Self-unloading crane

A crane and self-unloading technology, which is applied in the direction of hoisting device, lifting frame, etc., can solve the problems of high cost, uneconomical crane, low manufacturing cost of lifting equipment, etc., and achieve the effect of convenient use and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

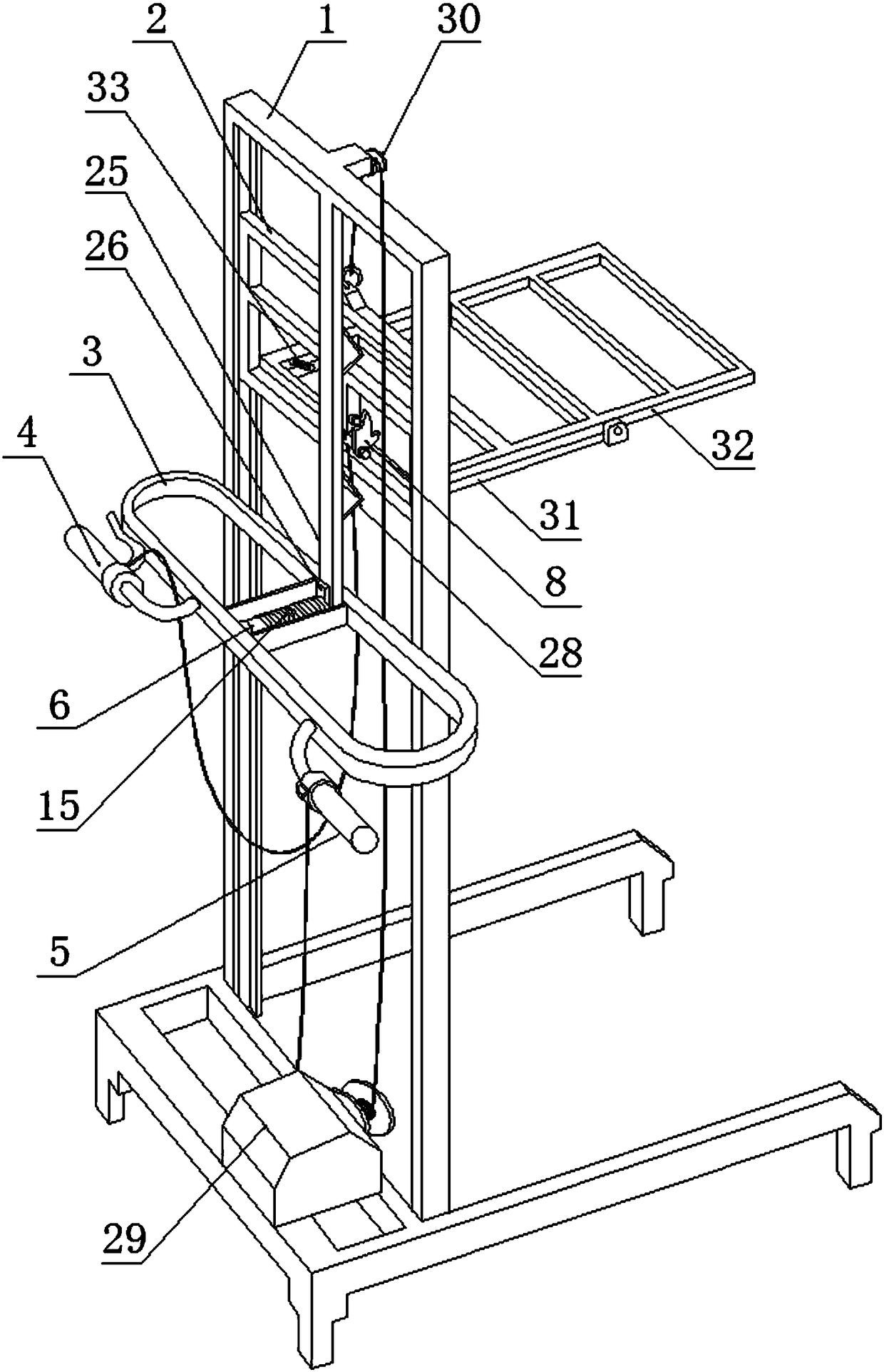

[0024] Example 1, reference figure 1 —3. A self-unloading crane, comprising a frame body 1, a lifting plate 2 is provided on the frame body 1, a dump mechanism is provided on the top of the lifting plate 2, and the frame body 1 is also provided There is a control mechanism mounting platform 3; the control mechanism mounting platform 3 includes a brake handle 4, a handle 5 for starting the lifting frame, and a cylindrical pin 6 fixed in the middle of the control mechanism mounting platform 3;

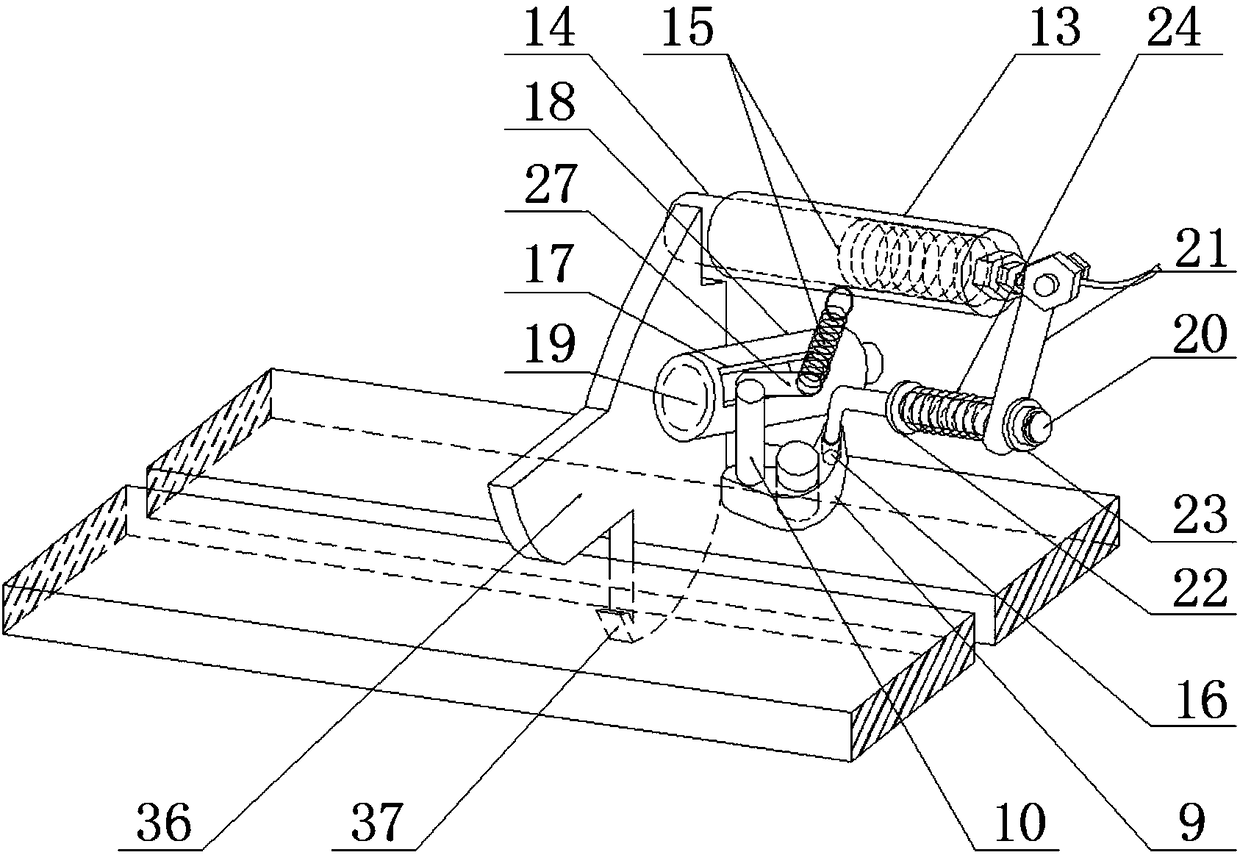

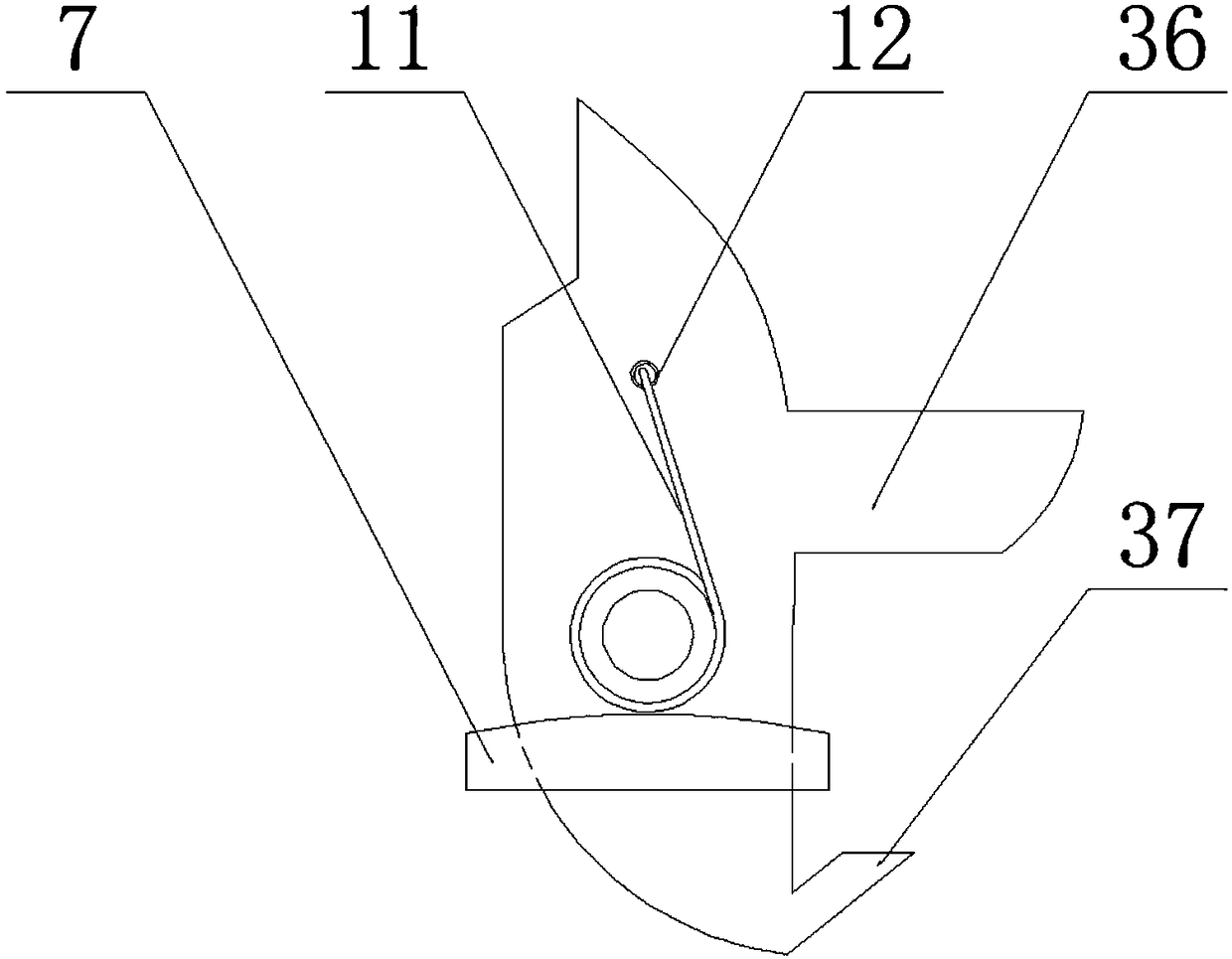

[0025] The self-unloading mechanism includes a rotating block mounting seat 7 fixedly mounted on the top of the aforementioned lifting plate 2, a rotating block 8 rotatably connected to the rotating block mounting seat 7, a shaft sleeve assembly fixedly mounted on the rotating block 8, and the aforementioned The pin shaft assembly used in conjunction with the rotating block 8, the rotating seat 9 and the pitch-adjusting assembly rotatably connected to the top end of the lifting plate 2; the ...

Embodiment 2

[0033] In the second embodiment, in the dump crane described in the first embodiment, the elastic element 15 adopts a compression spring.

Embodiment 3

[0034] In Embodiment 3, in the dump crane described in Embodiment 1, the rotating block return spring 11 is a torsion spring. After the rotating block 8 rotates, the resetting action can be realized by the rotating block return spring 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com