Load equipment of tunnel lining structural mechanics property simulation test device

A technology of structural mechanics and simulation test, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., to achieve the effect of convenient operation, meeting the test requirements, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

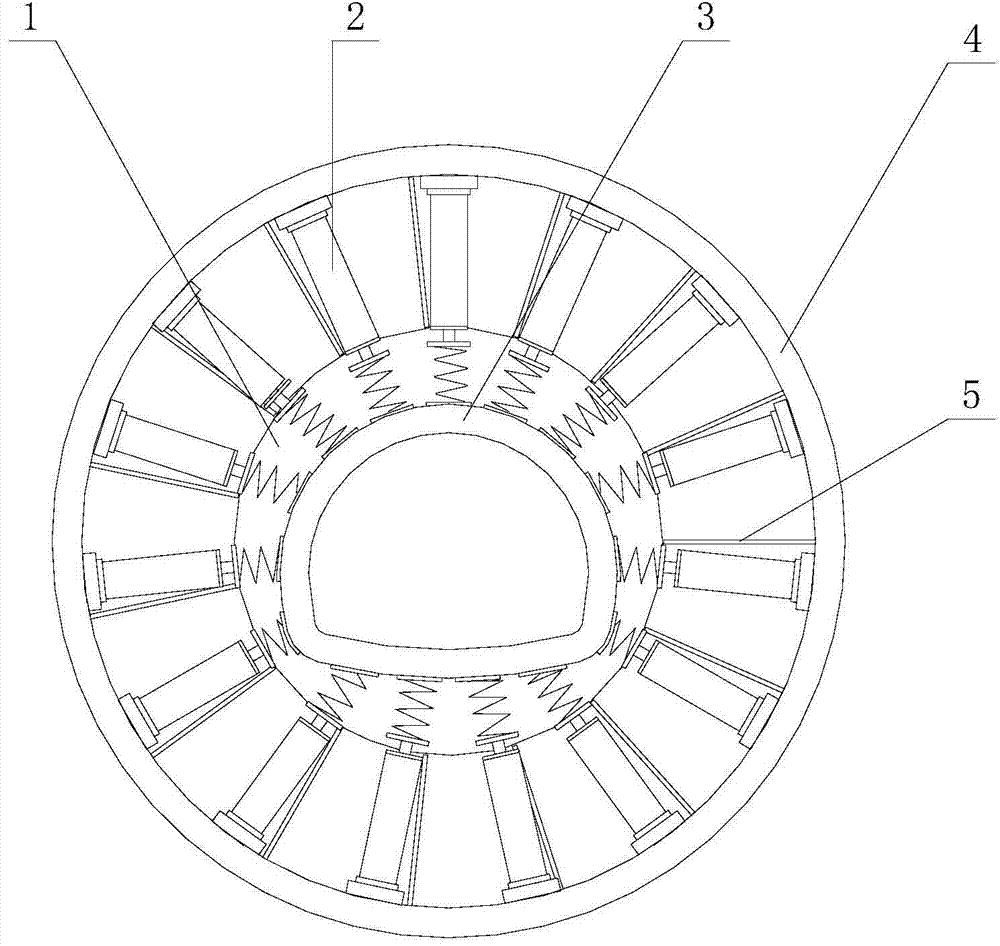

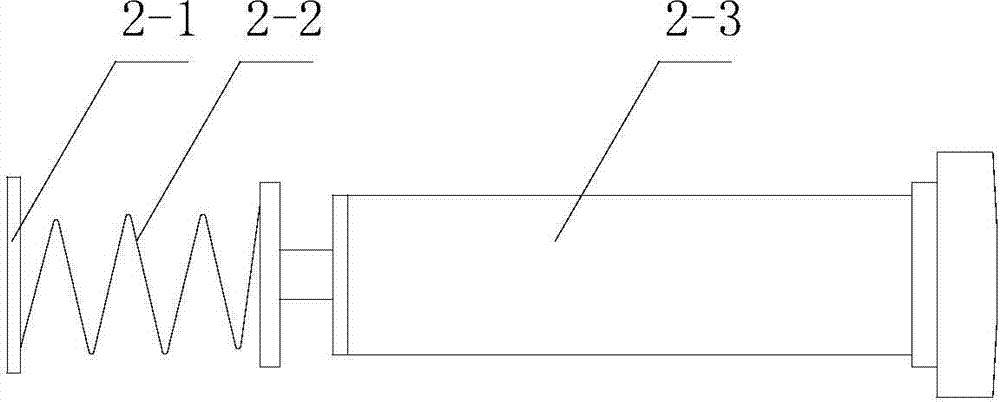

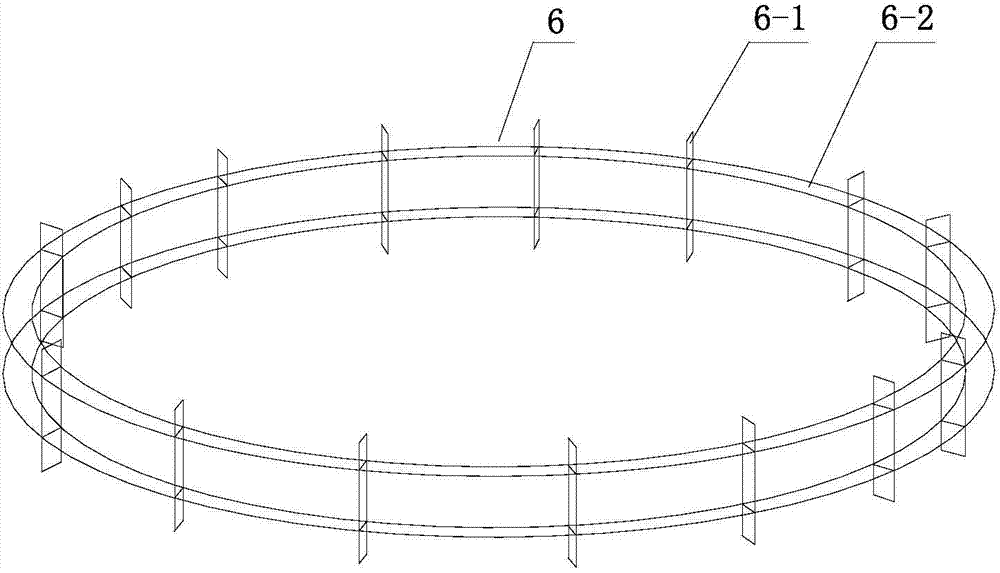

[0018] Such as figure 1 As shown, the loading equipment of the tunnel lining structure mechanical properties simulation test device in this embodiment is composed of a displacement limiting panel 1, a peripheral baffle plate 4, a gasket 2-1, a spring 2-2, a hydraulic jack 2-3, and a connecting support 5 1. The reinforcement steel ring 6-2 and the reinforcement rib 6-1 are connected to form.

[0019] The displacement limiting panel 1 of the present embodiment is a circular steel plate with a diameter of 150 cm and a thickness of 3 cm. A limiting groove is processed on the upper surface of the displacement limiting panel 1. The groove depth of the limiting groove is 3 cm, and the groove width is 6 cm. The shape is the same as the cross-sectional shape of the road tunnel lining 3, that is, the outline of the road tunnel lining 3, which can fix the road tunnel lining 3 in the limit groove, restricting the displacement of the bottom end of the tunnel lining 3 under the surrounding ...

Embodiment 2

[0028]The displacement limiting panel 1 of the present embodiment is a circular steel plate with a diameter of 150 cm and a thickness of 3 cm. A limiting groove is processed on the upper surface of the displacement limiting panel 1. The depth of the limiting groove is 4 cm, and the groove width is 6 cm. The shape is the same as the cross-sectional shape of the railway tunnel lining 3, that is, the outline of the railway tunnel lining 3, which can fix the railway tunnel lining 3 in the limit groove and limit the displacement of the bottom end of the railway tunnel lining 3 under the peripheral force. The edge of the displacement limiting panel 1 is fixedly installed with connecting supports 5 with threaded fasteners. The connecting supports 5 are arranged along the radial direction of the tunnel lining 3 and evenly distributed on the same circumference. The other end of the connecting supports 5 is fixed at the displacement The bottom edge of the peripheral baffle plate 4 on the...

Embodiment 3

[0031] In this embodiment, 18 steel spacers 2-1 are bonded with superglue on the outer wall of the tunnel lining 3, and a cylindrical protrusion is processed at the center of each spacer 2-1. The upper cover is equipped with a high-hardness stainless steel spring 2-2, and the spring 2-2 extends in the normal direction along the outer surface of the railway tunnel lining 3, and the other end of the spring 2-2 is connected with a hydraulic jack 2-3 through a connecting piece. The hydraulic jack 2-3 is also arranged along the normal direction of the outer surface of the railway tunnel lining 3, and the contact area between the gasket 2-1 and the lining is 3.5 times the area of the head of the jack. The cylinder barrel of the hydraulic jack 2-3 is fixedly installed on the inner wall of the peripheral baffle plate 4 through the connecting piece. The peripheral baffle plate 4 of the present embodiment is a ring plate with an inner diameter of 180cm, and its height is 1.5cm. The hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com