Novel zinc oxide desulfurization method and device

A desulfurization equipment and zinc oxide technology, applied in the field of desulfurization, can solve the problems of difficulty in recycling, low concentration of by-products, unstable absorption rate of zinc oxide desulfurization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

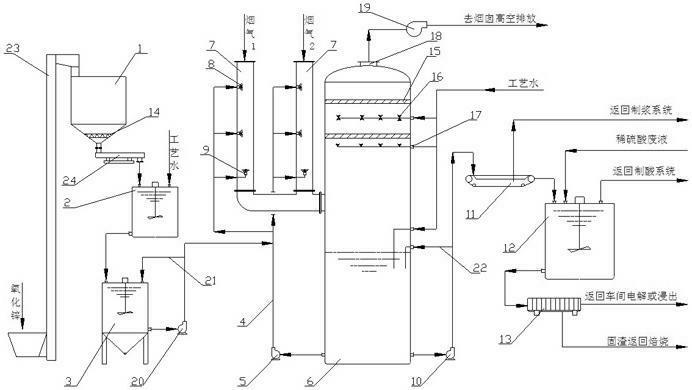

[0033] Embodiment: a kind of novel zinc oxide desulfurization method of this example, its step is:

[0034] a. The zinc oxide powder is transported to the high-level silo 1 through the elevator 23, and the zinc oxide powder in the high-level silo is transported to the screw conveyor 24 through air vibration or scraping and stirring, and then transported to the slurry mixing tank by the screw conveyor In 2, process water is added into the slurry mixing tank to form a zinc oxide slurry, the concentration of the zinc oxide slurry is 20%, and the zinc oxide slurry that has been mixed enters the slurry storage tank 3 for storage;

[0035] b. The zinc oxide slurry in the slurry storage tank is directly pumped by the slurry pump 20 into the circulation pipeline 4 connected with the washing tower 6, the zinc oxide slurry enters the washing pipe 7 from the circulation pipeline, and the upper part of the washing pipe is passed into the fume to be treated. Gas, zinc oxide slurry 90o si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com