Separated roll-up device for plastic bags

A technology of a winding device and a plastic bag, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of difficulty in completion, low production efficiency, and large time consumption, and achieves easy manufacturing, time saving, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

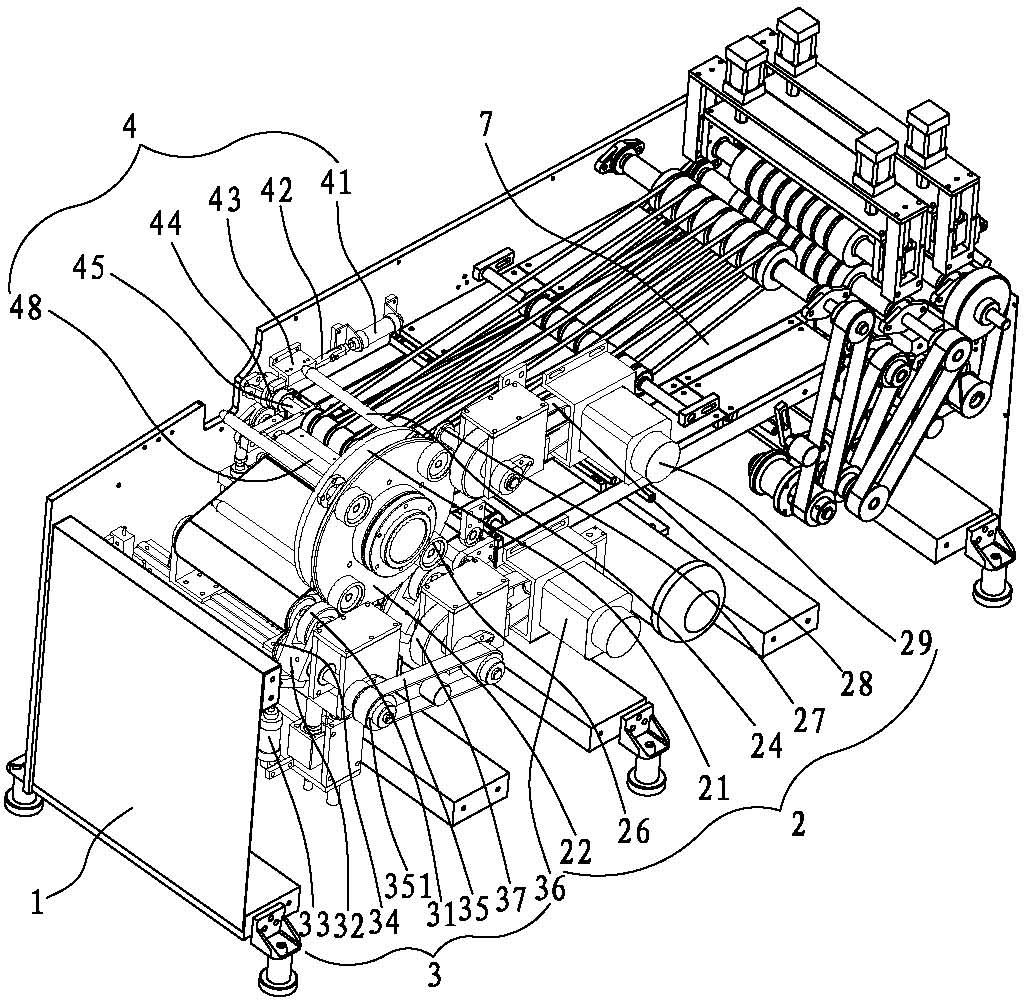

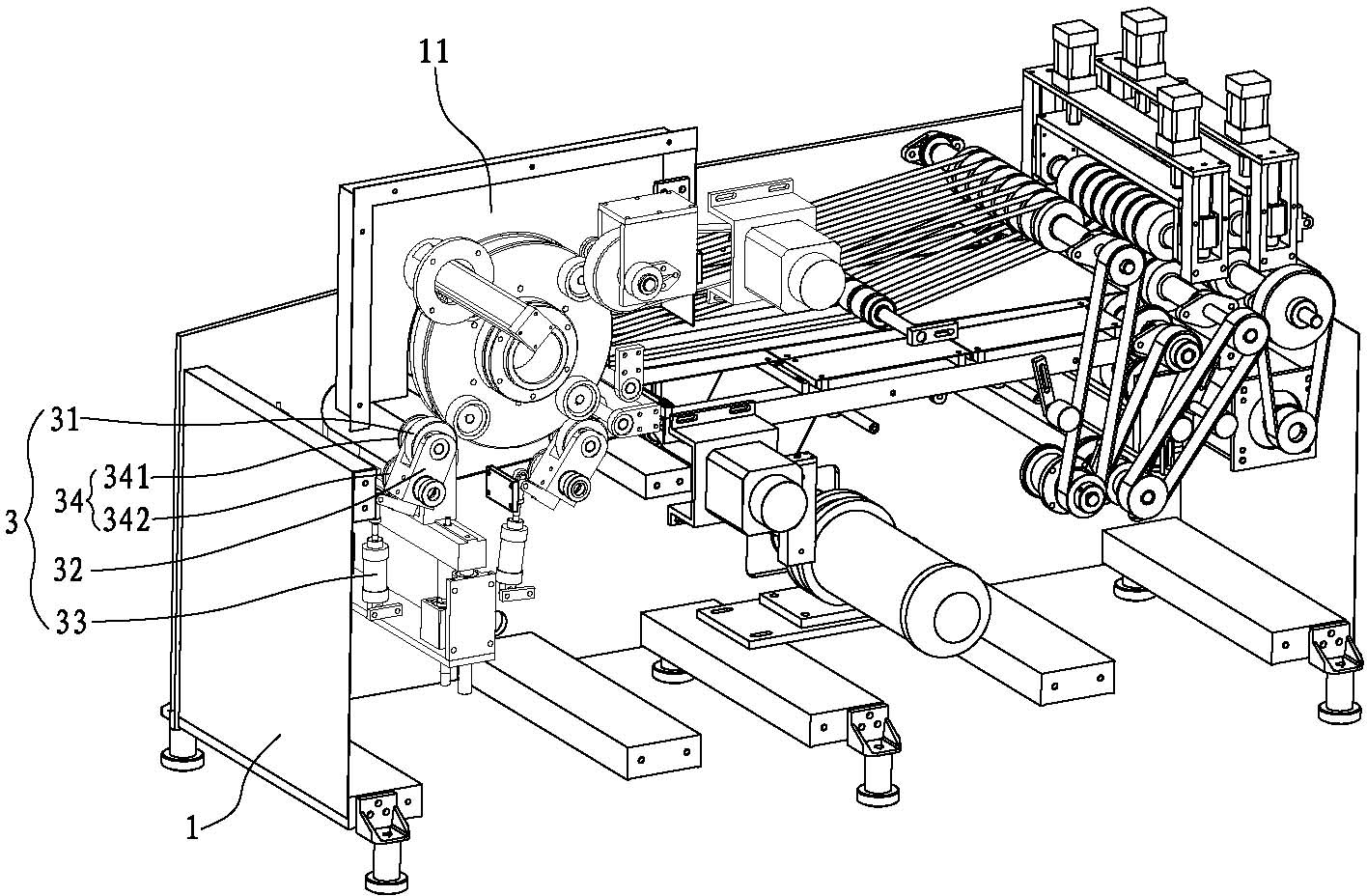

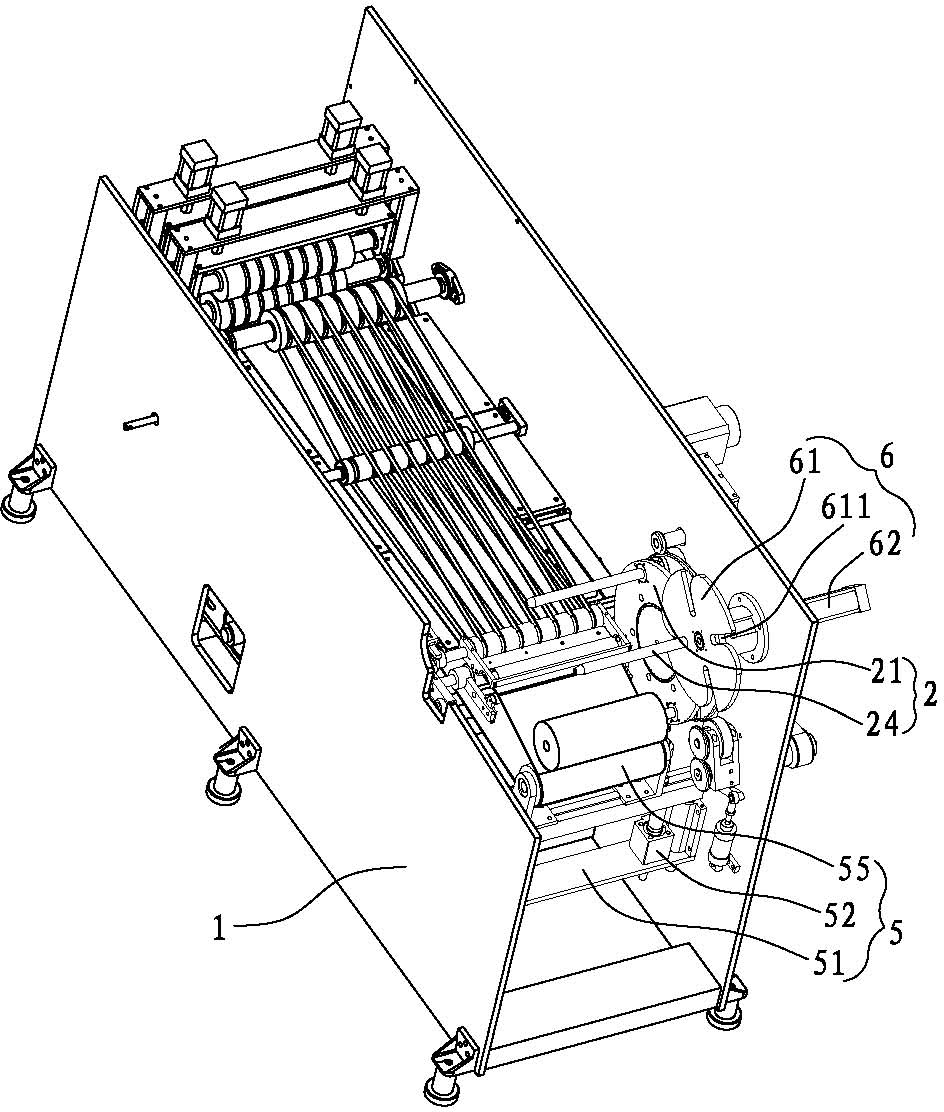

[0030] Such as figure 1 , image 3 As shown, the present invention is a splitting and rolling device for plastic bags, which mainly consists of a frame 1, a four-position turntable device 2, a winding drive device 3, a winding conversion device 4, a top roller device 5, and a position turntable The organization consists of 6.

[0031] Such as figure 1 , Figure 4 , Figure 5 As shown, the four-position turntable device 2 includes a rotatable device mounted on the frame 1, which is mainly composed of a turntable 21, a gear plate 22, a gear sleeve 23, four winding shafts 24, a positioning flange 25, a friction collection Scroll wheel 26, indexing gear 27, synchronous pulley group 28, indexing motor 29. The turntable 21 and the gear plate 22 are stacked together at intervals through the gear sleeve 23, the gear sleeve 23 is sleeved on the positioning flange 25 through the bearing 231, and the positioning flange 25 is installed on the side plate 11 of the frame 1 The four wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com