Feeder capable of reversely conveying materials, dropping materials from inclined side, reducing interferences and dynamically weighing and metering

A technology of dynamic weighing and reverse blanking, which is applied in the electromechanical field and can solve problems such as belt breakage, large impact force, and large expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

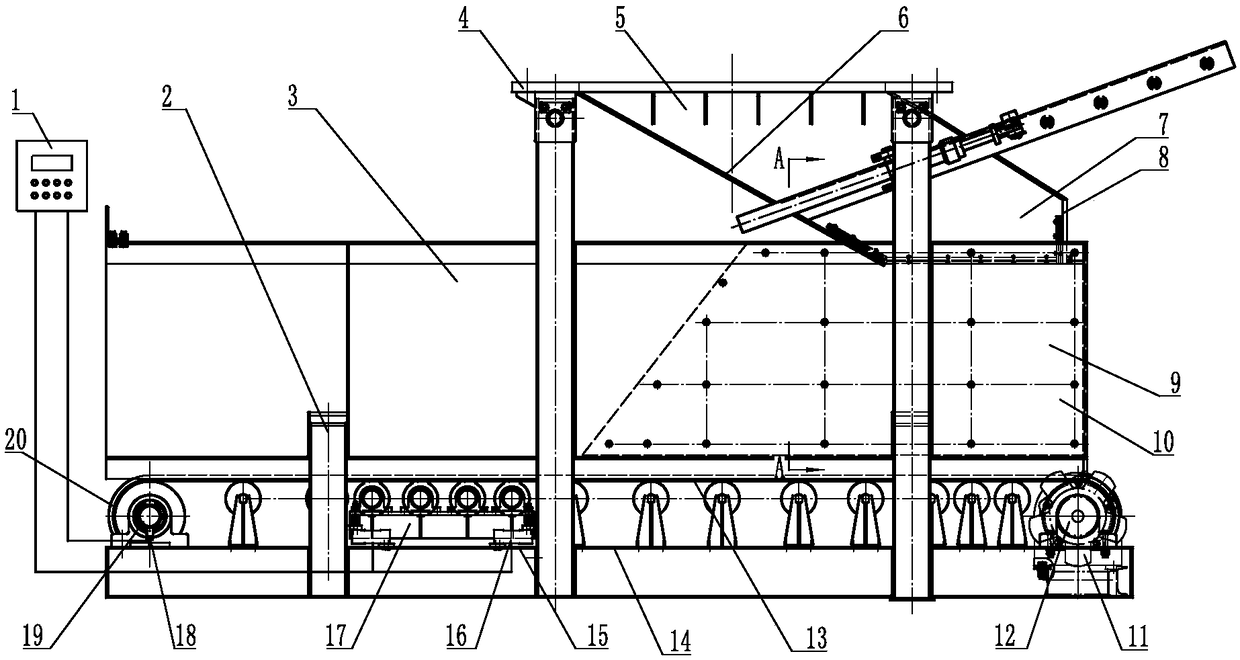

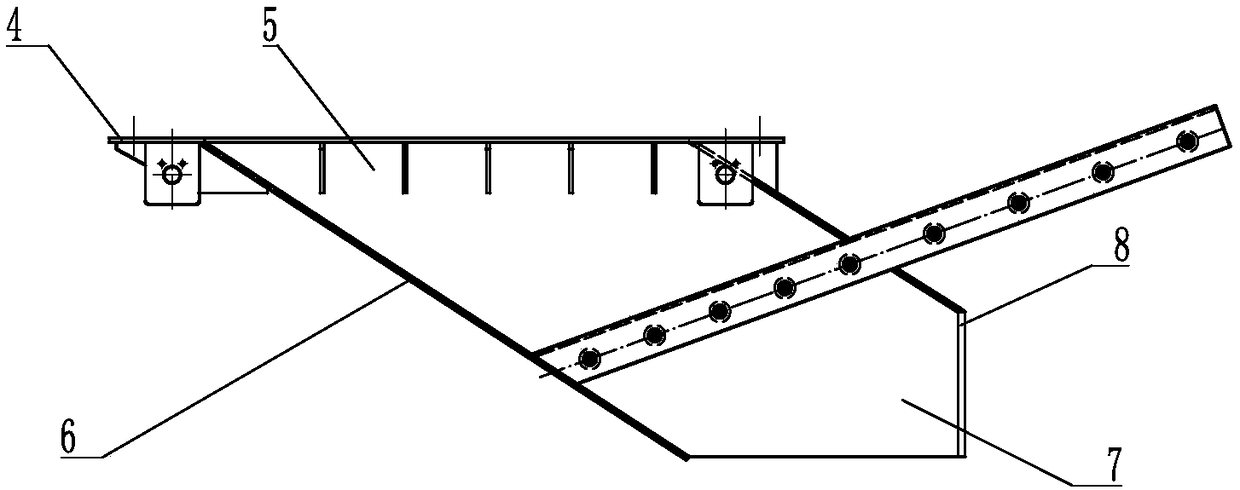

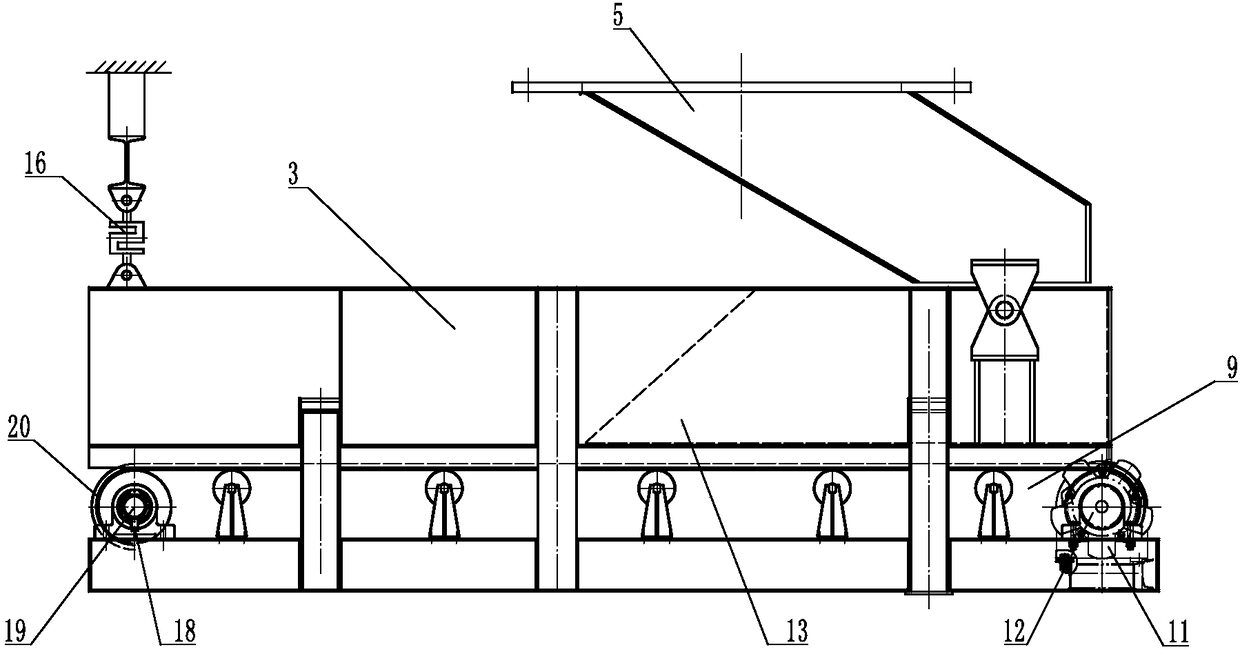

[0089] Figure 1 to Figure 4 It is the reverse feeding oblique side blanking reducing interference dynamic weighing metering feeder described in embodiment 1, including reverse feeding frame 2 and weighing feeder 14, etc., reverse feeding frame 2 Including reverse feeding inclined side blanking material receiver 5 and frame guide groove 3, etc., weighing feeder 14 includes reverse extending feeding device 9, driving device 11 and weighing device 17, etc., reverse feeding inclined The side blanking material receiver 5 includes the articulated inclined plate material guide chute 4, the inclined plate reverse feed guide 6 and the oblique side reverse blanking opening 8, etc., and the reverse extension feeding device 9 includes a driving drum 12, a modified To the roller 19 and the endless conveyor belt 20, etc., the frame guide groove 3 is arranged on the upper part of the endless conveyor belt 20, etc., and the lower part of the inclined plate guide groove part 4 is connected to...

Embodiment 2

[0094] Such as Figure 5 to Figure 8 As shown, it is the reverse feeding slant side blanking reducing interference dynamic weighing metering feeder described in embodiment 2, the frame guide groove 3 and / or the reverse feeding slant side blanking hopper 7, etc. Including the material receiving and conveying shaper 22, the frame guide chute 3 includes the upper feed opening 21 of the feed trough, the left side plate 25 of the feed trough, the right side plate 29 of the feed chute and the rear baffle 27 of the feed trough, etc. The left side plate 25 etc. of the material guide groove are arranged on the left side of the frame material guide groove 3, the material guide groove right side plates 29 etc. are arranged on the right side of the frame material guide groove 3, and the material guide groove back baffle plate 27 etc. are arranged on the guide groove Feed chute rear end and form frame guide hopper 28 etc. with feed chute left side plate 25 and feed chute right side plate 2...

Embodiment 3

[0098] Such as Figure 9 to Figure 14 It is the reverse feeding oblique side blanking reducing interference dynamic weighing metering feeder described in Example 3. The adjustable support 31 includes a screw spacer adjustment support 32 and / or a threaded sleeve guide rod adjustment support 47 etc., the screw spacer adjustment support 32 includes the left screw spacer adjustment support 35 and / or the right screw spacer adjustment support 40, etc., when the left screw spacer adjustment support 35 is used, the left screw spacer adjustment support 35 includes the left adjustment screw 36, the left adjustment spacer 38 and the left adjustment nut 33 etc., the shaper 26 on the left side of the material guide groove also includes the left adjustment shaping plate 39, etc., the left adjustment shaping plate 39 is provided with the left adjustment plate screw hole 37, etc., and in the material guide The left side plate screw hole 34 etc. corresponding to the left adjustment plate screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com