Detection method for fastener and detection device thereof

A detection method and detection device technology, which can be used to measure the direction of torque/torsion during tightening, which can solve problems such as hidden safety hazards, poor detection effect, and strong work of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

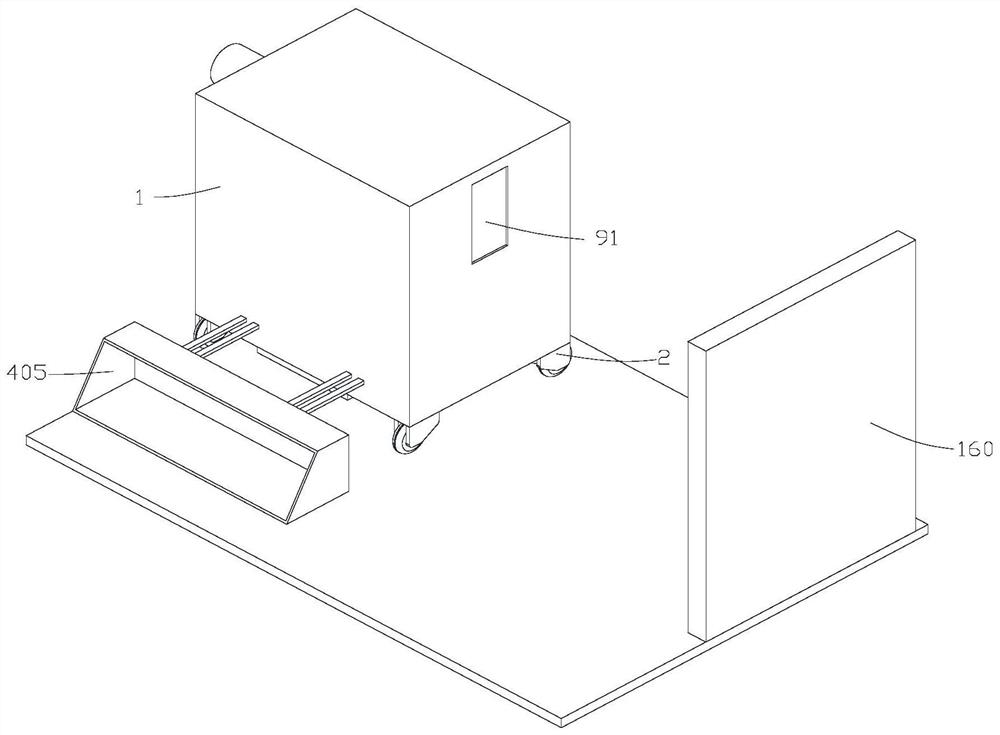

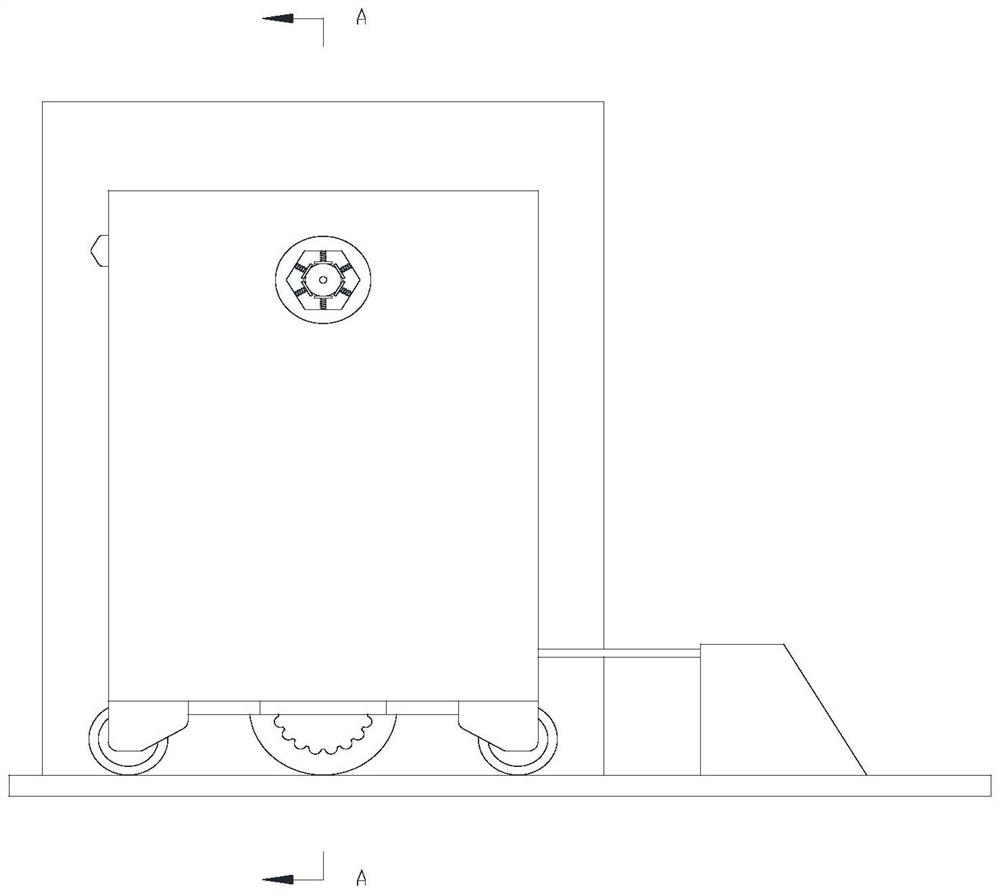

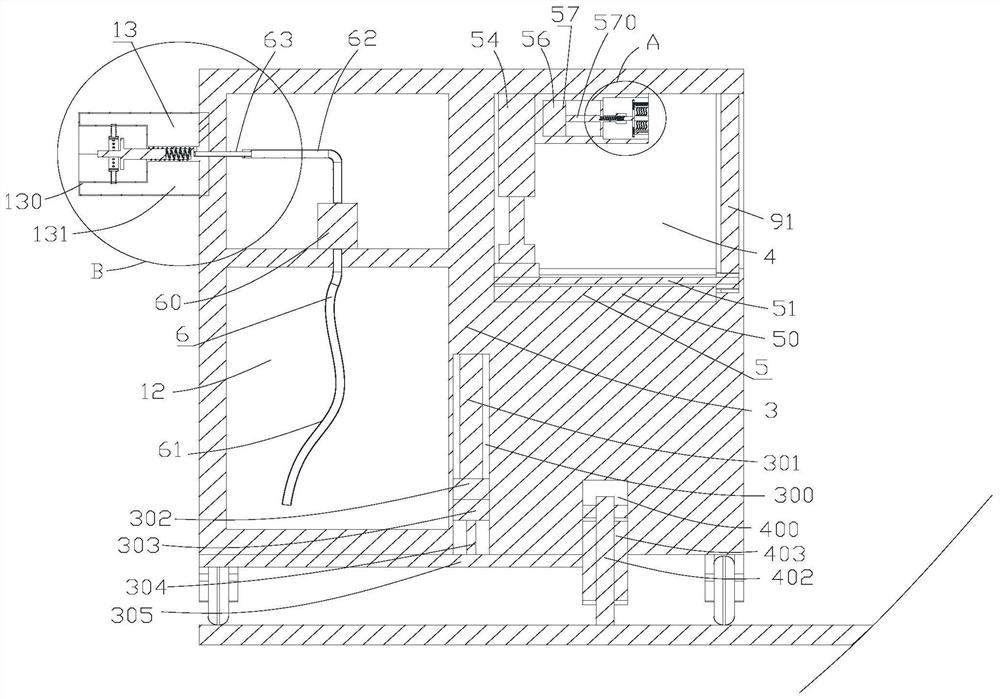

[0045] Such as Figure 1-16 As shown, a detection method for fasteners, including pre-tightening force detection and loose detection, the pre-tightening force detection includes the following steps:

[0046] Step 1. The head of the fastener is coated with a luminescent material. When there is stress or strain on the head, the mechanoluminescent material will emit light accordingly;

[0047] Step 2. When the strain change is generated by the mechanoluminescent material, when the installation tool detects the color change of the light, the camera equipment is placed in the installation tool, and through taking pictures, comparison, feedback and alarm, when the luminous color reaches the preset value, That is, the alarm reminds that the pre-tightening force is installed in place, and the installation tool stops the installation.

[0048] Described loose detection comprises the following steps:

[0049] Step 1. Both the side of the fastener head and the base material of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com