Patents

Literature

34results about How to "Accurate preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

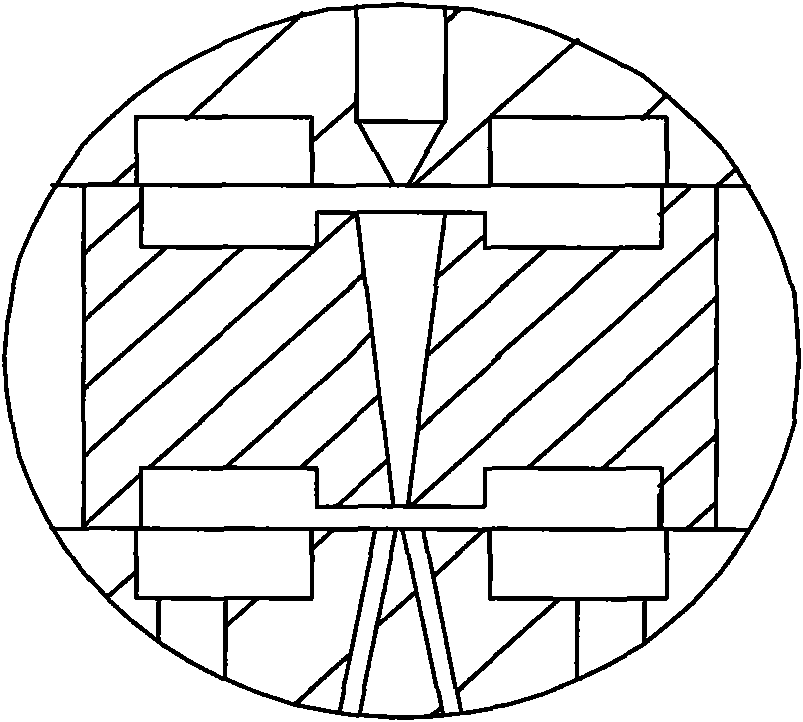

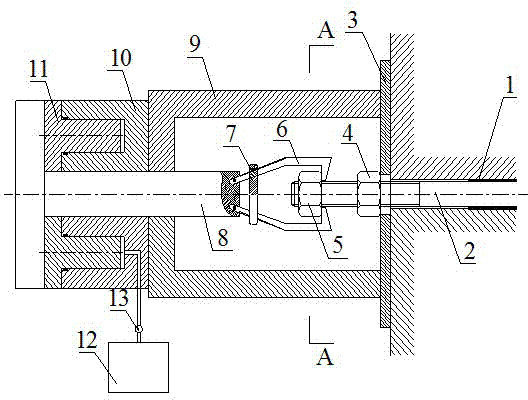

Accelerometer sensor for detecting knocks and method for making same

InactiveUS6212940B1Repeatable in mass-productionAccurate settingAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesAccelerometerEngineering

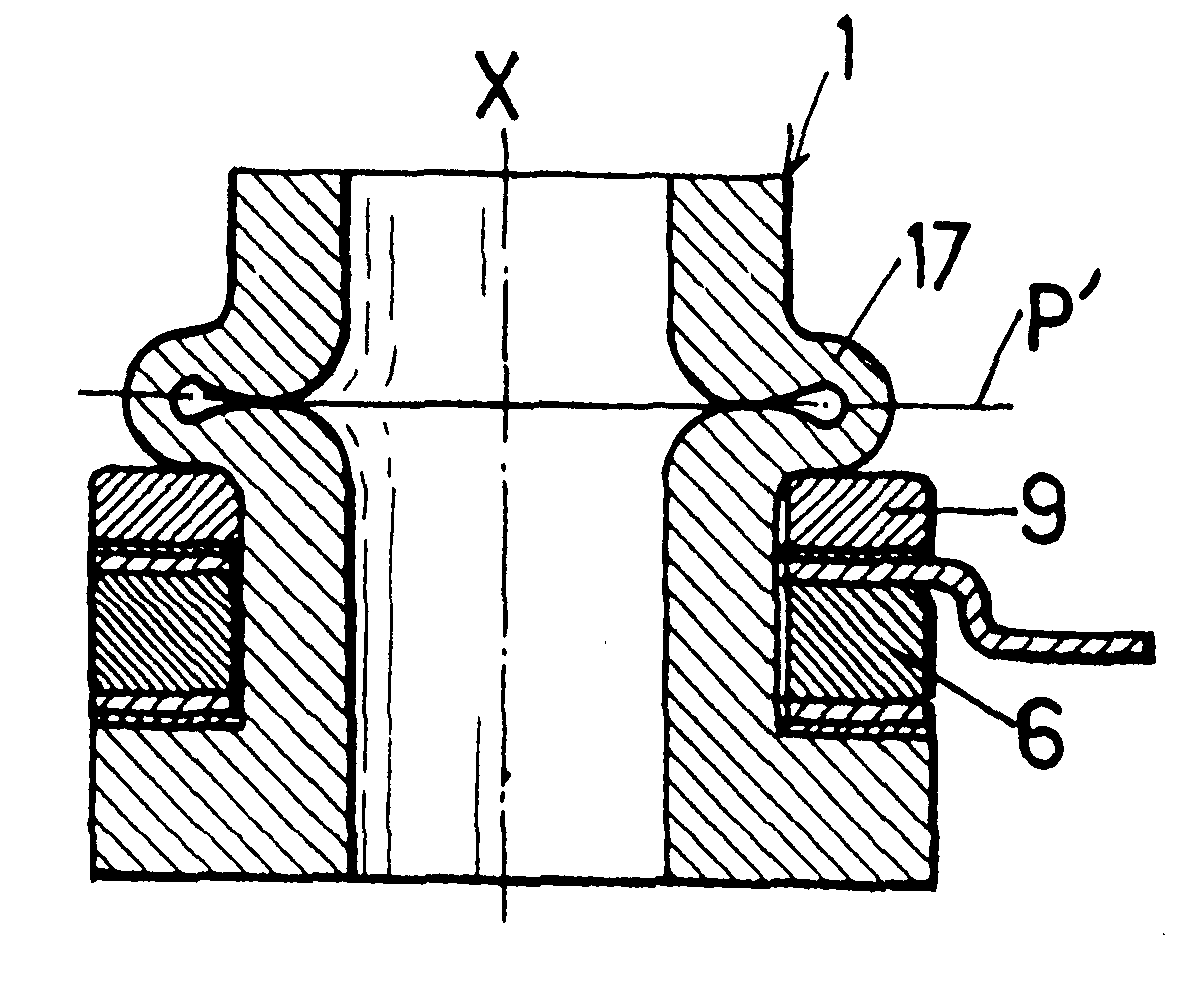

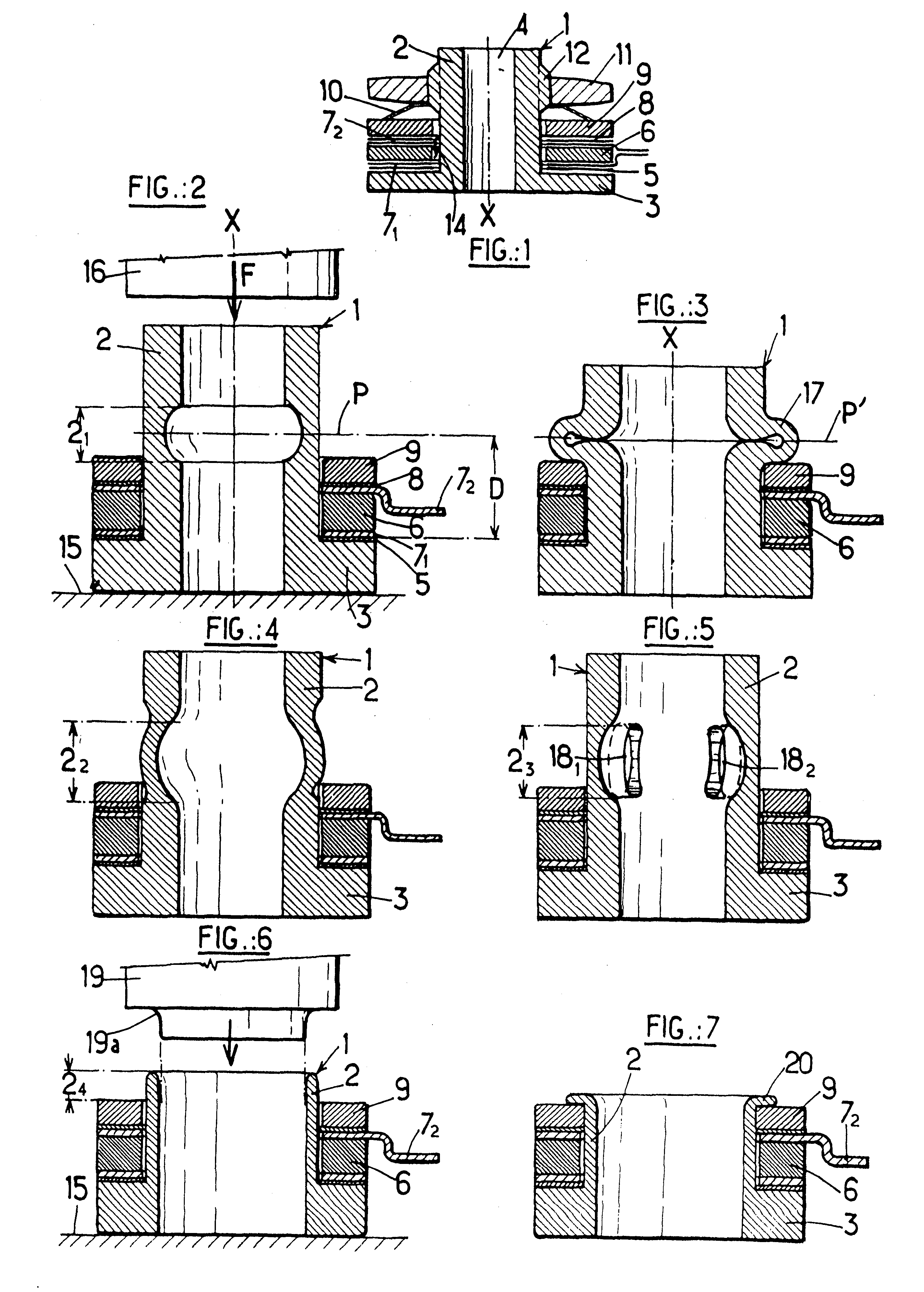

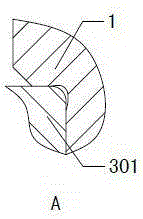

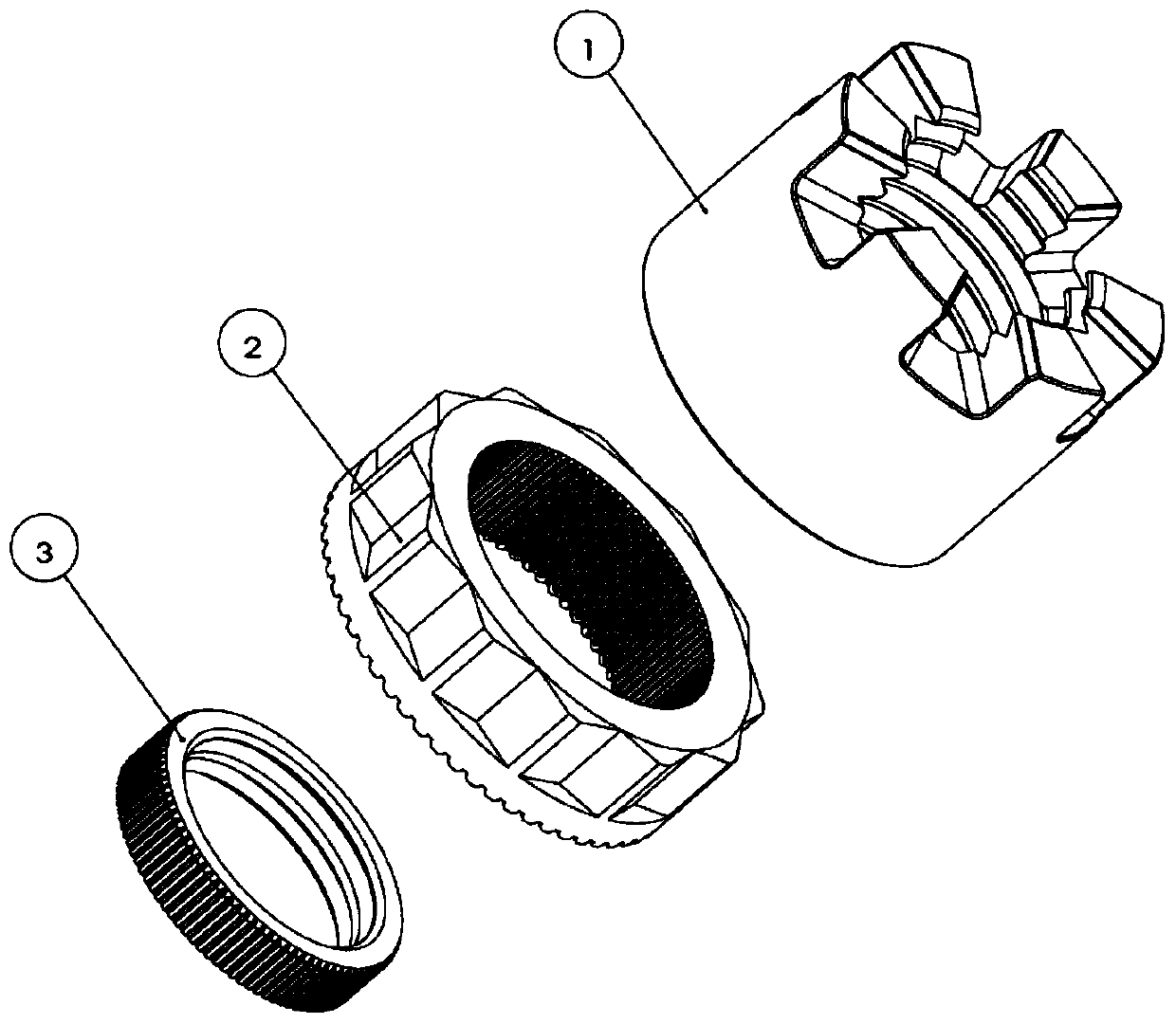

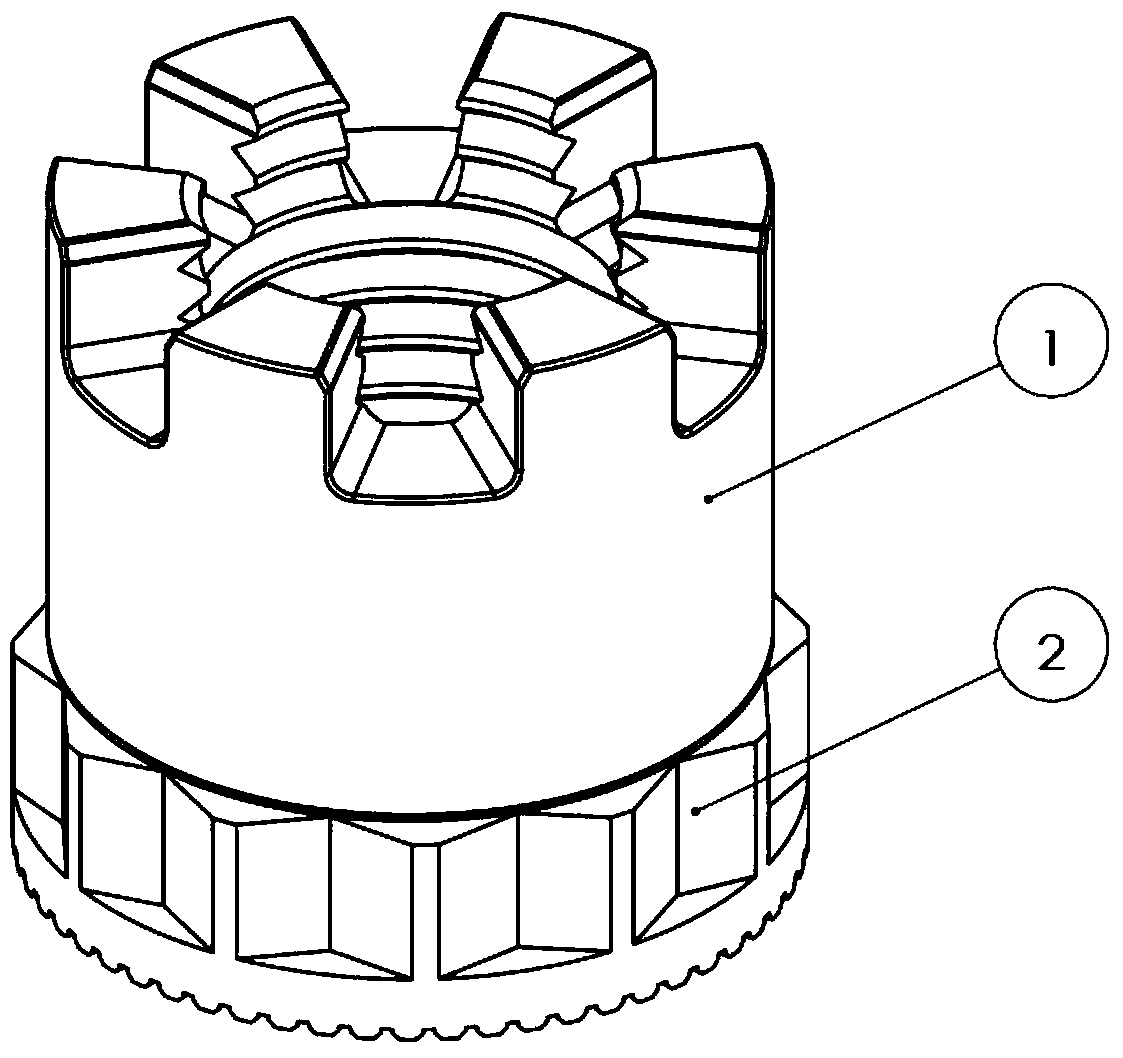

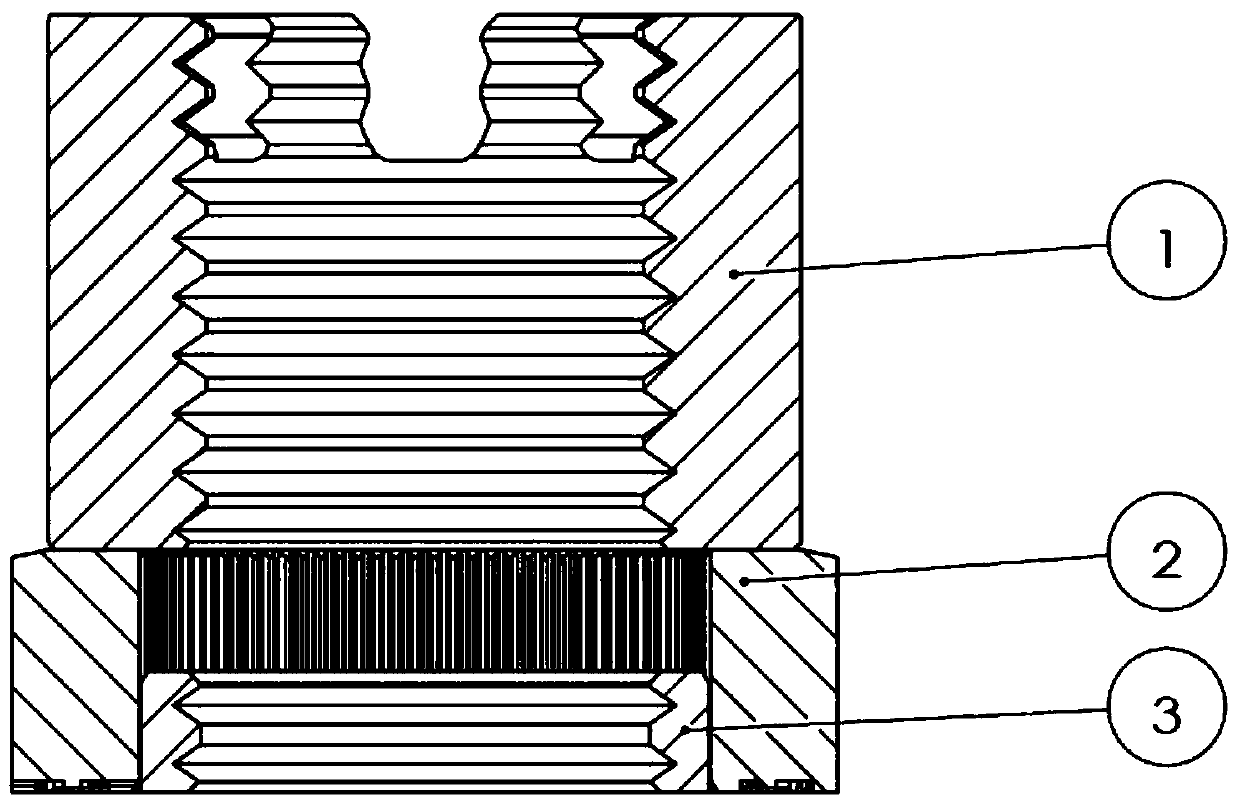

It comprises a) a cylindrical base (1) formed of an axial barrel (2) protruding from an annular shoulder (3), through both of which there passes an axial hole (4), b) a washer (6) made of a piezoelectric material slipped over the barrel, c) means (71, 72) for picking off the electrical voltage there is between two radial faces of said washer, e) an annular mass (9), also slipped over the barrel (2) and e) a retaining means collaborating with the annular shoulder (3) to trap said washer (6) and said mass (9) between them. The retaining means consists of a bulge (17) protruding radially from said barrel (2) and formed of the material of a predetermined portion thereof, deformed under an axial force for crushing said base (1).

Owner:SIEMENS AUTOMOTIVE

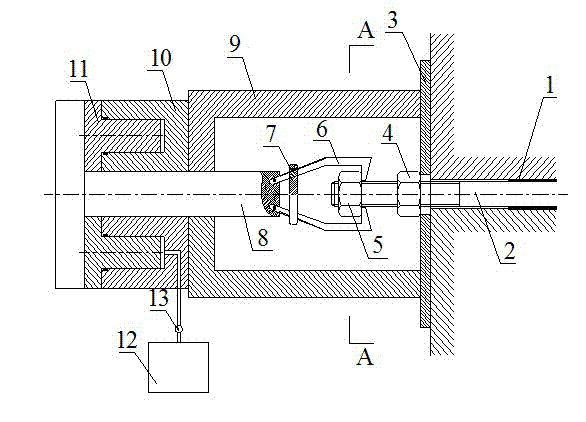

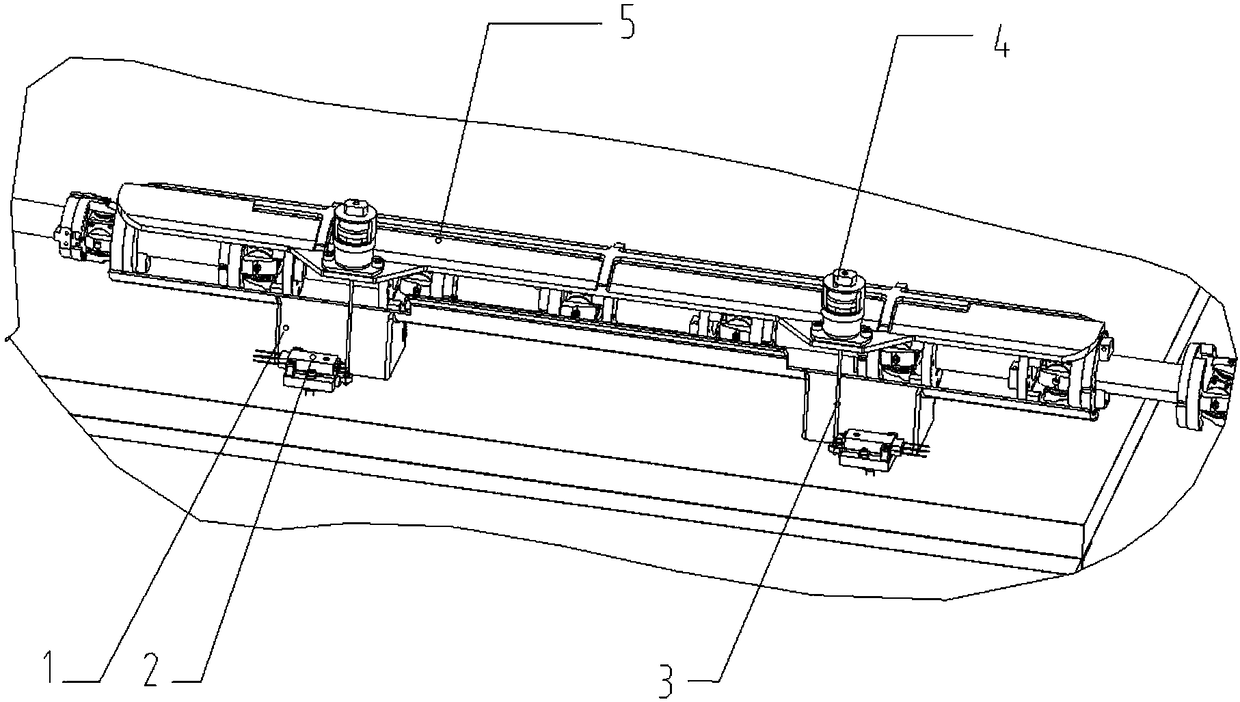

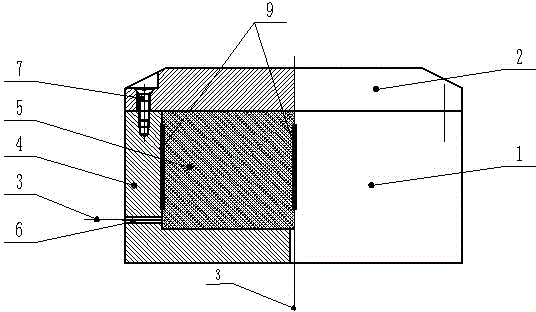

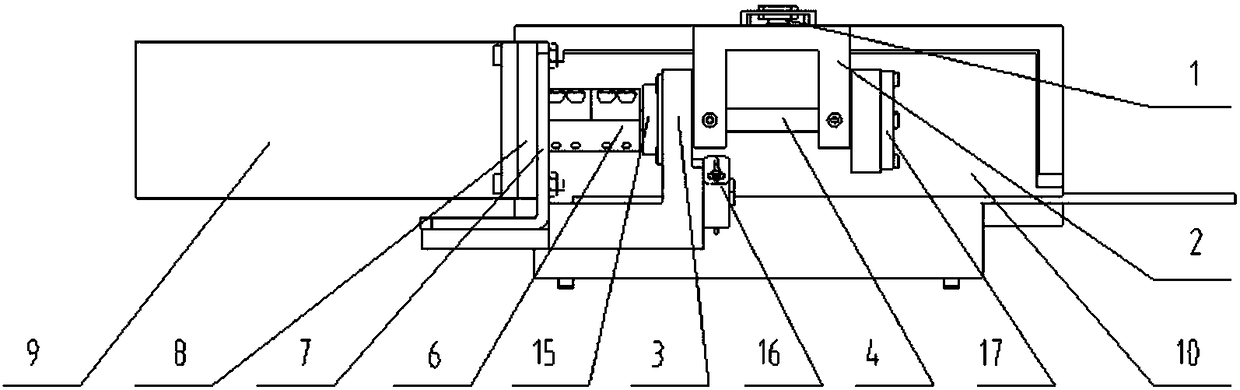

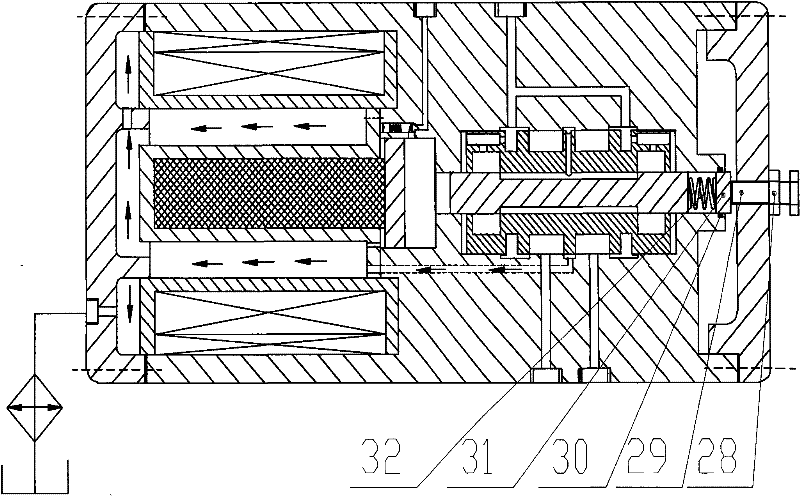

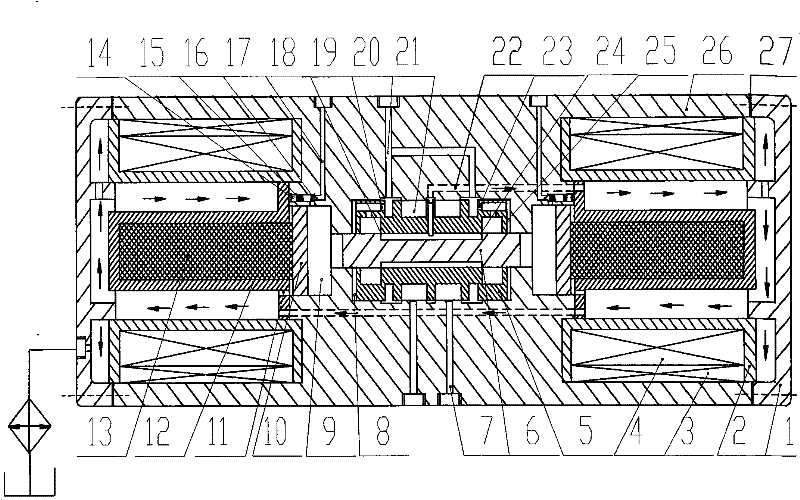

Super magnetostrictive actuator driving single-stage direct-acting jet pipe servo valve

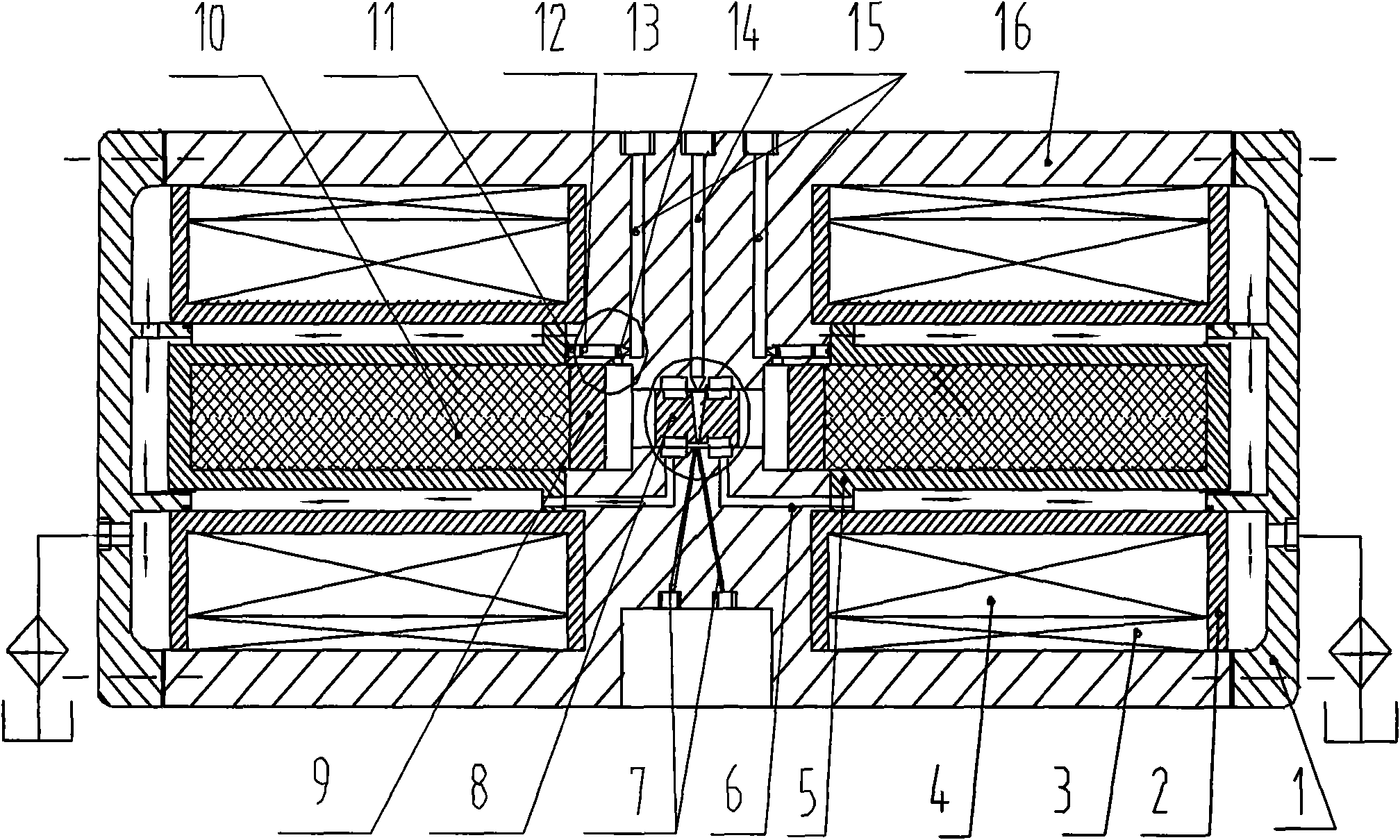

The invention discloses a super magnetostrictive actuator driving single-stage direct-acting jet pipe servo valve, and belongs to the technical field of hydraulic servo control. The servo valve comprises a valve body (16), a flow distributor (8), a pair of electro-mechanical converters, and a pair of micrometric displacement amplifiers positioned between the electro-mechanical converters and the flow distributor (8), wherein each electro-mechanical converter comprises a thermal compensation hood (5), a super magnetostrictive rod (10) mounted in the thermal compensation hood, and a coil frame (2) positioned outside the thermal compensation hood (5), and also comprises a drive coil (4) and a bias coil (3) which are orderly wound outside the coil frame (2); each micrometric displacement amplifier comprises a cylinder, a big piston (9) arranged at one end of the cylinder and connected with the corresponding super magnetostrictive rod (10); and the other end of the cylinder is connected with the flow distributor (8). The jet pipe servo valve has obvious characteristics of quick response, big driving power and control flow, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method and device for exerting anchor rod pretightening force

ActiveCN103244159AReduce material requirementsAvoid damageAnchoring boltsHydraulic cylinderAxial force

The invention provides a method and a device for exerting an anchor rod pretightening force and is suitable for general tunnel and roadway surrounding rock timbering engineering. During anchor rod pretightening force exerting, an anchor rod drilling hole is firstly constructed through a drilling machine, a resin medicine roll and an anchor rod are filled in the drilling hole sequentially, and a tray and a nut are sleeved on an external road section of the anchor rod. A pneumatic rock drill drives the anchor rod to rotate so as to break the medicine roll, and strength can be formed when the medicine roll is solidified; a hydraulic tensioner is installed; a hydraulic cylinder is started to exert a tension pretightening force on the anchor rod, and a suspended nut is screwed in by a wrench to be contacted with the tray; and the pressure of the hydraulic cylinder is reduced to be zero, and the hydraulic tensioner is removed. By means of the method and the device for exerting the anchor rod pretightening force, anchor rod pretightening force construction can meet the design requirements easily, the process that a traditional torque circumferential force is converted into an axial force in an anchor rod pretightening force construction method is changed, requirements on materials of the anchor is reduced, damage to the anchor rod is avoided, and the construction efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

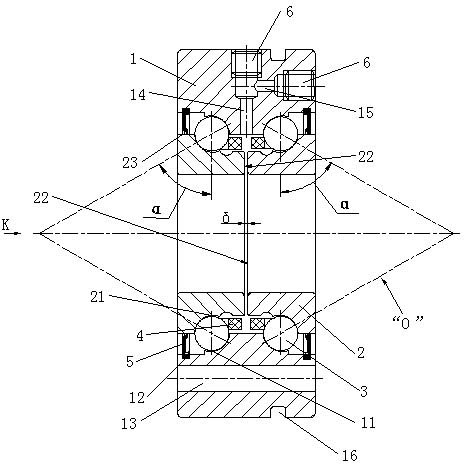

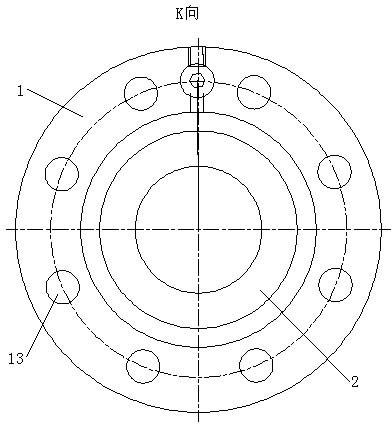

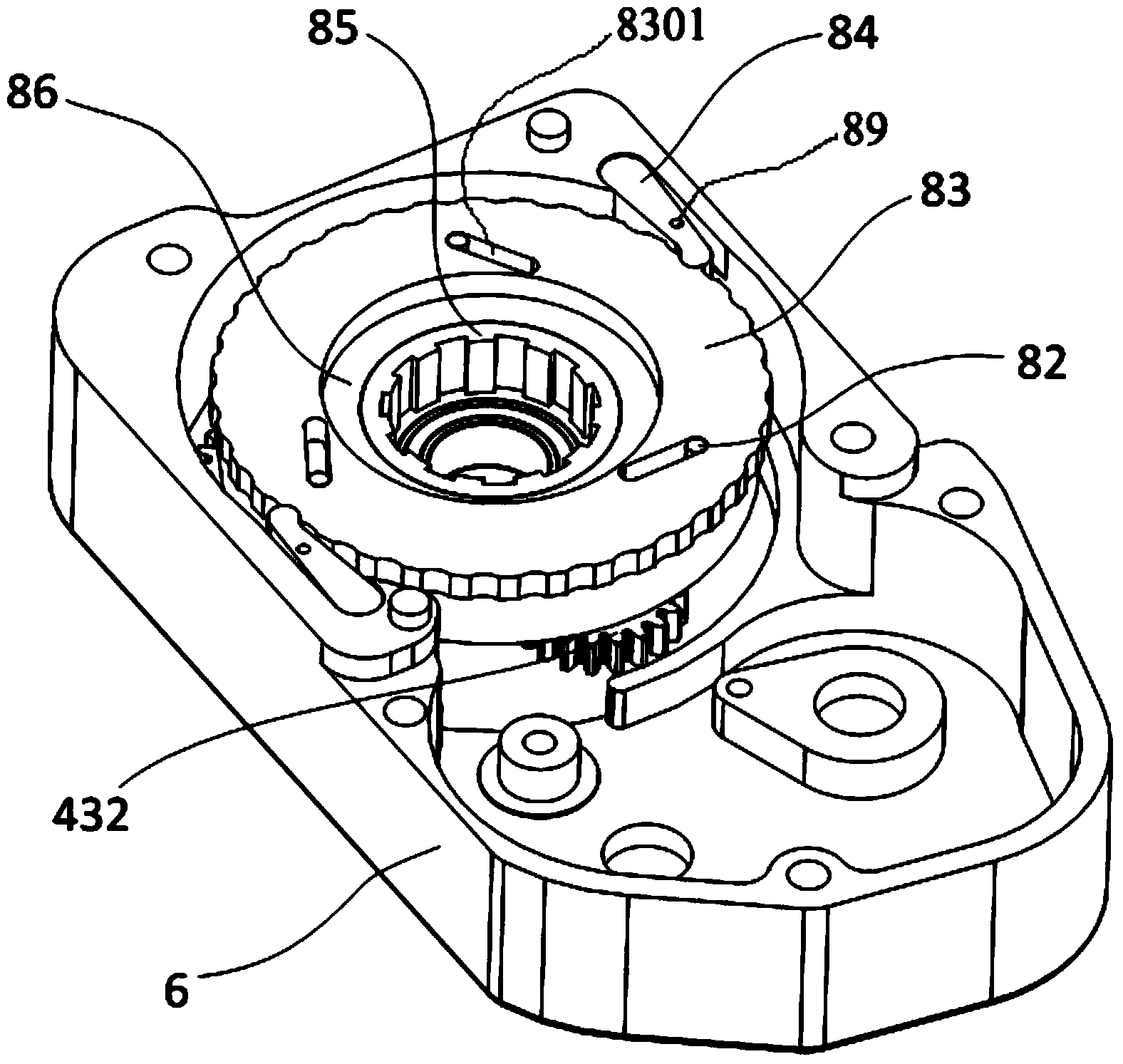

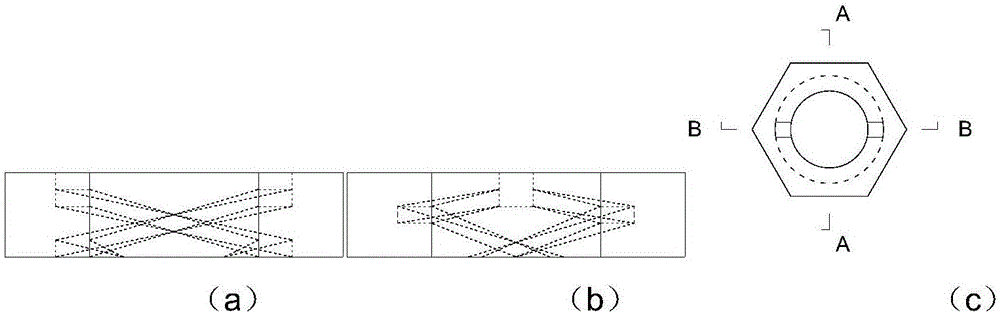

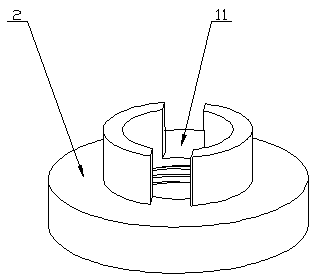

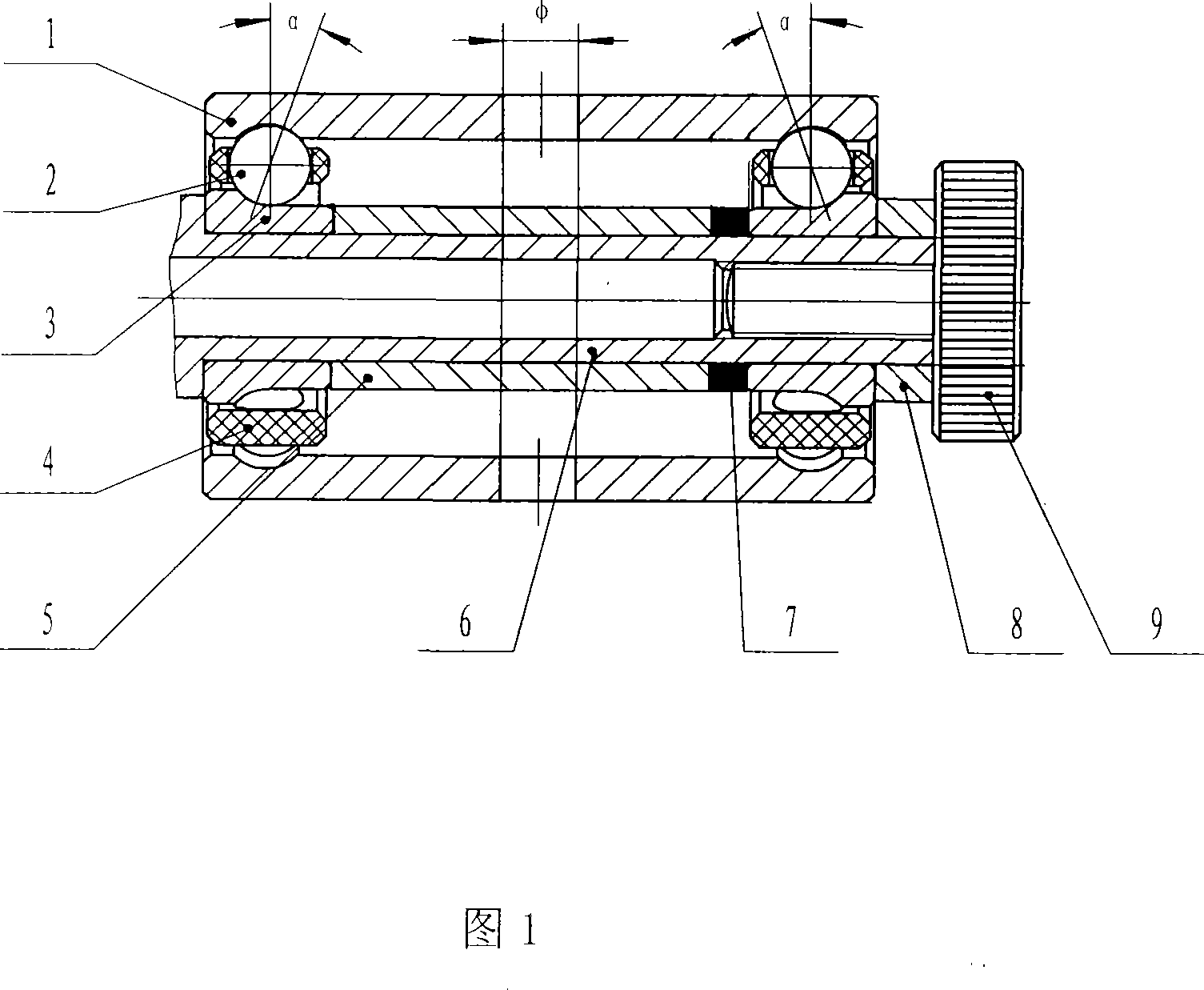

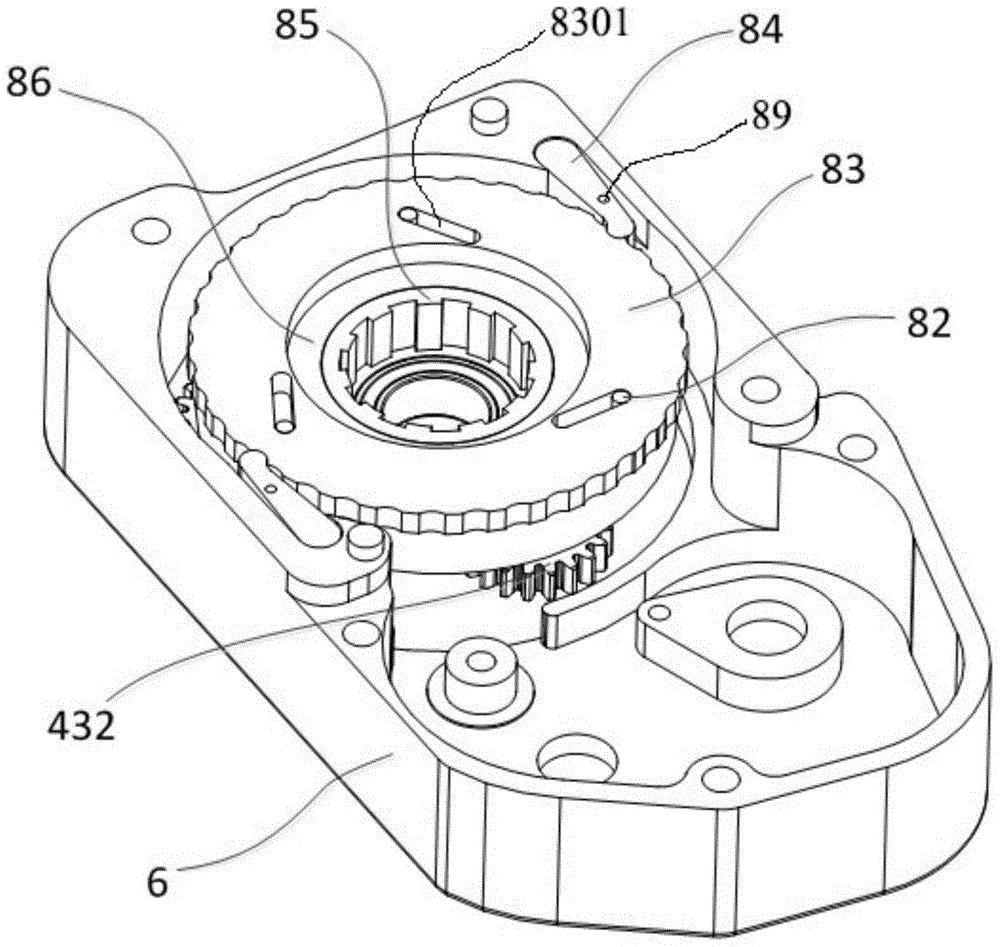

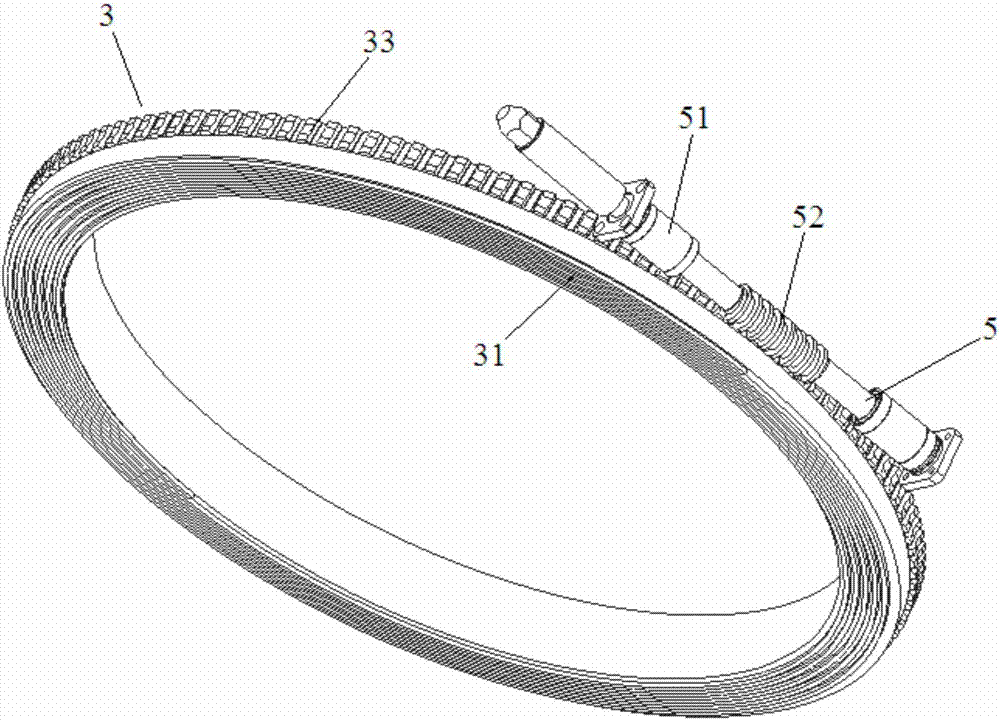

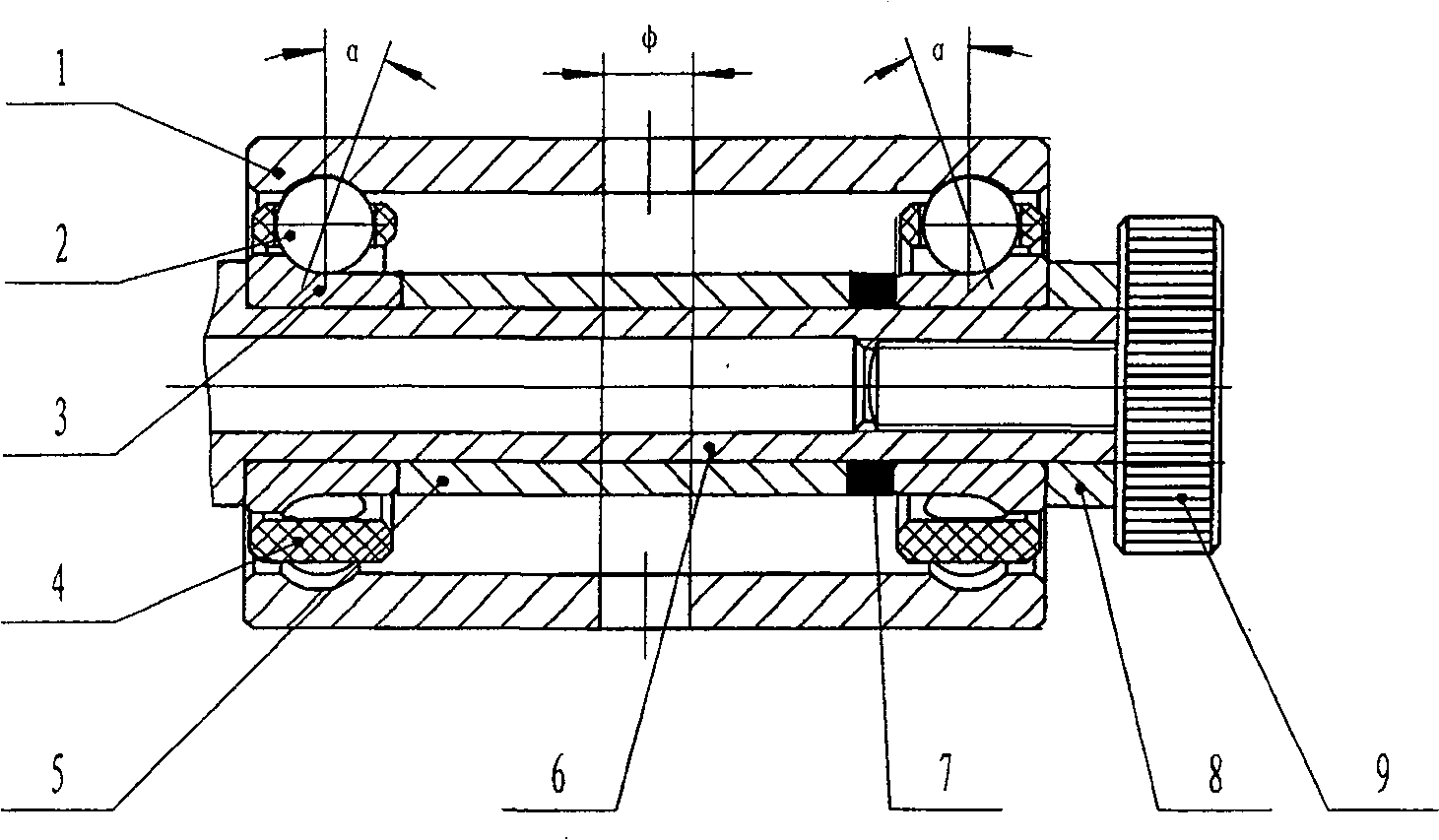

Bidirectional angular contact thrust ball bearing assembly

InactiveCN102182754AImprove axial stiffnessImprove support rigidityRolling contact bearingsBearing componentsBall bearingEngineering

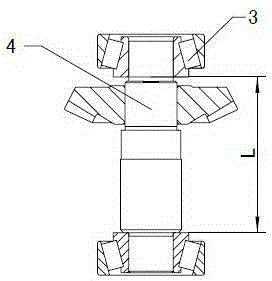

The invention discloses a bidirectional angular contact thrust ball bearing assembly. Two sides of the inner wall of an outer ring and the outer walls of the inner sides of two inner rings are respectively provided with outer trenches and inner trenches, wherein the outer trenches and the inner trenches are used for mounting a row of steel balls; two retainers respectively retain a row of steel balls and enable the steel balls to be separated circumferentially and uniformly; the thin end surfaces of the two inner rings are opposite and are provided with a preload regulating clearance; the nominal contact angle of the bearing assembly is 58 degrees-62 degrees; a seal ring is arranged between the outer wall of the outer side of each inner ring and the groove of the inner wall of the outer ring; the end surface of the outer ring is provided with an axial flange mounting through hole and an axial fat feed channel; the outer diameter of the outer ring is provided with a radial fat feed channel; the ports of the axial fat feed channel and the radial fat feed channel are all provided with oil filler plugs; and the outer diameter of the outer ring close to the end of the axial fat feed channel is provided with a circumferential dismounting groove which is convenient to clamp a bearing. The bearing assembly has a reasonable structure, is convenient to install, can bear radial and axial loading, is provided with pretension loading, has higher axial rigidity and can be lubricated again at a fixed period.

Owner:中山市盈科轴承制造有限公司

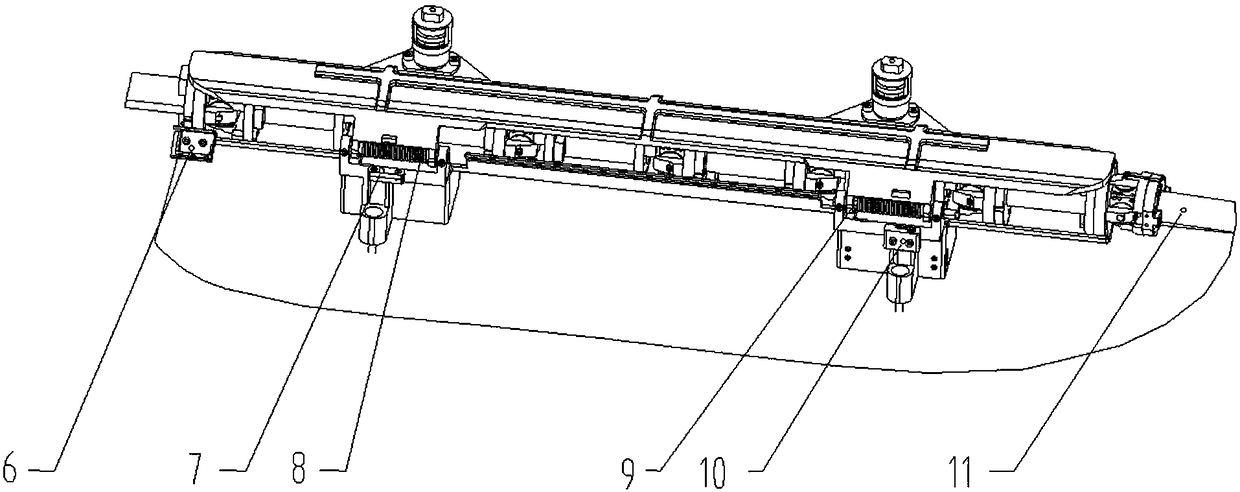

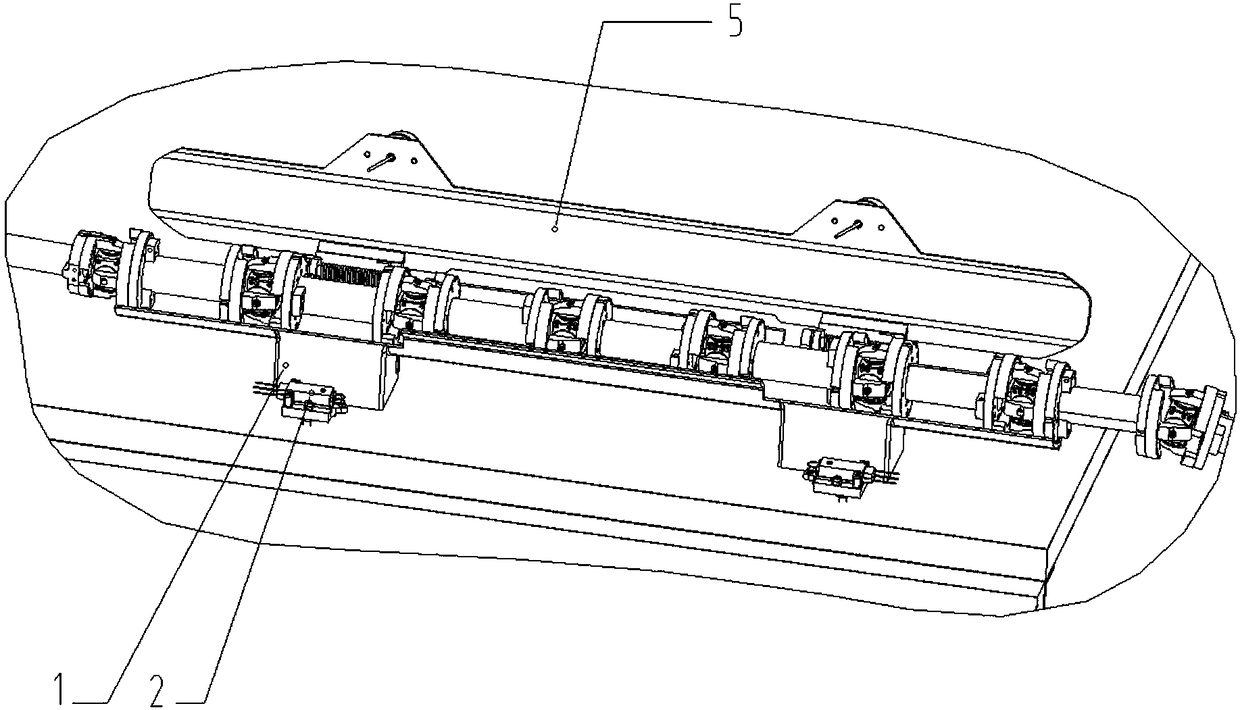

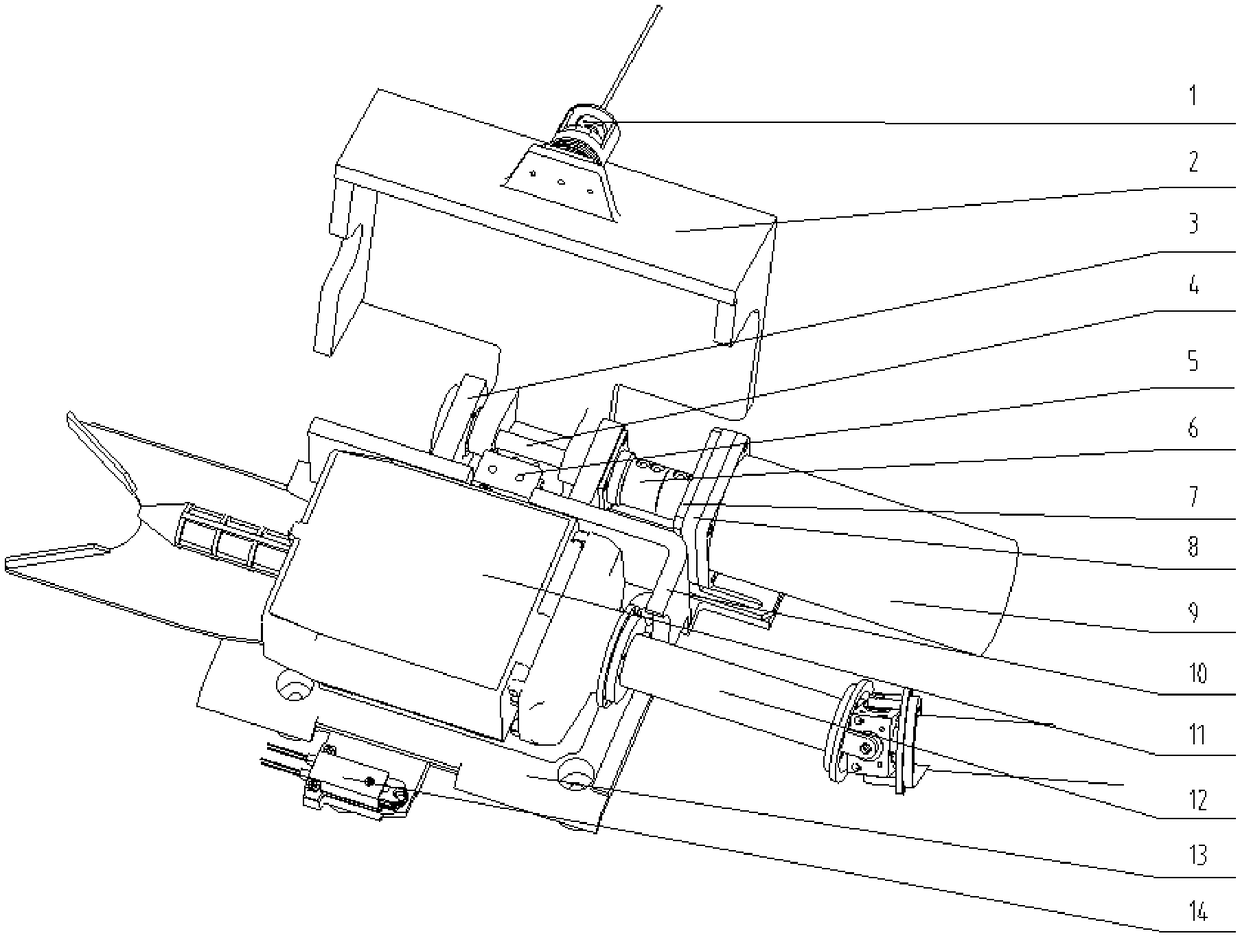

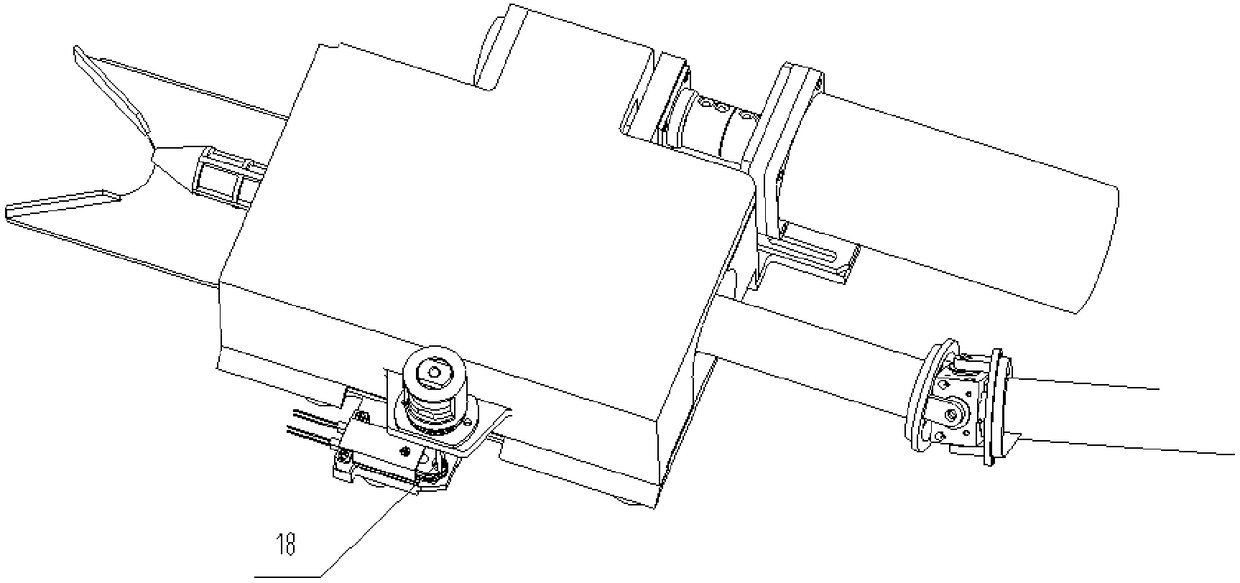

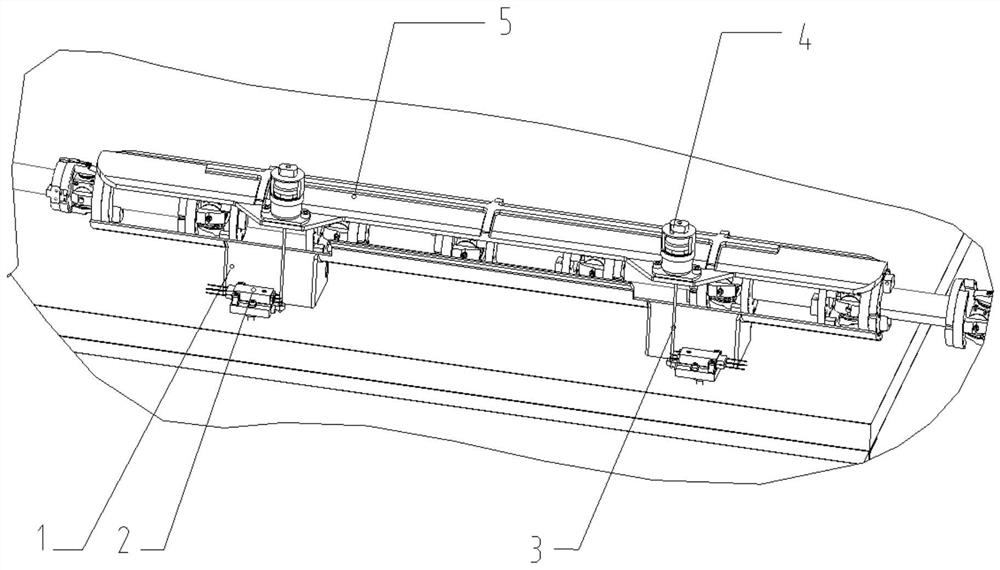

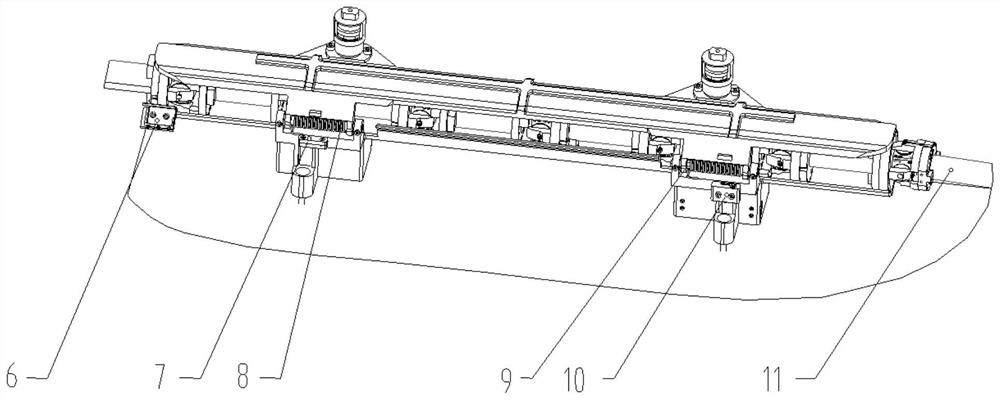

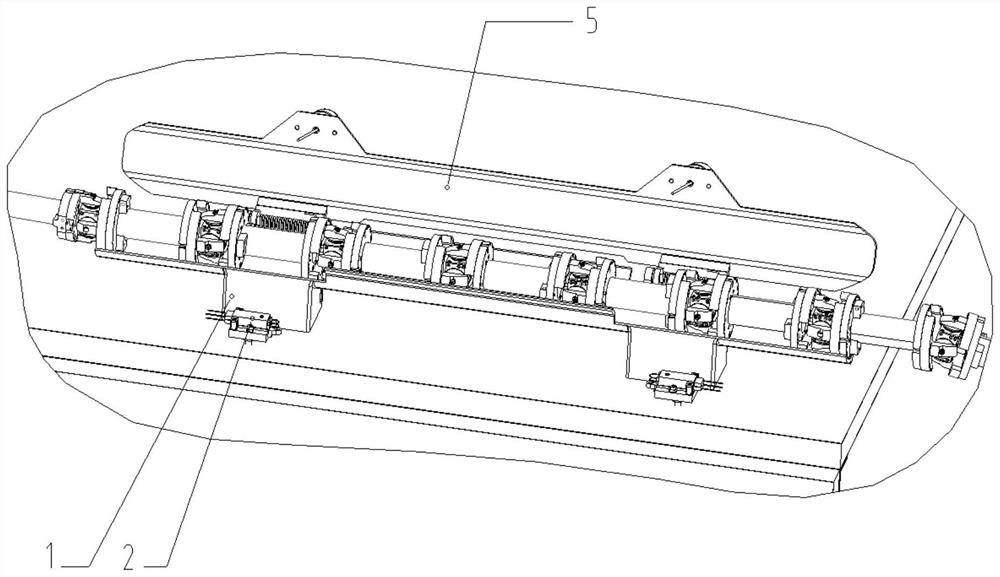

Space flexible arm pressing releasing mechanism for wire fuse unlocking

The invention provides a space flexible arm pressing releasing mechanism for wire fuse unlocking, and belongs to the technical field of the space flexible arm pressing releasing mechanism. The space flexible arm pressing releasing mechanism comprises a fixed base, a wire fuse unlocking device, a pressing cover plate, a position detecting micro switch, phenyl silicone rubber sheets, torsion springs, hinge pins and limiting micro switches. Before launching, locking machines of the wire fuse unlocking device is adjusted, and proper pre-tightening force is applied to the pressing cover plate through stays to press a space flexible arm against the fixed base. After orbit injection, a command is sent from the ground, a cutter of the wire fuse unlocking device is energized, and a resistance wireof the cutter is rapidly heated to melt the stays. The space flexible arm pressing releasing mechanism for wire fuse unlocking is reliable in pressing and adopts the wire fuse unlocking device as a pressing and unlocking tool, the structure is simple, the relatively accurate pre-tightening force can be applied, and the assembly and adjustment are convenient; and no impact or vibration is generatedwhen unlocking, the space flexible arm can be protected from being damaged by the vibration shock load during launching, and the space flexible arm pressing releasing mechanism for wire fuse unlocking is suitable for the occasion in which the locking force of the space flexible arm is not required too much.

Owner:HARBIN INST OF TECH +1

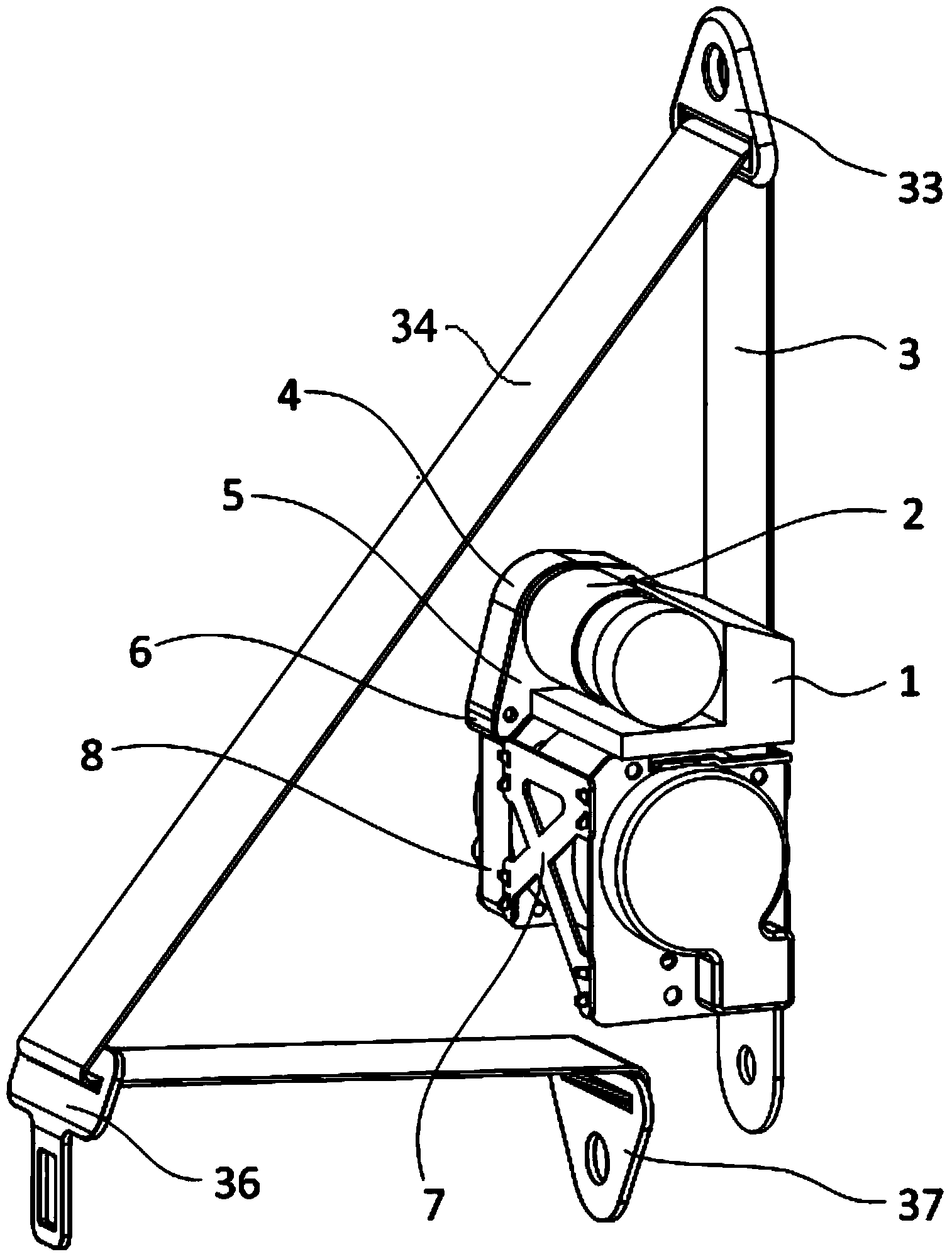

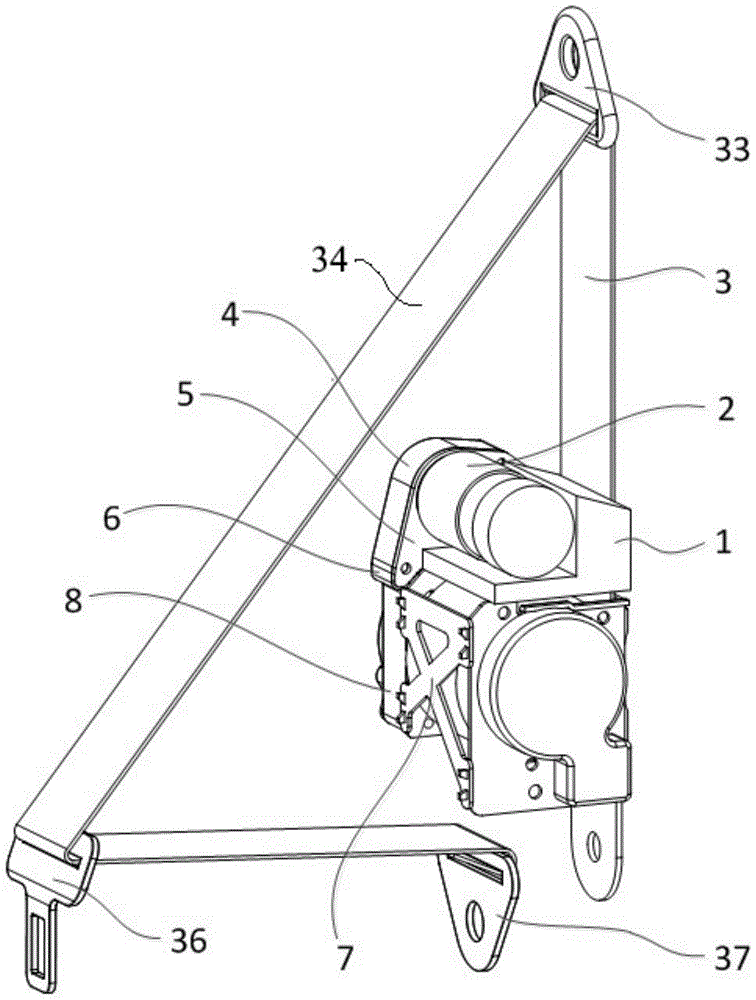

Automobile active type pre-tightening safety belt

The invention discloses an automobile active type pre-tightening safety belt, and belongs to the technical field of passenger injury protection during automobile collision accidents. The safety belt comprises a direct current motor, a transmission system, a retractor and a weaving belt kit, wherein the direct current motor is connected with the transmission system, and responds to a control signal of an accident pre-tightening device to work, the transmission system is connected with the direct current motor, and the decelerated power of the motor is transmitted to a one-way device and the retractor. The safety belt has the advantages that a weaving belt double-side pre-tightening structure is adopted, so the safety weaving belt can be simultaneously retracted at the shoulder belt part and the waist belt part to reach the double-side pre-tightening purpose, the wearing gap between a shoulder belt and a waist belt is eliminated, the body forward movement amount of a passenger during collision accidents is obviously reduced, and the slippage of the passenger is prevented; by integrating the force limiting and emergency locking functions, the collision injury to the passenger is minimized.

Owner:HUNAN UNIV +1

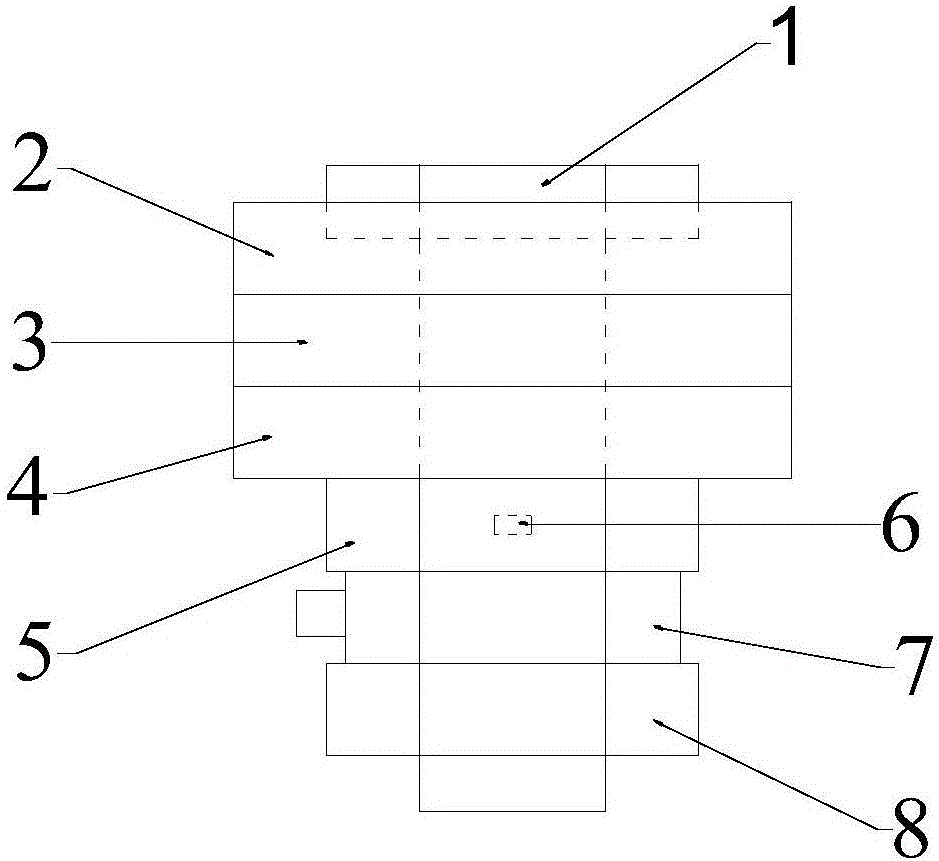

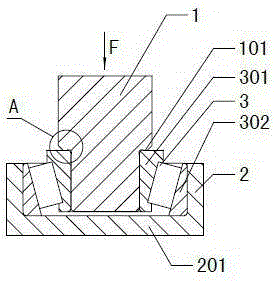

Device and method for measuring pretightening force of bolt

ActiveCN106289621ASimple methodHigh precisionMeasurement of torque/twisting force while tighteningForce measurement using piezo-electric devicesEngineeringMechanical engineering

The invention discloses a device and a method for measuring a pretightening force of a bolt. The device comprises a holed bolt, and three temporarily pressed sheets, a specially-made nut, a pressure tester and a nut which sleeve the holed bolt are mutually overlapped sequentially from the top to the bottom, wherein a reserved hole in the holed bolt stretches out of the bottommost temporarily pressed sheet; a pin is horizontally inserted into the reserved hole in the holed bolt and stretches out along the two side walls of the holed bolt; a reserved groove in the specially-made nut sleeving the holed bolt is butted with the pin; the inside diameter of the pressure tester sleeving the holed bolt is greater than the outside diameter of the holed bolt, and the pressure tester does not contact the side wall of the holed bolt; the nut is screwed at the tail end of the holed bolt. The device calculates the pretightening force of the bolt by sequentially twisting the nut and the specially-made nut to stretch the bolt twice. The device improves the method for measuring the pretightening force of the bolt, improves the accuracy for measuring the pretightening force of the bolt, and finally measures a more accurate pretightening force, so that in the actual using process, the device is more convenient.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

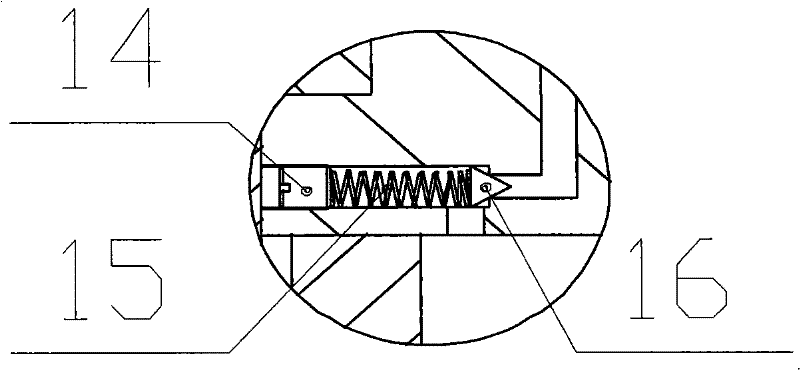

Locknut pushing pre-tightening system

The invention belongs to the technical field of pushing pre-tightening devices, and particularly relates to a locknut pushing pre-tightening system. The system comprises a fixed base; a main nut, a pushing sliding piece, an auxiliary nut, and a main bolt are included; the main bolt is arranged on a connected part, the main nut is provided with a first thread hole, a thread groove is formed in thebottom end of the main nut, a second thread hole is formed in the auxiliary nut, a mounting groove is formed in the upper end of the auxiliary nut, the main bolt is sleeved with the pushing sliding piece, a first outer thread and a second outer thread are arranged on the outer side of the pushing sliding piece, a pushing spring is arranged in the mounting groove, the top end of the pushing slidingpiece is in threaded connection with the thread groove through the first outer thread, the bottom end of the pushing sliding piece is in threaded connection with the mounting groove through the second outer thread, and the bottom end of the pushing sliding piece is in contact fit with the pushing spring. The phenomenon that when the connected part vibrates, the main bolt loosens can be avoided; and firm connection of the main bolt and the main nut can be improved, and loosening can be avoided.

Owner:六安联众工业自动化技术有限公司

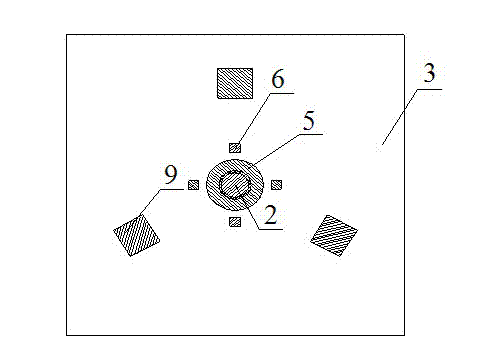

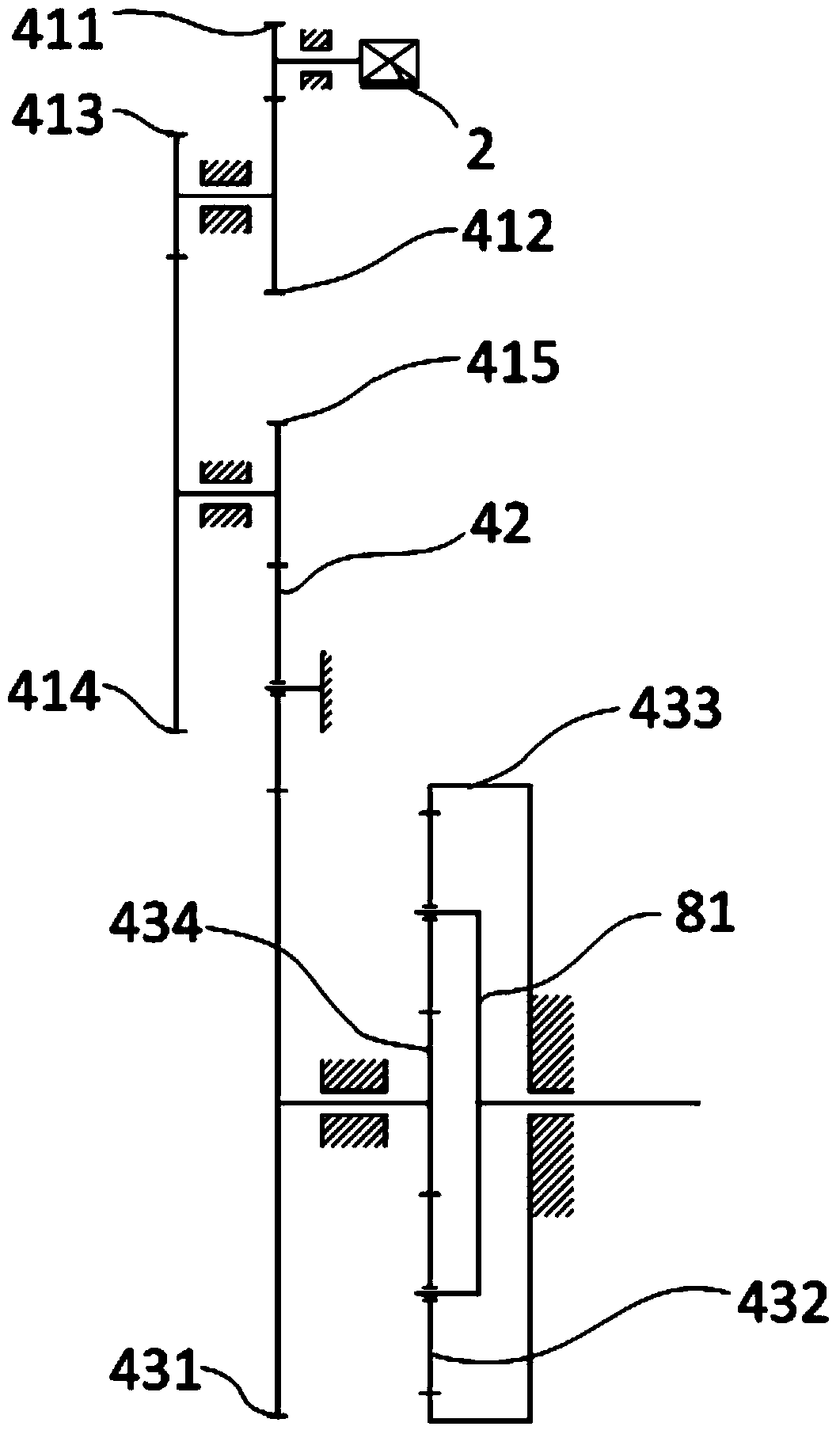

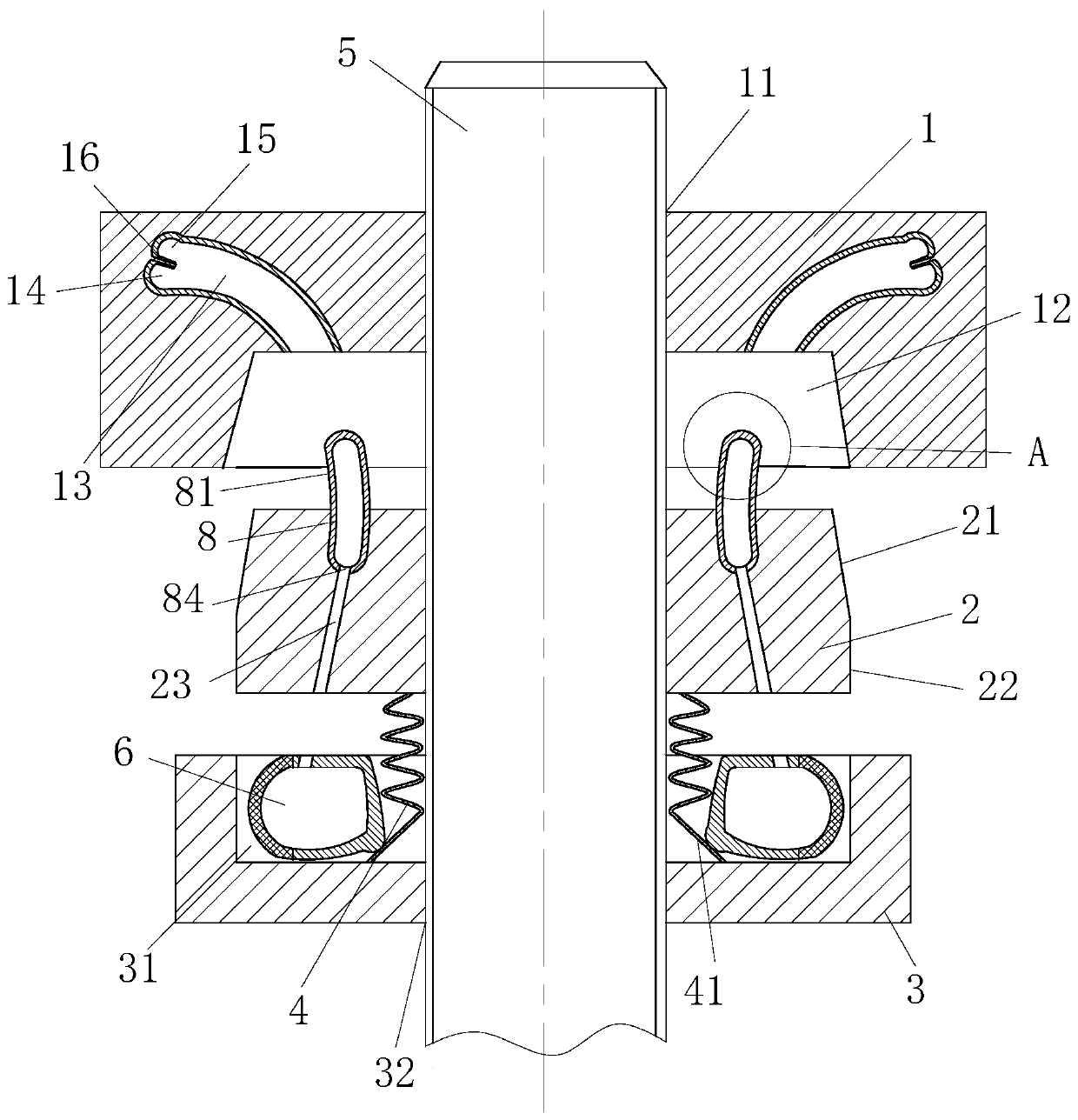

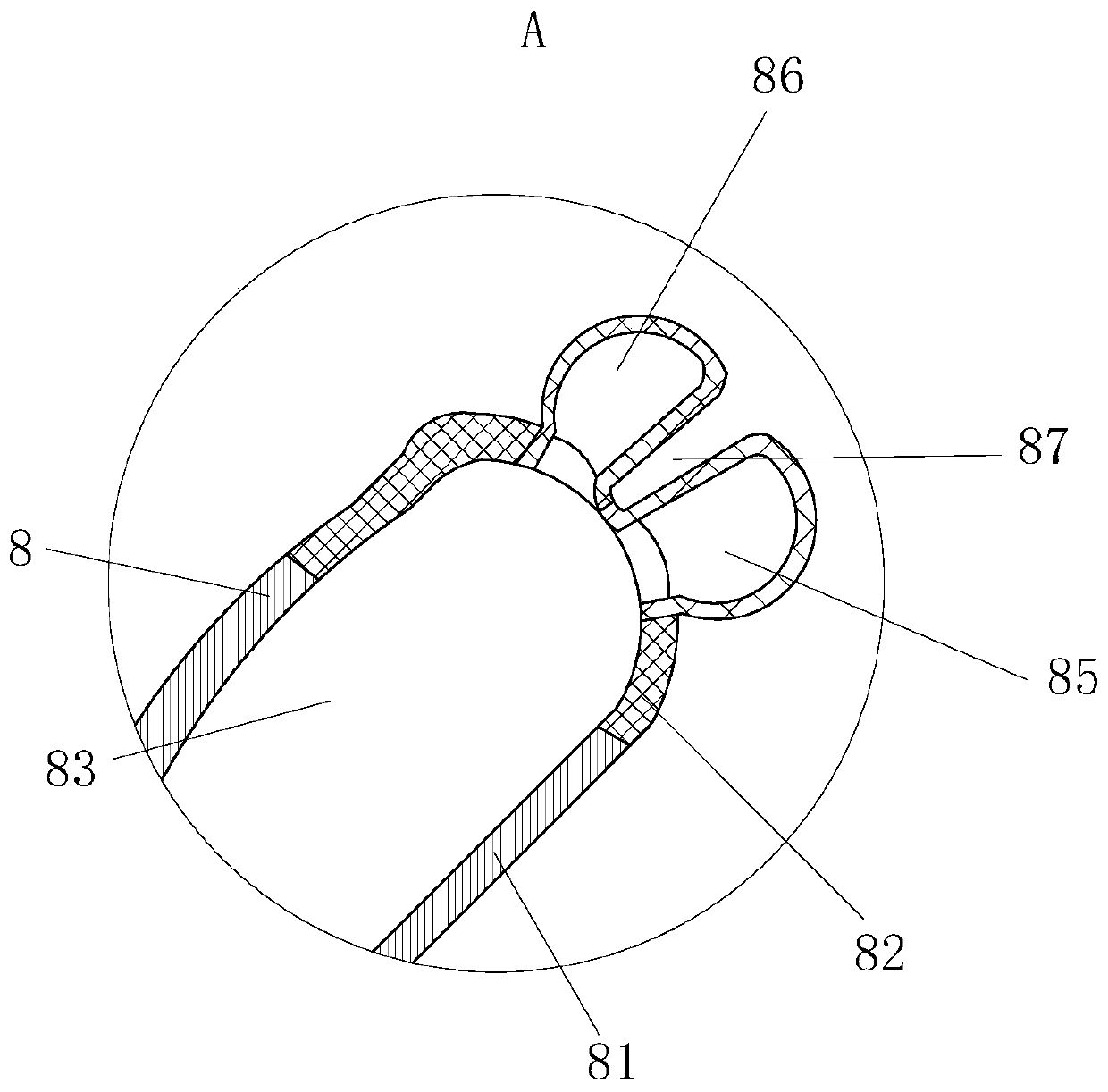

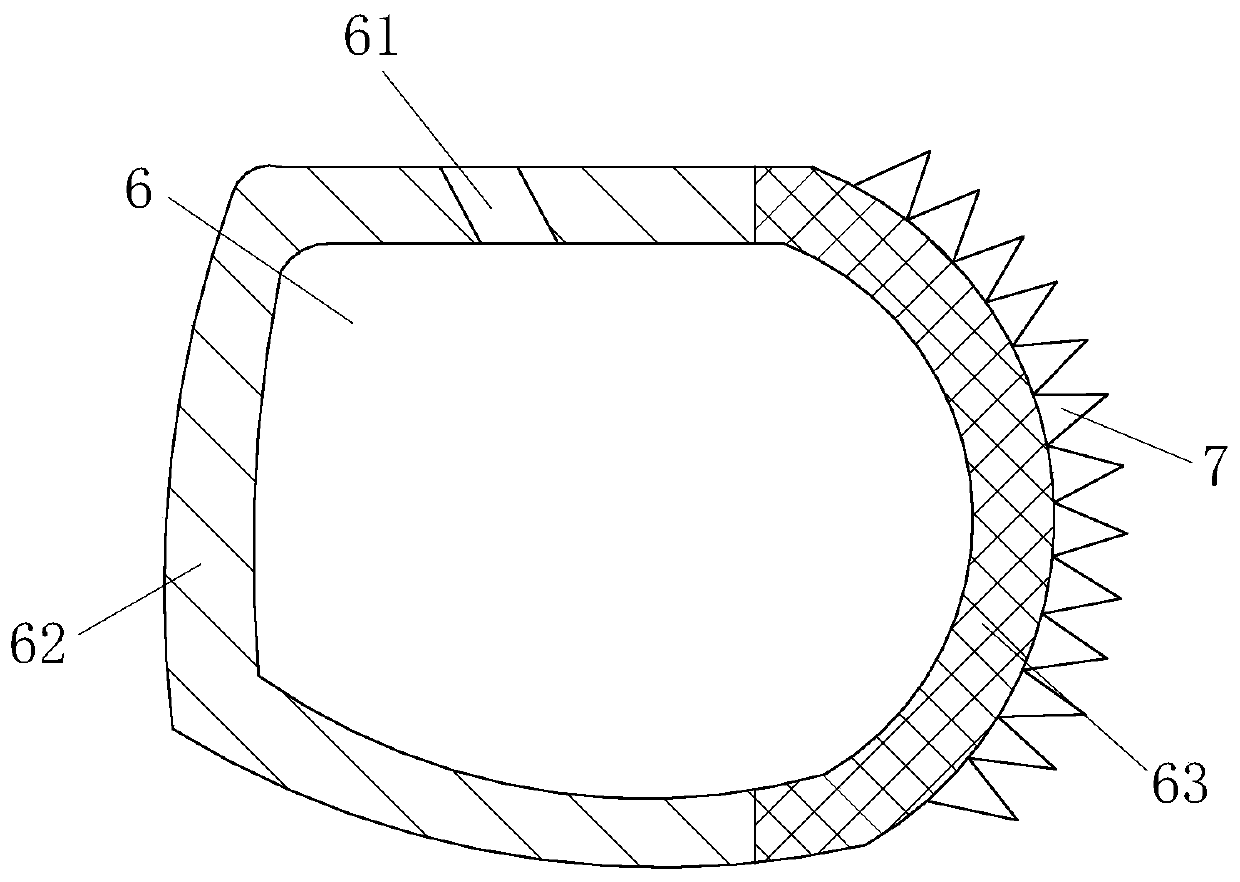

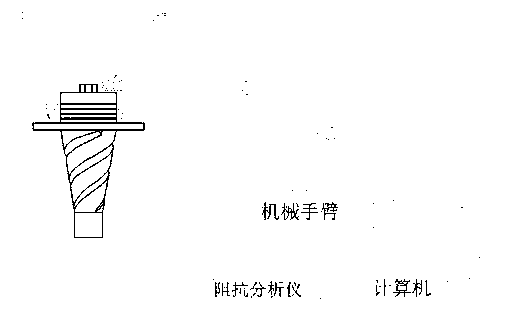

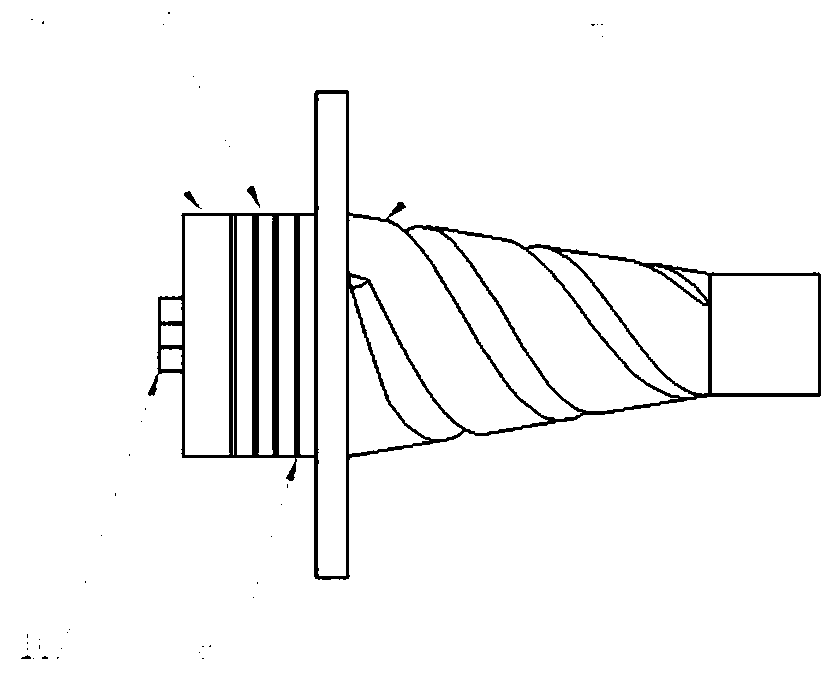

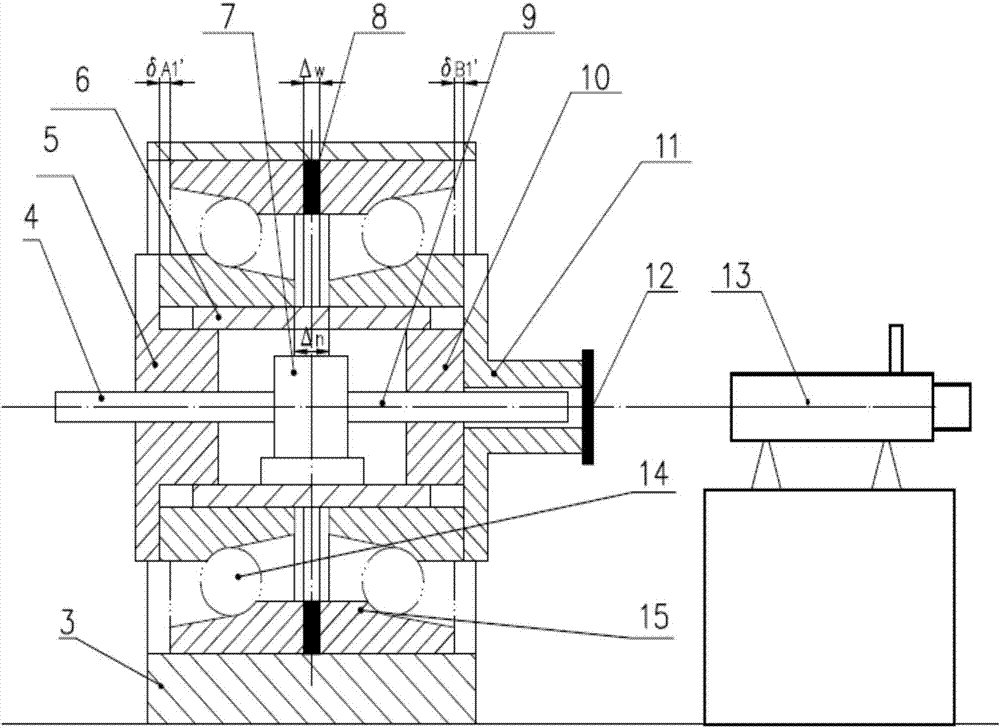

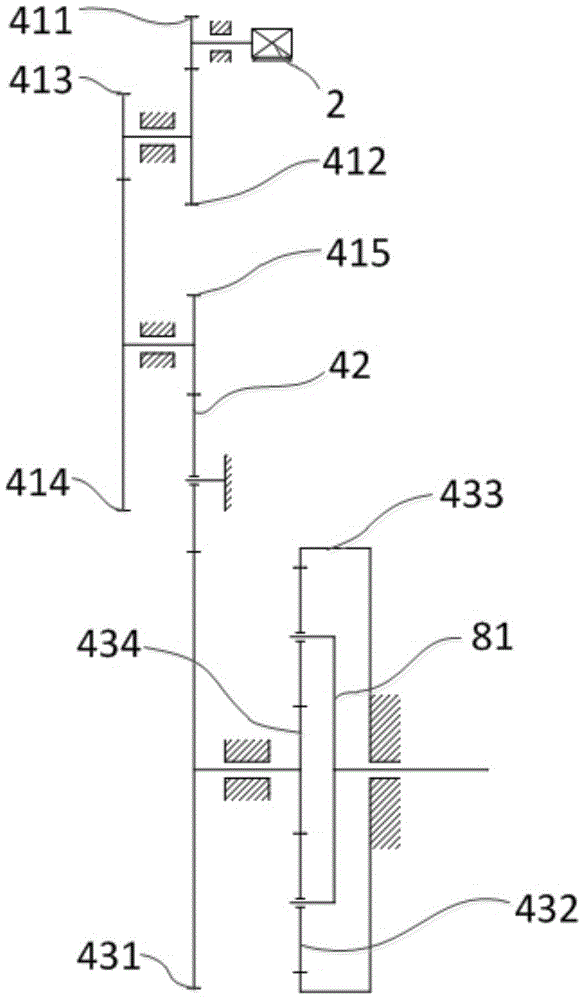

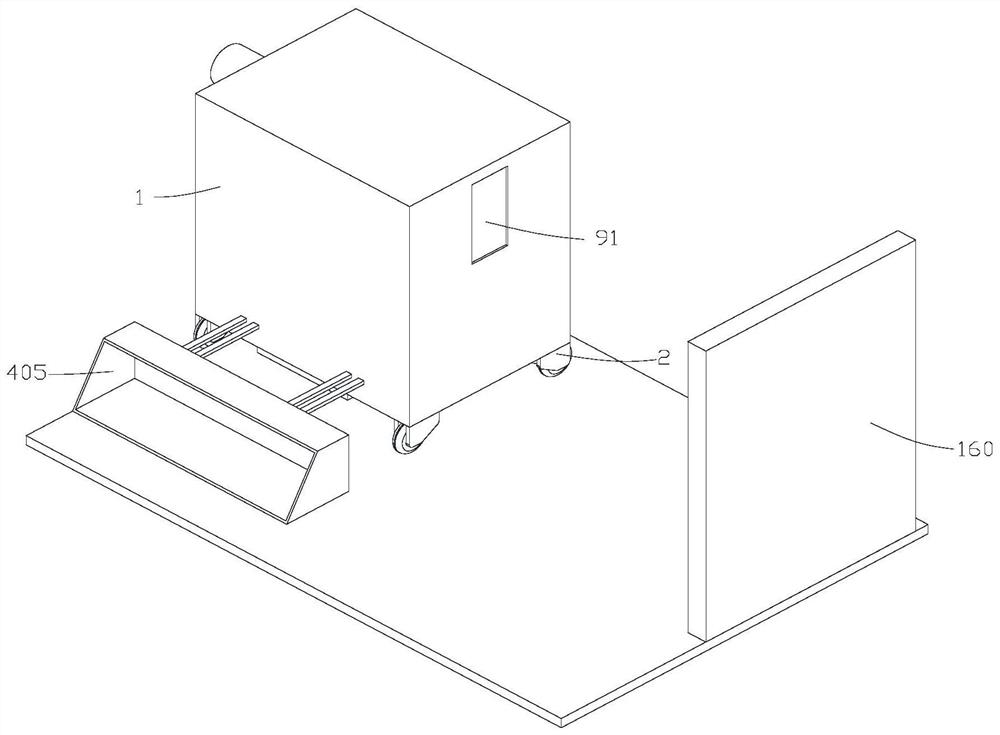

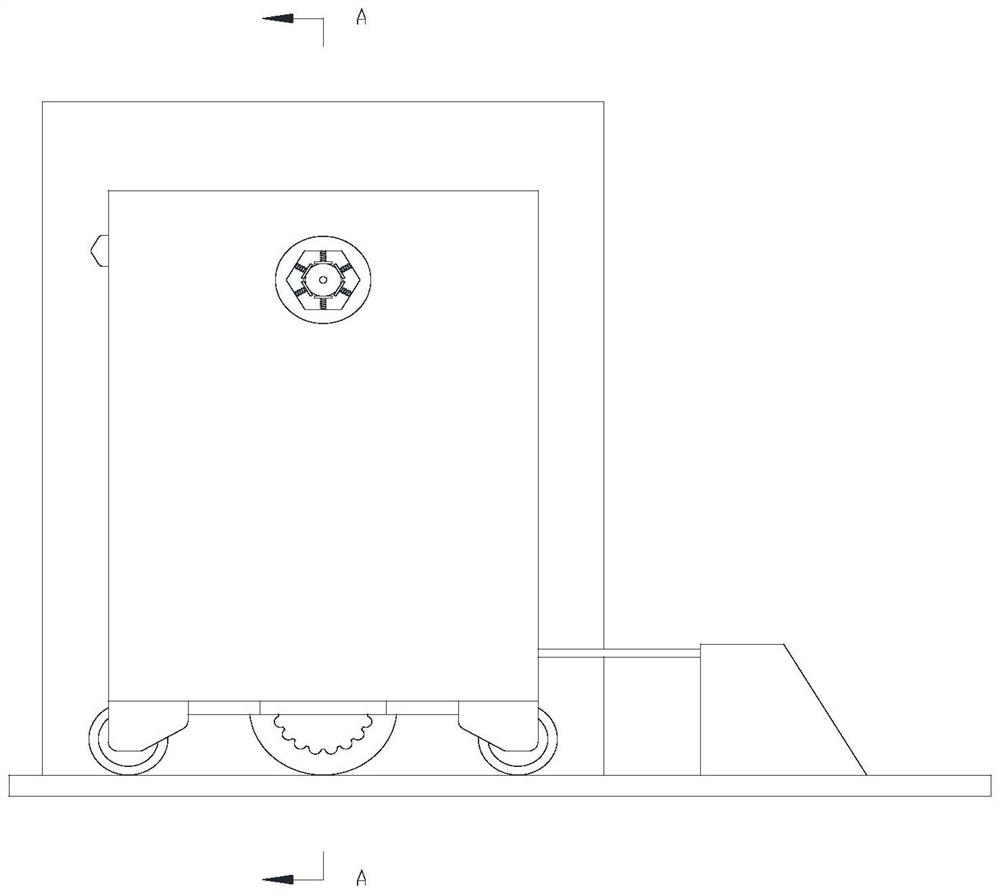

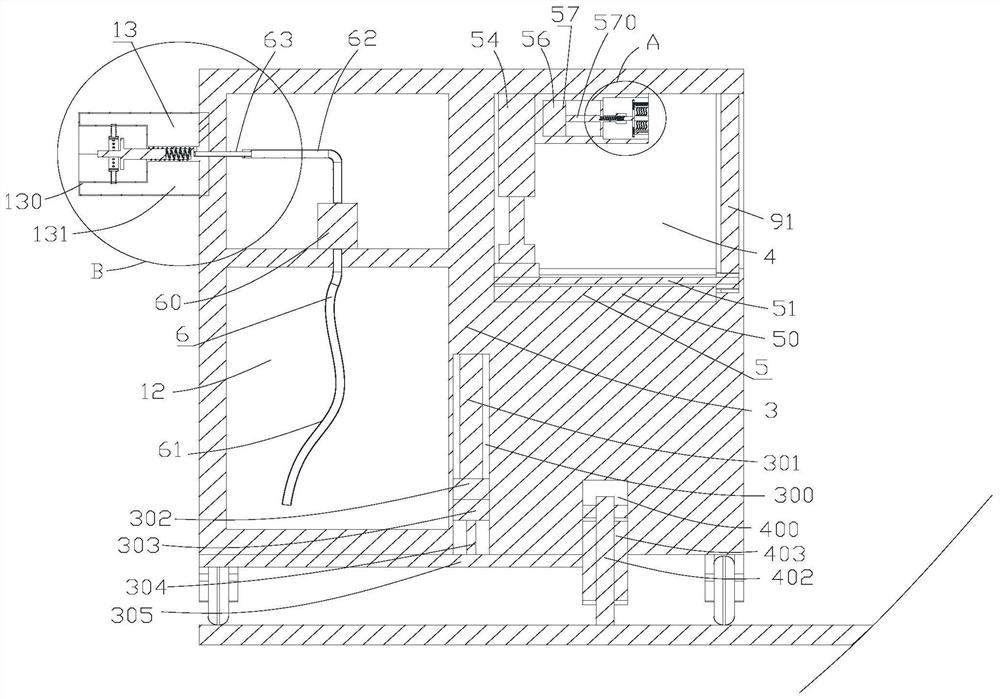

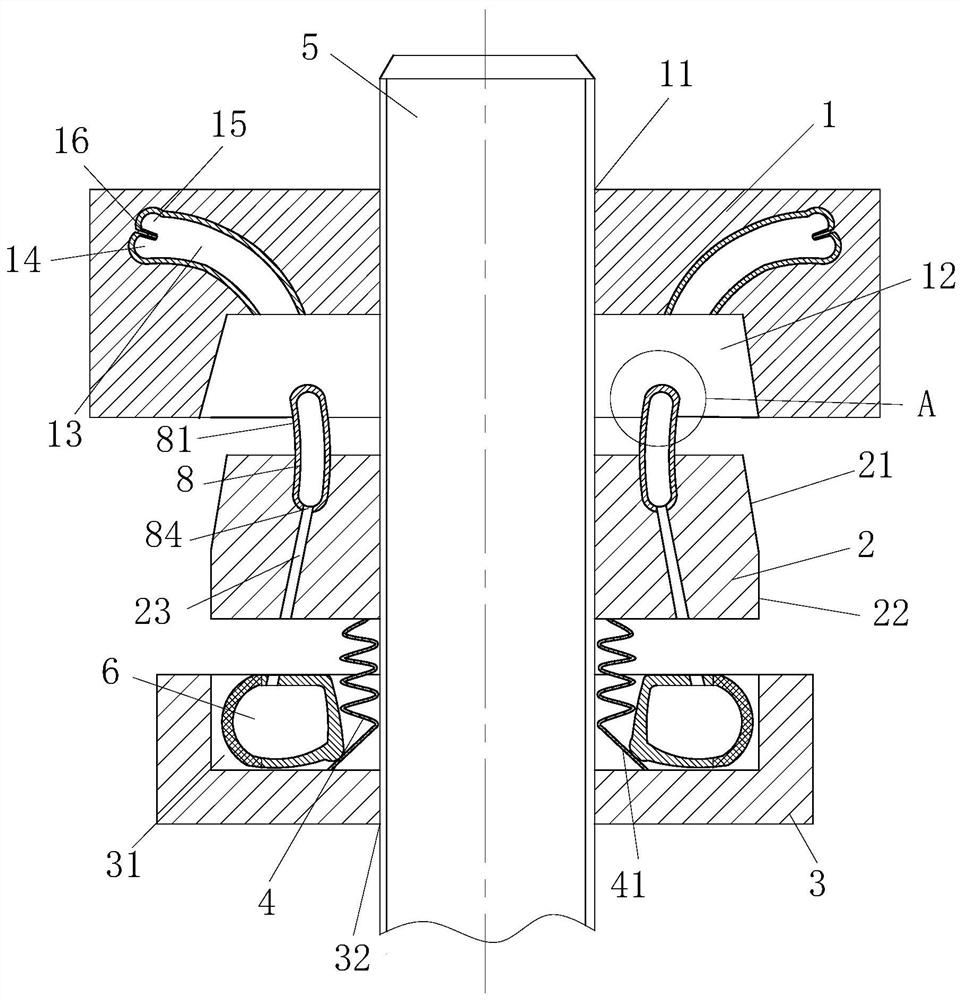

Method and device for on-line monitoring and pre-tightening force application of assembly of sandwich type longitudinal vibration transducer

ActiveCN108918014ASuppress automationAccurate preloadSustainable transportationAssembly machinesElectricityRobotic arm

Owner:HENAN POLYTECHNIC UNIV

Pressure heavy load sensor of concrete filled steel tube

InactiveCN104155050ASimple structureEasy to processFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceEngineering

Disclosed is a one-dimensional heavy load sensor which is high in accuracy, high in rigidity, large in load and low in cost. The concrete filled steel tube structure is adopted as a bearing body, the outer portion of the concrete filled steel tube structure is of a cylindrical structure, two sets of resistance strain sheets are arranged in the bearing body, the first set comprises four resistance strain sheets vertically and evenly distributed on the contact surface of concrete and the steel tube, the other set comprises one resistance strain sheet which is arranged in the center of the concrete filled steel tube, the two ends of the resistance strain sheets are connected with wires, and the wires on the resistance strain sheets are connected to external equipment through through holes in the wall and the bottom end of the sensor. The concrete filled steel tube is adopted as the bearing body, the load bearing capacity is largely increased, and the size of the bearing body can be largely reduced. The sensor is provided with the two sets of resistance strain sheets which are five in number, so that the sensitivity and accuracy of the sensor are improved. The pressure heavy load sensor of the concrete filled steel tube has the advantages of being simple in structure, convenient to machine, reliable in performance, good in load bearing capacity, high in measurement accuracy, small in size, high in rigidity, stable in performance and the like.

Owner:UNIV OF JINAN

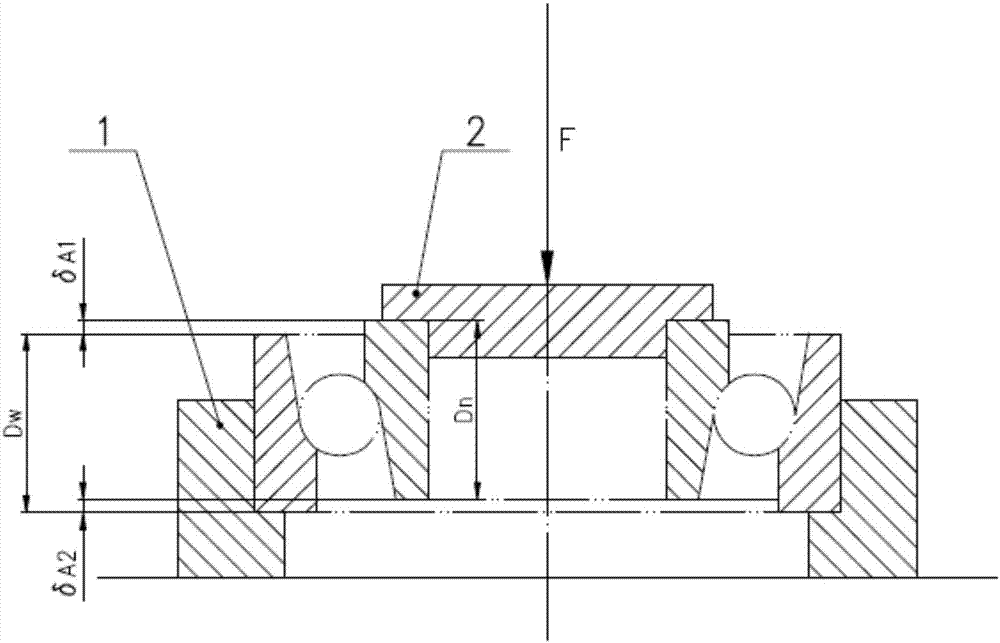

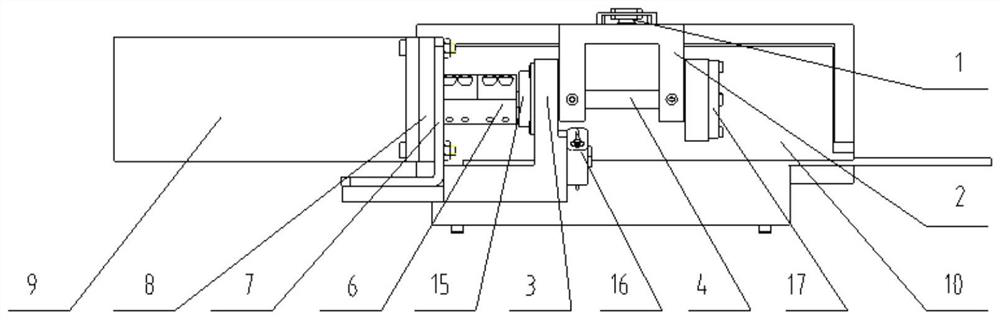

Precision matched bearing rapid adjustment device and usage method thereof

ActiveCN106949814AAccurate preloadHigh precisionMechanical clearance measurementsElectric machineryMeasurement device

The present invention belongs to the precision machinery engineering technology field, and especially relates to a precision matched bearing rapid adjustment device and a usage method thereof. The device comprises a single-bearing special measuring device and a matched bearing preload special measuring device. The device adjusts a matched bearing and applies preload at two ends of the matched bearing to avoid the problem that one bearing preload force is too large and another bearing has the unloading phenomenon in the preload loading process so as to allow the obtained matched bearing preload force to be more accurate and reasonable; a precision motor and a precision ball screw are employed to perform applying of the preload force of the matched bearing, the precision is high, and the stability is good; and moreover, the process of error test in the current operation process is avoided, the generation cost is saved, and the production efficiency is improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Double groove conjoined angular contact ball bearing

InactiveCN101113758AImprove coaxialityHigh precisionRolling contact bearingsBearing componentsEngineeringBall bearing

The invention provides a double-groove siamesed edge-contact spherical bearing, comprising an outer bearing ring, two arrays of bearing beads, two inner bearing rings, two support stands, an inner ring bushing, and a regulation gasket. Both ends of the outer bearing ring are respectively provided with a ring rolling channel corresponding with rolling channels of the two inner bearing rings, and form a contact angle; the inner ring bushing, a shoulder and the regulation gasket lock the inner bearing rings; the invention is assembled by a shaft, a craft gasket and craft screws into a detachable siamesed bearing. The invention adopts siamesed outer bearing rings, which can increase such size and position requirements as concentricity and perpendicularity of the shaft system, and endows the bearing with high precision, thus prolonging the service life of the bearings without increasing the working difficulty. The invention also has the advantages of simple structure, being convenient to be arranged, and adjustable axial preload and so on.

Owner:CHONGQING HUAYU ELECTRIC GRP

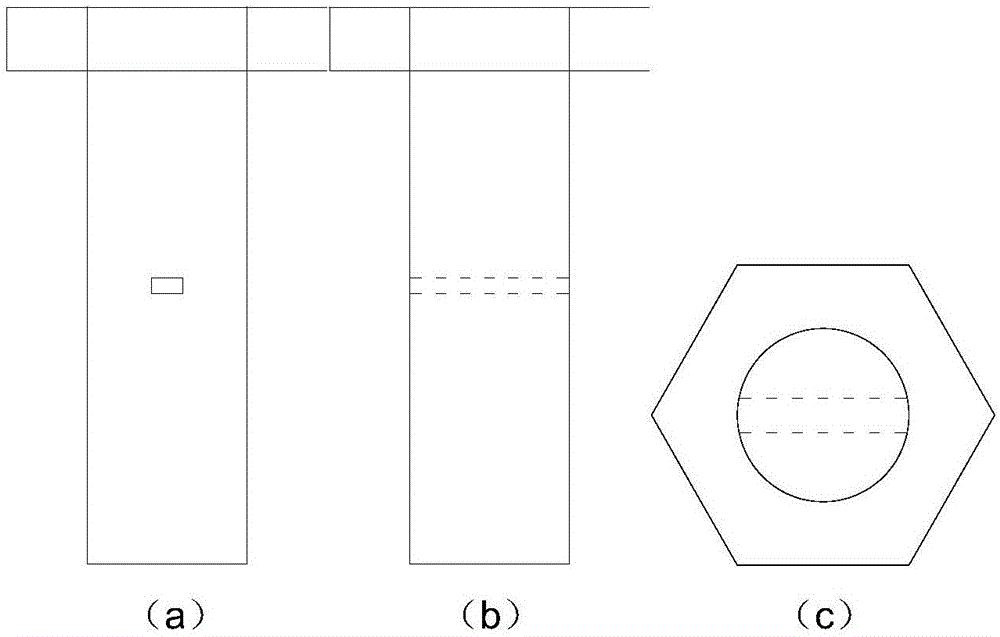

Precise pre-tightening bolt

PendingCN108571504APrecise preloadImprove durabilityScrewsMechanical measuring arrangementsHeight increasedEngineering

The invention provides a precise pre-tightening bolt. The precise pre-tightening bolt comprises a head, a screw, a mandrel and an indication wheel, wherein a through hole is formed in the end surfaceof the head, a blind hole is formed in one end of the screw, the end, where the blind hole is formed, of the screw is fixed with the head, and the though hole is coaxial with the blind hole; the mandrel is located in the through hole and the blind hole, one end of the mandrel is arranged at the bottom of the blind hole, the other end of the mandrel penetrates through the through hole and is fixedwith the indication wheel, and the distance between the indication wheel and the end surface of the head is the height increase distance of the blind hole after the precise pre-tightening bolt is mounted and reaches required pre-tightening force. The precise pre-tightening bolt has the advantages that the precise pre-tightening bolt can solve the problems that the pre-tightening force errors are large during pre-tightening mounting, pre-tightening is inconvenient and whether bolt pre-tightening is loose or not cannot be judged.

Owner:SHANGHAI WINNER ENG

Experimental device with easy-to-disassemble adjustable anchorage length and experimental method thereof

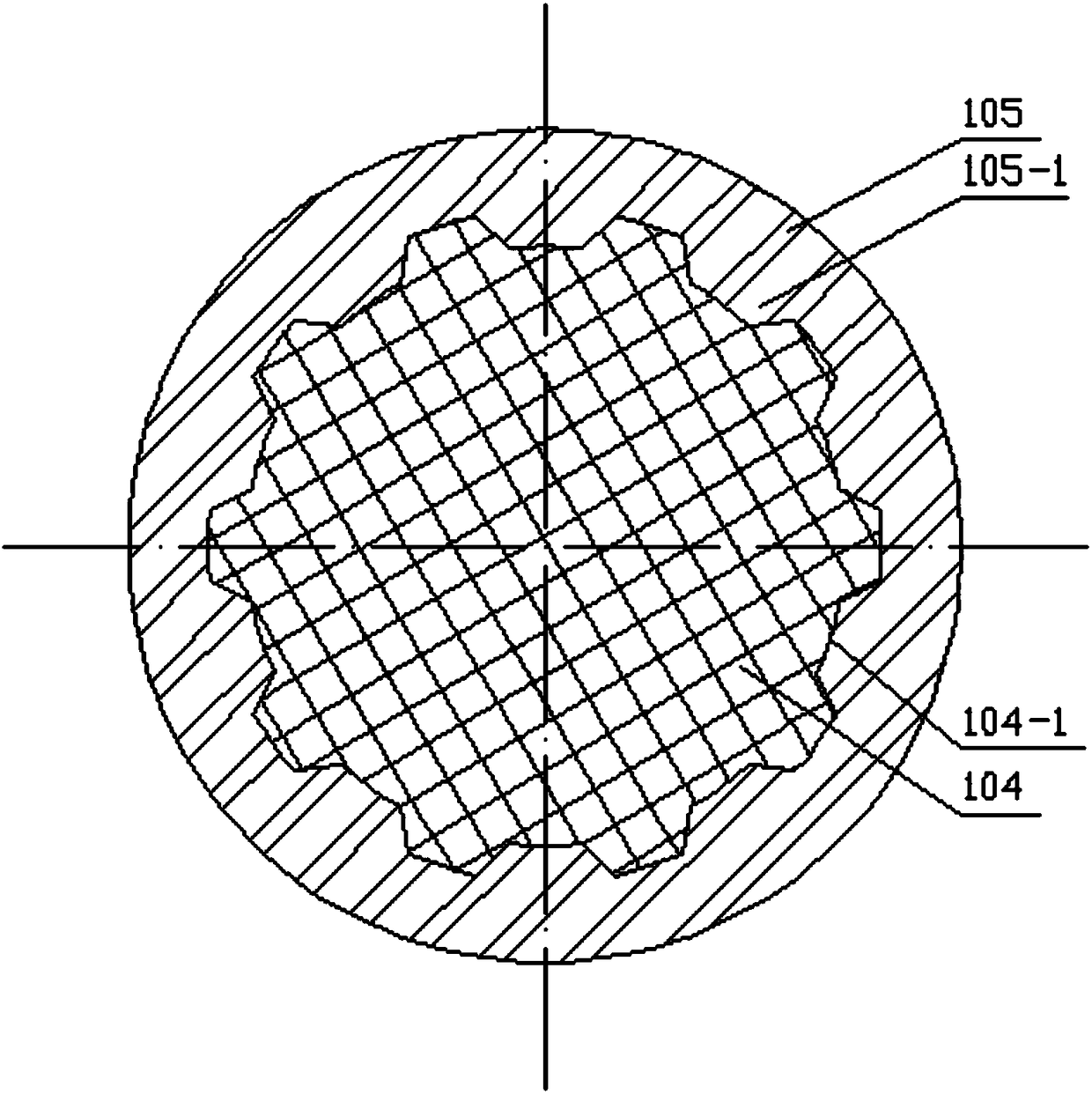

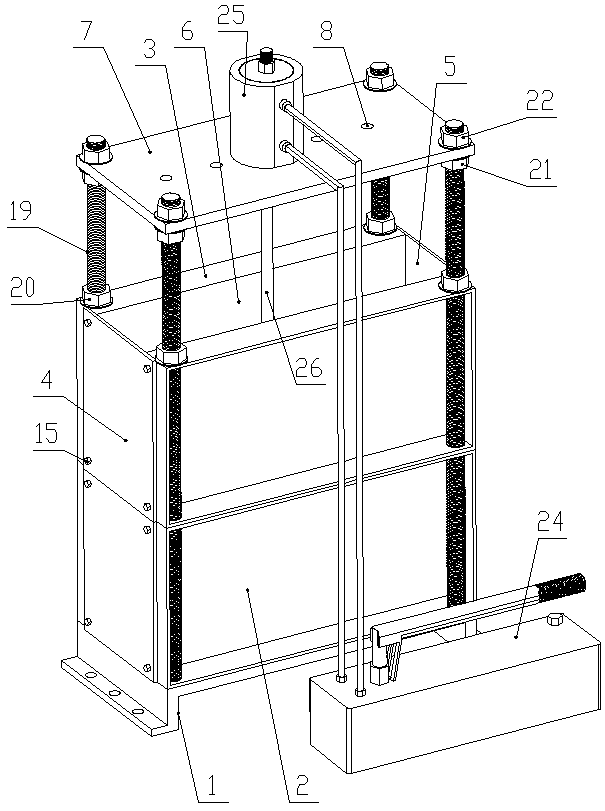

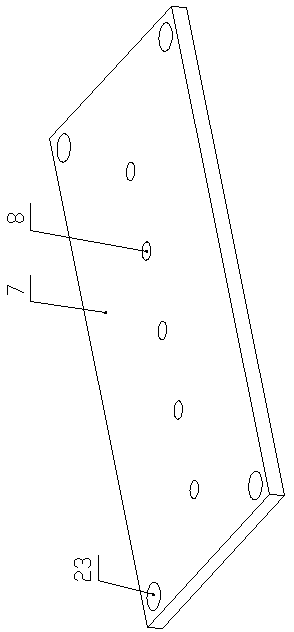

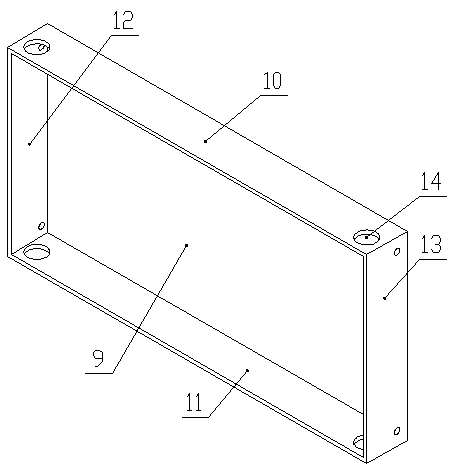

PendingCN109163896APrecise and quick application of preloadAccurate preloadMachine part testingMaterial strength using tensile/compressive forcesExperimental methodsEngineering

The invention relates to an experimental device with easy-to-disassemble adjustable anchorage length, which comprises a support, wherein a plurality of layers of front quadrangular enclosing plates are vertically arranged on the front side of the upper side of the support through two front screw components; a plurality of layers of rear quadrangular enclosing plates are vertically arranged on therear side of the upper surface of the support through two rear screw components; a layer of left flat enclosing plate is arranged on the left side of each layer of the front quadrangular enclosing plate and the rear quadrangular enclosing plate; a layer of right flat enclosing plate is arranged on the right side of each layer of the front quadrangular enclosing plate and the rear quadrangular enclosing plate; an anchorage experimental panel is horizontally arranged on the front screw component and the rear screw component; a plurality of vertical pass-through anchorage holes are formed in theanchorage experimental panel. The invention further discloses an experimental method of the experimental device with easy-to-disassemble adjustable anchorage length. The experimental device with easy-to-disassemble adjustable anchorage length and experimental method thereof in the invention can simulate the whole process of the roadway bolt or anchor cable support in an intuitive system, facilitate the research of the on-site anchor bolt or anchor cable support construction process, and also facilitate the detection of the quality of the on-site anchor bolt or anchor cable support; meanwhile,the anchoring process of the roadway bolt or anchor cable can be simulated.

Owner:HENAN POLYTECHNIC UNIV

Space flexible arm tail end tool box pressing and anti-radiation protection mechanism

The invention provides a space flexible arm tail end tool box pressing and anti-radiation protection mechanism, belonging to the technical field of tool box pressing and anti-radiation protection. Ananti-radiation cover plate is connected with a transmission shaft through a screw; a position detection micro switch, bearing blocks and an L-shaped motor base are connected to a fixed base by screws;the left end of the transmission shaft is connected with a drive motor and a reducer assembly through a coupling, the drive motor and the reducer assembly are connected to the L-shaped motor base through a heat insulating pad by bolts; a limit micro switch is connected to the bearing blocks by screws, and deep groove ball bearings are mounted on the bearing blocks, and the transmission shaft is mounted on a bearing through positioning parts such as a right bearing end cap, a left bearing end cap and a shaft sleeve. According to the invention, relatively accurate pre-tightening force can be applied, assembly and adjustment are convenient, and no impact and vibration during unlocking are caused; smooth in and out and anti-radiation protection of a tail end tool box can be realized; and thetail end of a flexible arm cannot be thrown out under the effect of large inertia force.

Owner:HARBIN INST OF TECH +1

A method and device for applying pre-tightening force on anchor rods

ActiveCN103244159BReduce material requirementsAvoid damageAnchoring boltsHydraulic cylinderAxial force

The invention provides a method and a device for exerting an anchor rod pretightening force and is suitable for general tunnel and roadway surrounding rock timbering engineering. During anchor rod pretightening force exerting, an anchor rod drilling hole is firstly constructed through a drilling machine, a resin medicine roll and an anchor rod are filled in the drilling hole sequentially, and a tray and a nut are sleeved on an external road section of the anchor rod. A pneumatic rock drill drives the anchor rod to rotate so as to break the medicine roll, and strength can be formed when the medicine roll is solidified; a hydraulic tensioner is installed; a hydraulic cylinder is started to exert a tension pretightening force on the anchor rod, and a suspended nut is screwed in by a wrench to be contacted with the tray; and the pressure of the hydraulic cylinder is reduced to be zero, and the hydraulic tensioner is removed. By means of the method and the device for exerting the anchor rod pretightening force, anchor rod pretightening force construction can meet the design requirements easily, the process that a traditional torque circumferential force is converted into an axial force in an anchor rod pretightening force construction method is changed, requirements on materials of the anchor is reduced, damage to the anchor rod is avoided, and the construction efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

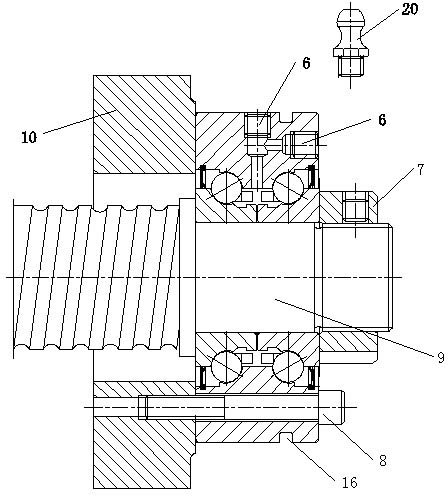

Two-stage slide valve electro-hydraulic servo valve driven by giant magnetostrictive actuator

InactiveCN101598150BAvoid or overcome hysteresisHigh driving powerServomotor componentsMagnetostrictive actuatorElectro hydraulic

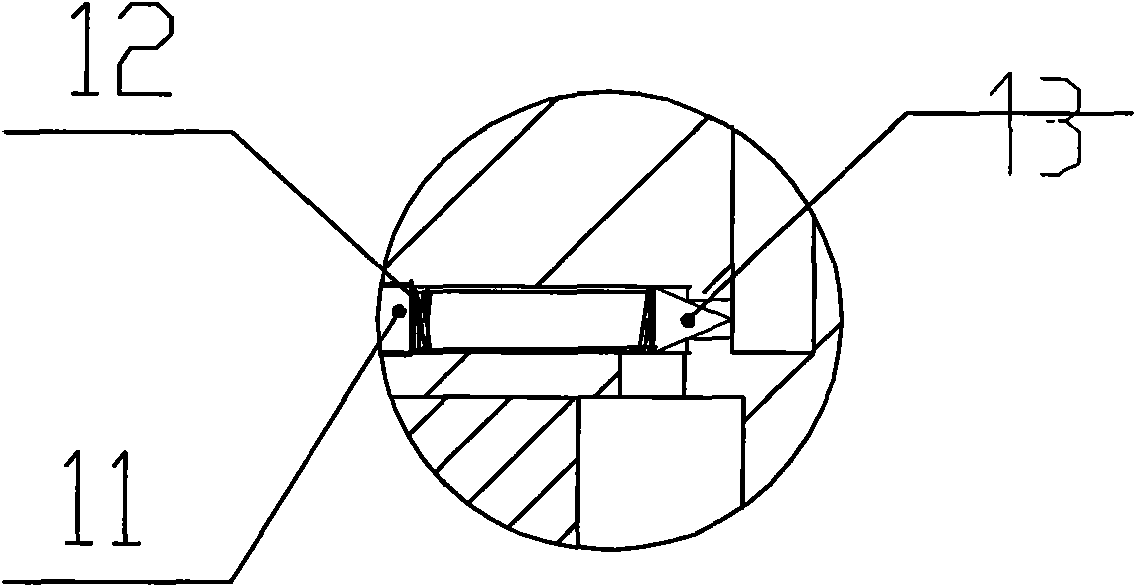

A two-stage slide valve electro-hydraulic servo valve driven by a giant magnetostrictive actuator belongs to the technical field of hydraulic servo control. The two-stage slide valve electro-hydraulic servo valve comprises a valve body (26), a main valve plug (5), a pilot valve plug (6), a giant magnetostrictive actuator, a micrometric displacement amplifier located between the giant magnetostrictive actuator and the pilot valve plug (6); the above giant magnetostrictive actuator comprises a thermal compensation cover (12), a giant magnetostrictive rod (13) arranged in the thermal compensation cover, a coil framework located at the external side of the thermal compensation cover (12) and a drive coil (4) and a bias coil (3) which are wound around the external side of the coil framework (2) in sequence; and the servo valve has the characteristics of large drive power and quick response speed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Space Flexible Arm Compression Release Mechanism for Fusible Link Unlocking

The invention provides a space flexible arm pressing and releasing mechanism for fuse unlocking, which belongs to the technical field of space flexible arm pressing and releasing mechanisms. The invention includes a fixed base, a fuse unlocking device, a pressing cover, a position detection micro switch, a phenyl silicone rubber sheet, a torsion spring, a pin shaft and a limit micro switch; before launching, adjust the position of the fuse unlocking device The locking device exerts an appropriate pre-tightening force on the pressing cover plate through the pull rope, so that the space flexible arm is pressed on the fixed base. After entering orbit, the ground sends a command to energize the cutter of the fuse unlocking device, and the resistance wire of the cutter heats up rapidly to fuse the pull rope. The present invention is reliable in compression, adopts the fusible wire unlocking device as the compression and unlocking tool, has a simple structure, can apply more accurate pre-tightening force, and is convenient for assembly and adjustment; there is no shock and vibration when unlocking, and can protect the space flexible arm from being damaged when launching. The damage caused by vibration and shock load is suitable for occasions where the locking force of the space flexible arm is not required.

Owner:HARBIN INST OF TECH +1

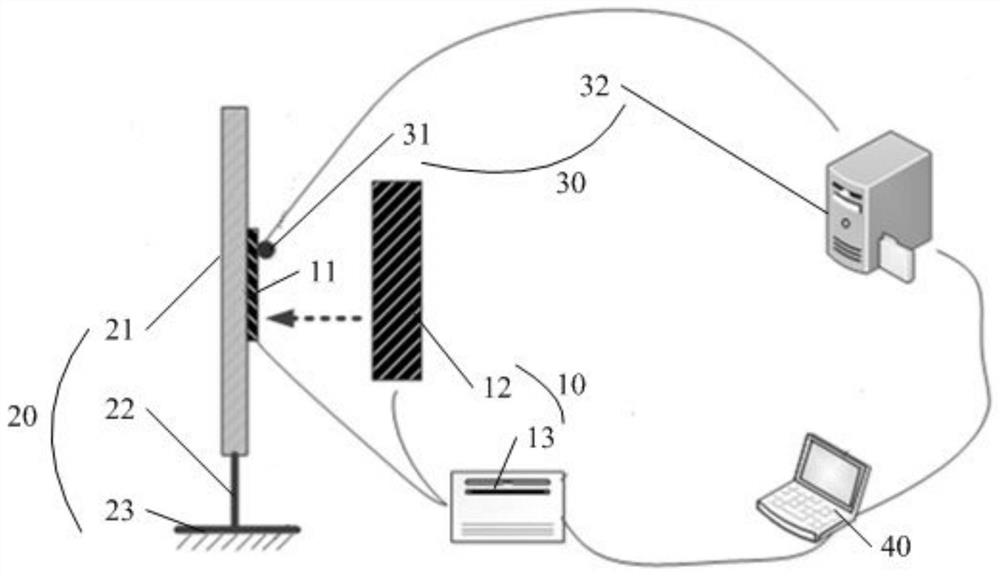

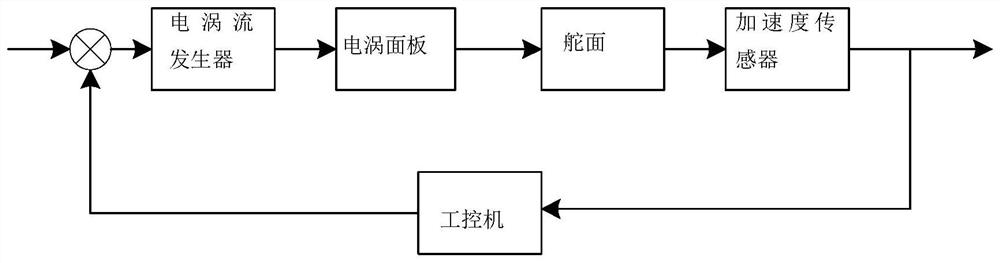

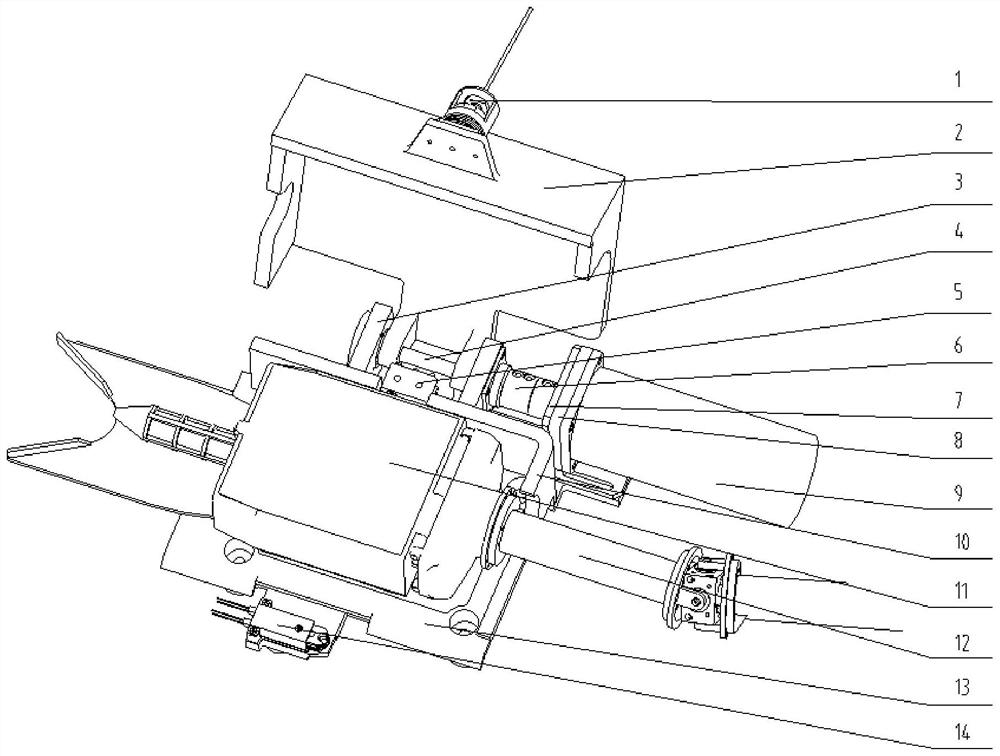

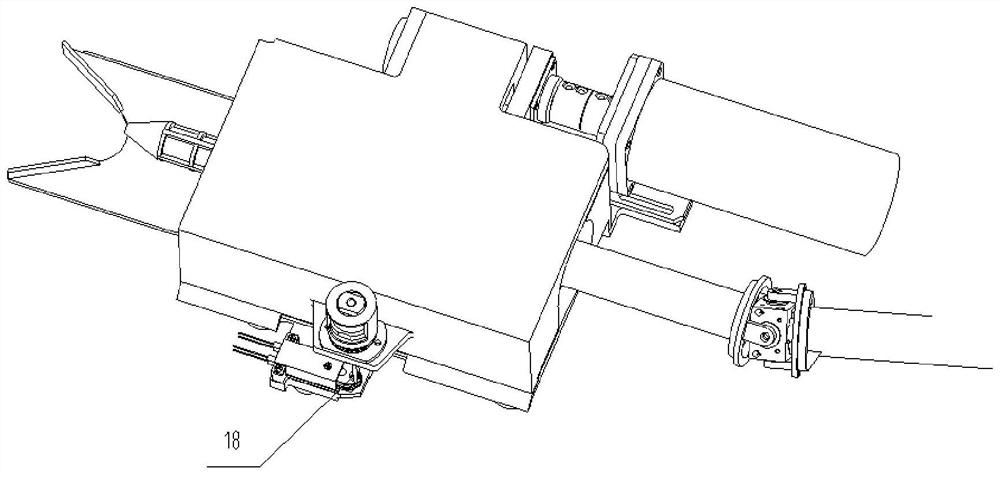

Modal test preload applying device, modal test system and preload applying method

PendingCN114295465AAccurate preloadEasy to adjustMachine part testingAircraft components testingControl engineeringControl cell

The invention provides a modal test preload applying device, a modal test system and a preload applying method, the device comprises a preload applying unit, a preload feedback unit and a preload control unit, the preload applying unit is used for applying preload to a test piece; the preload feedback unit is used for acquiring the preload applying time and the normal displacement of the test piece; the preload control unit is used for calculating a preload value according to the time and the normal displacement, comparing the preload value with a preset preload value, and controlling the preload applying unit to reduce the preload applied to the test piece when the preload value is greater than the preset preload value; and when the value of the preload is smaller than the preset preload value, the preload applying unit is controlled to increase the preload applied to the test piece. According to the technical scheme, the technical problems that in the prior art, preloading cannot be adjusted adaptively and accurately, and stable and complete modal parameters cannot be obtained are solved.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

A space flexible arm end tool box compression and anti-radiation protection mechanism

The invention provides a space flexible arm end tool box compression and anti-radiation protection mechanism, which belongs to the technical field of tool box compression and anti-radiation protection. In the present invention, the anti-radiation cover is connected to the transmission shaft through screws; the position detection microswitch, the bearing seat and the L-shaped motor seat are connected to the fixed base through screws; the left end of the transmission shaft is connected to the drive motor and The reducer components are connected, the drive motor and reducer components are connected to the L-shaped motor base through bolts through the heat insulation pad; the limit micro switch is connected to the bearing base through screws, and deep groove ball bearings are installed on the bearing base, and the drive shaft passes through the left Positioning parts such as bearing end cover, right bearing end cover and shaft sleeve are installed on the bearing. The present invention can apply more accurate pre-tightening force, is convenient for assembly and adjustment, and when unlocking, there is no impact or vibration; it can realize the smooth entry and exit of the end tool box and radiation protection; it can prevent the end of the flexible arm from being affected by a large inertial force was thrown out.

Owner:HARBIN INST OF TECH +1

A kind of active pretensioning safety belt of automobile

Owner:HUNAN UNIV +1

Detection method for fastener and detection device thereof

PendingCN113670497AAccurate preloadMeasurement of torque/twisting force while tighteningEngineeringRelative slip

The invention discloses a fastener looseness detection method and a detection device thereof, and the method comprises residual pre-tightening force detection and looseness detection, and the pre-tightening force detection comprises the following steps: step 1, coating the head of a fastener with a luminescent material; and step 2, enabling the mechanoluminescent material to generate strain change. The looseness detection includes the following steps: step 1, enabling the side face of the head of a fastening piece and a base material of a connected piece to be provided with scribed lines; and 2, comparing the lineation on the fastening piece with the lineation on the base material of the connected piece to judge whether relative slip occurs or not. After the fastener is loosened, the loosened fastener is mounted, and in the mounting process, the corresponding wavelength can be compared according to the color emitted by the luminescent material, and then the pre-tightening force is loaded, so that accurate pre-tightening force mounting is realized, a worker does not need to independently check the loosening phenomenon of the fastener. The automatic setting is more convenient and faster, and the labor cost is reduced.

Owner:烟台中天连接技术研究院

A jack-up pre-tightening system for locknuts

Owner:六安联众工业自动化技术有限公司

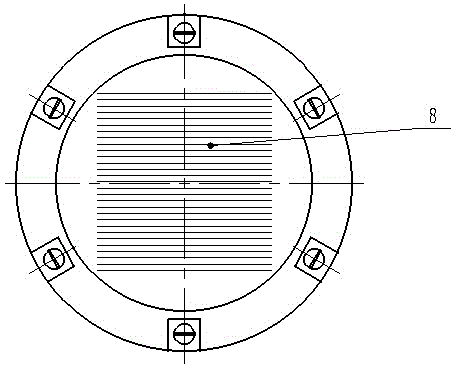

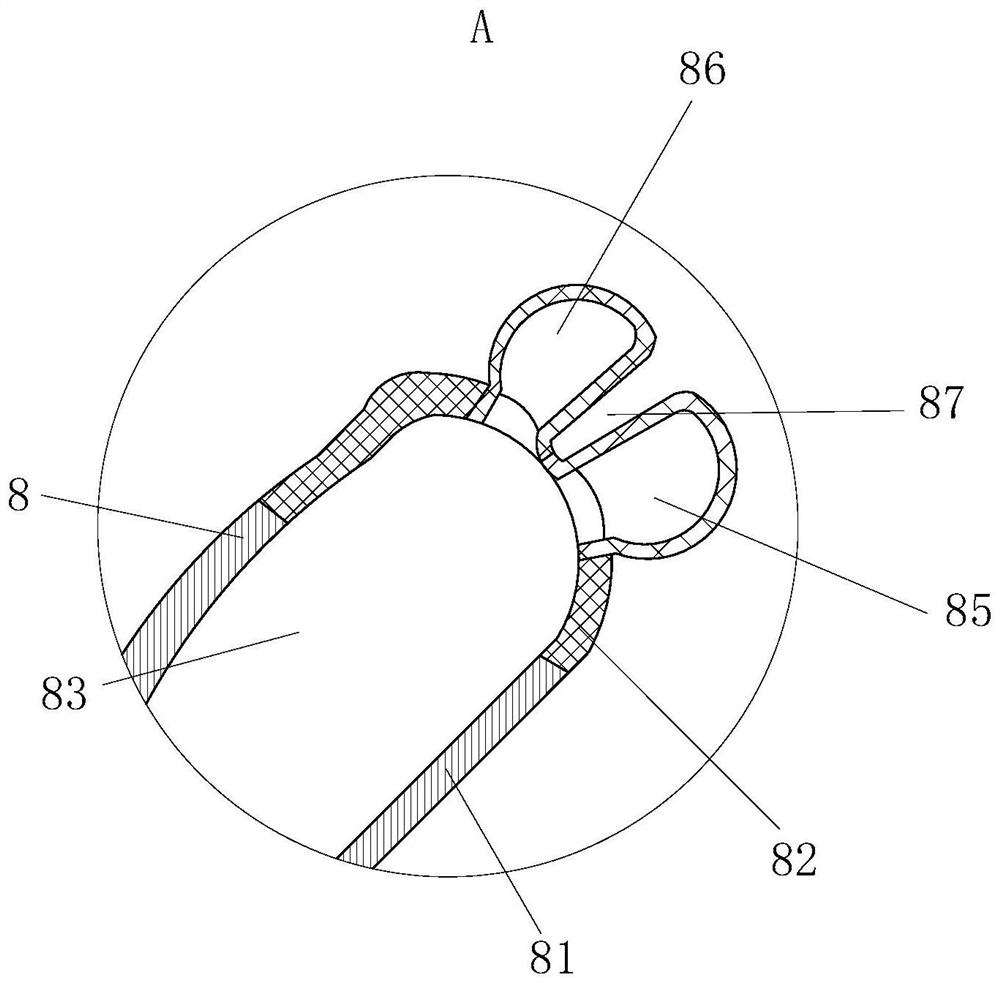

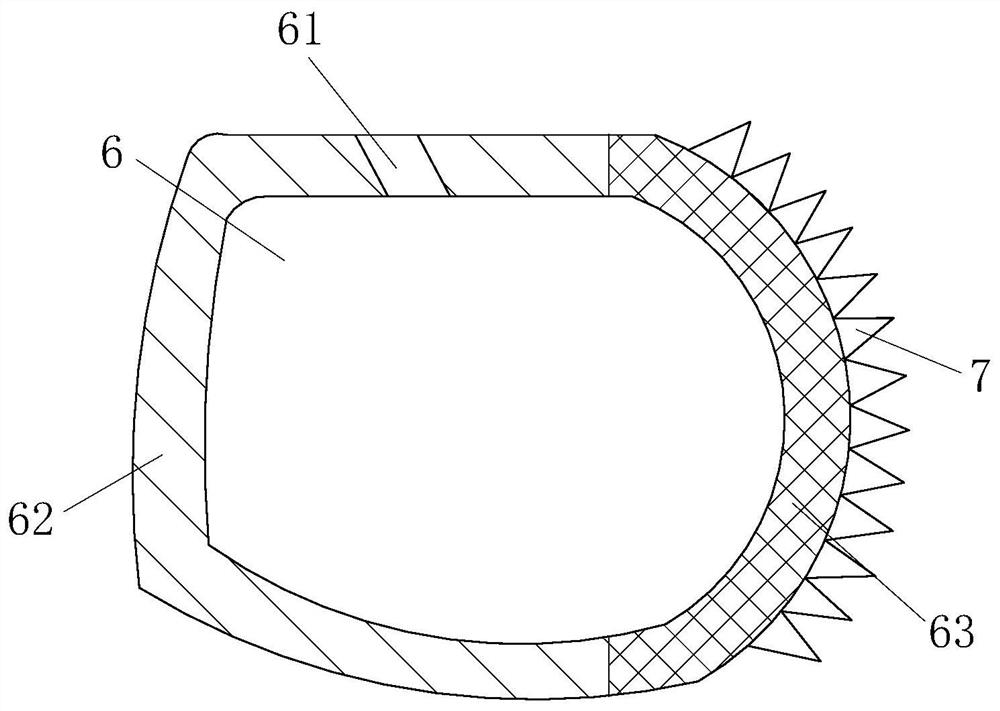

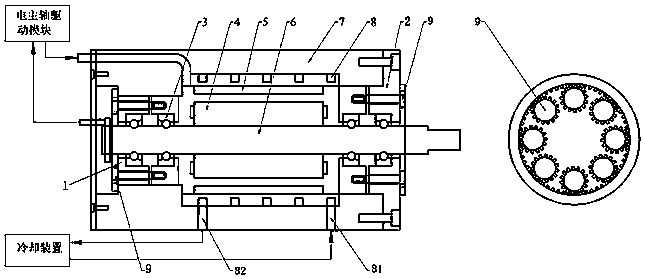

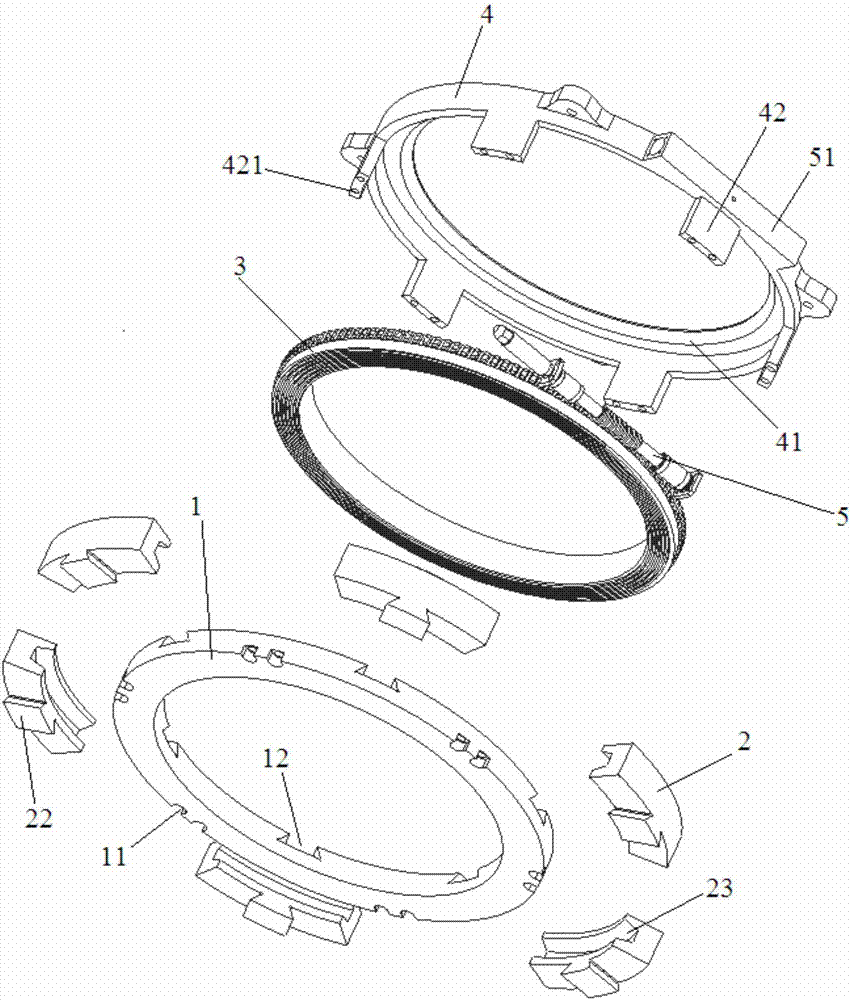

Numerically-controlled machine tool electric spindle adopting integrated bearings

InactiveCN108544251AGuaranteed preload sizeUniform preloadLarge fixed membersMaintainance and safety accessoriesNumerical controlBall bearing

The invention discloses a numerically-controlled machine tool electric spindle adopting integrated bearings, and relates to the field of numerical control. The numerically-controlled machine tool electric spindle can solve the problem that the machining quality and the machining accuracy are influenced by unreasonable electric spindle arrangement in the prior art. The numerically-controlled machine tool electric spindle comprises a motor shell and a spindle body, a cooling groove is formed inside a shell, and a stator winding is sleeved with the inner side of the shell and is connected with anelectric spindle driving module. The spindle body and angular contact ball bearings are combined and assembled to form inner-ring-free integrated shaft and bearings, the spindle body is sleeved witha rotor winding, and the rotor winding is connected with the electric spindle driving module. The two ends of the shell are provided with bearing blocks, the bearing block at the right end is fixedlyconnected with the shell through a fixing bolt, each pair of angular contact ball bearings and the corresponding pair of bearing blocks are installed in a mirror image manner, pre-tightening bolts onthe outer sides of each pair of bearing blocks are connected through cooperation of large and small gears, and a bearing pre-tightening linkage device is formed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

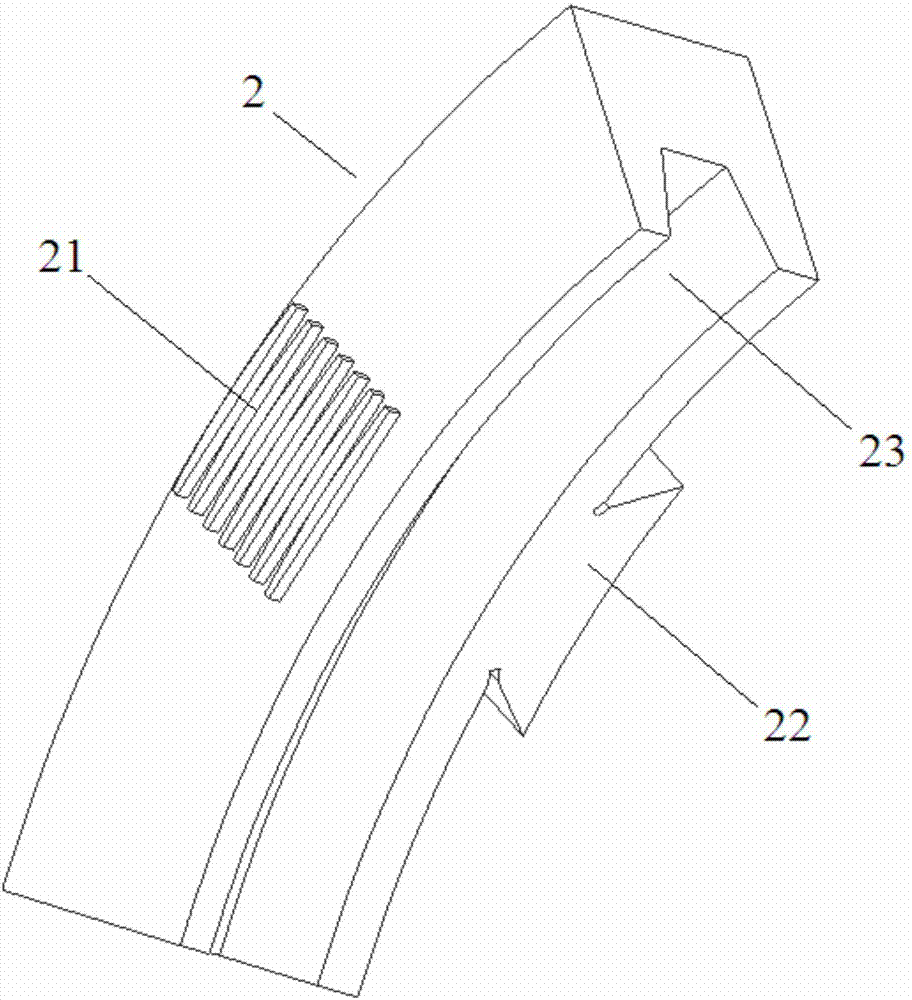

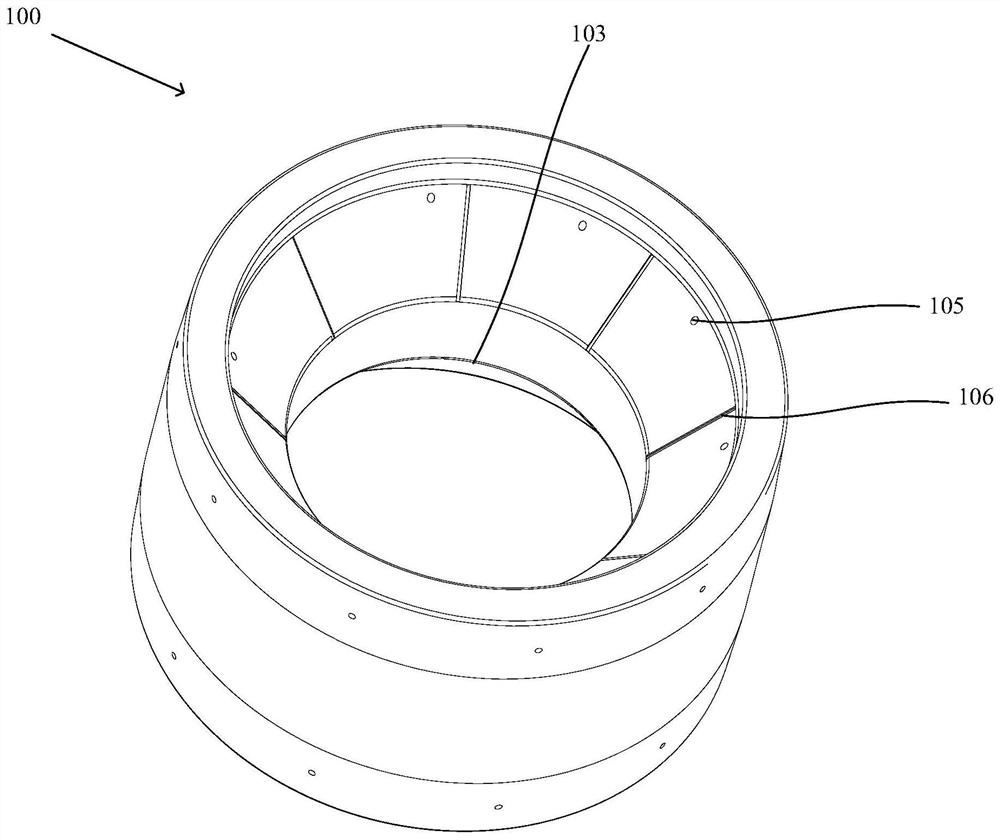

a precision chuck

The invention discloses a precise chuck plate. The precise chuck plate comprises a threaded rotary disc, a fixed ring, clamping clacks, a guiding ring and a worm, wherein the threaded rotary disc is in a disc shape and comprises an annular side surface and a cylindrical outer surface; a first pre-tightened thread of which the lead direction is distributed in the radial direction of the threaded rotary disc is formed on the side surface of the threaded rotary disc; a gear structure is formed on the outer surface of the threaded rotary disc; the threaded rotary disc is accommodated in a cavity body of the fixed ring and can rotate around the axis of the fixed ring; the guide ring and the fixed ring are oppositely arranged and fixedly connected; the side surface of the guide ring makes contact with the other sides of the clamping clacks; and the worm and the threaded rotary disc form a worm wheel and worm transmission structure. According to the precise chuck plate provided by the invention, the shrinkable clamping clacks are arranged in the precise chuck plate, and the worm wheel and worm transmission structure is used, so that the function of controlling the clamping clacks to be shrunk or released synchronously and concentrically is achieved by screwing the worm; the structure of a clamping hoop is precise, and precise pre-tightening can be achieved; and in addition, pre-tightening operation is easy, the manual operation difficulty is reduced, and remote control operation is achieved conveniently through a mechanical hand.

Owner:DONGGUAN NEUTRON SCI CENT +2

Double groove conjoined angular contact ball bearing

InactiveCN100458365CHigh precisionImprove coaxialityRolling contact bearingsBearing componentsBall bearingSpherical bearing

The invention provides a double-groove siamesed edge-contact spherical bearing, comprising an outer bearing ring, two arrays of bearing beads, two inner bearing rings, two support stands, an inner ring bushing, and a regulation gasket. Both ends of the outer bearing ring are respectively provided with a ring rolling channel corresponding with rolling channels of the two inner bearing rings, and form a contact angle; the inner ring bushing, a shoulder and the regulation gasket lock the inner bearing rings; the invention is assembled by a shaft, a craft gasket and craft screws into a detachable siamesed bearing. The invention adopts siamesed outer bearing rings, which can increase such size and position requirements as concentricity and perpendicularity of the shaft system, and endows the bearing with high precision, thus prolonging the service life of the bearings without increasing the working difficulty. The invention also has the advantages of simple structure, being convenient to be arranged, and adjustable axial preload and so on.

Owner:CHONGQING HUAYU ELECTRIC GRP

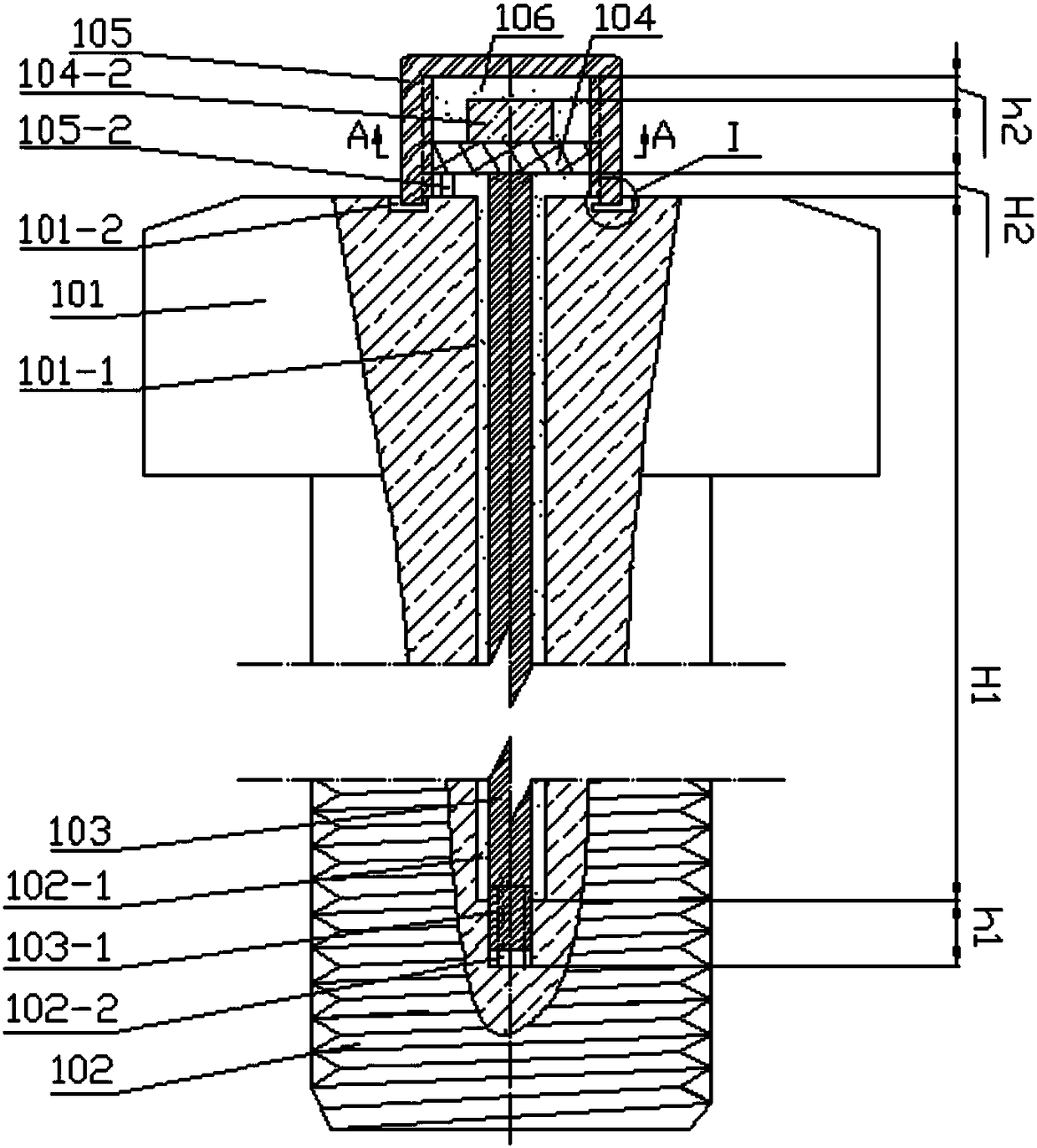

Taper bearing installation method using taper bearing test tool

ActiveCN103292996BImprove installation accuracyExtended service lifeMachine bearings testingMechanical measuring arrangementsRelative displacementEngineering

Owner:山东华成中德传动设备有限公司

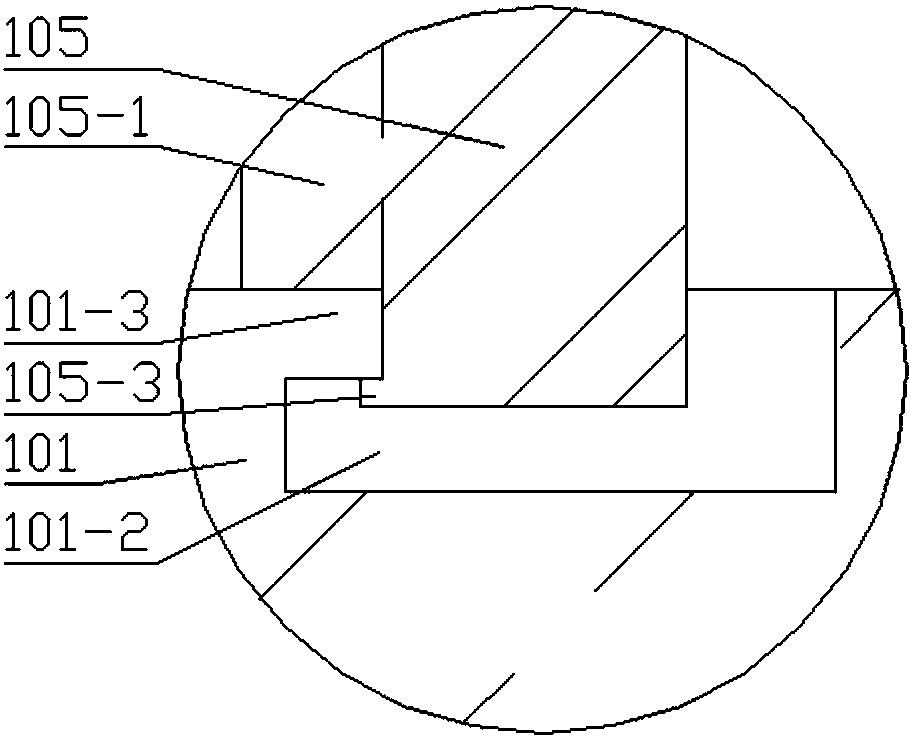

Main speed reducer bearing unit and assembling method

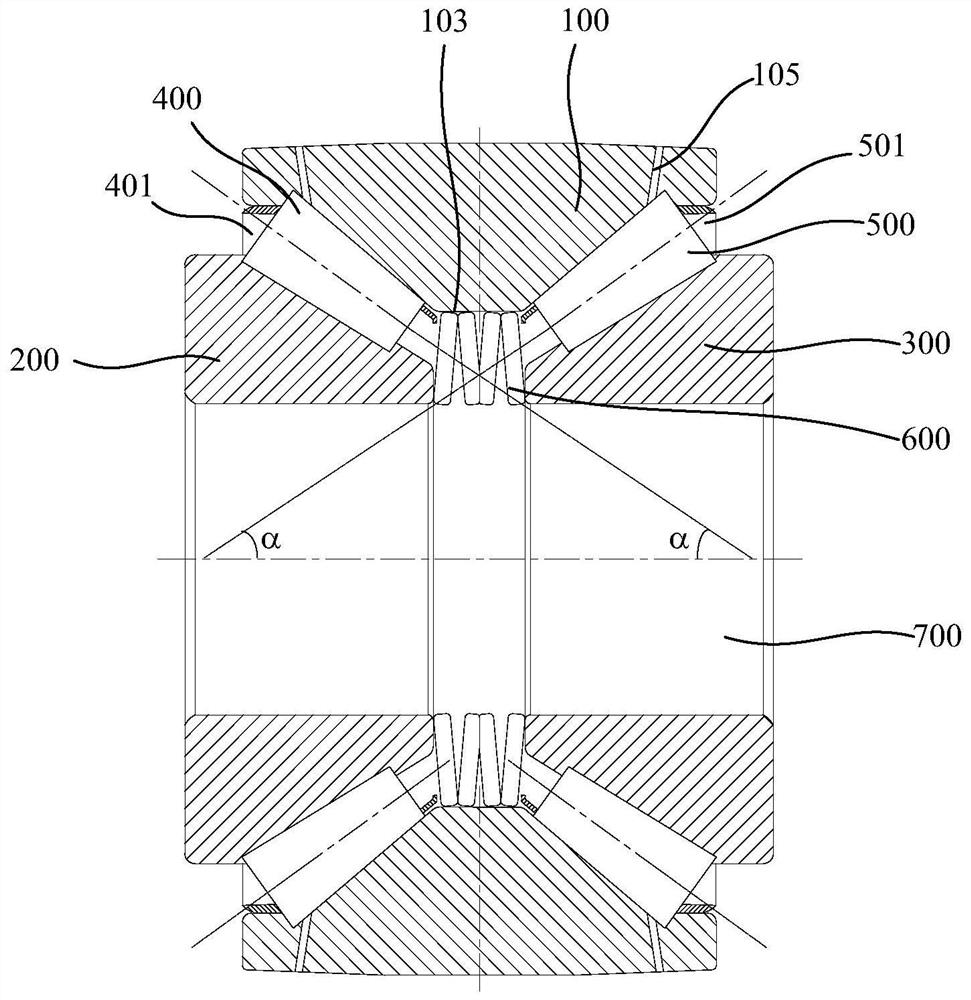

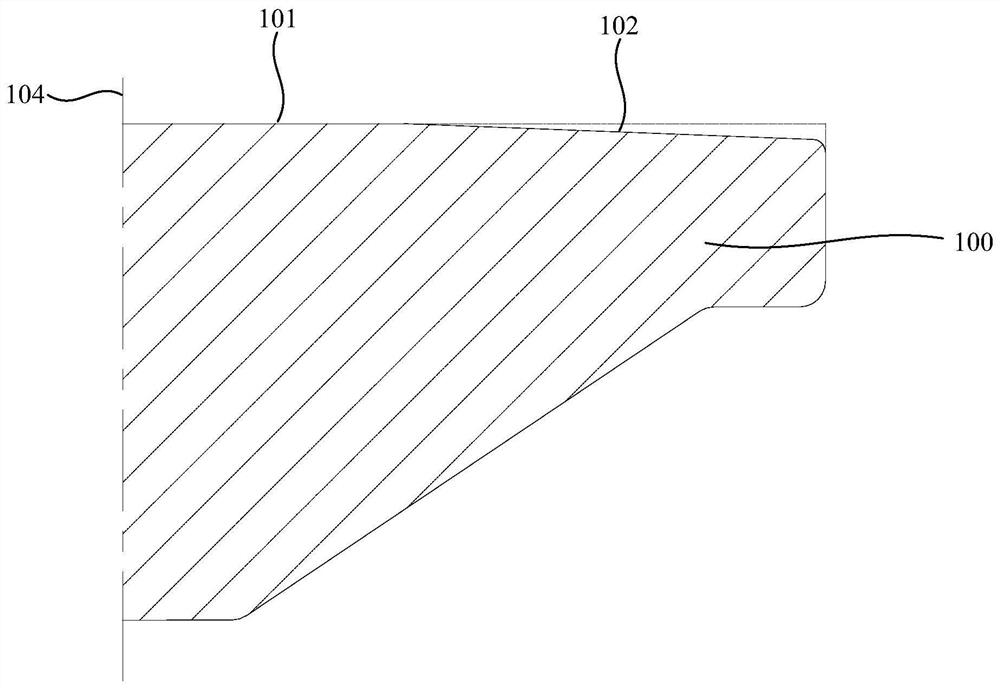

PendingCN113374787AExtended service lifeAccurate preloadRolling contact bearingsShaftsReduction driveClassical mechanics

The invention provides a main speed reducer bearing unit and an assembling method. The main speed reducer bearing unit comprises a bearing outer ring, a first bearing inner ring, a second bearing inner ring, first tapered rollers, second tapered rollers and elastic bodies. The bearing outer ring is mounted on a bearing seat of a main speed reducer; the first bearing inner ring is coaxially and rotatably mounted at the inner side of the bearing outer ring, and the first bearing inner ring and the bearing outer ring form a first tapered roller path; the second bearing inner ring is coaxially and rotatably mounted at the inner side of the bearing outer ring, and the second bearing inner ring and the bearing outer ring form a second tapered roller path; the first tapered rollers are mounted in the first tapered roller path; the second tapered rollers are mounted in the second tapered roller path; and the elastic bodies are installed between the first bearing inner ring and the second bearing inner ring. The main speed reducer bearing unit is simple in structure, and solves the problem that accurate axial pre-tightening is not prone to be realized when a gasket is adopted to adjust the distance between the the bearing inner rings in the prior art.

Owner:山东朝阳轴承有限公司

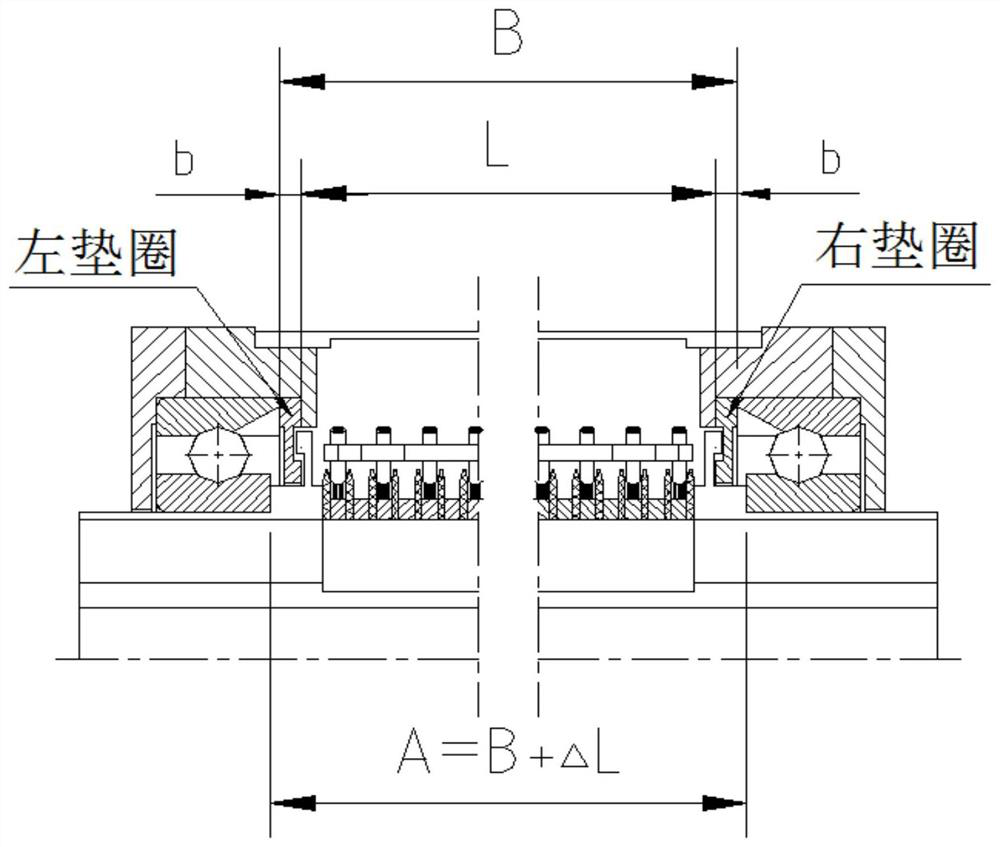

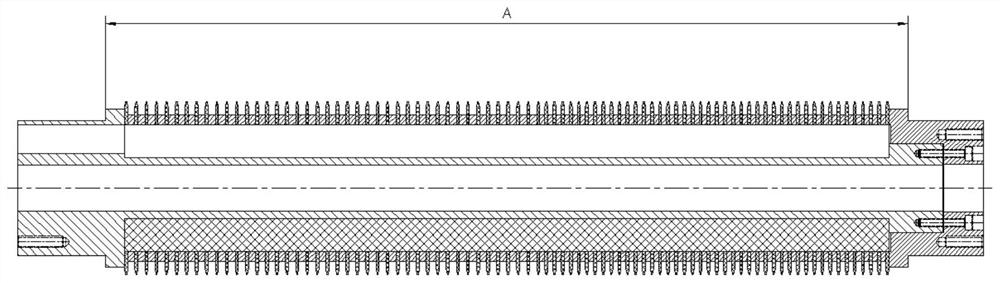

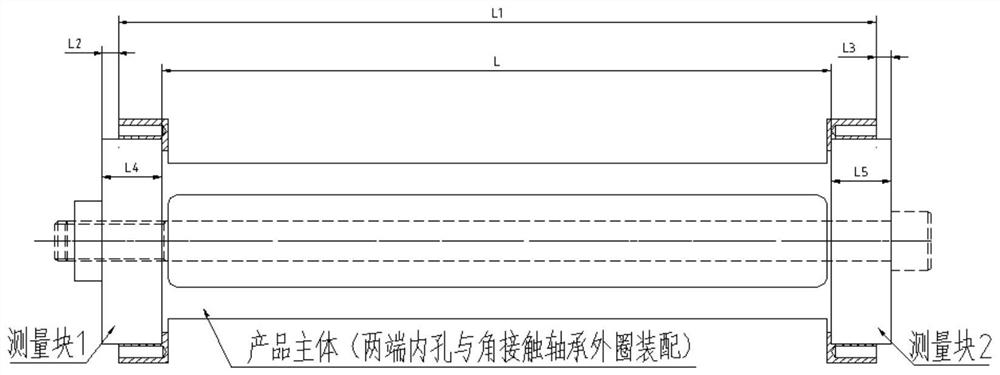

Angular contact bearing pre-tightening method

ActiveCN112879444APrecise relative movementGuaranteed preloadBearing unit rigid supportStructural engineeringDistance measurement

The invention relates to the technical field of bearing pre-tightening, in particular to an angular contact bearing pre-tightening method. The method comprises the following steps that the length of a bearing inner ring mounting position is measured; the left side end of an angular contact bearing is provided with a first measuring block, and the right side end of the angular contact bearing is provided with a second measuring block; the thickness of the first measuring block and the thickness of the second measuring block are measured through a measuring instrument; the first measuring block and the second measuring block are installed in a mounting bearing outer ring part main body, so that the mounting end face is tightly attached to the main body mounting bearing end face; the high-precision measuring instrument is used for measuring the distance between the opposite end faces of the first measuring block and the second measuring block, the distance between the outer side end face of the first measuring block and the left side end face of the main body as well as the distance between the outer side end face of the second measuring block and the right side end face of the main body; the distance L between the two end faces of the mounting bearing outer ring part main body is calculated; and the thickness of a gasket is calculated through the value L. By adoption of the method, the accurate size of the angular contact bearing adjusting gasket is obtained by arranging the measuring blocks, and it is guaranteed that the pre-tightening force of the angular contact bearing is achieved.

Owner:杭州全盛机电科技有限公司

A combined self-reaction anti-loosening nut with high-precision torque coefficient

ActiveCN106837980BReduce failureImprove operational reliabilityNutsBoltsProcess engineeringPetrochemical

The invention relates to a combined type self-reaction-force locknut with a high-precision torque coefficient. The combined type self-reaction-force locknut comprises a slotted nut, a gasket and a thread ring. When a working bolt is in a tightened state, the thread ring is embedded between the gasket and the bolt in the form of a wedge-shaped ring, and connection between the working bolt and the nut is effectively prevented from loosening. According to the combined type self-reaction-force locknut, in bolt and nut connection in the mechanical industry, mounting is achieved at the level of the small friction coefficient to obtain precise bolt pre-tightening force, and the anti-loose function is kept all the time in the equipment operating process. According to the combined type self-reaction-force locknut, in the equipment operating process of the mechanical industry, especially the petroleum and petrochemical industry, the power generation industry, the offshore wind power industry, the nuclear power industry, the high-speed rail industry, the bridge industry and the like, the reliability and safety of bolt and nut connection are greatly increased, and therefore the frequency of manual point detection and maintenance of bolts and nuts is greatly reduced. By means of scale use and popularization of the combined type self-reaction-force locknut, unlimited economic value can be generated.

Owner:倍扣(上海)技术开发经营中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com