Carbide slag dry power anti-blocking device and carbide slag dry power storage method

A technology of slag dry powder and calcium carbide slag, which is applied in the field of calcium carbide slag dry powder anti-blocking devices, can solve the problems of affecting subsequent production, easy agglomeration of carbide slag, and poor discharge, so as to improve production efficiency, prevent unsmooth discharge, The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

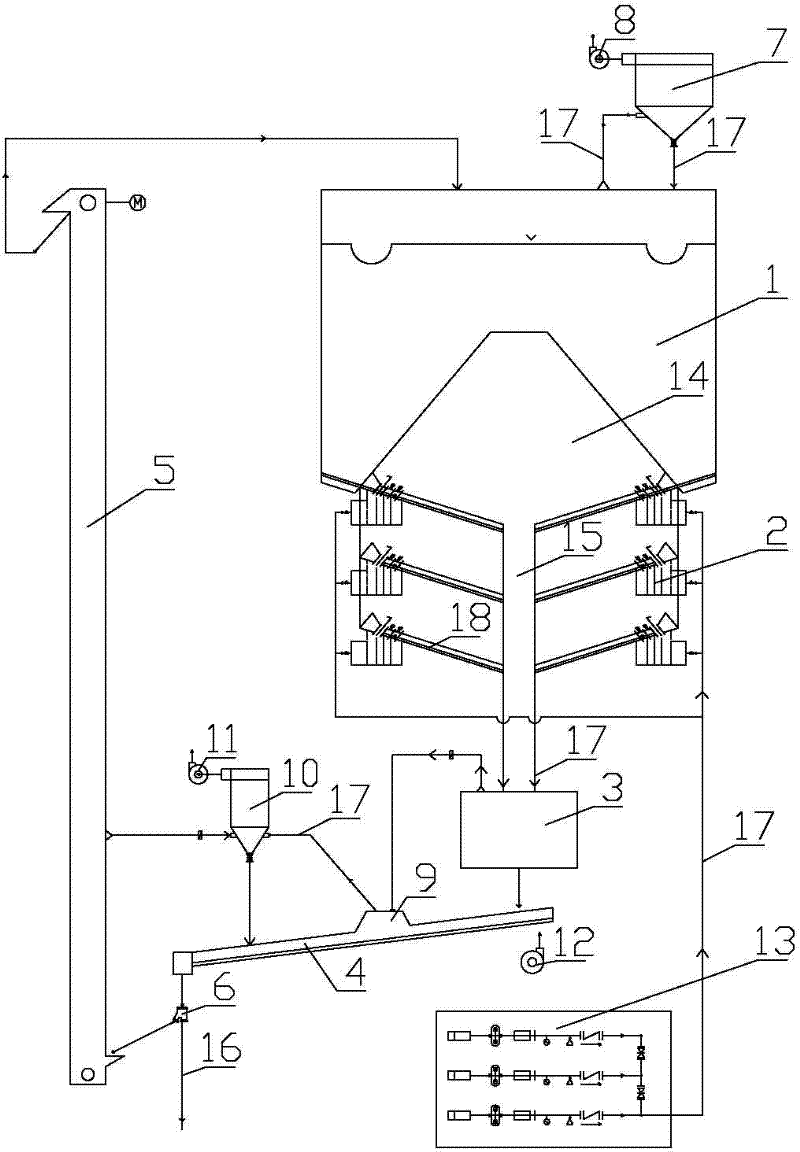

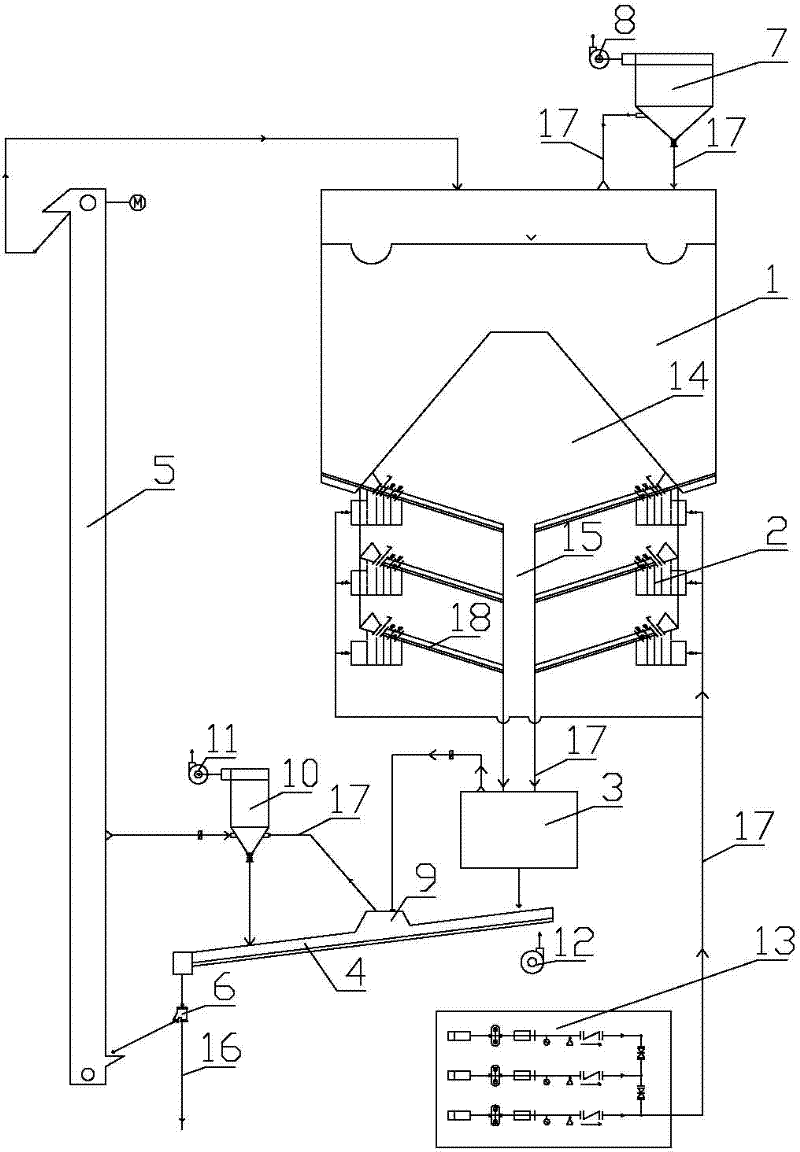

[0020] Embodiment 1: as attached figure 1 As shown, the calcium carbide slag dry powder anti-blocking device includes a calcium carbide slag storage storehouse 1, a discharge device 2, a buffer bin 3, a sealed discharge barrel 4, and an elevator 5; There are outlets on both sides of the retaining plate 14, a lower end of the calcium carbide slag storage 1 is fixed with a feeding pipe 15, and at least one group is fixedly installed below the carbide slag storage 1 through a bracket to connect with the discharge outlet and the carbide slag storage 1 respectively. The unloading device 2 connected with the feeding pipe 15 is fixedly installed with a buffer bin 3 connected with the feeding pipe 15 through a bracket at the lower end of the feeding pipe 15, and a sealed discharge cylinder 4 is fixedly installed under the buffer bin 3 through a bracket. , the discharge port of the buffer bin 3 is connected with the feed port of the sealed discharge cylinder 4 through the pipeline 17, ...

Embodiment 2

[0026] Embodiment 2: The method for storing calcium carbide slag dry powder using the above-mentioned calcium carbide slag dry powder anti-blocking device is carried out according to the following steps:

[0027] (1) Carbide slag powder is imported from the outside to the carbide slag storage 1 through the conveying device. At this time, the gas and water vapor released by the carbide slag powder in the carbide slag storage 1 are collected in the dust collector on the top of the silo through the pipeline. 7, and extracted through the first dust collector motor 8.

[0028] (2) The calcium carbide slag powder in the calcium carbide slag storage 1 leaks into the buffer bin 3 through the unloading device 2, and the carbide slag powder in the buffer bin 3 passes through the third part of the sealed discharge cylinder 4 and the three-way distribution valve 6. end enters the next process of carbide slag utilization; when the next process of carbide slag utilization fails, the carbide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com