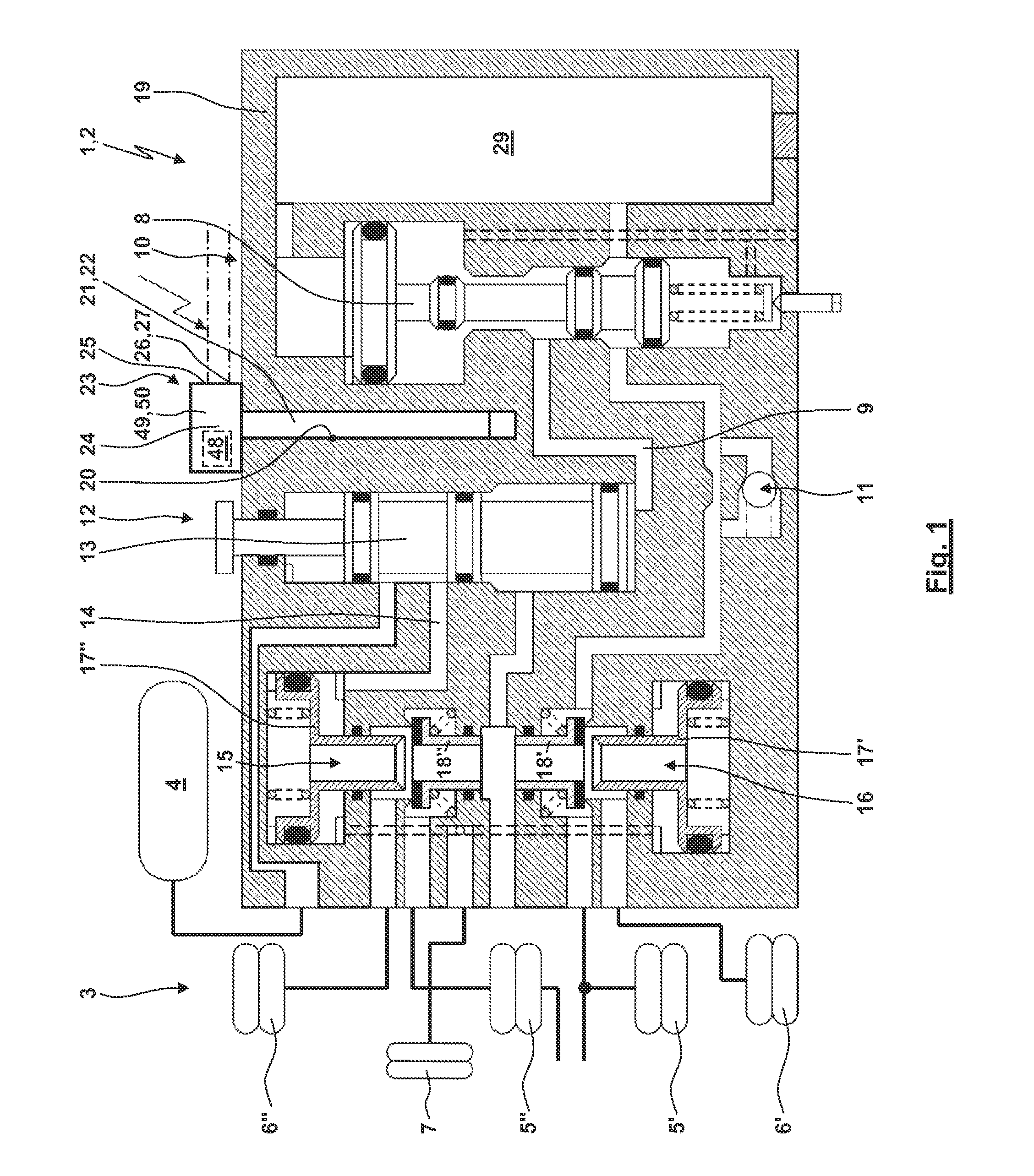

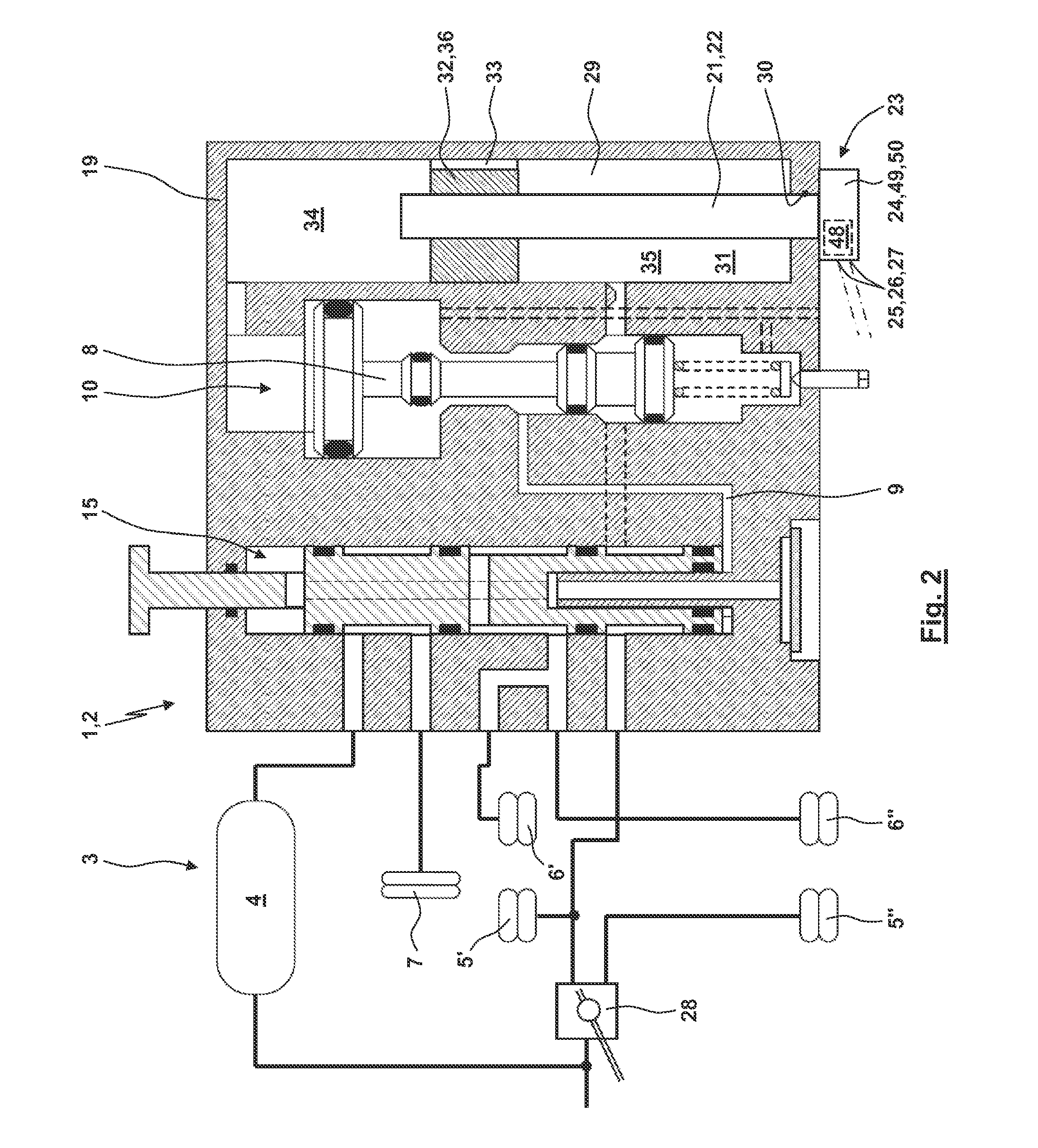

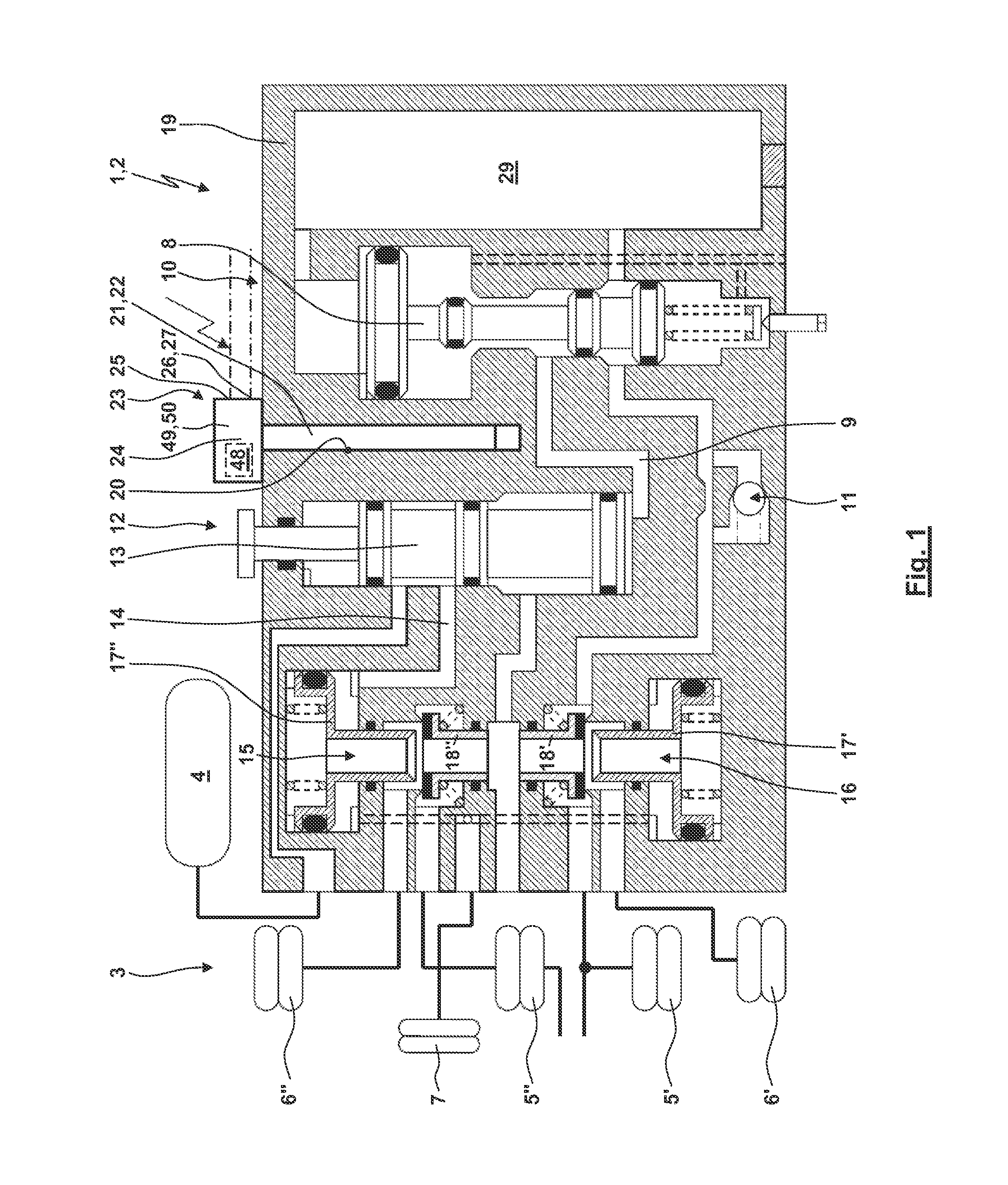

Lift axle valve unit

InactiveUS8931788B2Raise transfer toEasy transferValve members for heating/coolingPipe heating/coolingEngineeringAir suspension

The invention relates to a lift axle valve unit of any type for lifting or lowering a lift axle of a utility vehicle having an air suspension.According to the invention, the lift axle valve unit comprises a heating device. By means of the heating device it Is possible to heat the lift axle valve unit when using the utility vehicle in regions and in wintertime with low temperatures. The heating device comprises a heating element built with a heating rod or a heating mat.

Owner:HALDEX BRAKE PROD AB

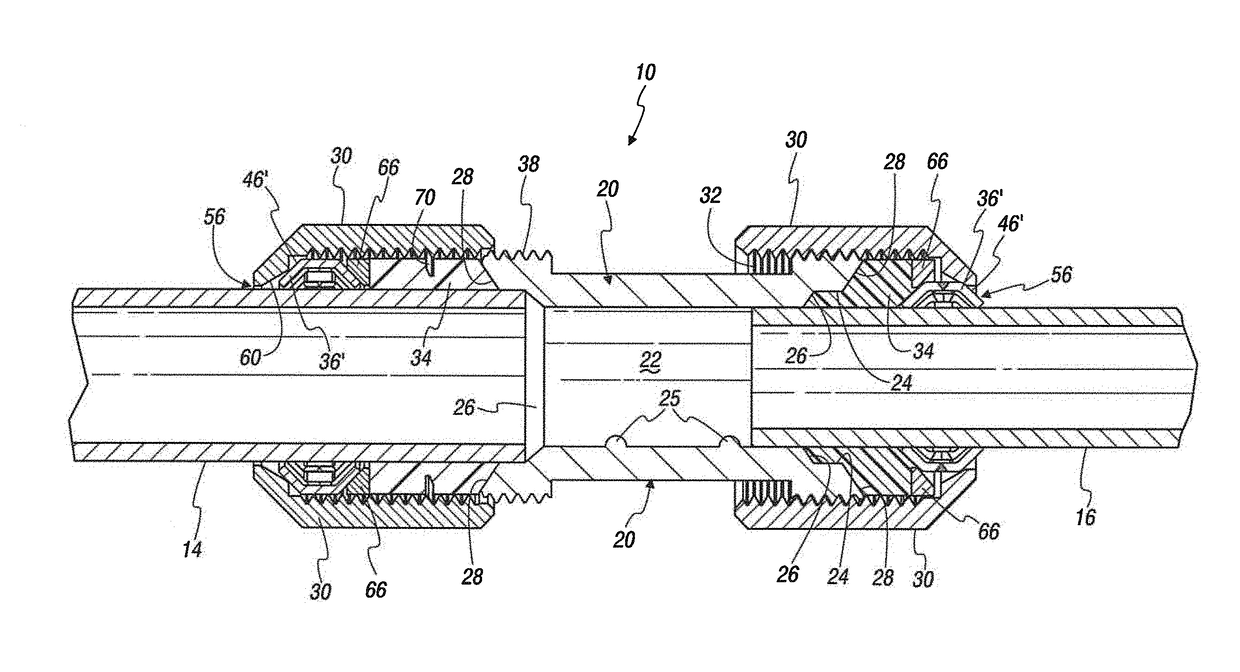

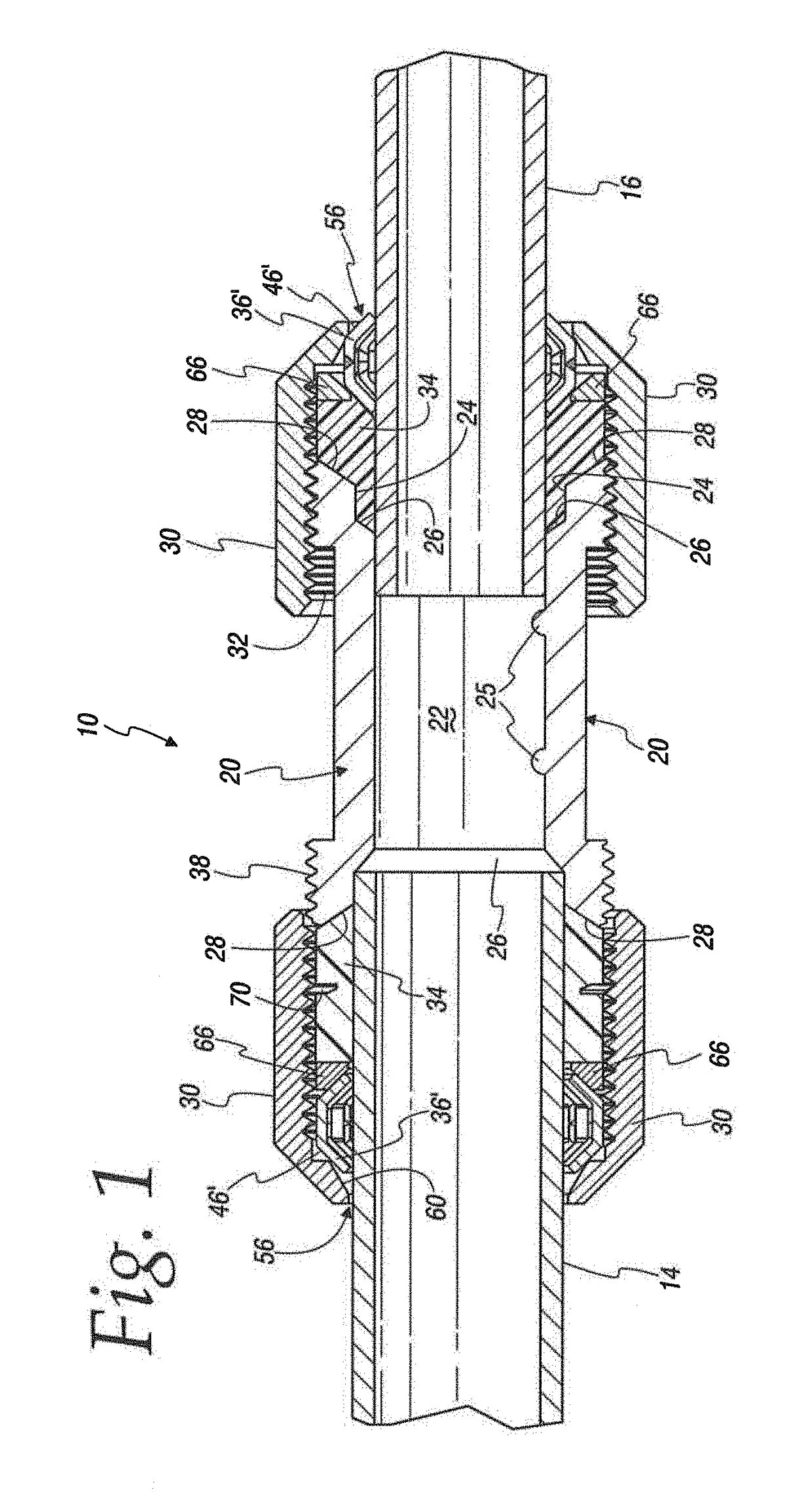

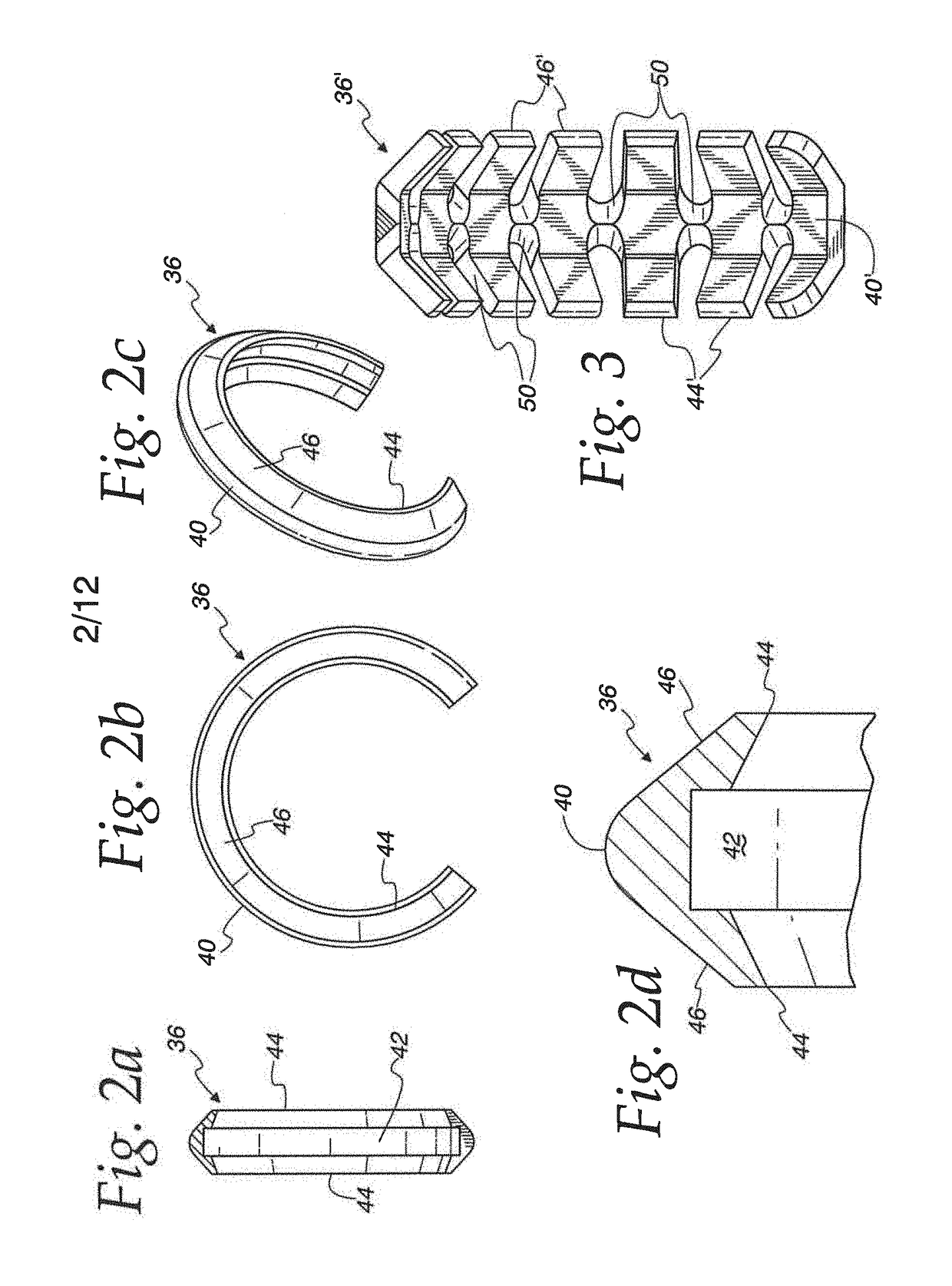

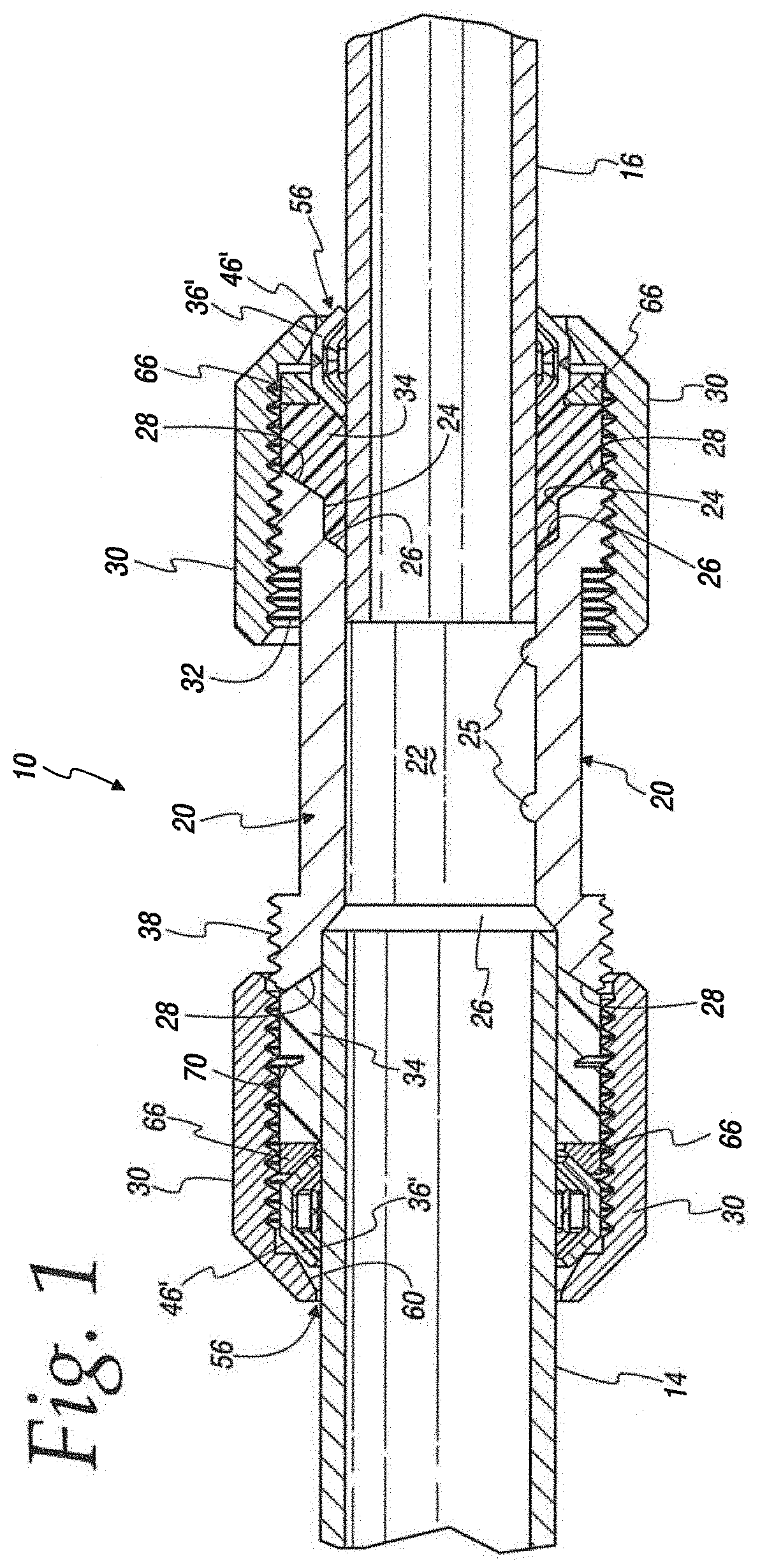

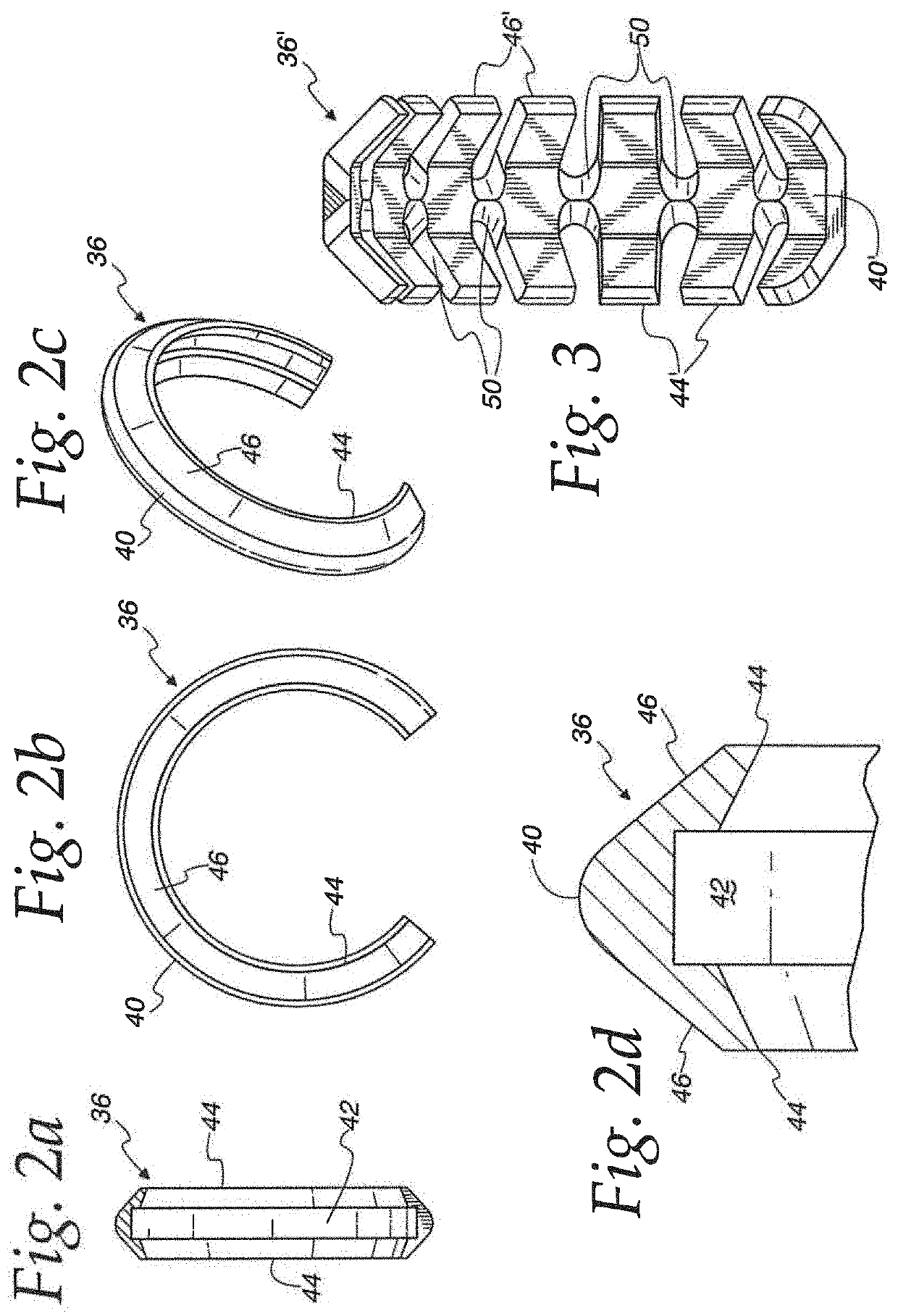

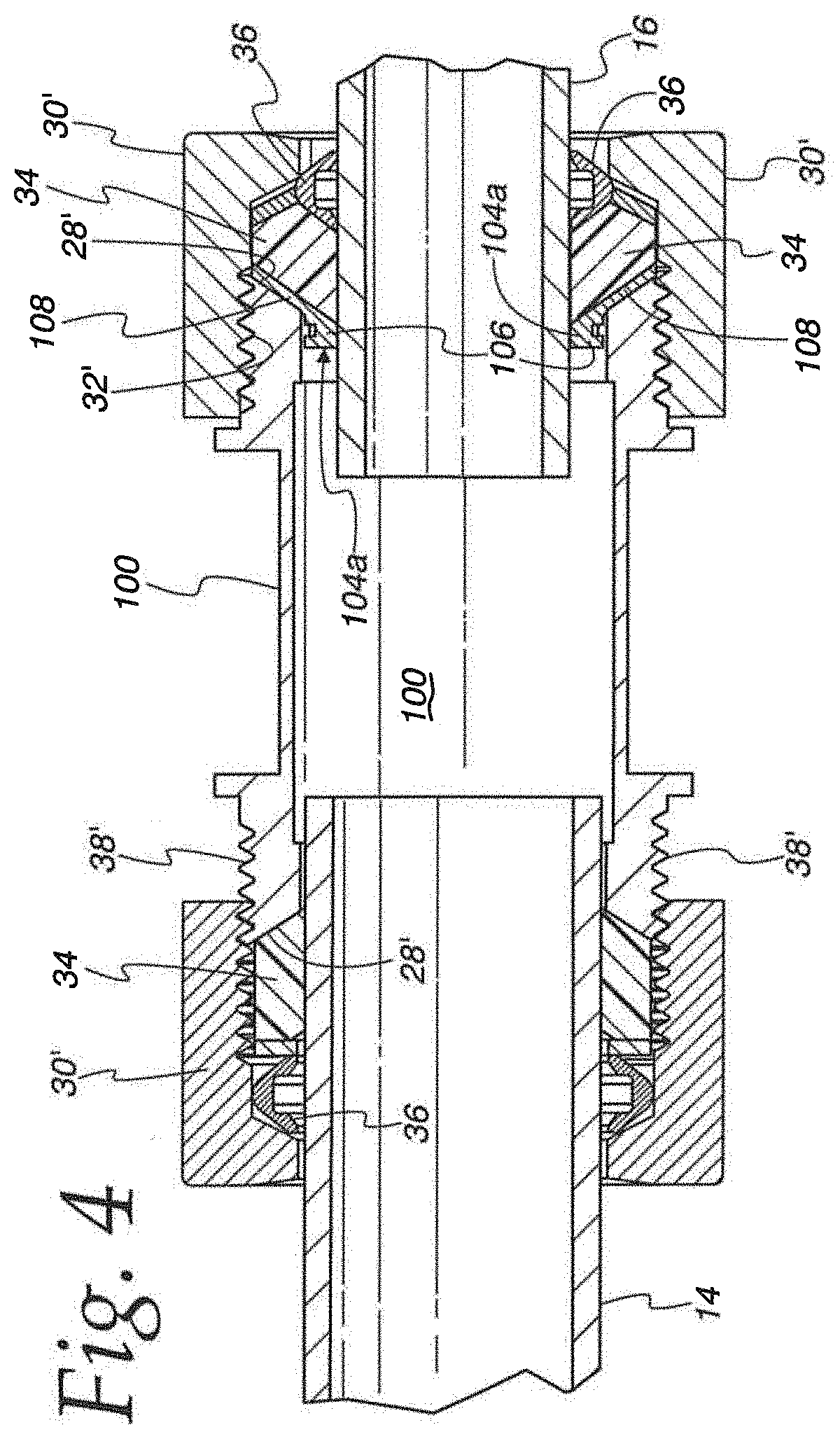

Compression pipe fitting with wide range grip rings

Compression fittings for pipes having a range of diameters, including a support body with a central section between end sections, the central section having a smaller diameter than the end sections, with a transition surface between the central section and each end section. A gasket fits over a pipe and engages one of the support body end section end surfaces. A fitting nut is movable axially over the support body to draw the support body and the gasket together in the axial direction and bias the gasket radially inward against the pipe. A grip ring encircles the pipe at one gasket end and has a surface engaging the fitting nut whereby the fitting nut biases the grip ring radially inwardly toward the pipe. An insert adapter has a hub with a radially extending flange may block the other gasket end to load the gasket between its axial ends.

Owner:A Y MCDONALD MFG

Lift Axle Valve Unit

InactiveUS20130048101A1Avoid unloadingRaise transfer toValve members for heating/coolingPipe heating/coolingEngineeringAir suspension

The invention relates to a lift axle valve unit of any type for lifting or lowering a lift axle of a utility vehicle having an air suspension.According to the invention, the lift axle valve unit comprises a heating device. By means of the heating device it Is possible to heat the lift axle valve unit when using the utility vehicle in regions and in wintertime with low temperatures. The heating device comprises a heating element built with a heating rod or a heating mat.

Owner:HALDEX BRAKE PROD AB

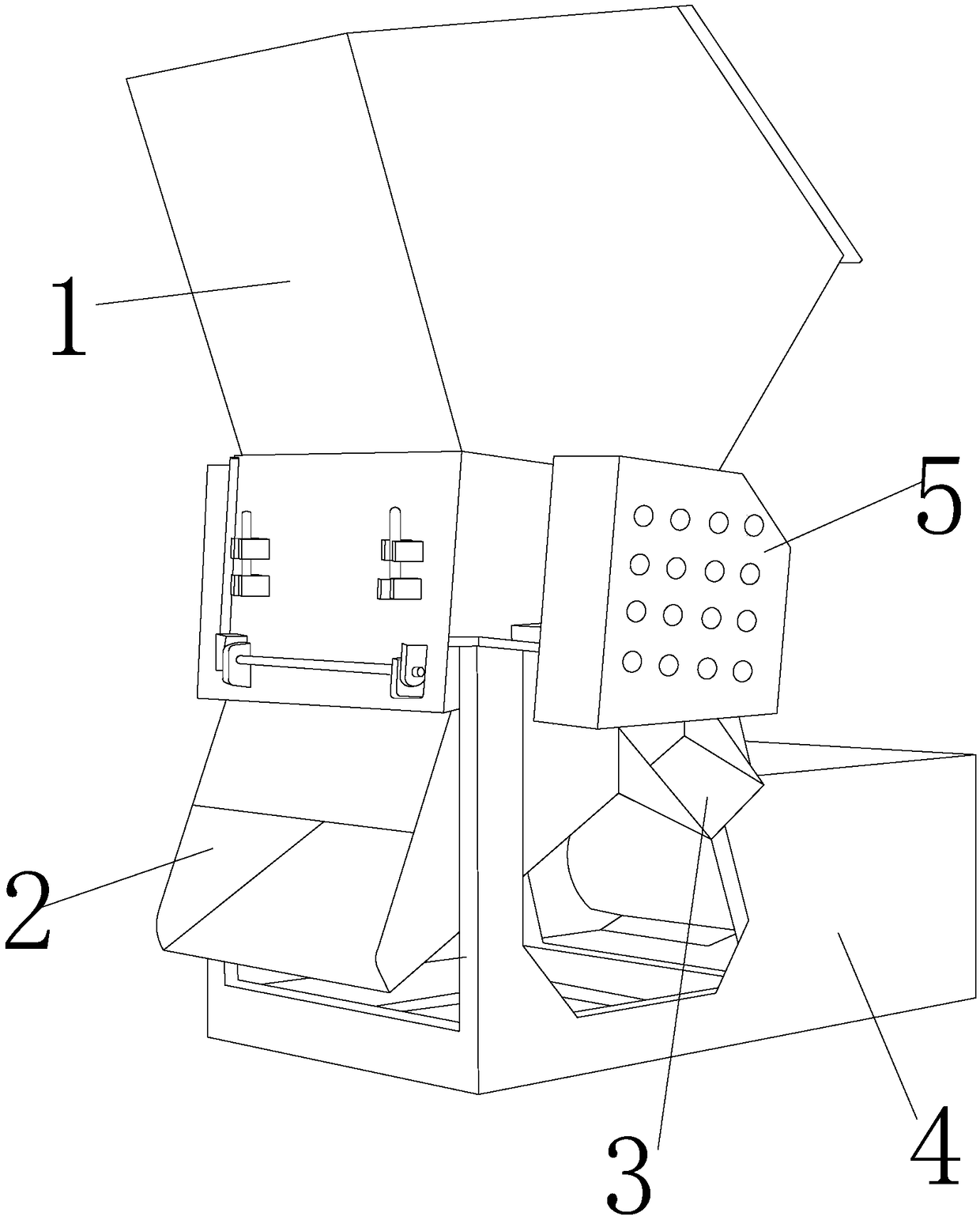

Waste tire crushing device for rubber and plastic

InactiveCN108422594AEnsure personal safetyReduce consumptionPlastic recyclingMechanical material recoveryWaste tiresWaste management

The invention discloses a waste tire crushing device for rubber and plastic. The waste tire crushing device structurally comprises a pulverizer body, a fine material discharging hopper, a coarse material discharging hopper, a supporting seat and a controller, wherein the left side and the right side of the pulverizer body are correspondingly connected with the left inner side and the right inner side of the supporting seat in a mechanical connection mode, the bottom of the pulverizer body is connected with the fine material discharging hopper, and the bottom of the pulverizer communicates withthe fine material discharging hopper. The waste tire crushing device for the rubber and the plastic has the beneficial effects that a high-efficiency energy-saving motor is adopted in the device, sothat secondary crushing can be carried out on a waste tire, and the thickness classification function on the crushed plastic is further achieved; noise pollution can be effectively avoided, so that the daily life of people is not affected, and the personal safety of an operator is guaranteed; and meanwhile, the operation cost is reduced, the electric energy consumption is low, the working efficiency is high, and the productivity is high.

Owner:郑 丽凤

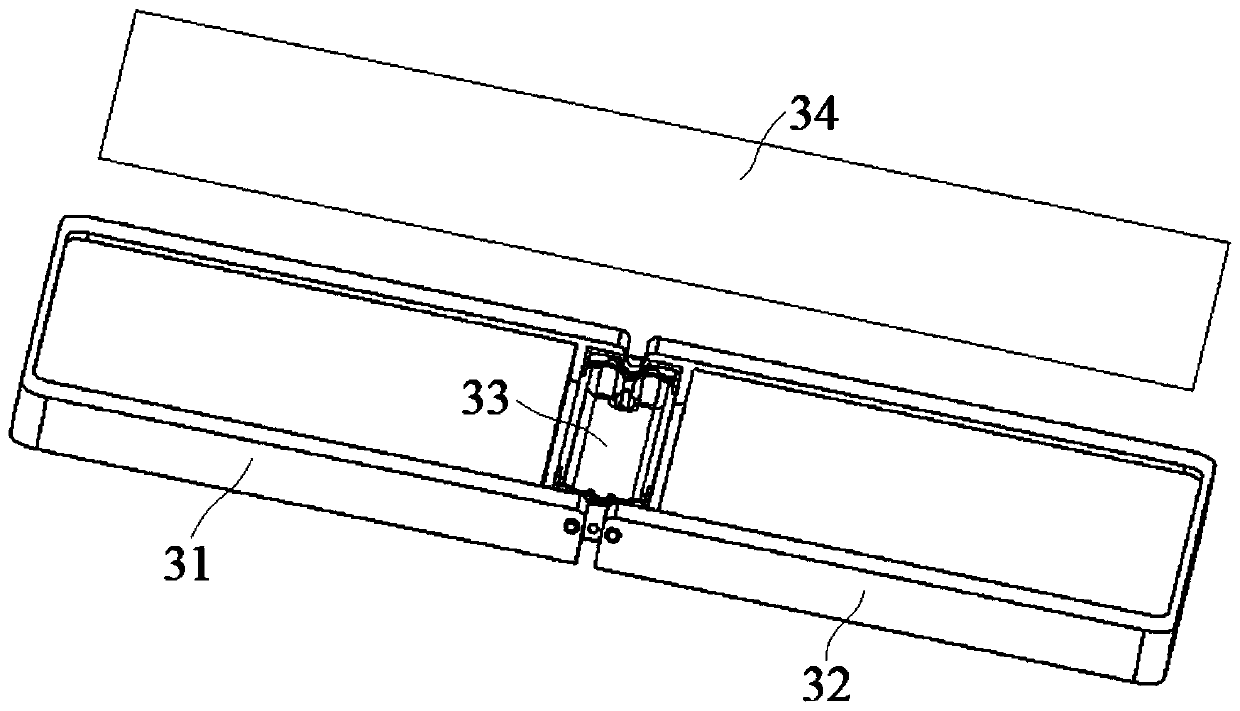

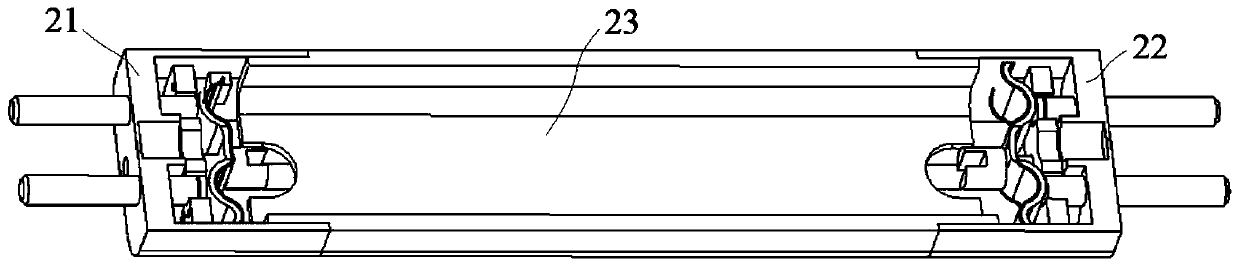

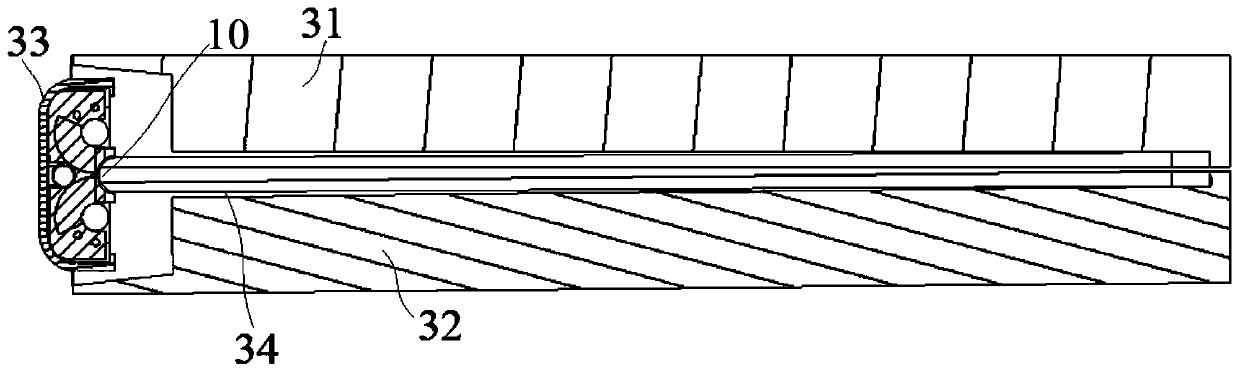

Full screen mobile phone

The invention discloses a full screen mobile phone. The full screen mobile phone comprises a first support plate, a second support plate, a rotating shaft assembly for connecting the first support plate and the second support plate, and a flexible screen, the rotating shaft assembly is located between the first supporting plate and the second supporting plate. The two ends of the flexible screen are connected with the first supporting plate and the second supporting plate respectively. The rotating shaft assembly comprises a first rotating shaft mechanism, a second rotating shaft mechanism anda connecting plate, the two ends of the connecting plate are connected with the first rotating shaft mechanism and the second rotating shaft mechanism respectively, the middle of the upper end face of the shell, the middle of the upper end face of the friction plate and the middle of the upper end face of the elastic pressing plate are respectively provided with an arc-shaped groove, and the connecting plate is provided with a groove for embedding the flexible screen. According to the invention, when the mobile phone is completely unfolded, the flexible screen is prevented from being stretched to cause damage to the screen, and when the mobile phone is folded, the flexible screen is prevented from being extruded to cause damage to the screen, so that the service life of the flexible screen is prolonged, and the aesthetic property of the flexible screen in the use process is ensured.

Owner:KUNSHAN KERSEN SCI & TECH

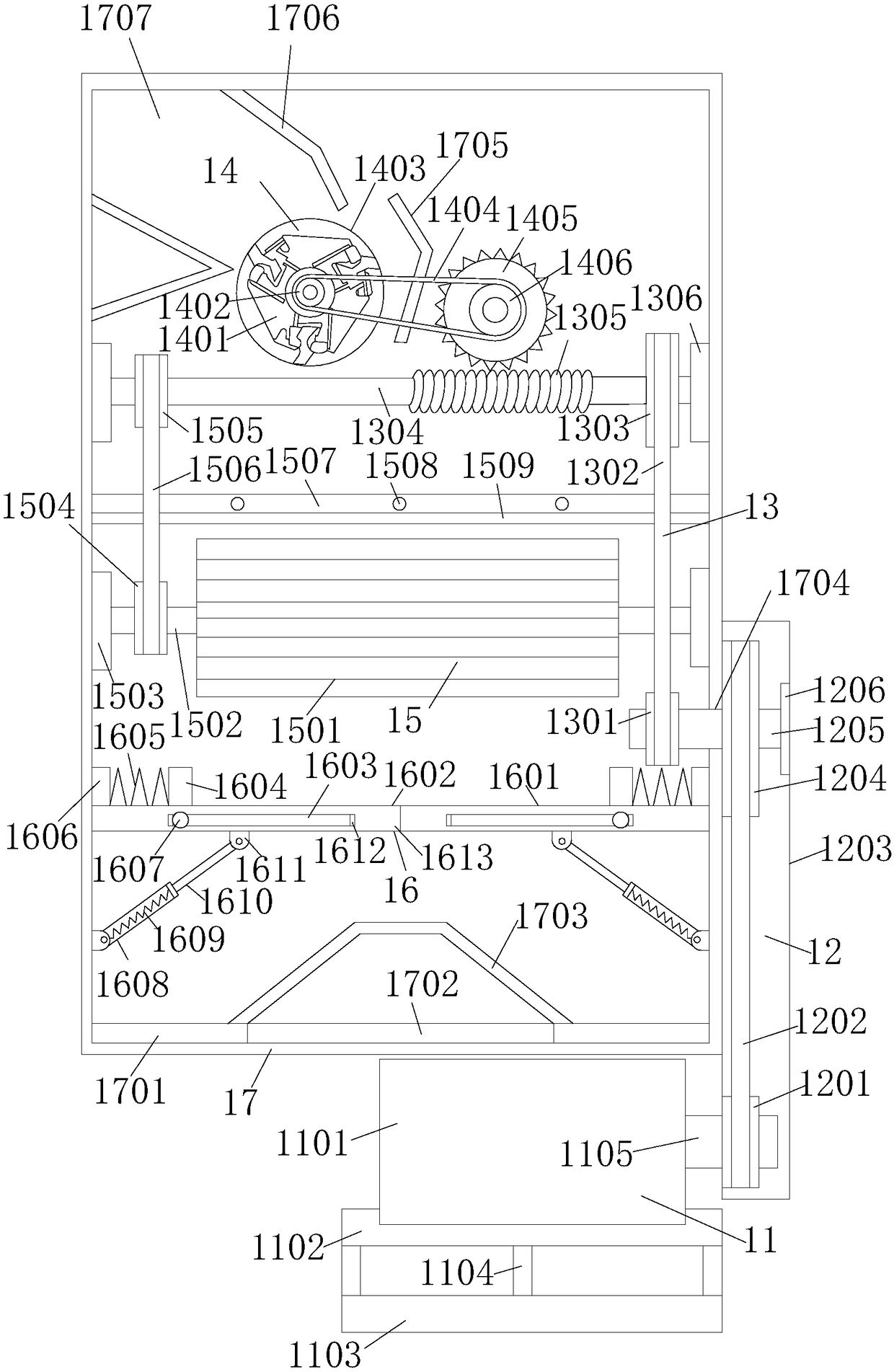

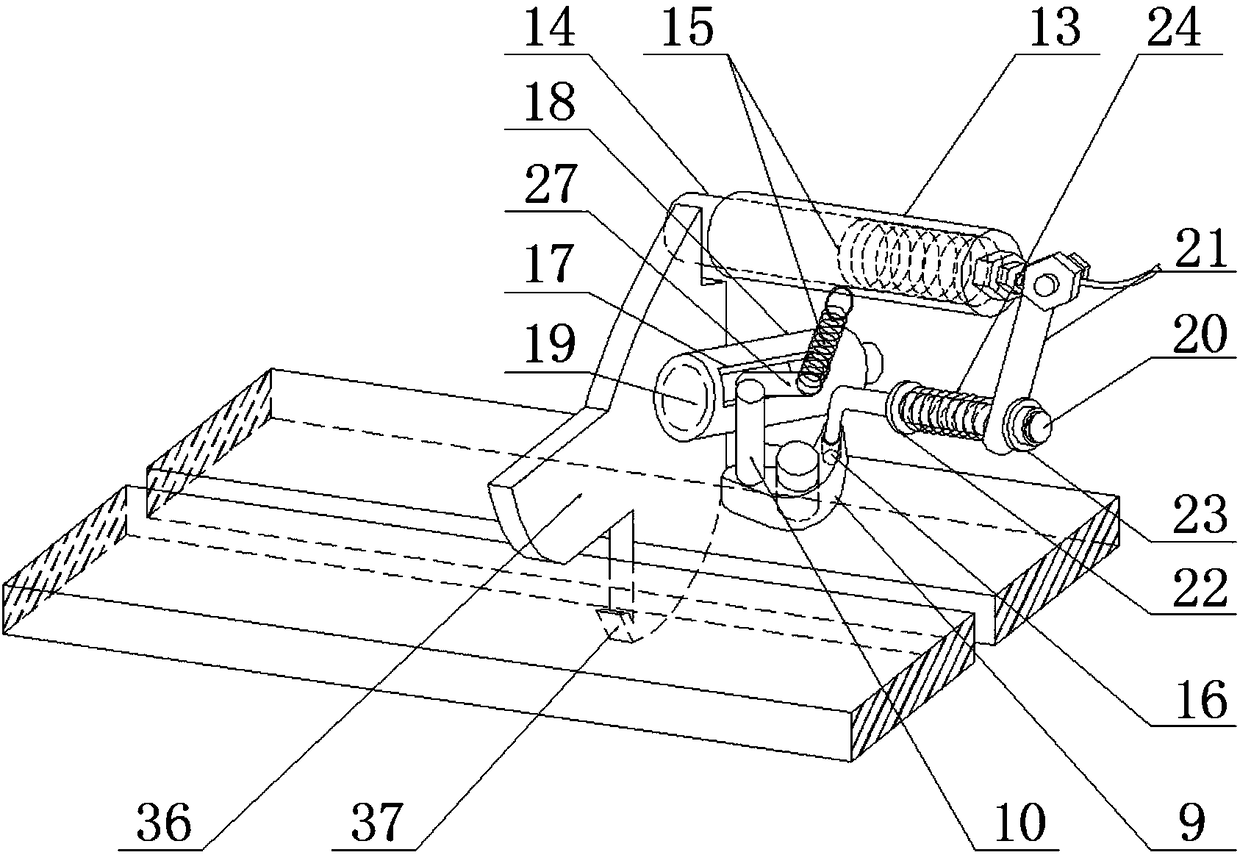

Caked silicate cement grinding, screening and recycling equipment for bridge construction engineering

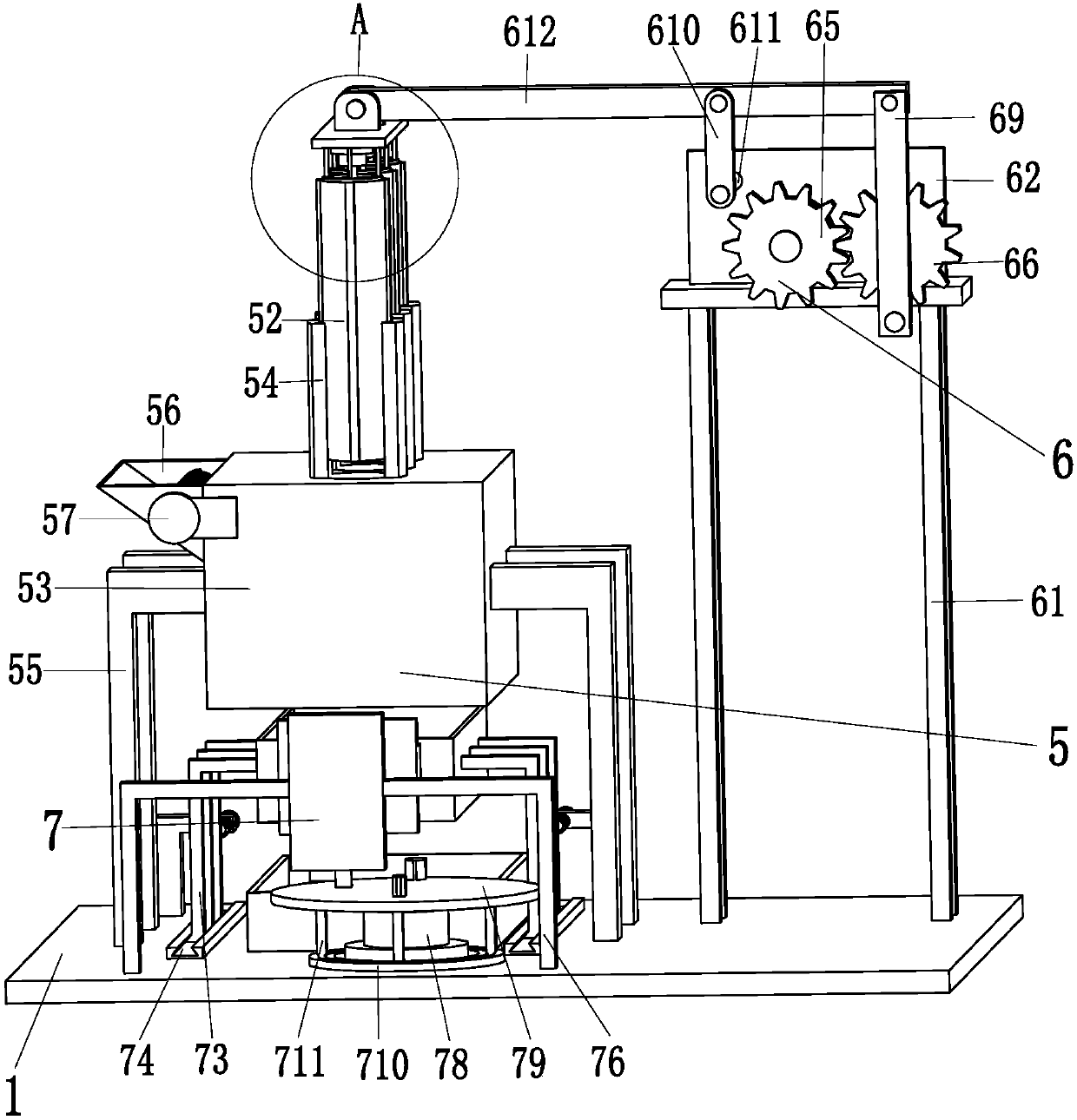

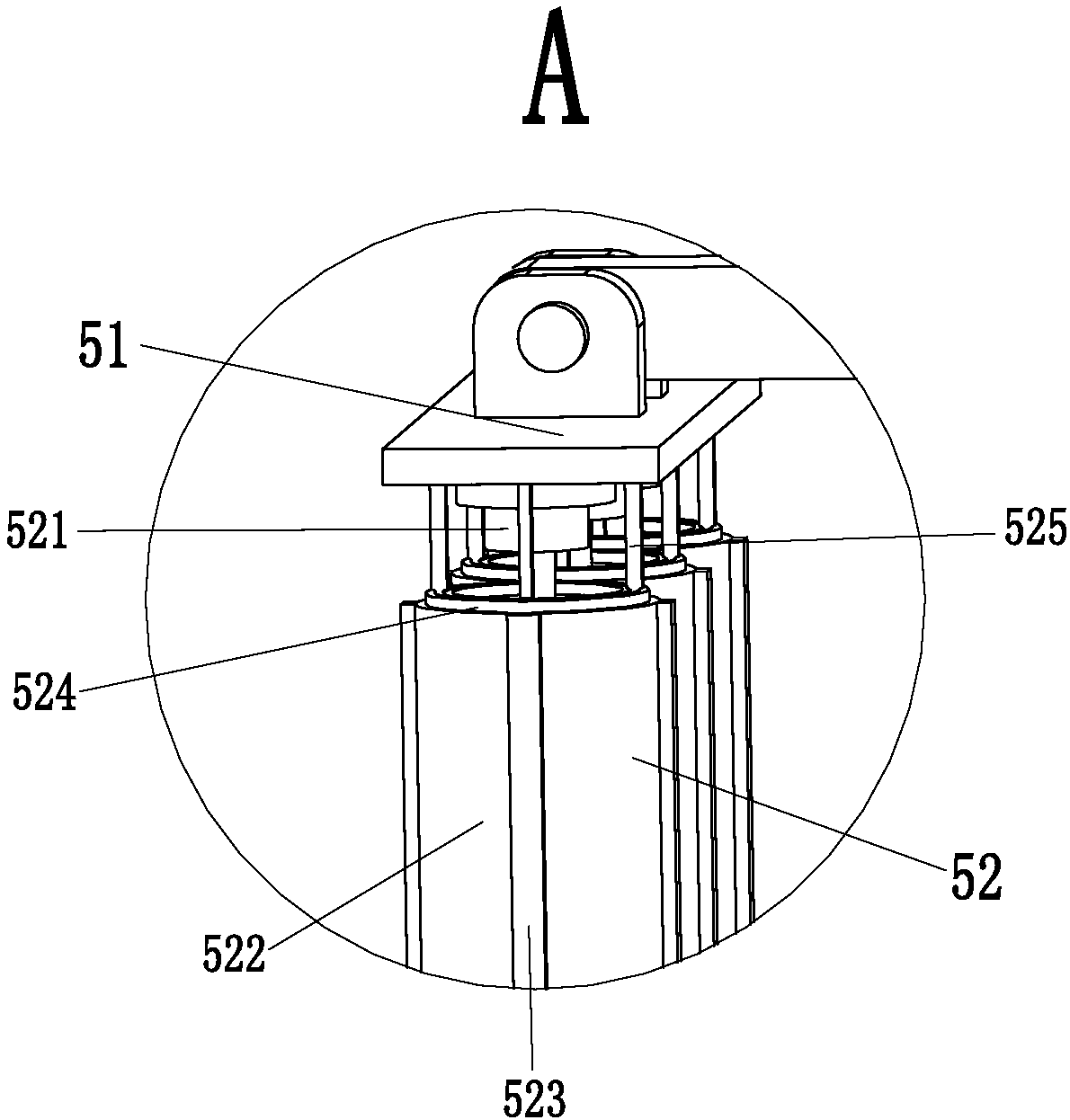

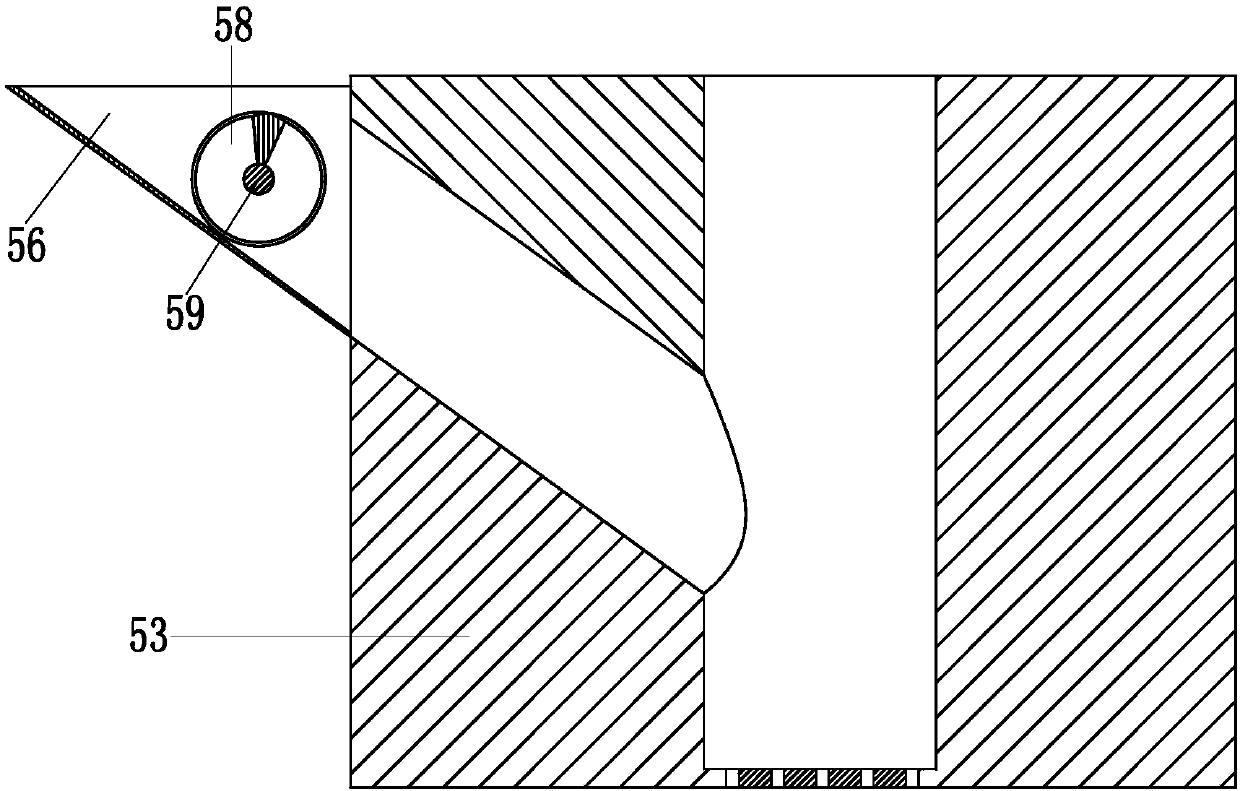

InactiveCN107694716AImprove work efficiencyReduce labor intensityGrain treatmentsEngineeringSilicate Cement

The present invention relates to a kind of agglomerated portland cement grinding, screening and recovery equipment for bridge construction engineering, comprising a support base plate, a crushing device, a lifting device and a screening device, and the crushing device is installed on the left side of the support base plate , the top of the smashing device is connected with the lifting device, the lifting device is installed on the right side of the supporting base, the screening device is located under the smashing device, and the screening device is connected with the supporting base. The present invention can solve the problems of low working efficiency existing in processing the agglomerated cement, the need to manually crush the agglomerated cement, the inability to automatically grind the agglomerated cement, the poor grinding effect, and the inability to automatically grind the ground cement. Screening and other problems; can realize the function of automatic grinding and automatic screening of agglomerated cement, with high work efficiency, automatic crushing of agglomerated cement, automatic grinding of agglomerated cement, good grinding effect, automatic grinding The ground cement has the advantages of sieving and so on.

Owner:高雅

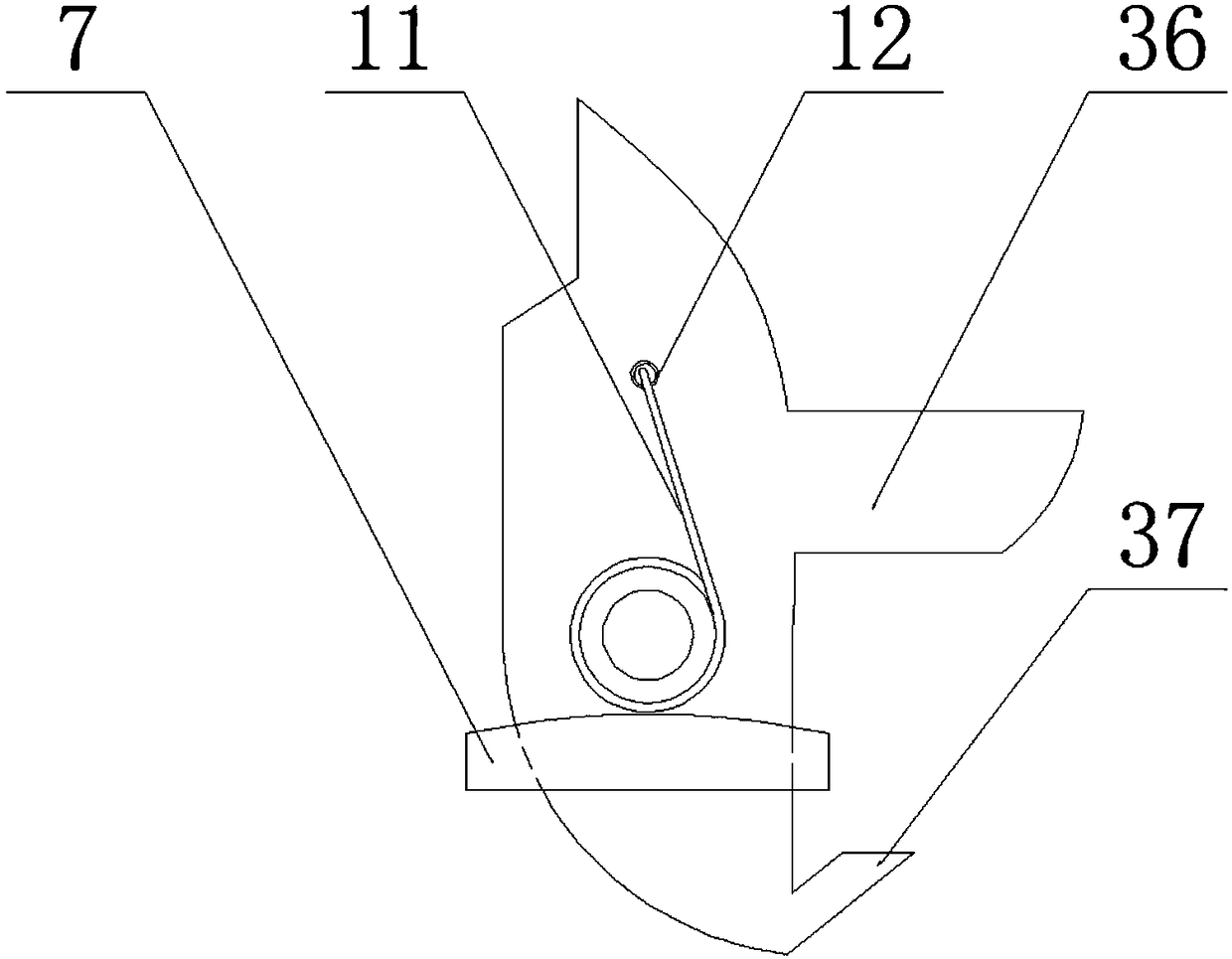

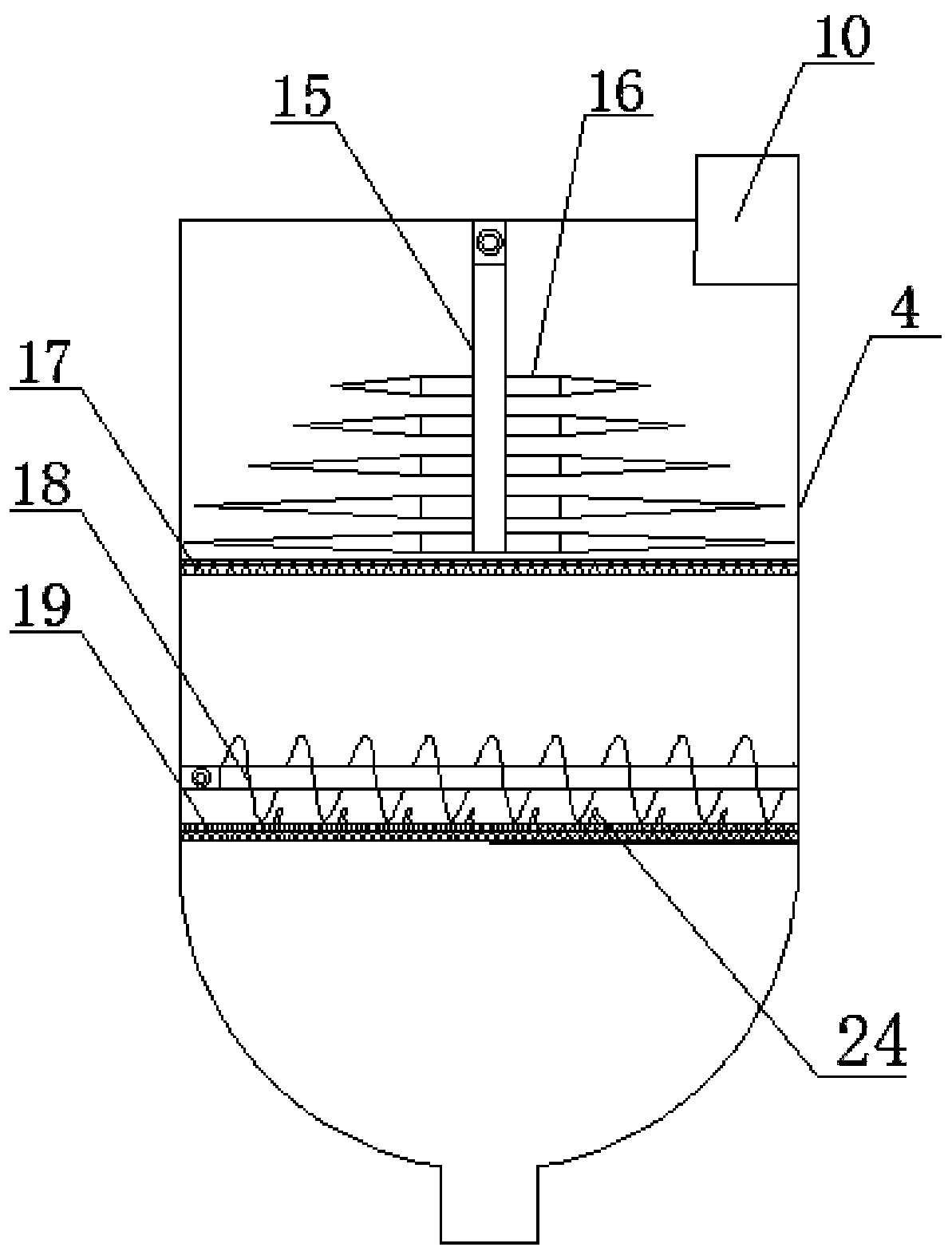

Malt wet crushing device

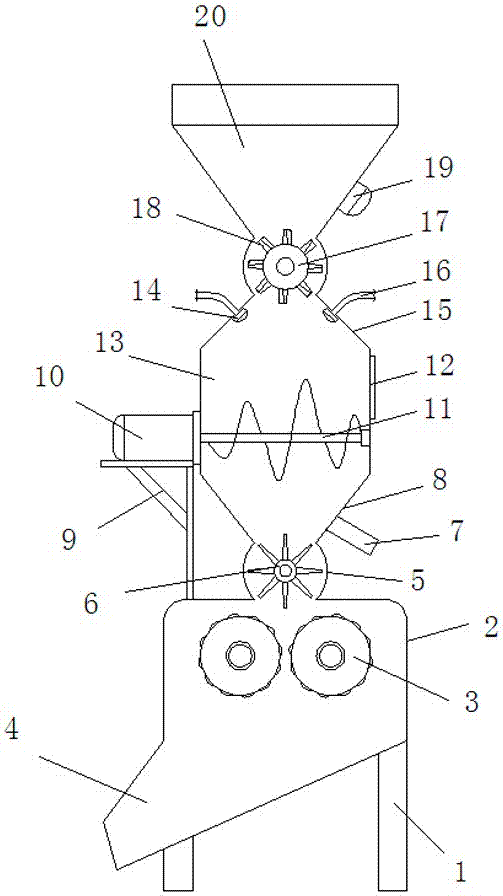

InactiveCN106984387AGuaranteed cleanlinessEasy feedingWort preparationHollow article cleaningEngineeringCrusher

The invention discloses a malt wet crushing device, which comprises a feeding hopper, a wetting bin and a crushing device. The top of the wetting bin is provided with an inverted top V-shaped bin body, and the inclined bin walls of the top V-shaped bin body are installed in a distributed manner. There is a spray head, and the upper part of the top V-shaped bin communicates with the bottom of the feed hopper through the inlet cylinder arranged longitudinally. The outer wall of the material guide roller is distributed with oblique feeding scrapers along the circumferential direction; the bottom of the wet bin is provided with a bottom V-shaped bin body, and the bottom V-shaped bin body passes through the longitudinally arranged outlet cylinder and the crushing shell of the crushing device. The inlet end of the body is connected, and the discharge guide roller is arranged in the outlet cylinder. The structure design of the invention is reasonable, the material feeding and discharging are smooth, and there is no blockage, which effectively avoids malt arching and cannot be discharged. health and safety.

Owner:射阳春蕾麦芽有限公司

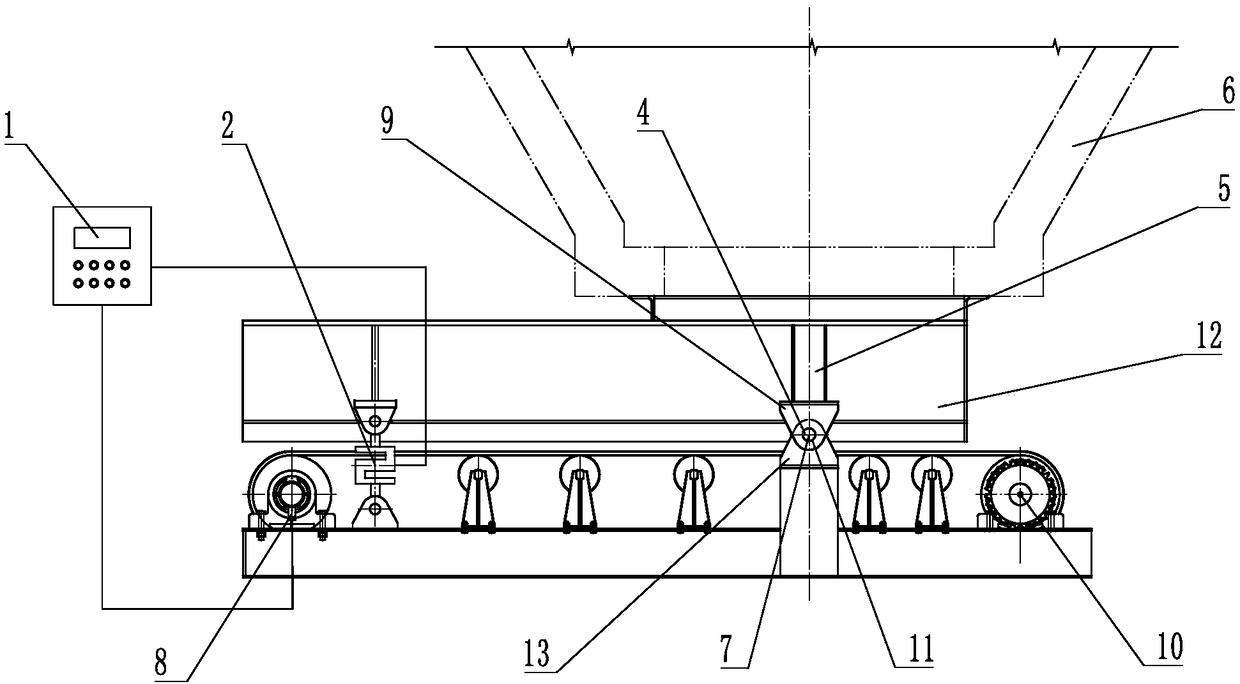

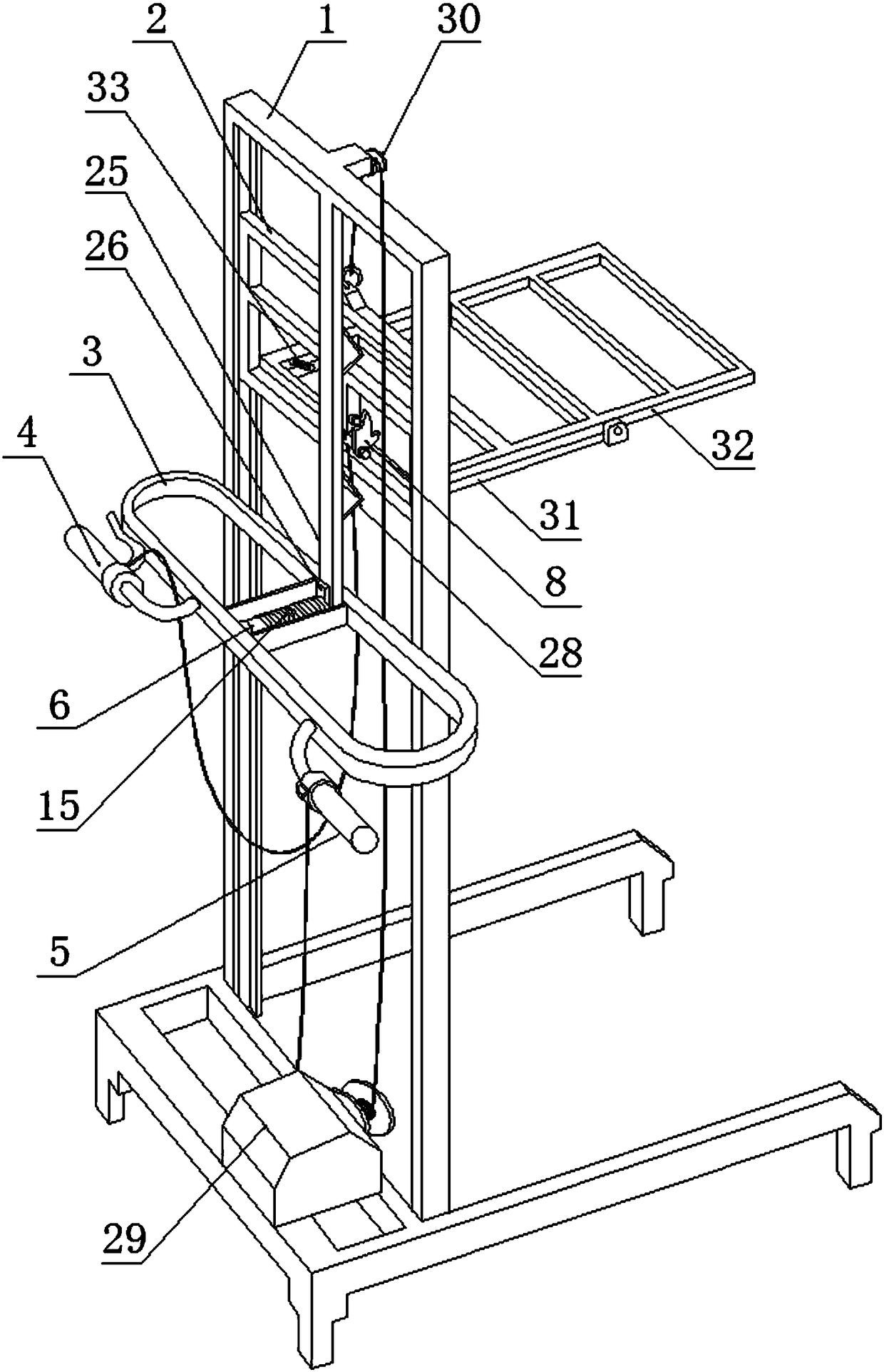

Feeder capable of reversely conveying materials, dropping materials from inclined side, reducing interferences and dynamically weighing and metering

The invention discloses a feeder capable of reversely conveying materials, dropping materials from an inclined side, reducing interferences and dynamically weighing and metering. The feeder comprisesa reverse conveying rack and a weighing conveyor, wherein the reverse conveying rack comprises a reverse-guide inclined-side-dropping receiver and a rack guide slot; the weighing conveyor comprises areverse-extending conveying device, a drive device and a weighing device; the reverse-guide inclined-side-dropping receiver comprises a hanging inclined plate guide slot part, an inclined plate reverse-guide part and an inclined-side reverse dropping hole part; a dropping hole of the inclined-side reverse dropping hole part is formed in a direction reverse to a material moving direction; a weighing sensor supports the reverse-extending conveying device to integrally weigh materials and the reverse-extending conveying device; while inducting weight of flowing materials, the weighing sensor is matched with a speed sensor for weighing the materials, so that effects of reversely conveying materials, dropping materials from the inclined side, reducing interferences and dynamically weighing andmetering are achieved; and hardness and adhesion force of the materials on the weighing conveyor belt are different when the temperature of the conveyor belt changes as tightening force of the conveyor belt is different, so that weighing precision is improved by tens of times.

Owner:刘素华

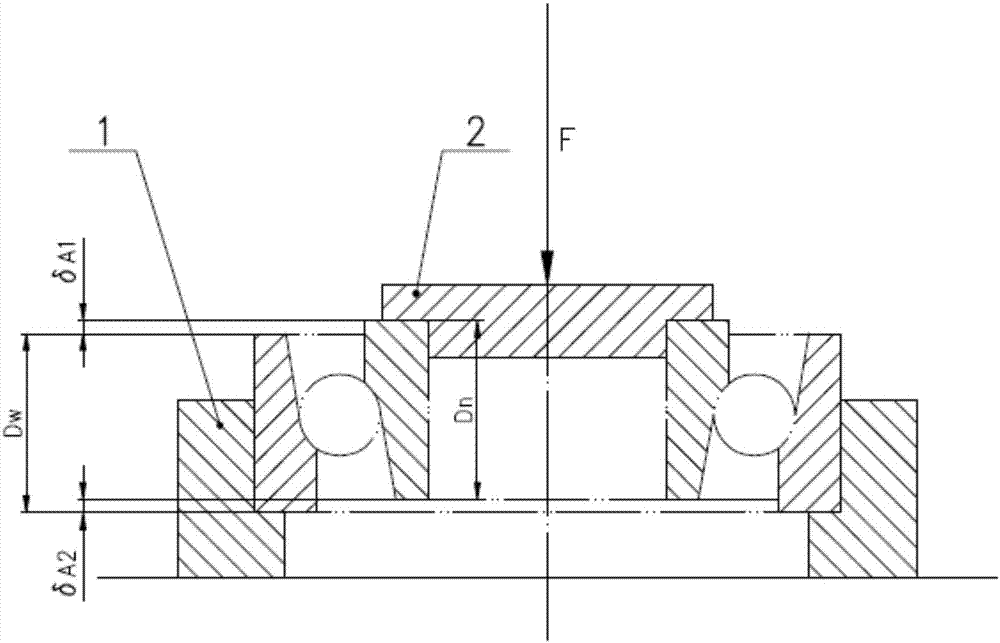

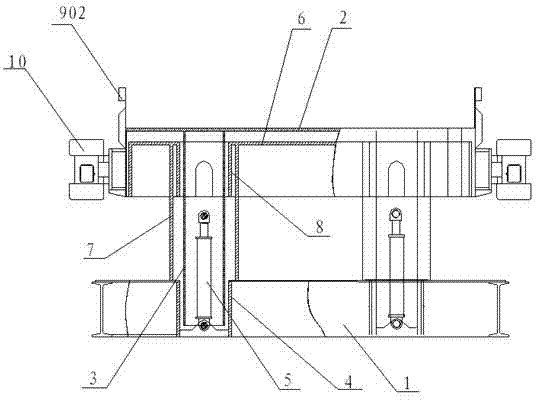

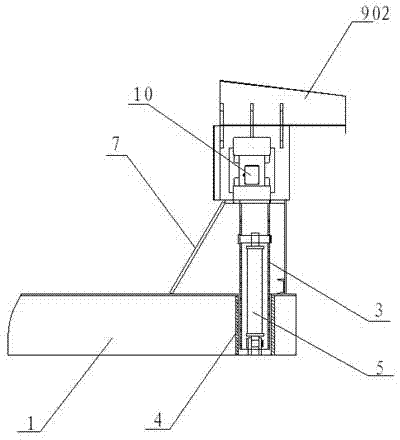

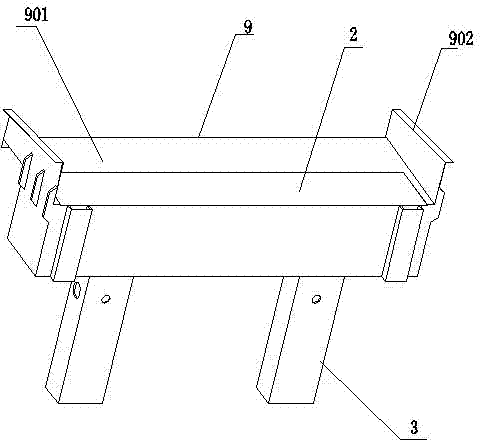

Precision matched bearing rapid adjustment device and usage method thereof

ActiveCN106949814AAccurate preloadHigh precisionMechanical clearance measurementsElectric machineryMeasurement device

The present invention belongs to the precision machinery engineering technology field, and especially relates to a precision matched bearing rapid adjustment device and a usage method thereof. The device comprises a single-bearing special measuring device and a matched bearing preload special measuring device. The device adjusts a matched bearing and applies preload at two ends of the matched bearing to avoid the problem that one bearing preload force is too large and another bearing has the unloading phenomenon in the preload loading process so as to allow the obtained matched bearing preload force to be more accurate and reasonable; a precision motor and a precision ball screw are employed to perform applying of the preload force of the matched bearing, the precision is high, and the stability is good; and moreover, the process of error test in the current operation process is avoided, the generation cost is saved, and the production efficiency is improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

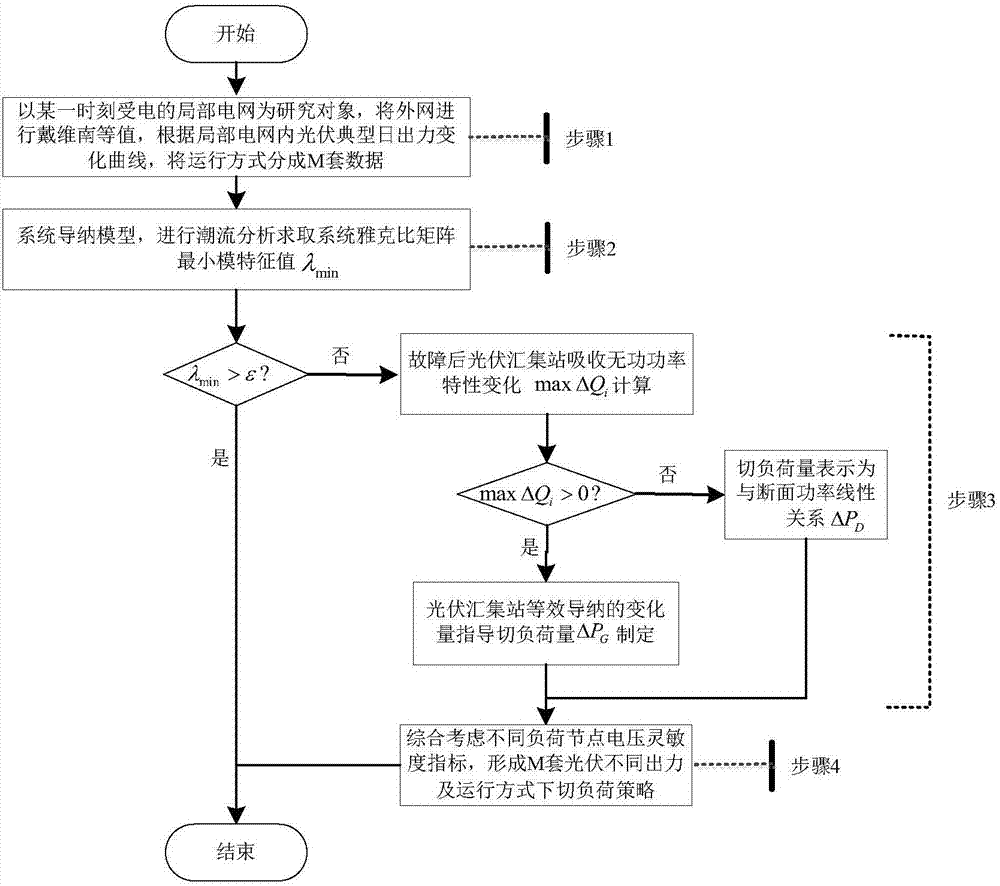

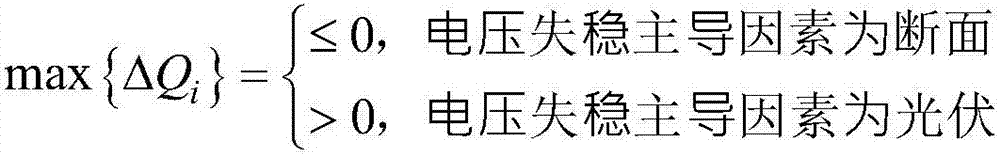

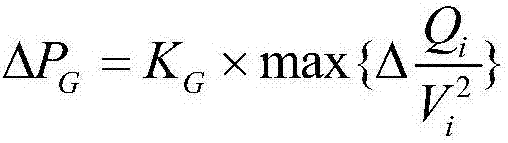

Load-shedding control method with consideration of system voltage stability after photovoltaic access

ActiveCN107359619AImprove effectivenessIncrease the level of automationPower network operation systems integrationEnergy industryPower system schedulingInstability

The invention, which belongs to the technical field of the power system and automation thereof, discloses a load-shedding control method with consideration of system voltage stability after photovoltaic access, so that the adverse influence on high-voltage grid voltage recovery after a fault by large-scale photovoltaic access to the grid is eliminated. An equivalent local grid static voltage stability index of an external network is calculated to determine a voltage instability situation; a dominant factor of voltage instability is identified based on a characteristic change of reactive power absorbing by a photovoltaic aggregation station after the fault; and then load-shedding control strategies are formulated on the condition of using a photovoltaic factor as the dominant instability factor and using a cross-section factor as the dominant instability factor, thereby realizing load-shedding control of the voltage weak node load. Therefore, the power system scheduling operation staff can obtain the inherent operation rule of the photovoltaic access system and the foundation is laid for formulating a load-shedding optimization strategy cooperatively, so that the effectiveness and automation level of secure and stable control of a large grid are improved.

Owner:NARI TECH CO LTD +2

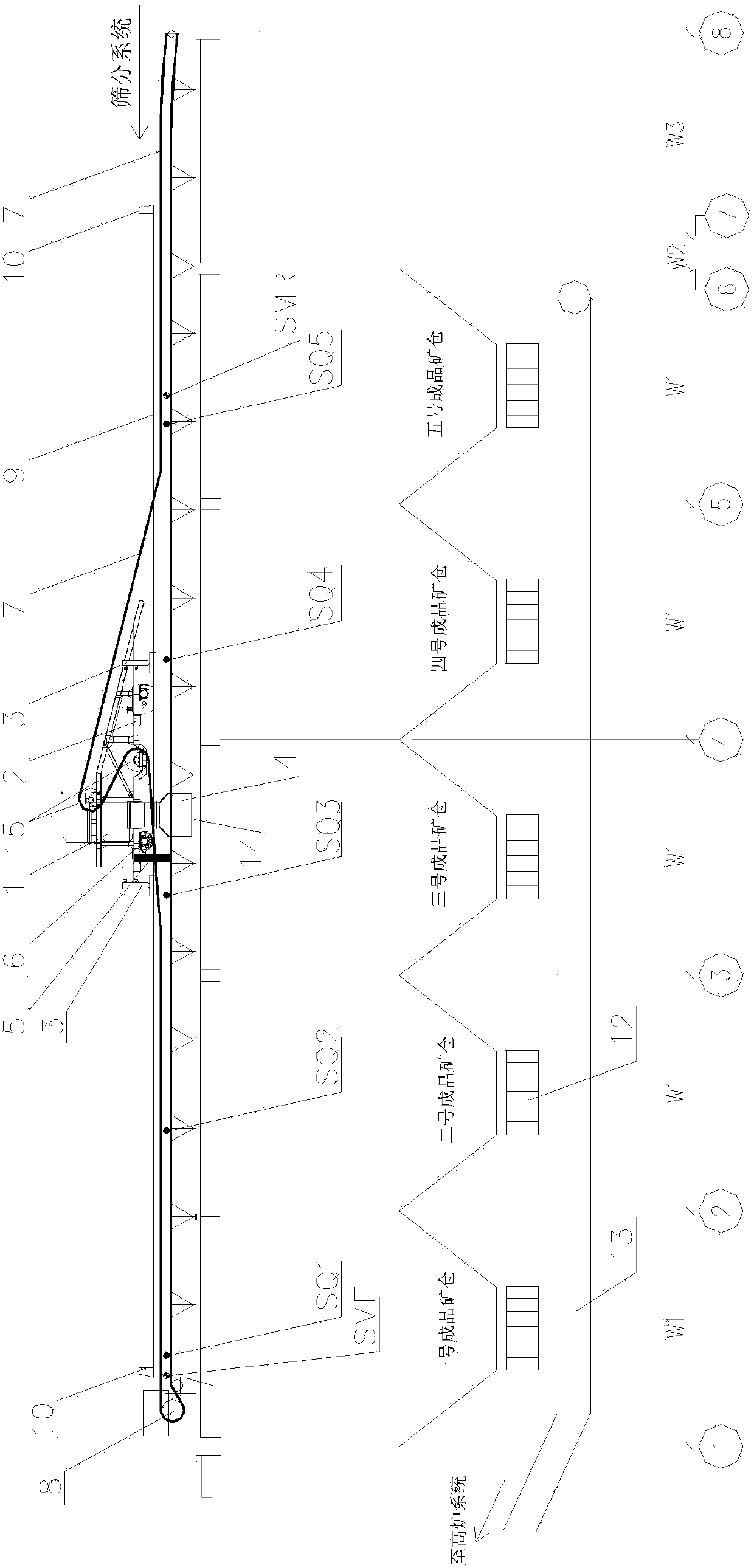

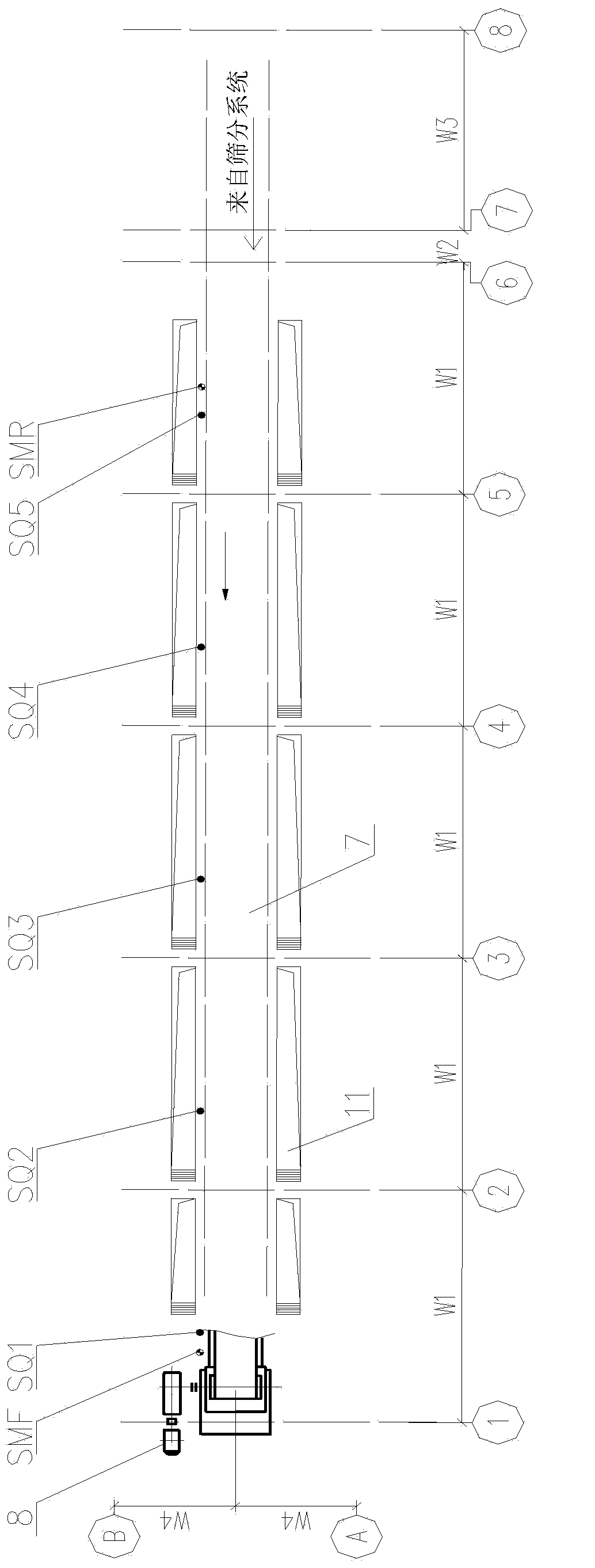

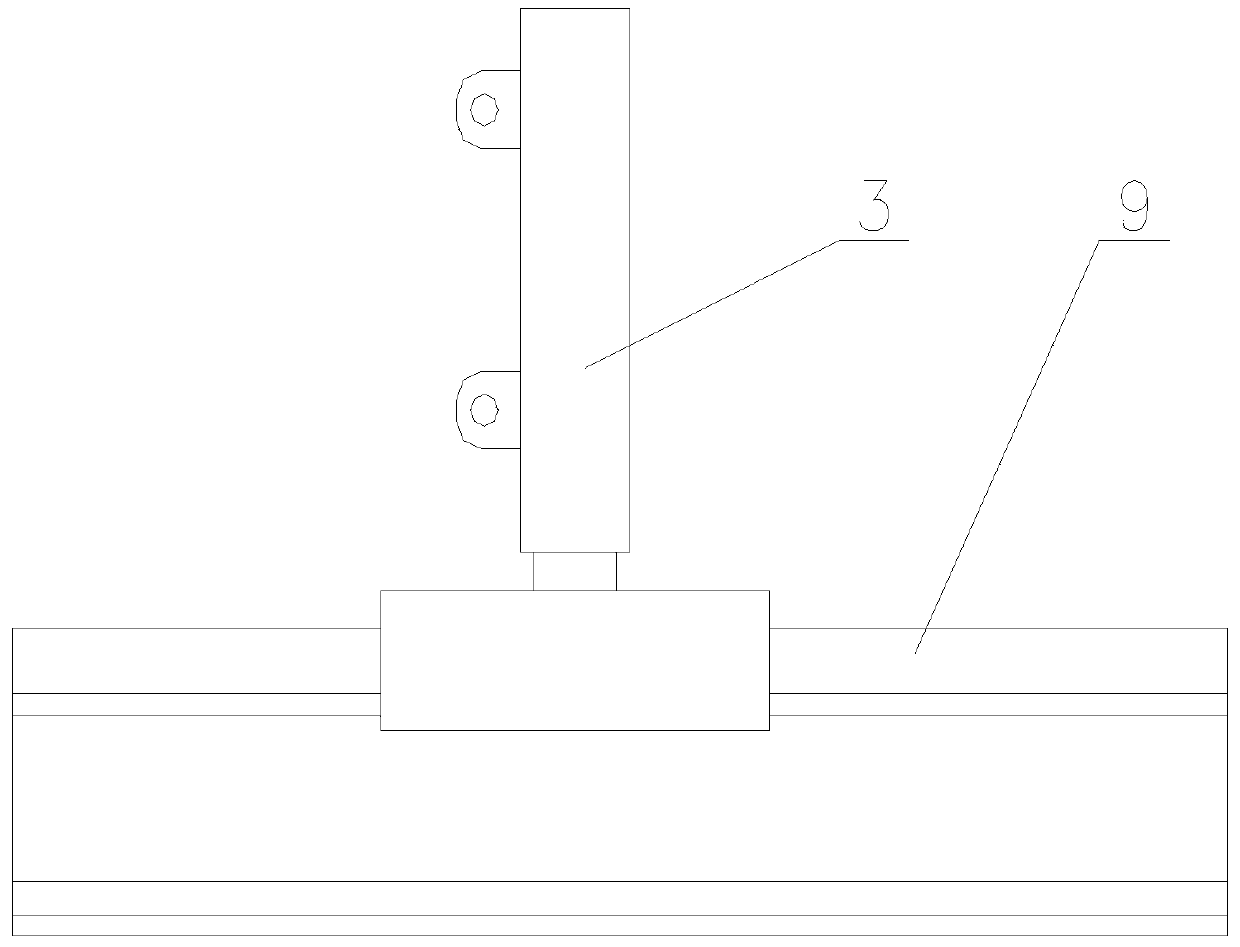

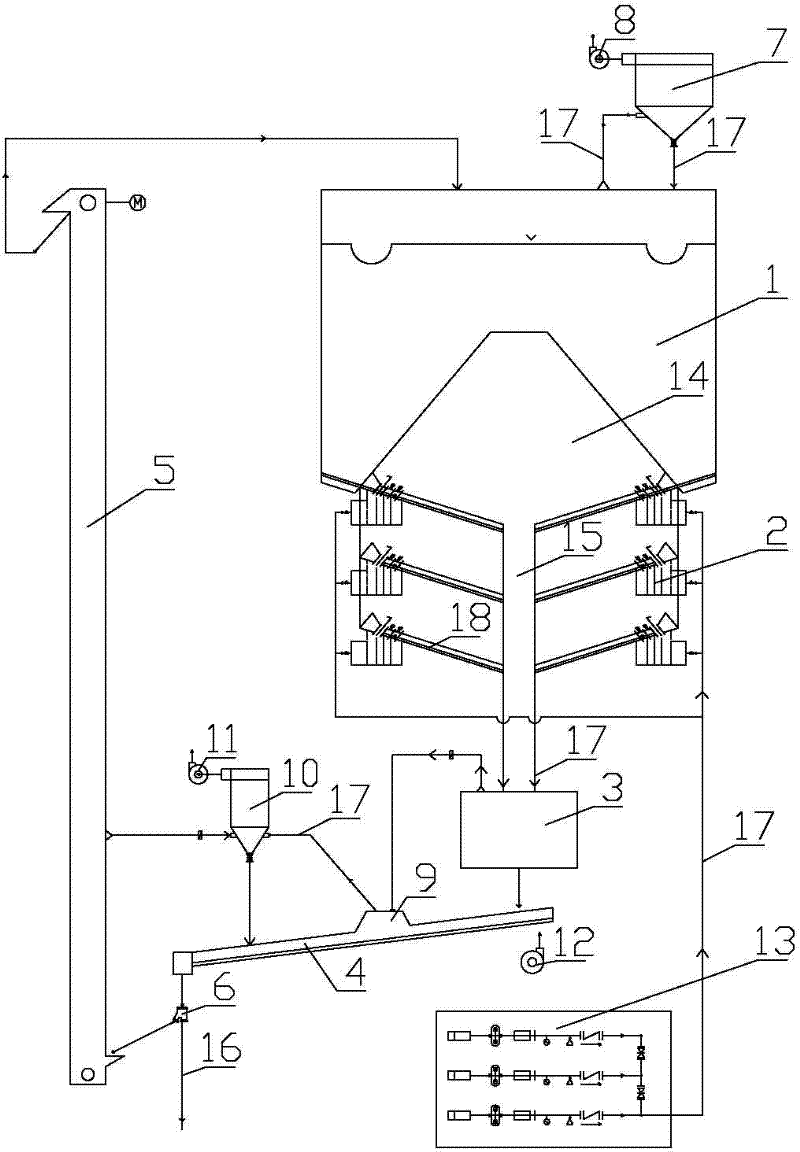

Sintered finished ore unloading system and brake

ActiveCN103693456AStop accurateAvoid unloadingLoading/unloadingTrack-braking member co-operationEngineeringElectromagnetic coil

The invention discloses a sintered finished ore unloading system which comprises a horizontal steel rail, a movable ore unloading trolley and a brake. The movable ore unloading trolley is arranged on the horizontal steel rail, and the brake comprises a mounting base, a first electromagnet, a second electromagnetic, electromagnetic coils and a brake portion; the mounting base is fixed onto the movable ore unloading trolley; the first electromagnet is fixed onto the mounting base; the second electromagnet is arranged on the mounting base and can move along the vertical direction, the first electromagnet and the second electromagnet are distributed up and down in the vertical direction, a movement gap is formed between the first electromagnet and the second electromagnet, and a compression spring which retains the movement gap is sleeved on the first electromagnet and the second electromagnet; the electromagnetic coils are wound on the first electromagnet and the second electromagnet along the same direction; the brake portion is connected with the second electromagnet and moves along the second electromagnet, so that the brake portion and the horizontal steel rail can be separated from each other or can cling to each other in a brake manner. The invention further discloses the brake. The sintered finished ore unloading system and the brake have the advantages that the movable ore unloading trolley can be effectively and accurately stopped, accordingly, unloading problems due to the fact that an existing movable ore unloading trolley cannot be stopped accurately can be solved, and production accidents due to the fact that the existing movable ore unloading trolley cannot be stopped accurately can be prevented.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Carbide slag dry power anti-blocking device and carbide slag dry power storage method

The invention relates to the technical field of carbide slag, in particular to a carbide slag dry power anti-blocking device and a carbide slag dry power storage method. The carbide slag dry power anti-blocking device comprises a carbide slag reservoir, a discharging device, a buffer bin, a sealed discharging tube and a lifter; a material baffle is fixed in the carbide slag reservoir, and the twosides of the material baffle are provided with discharging ports; a discharging tube is arranged below the carbide slag reservoir; and at least one group of discharging devices communicated with the discharging port and the discharging tube is fixedly installed at the bottom of the carbide slag reservoir through a support frame. The carbide slag dry power anti-blocking device and the carbide slagdry power storage method have the benefits that the structure is reasonable and compact, and the use is convenient; through the matching use of the discharging device, the buffer bin, the sealing discharging tube, a three-way material division valve and the lifter, the carbide slag dry power is always in a flowing state; and gas released by the carbide slag dry power and water vapor are discharged by a first dust collector motor and a second dust collector motor, so that unsmooth discharging, personnel poisoning and explosion caused by easy blocking of the dust collector motor are prevented, the production efficiency is improved, and the potential safety hazards are reduced.

Owner:新疆天山水泥有限责任公司

Self-unloading crane

The invention discloses a self-unloading crane. The self-unloading crane comprises a rack body. A lifting plate is arranged on the rack body. A self-unloading mechanism is arranged at the upper end ofthe lifting plate. A control mechanism installation platform is further arranged on the rack body and comprises a brake handle, a handle and a straight pin, wherein the handle is used for starting upa crane boom, and the straight pin is fixed to the middle of the control mechanism installation platform. The self-unloading mechanism comprises a rotary block installation base, a rotary block, a shaft sleeve assembly, a hinge pin assembly, a rotary base and a distance adjustment assembly, wherein the rotary block installation base is fixedly installed at the top end of a lifting plate, the rotary blocks is rotationally connected to the rotary block installation base, the shaft sleeve assembly is fixedly installed on the rotary block, the hinge pin assembly is used in cooperation with the rotary block, the rotary base is rotationally connected to the top end of the lifting plate, a limiting pin is arranged on the rotary base, a through hole is formed in the part, beside the limiting pin,of the rotary base, a rotary block reset spring is further arranged on the rotary block installation base, and a positioning hole is formed in the rotary block. The self-unloading crane is reasonablein design, convenient to operate for hoisting, and wide in application range.

Owner:赣榆区海头镇钦法电动车销售门市

Compression pipe fitting with wide range grip rings

ActiveUS11015748B2Easy to bendAvoid unloadingJoints with sealing surfacesPipe fittingClassical mechanics

Compression fittings for pipes having a range of diameters, including a support body with a central section between end sections, the central section having a smaller diameter than the end sections, with a transition surface between the central section and each end section. A gasket fits over a pipe and engages one of the support body end section end surfaces. A fitting nut is movable axially over the support body to draw the support body and the gasket together in the axial direction and bias the gasket radially inward against the pipe. A grip ring encircles the pipe at one gasket end and has a surface engaging the fitting nut whereby the fitting nut biases the grip ring radially inwardly toward the pipe. An insert adapter has a hub with a radially extending flange may block the other gasket end to load the gasket between its axial ends.

Owner:A Y MCDONALD MFG CO

Automatic slitting and winding device for fiberglass gridding cloth

InactiveCN113879889AAvoid unloadingReduce work intensitySevering textilesWebs handlingElectric machineryStructural engineering

Owner:沛县红成装饰材料有限公司

Material smashing and stirring device with abnormal smell treatment function based on organic fertilizer processing

ActiveCN110280353AAvoid odorAvoid interferenceDispersed particle separationGrain treatmentsEngineeringOrganic fertilizer

The invention discloses a material smashing and stirring device with an abnormal smell treatment function based on organic fertilizer processing. Before materials are smashed, a tank body is firstly subjected to gas exhaust through a gas exhaust pump, so that certain negative pressure is conveniently formed in the tank body relative to an external environment, then the materials in the tank body are smashed under the negative pressure, thus, the abnormal smell in the tank body can be effectively prevented from being exhausted, even when the tank body has tiny sealing problems, gas can come in and cannot be exhausted, thus, the internal gas is centralized after following smashing is completed, and interference in the external environment is avoided. The smashing efficiency of smashing mechanisms is high, the materials are sequentially smashed from top to bottom, the diameters of smashing blades of the upper smashing mechanism are gradually reduced from top to bottom, the internal materials can be effectively smashed sequentially, by means of lower auxiliary smashing blades on the lower portion, the materials can be rapidly smashed, and the smashing efficiency is effectively improved.

Owner:ANHUI SCI & TECH UNIV

Hydraulic lifting vehicle fixing device

ActiveCN103496600APrevent leakageImprove unloading safetyLifting framesLoading/unloadingMarine engineeringPiston rod

The invention provides a hydraulic lifting vehicle fixing device comprising a foundation platform and a lifting platform. The bottom of the lifting platform is provided with a supporting barrel, a lower sliding groove is arranged in the foundation platform, the lower portion of the supporting barrel is in clearance fit with the lower sliding groove, a hydraulic oil cylinder is arranged inside the supporting barrel, the cylinder body of the hydraulic oil cylinder is fixedly connected with the foundation platform, and a piston rod of the hydraulic oil cylinder is fixedly connected with the supporting barrel. The hydraulic lifting vehicle fixing device is firm and reliable in fixation and good in safety performance; the lifting height of the lifting platform can be adjusted within a certain range at will, and then unloading requirements of vehicles of various types can be met; materials are prevented from leaking out of the two sides of the lifting platform in the unloading process; when unloading is incomplete, a vibration motor can be started, manual unloading is avoided, and safety of unloading of the vehicles is improved.

Owner:JIUQUAN OK SEED MACHINERY

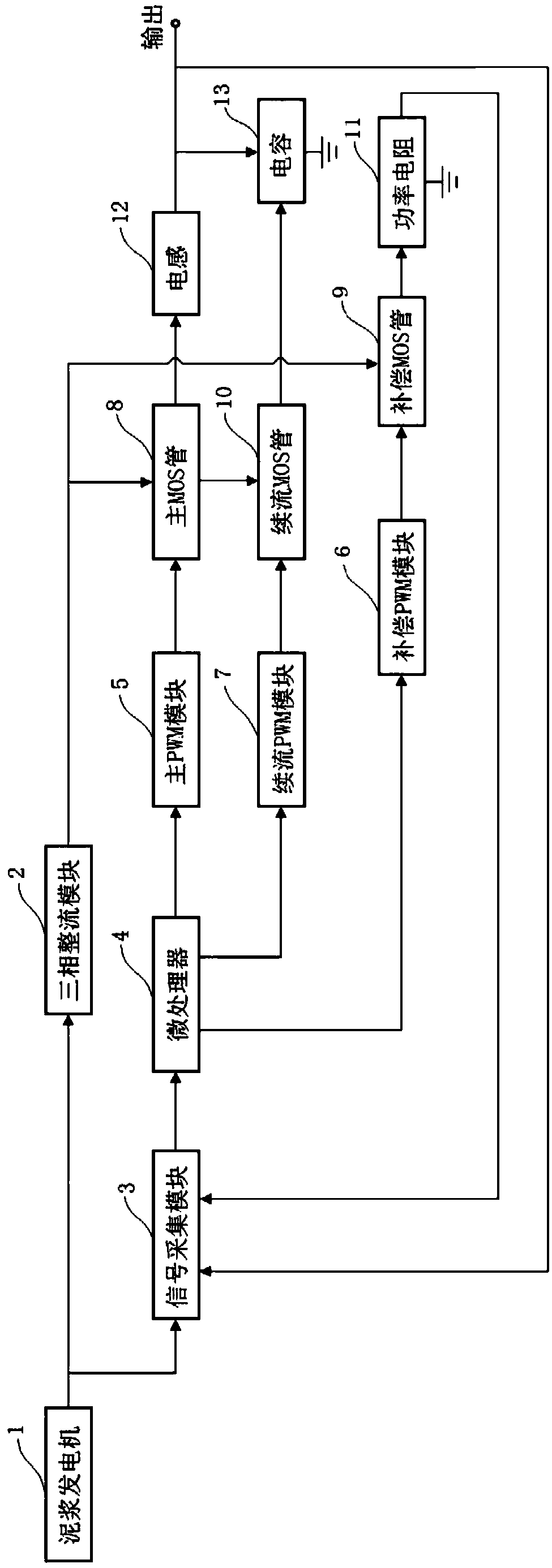

A downhole digital power supply system

PendingCN109256993AIncreased dynamic loadReduce speedElectric generator controlElectricityVoltage amplitude

The invention provides a downhole digital power supply system including a mud generator and a rectifying module connected to the output end of a mud generator. The rectifying module converts the induced alternating current generated by the mud generator into rectified current and outputs the rectified current. The rectifying module also includes a compensating fluctuation switch which conducts when the voltage amplitude of the induced alternating current output by the mud generator exceeds a preset range. A power load is connected to an output end of the rectifier module via a compensating fluctuation switch to be turned on. When the rotor and turbine blades of the mud generator are out of sync, the voltage amplitude of the induced alternating current output from the mud generator is not within the preset voltage amplitude range, At this time, that compensate fluctuation switch is turned on, so that the rectify electricity output by the rectifier module is connected into the power load, and at this time, the dynamic load of the mud generator instantaneously increases the rotational speed of the rotor is instantaneously reduced, the rotor tends to be stable, and then the turbine blades drive the rotor to increase the rotational speed through magnetic coupling, and in this process, the turbine blades and the rotor tend to be synchronous.

Owner:GUANGDONG PULUO MEASUREMENT & CONTROL TECH

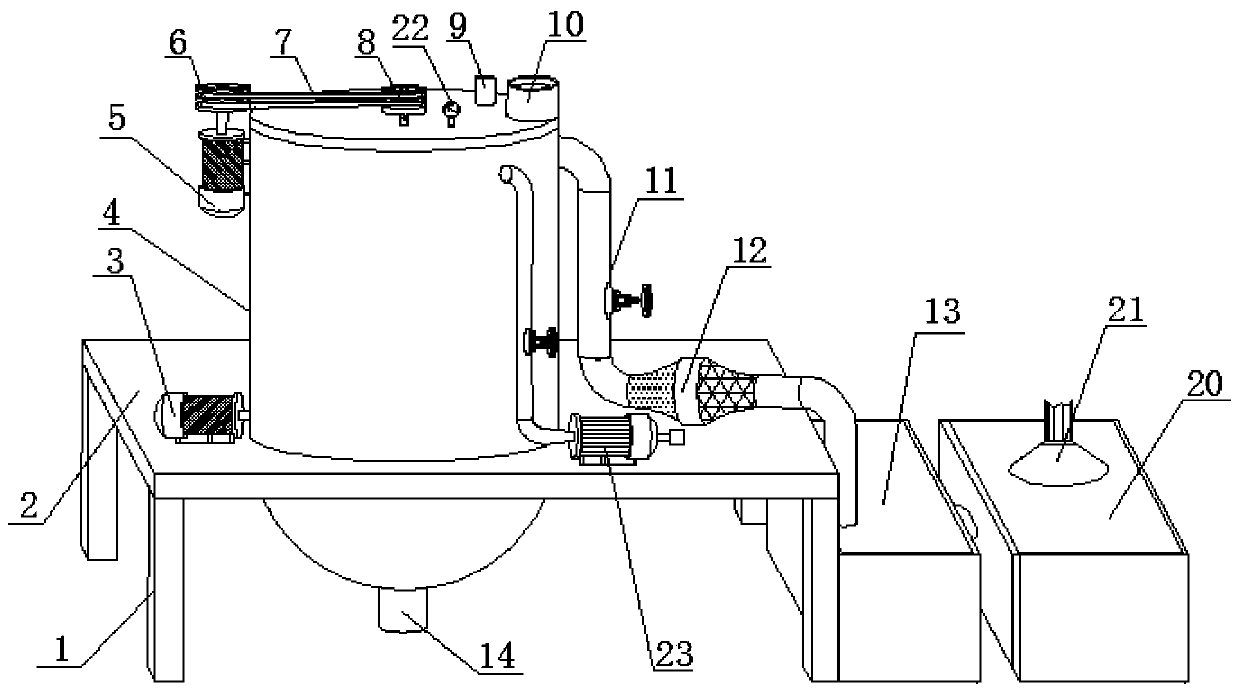

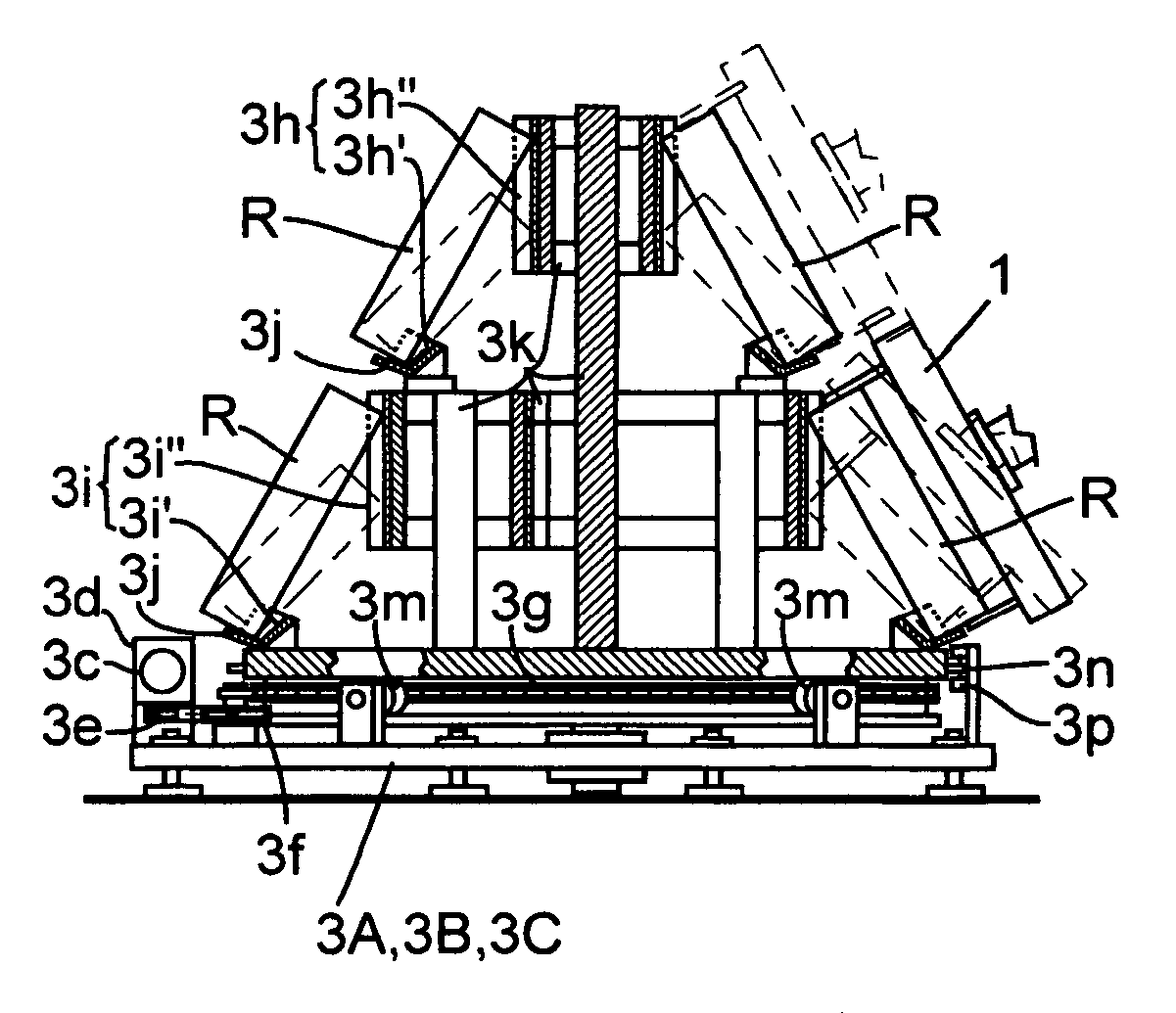

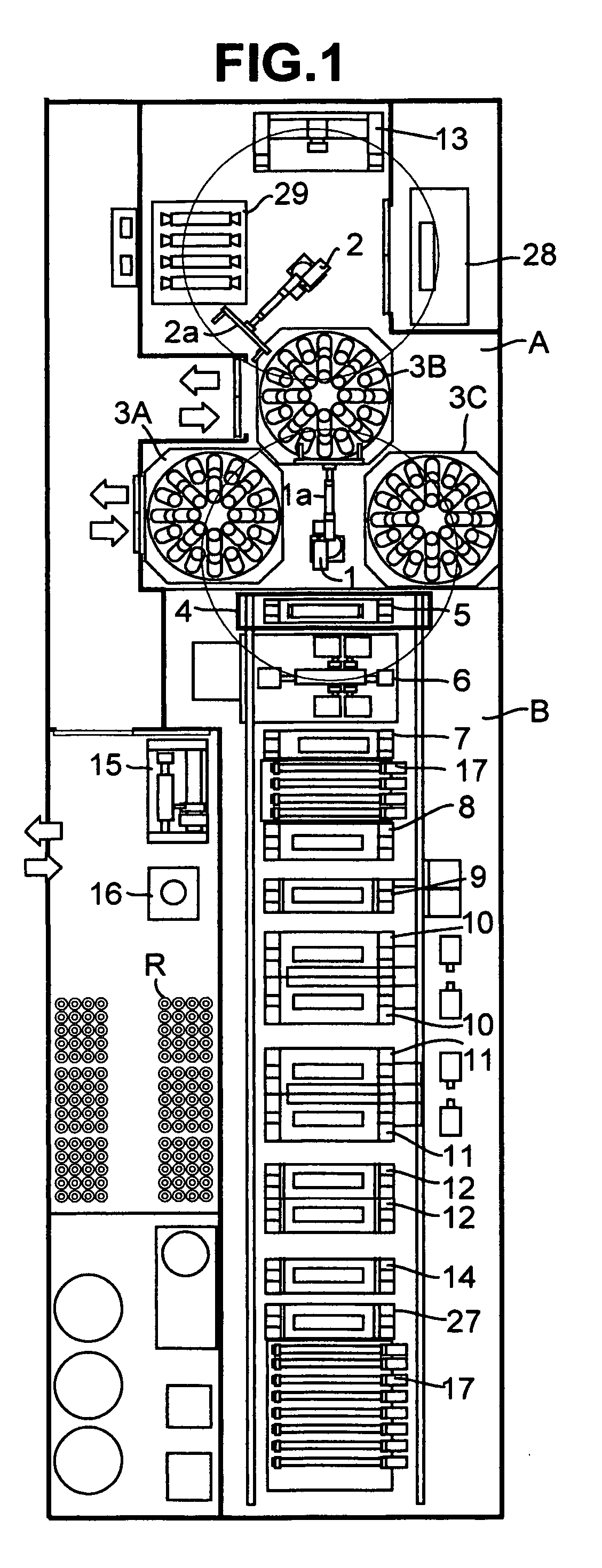

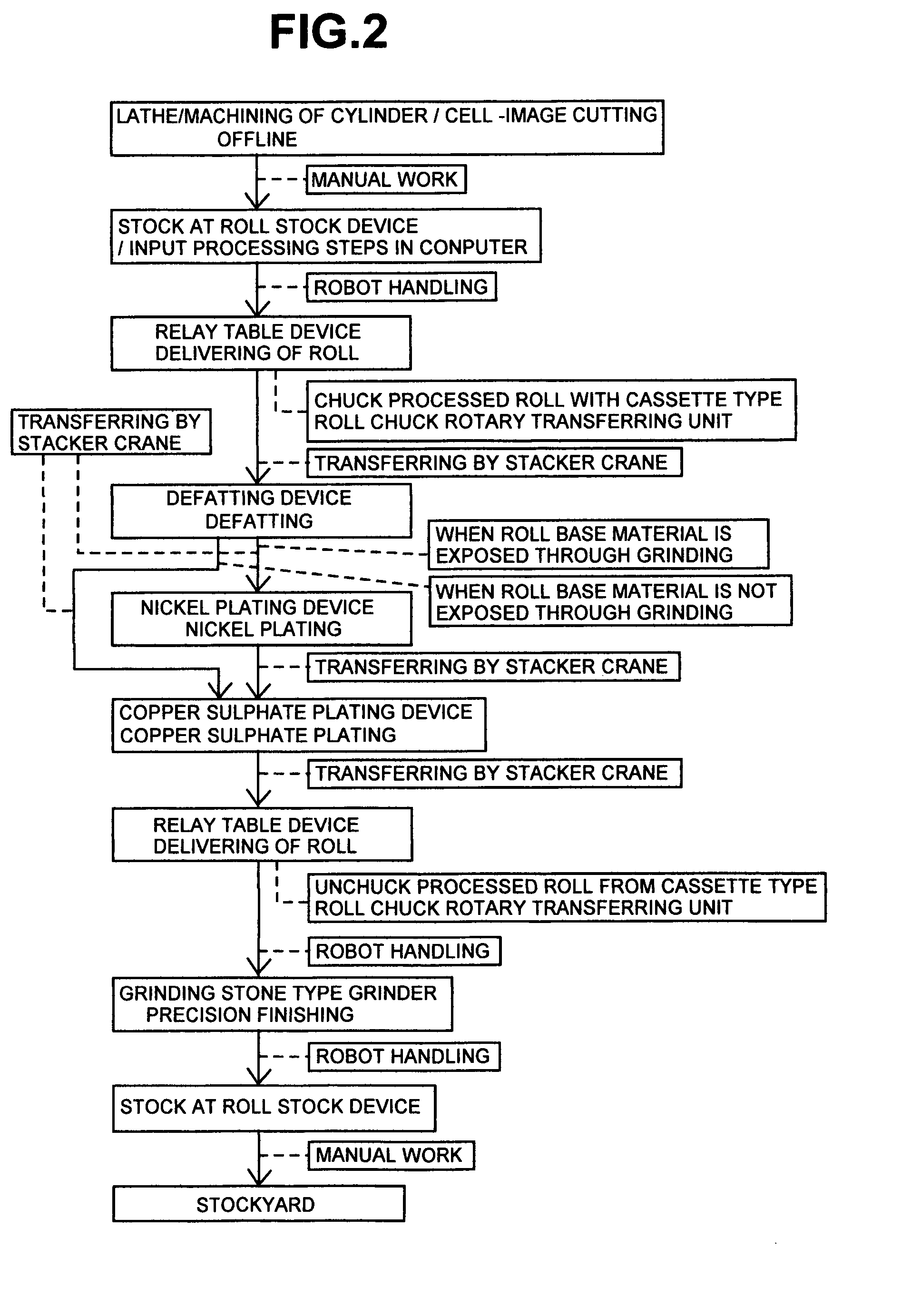

Turn-table type roll stock apparatus and plating factory for process roll for gravure printing

ActiveUS7194791B2Delivered in a short tactConveniently realizedTurning machine accessoriesPlate printingEngineeringPallet

There are provided a plating factory for process roll for a gravure printing and a turn-table type roll stock apparatus preferable to the gravure printing plate manufacturing factory where a series of plating steps can be performed against the process roll for the gravure printing in an unmanned state at night in a full-automatic operation and the cell can be formed. Many process rolls can be stood obliquely in a circumferential arrangement in one stage or two stages at a roll pallet in such a way that a longitudinal direction of the process rolls may coincide with a generatrix at a conical surface and an optional roll pallet can be stopped at a predetermined position so as to store or take out the process rolls in respect to the roll pallet.

Owner:THINK LABORATORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com