Automobile active type pre-tightening safety belt

An active, seat belt technology, applied in belt tensioners and other directions, can solve the problems of increasing the risk of collision between legs and car interiors, neck injury of seat belt occupants, insufficient pre-tightening of the belt, and eliminating the wearing gap. , The structure is simple, the effect of reducing occupant injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

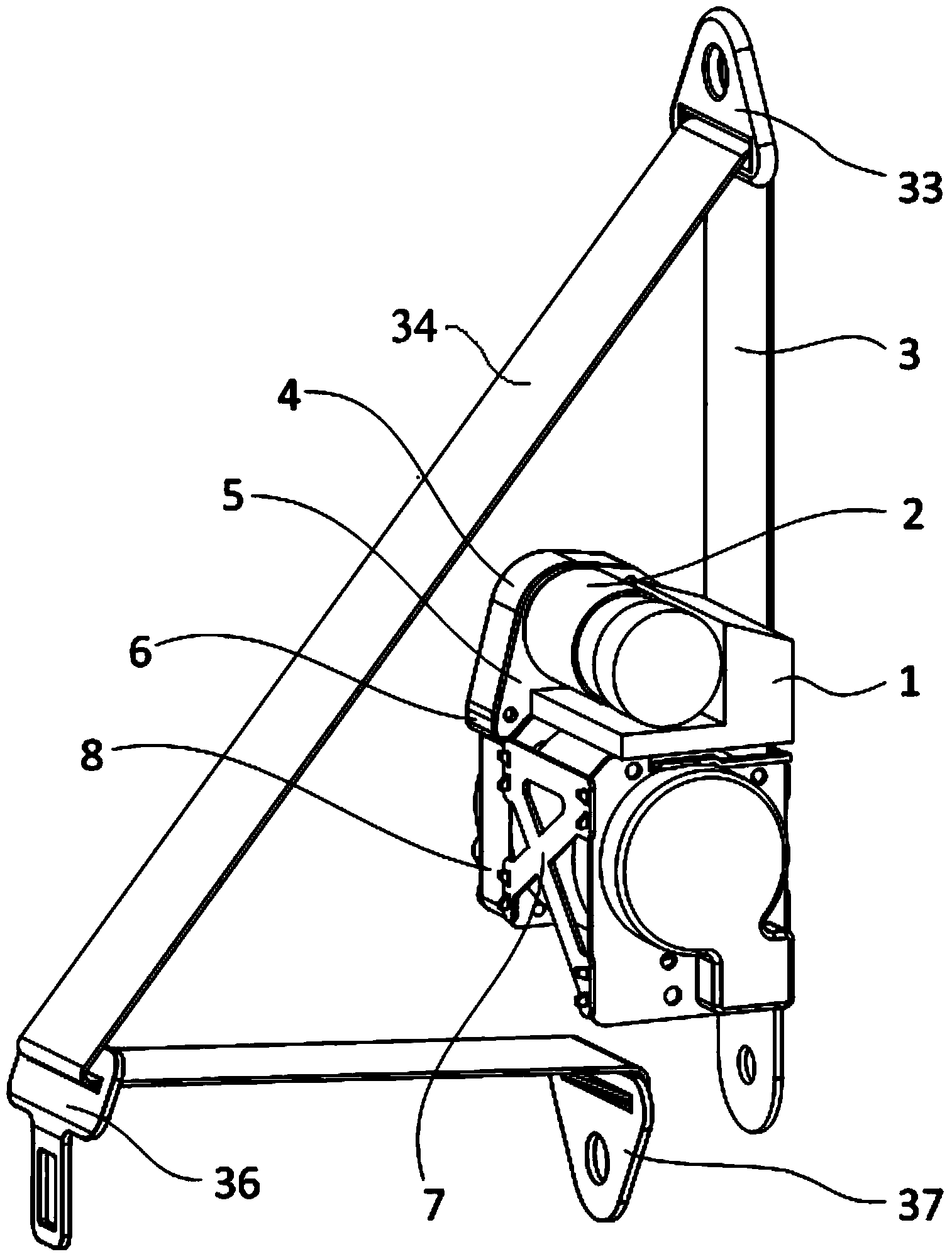

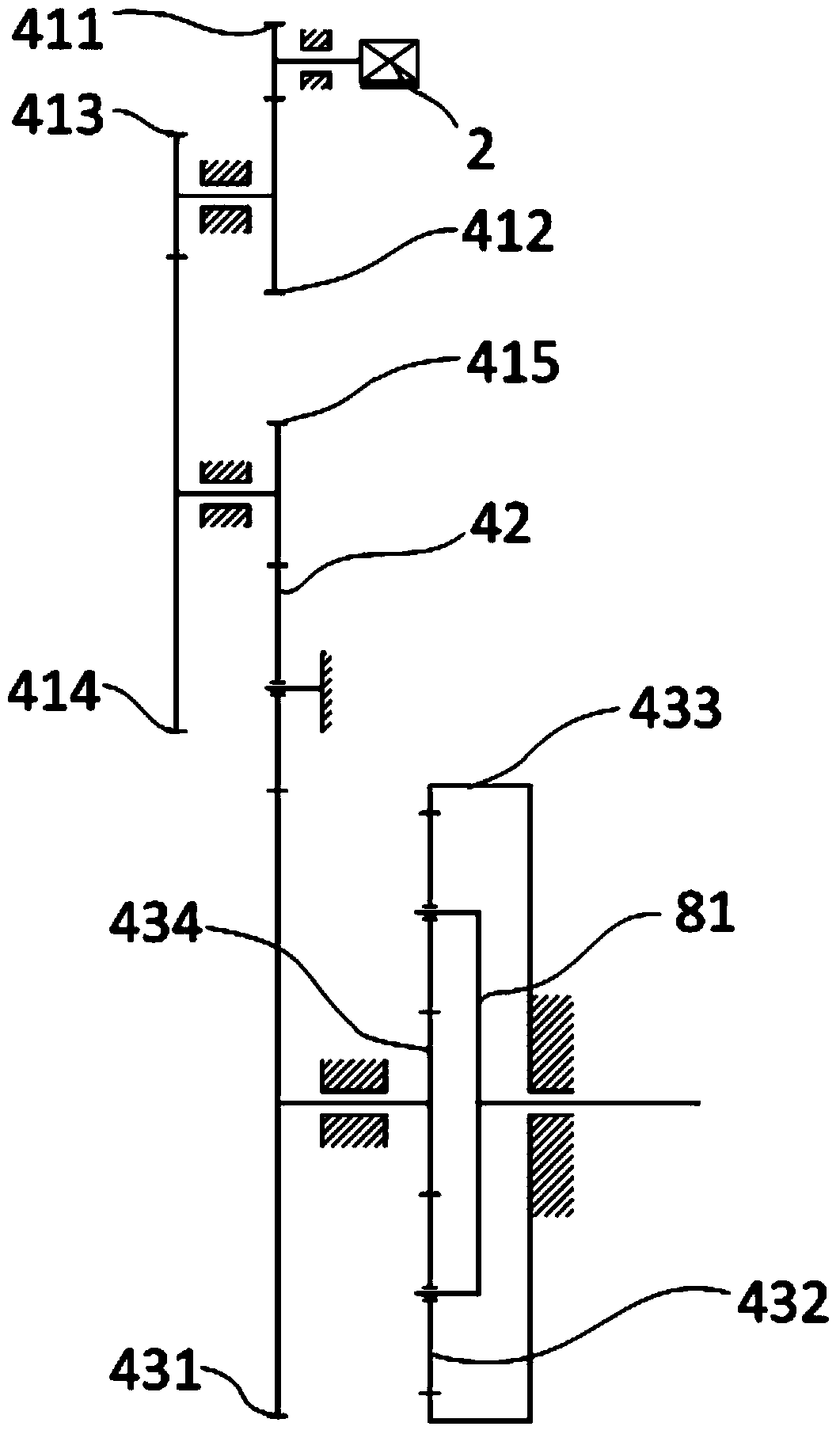

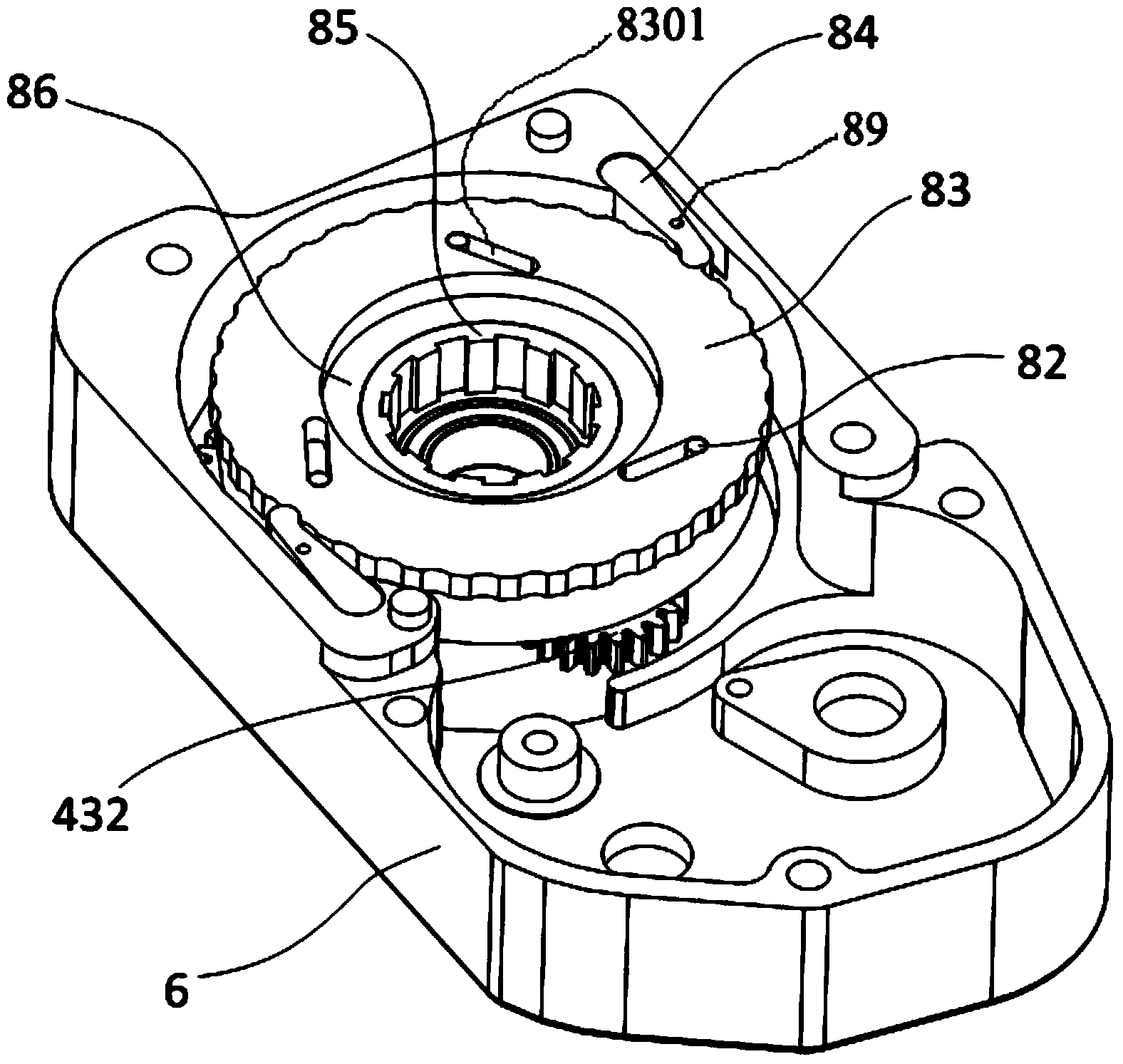

[0053] like figure 1 As shown, the accident warning device 1 is connected to the circuit at one end of the DC motor 2, which can judge whether an accident has occurred according to the degree of danger of the current driving state, the abnormal dynamic response of the vehicle, and the driver's intense manipulation behavior, and send out a warning signal before the collision accident occurs. The command controls the DC motor 2 to work. The DC motor 2 is riveted and fixed with the aluminum casing 6 through the mounting plate 5, and the power output shaft of the DC motor 2 is connected with the transmission system 4, the transmission system 4 is connected with the one-way device 8, and the one-way device 8 is connected with the retractor 7. One end of the mandrel 71 is splined, and the transmission system 4 and the one-way device 8 are installed in the groove of the aluminum casing 6, so the movement and power are decelerated through the transmission system 4, and then transmitte...

Embodiment 2

[0058] like Figure 6-9 As shown, the difference between this preferred embodiment and Embodiment 1 is that it adopts the double-sided pre-tightening structure of the seat belt. Stop pin 32 and anti-slip positioning buckle 35, both ends of webbing 34 are rope structures, that is, both ends of ordinary webbing are all folded back for a small section and sewed to be rope-like, and this rope-like structure can just insert a locking pin 32 The lower guide ring 31 replaces the lower end fixed anchor piece 37 that usually adopts, so that the upper and lower ends of the ribbon 34 can move freely; the two sides of the mandrel 71 are symmetrically provided with two strip grooves, and a set of rope ends of the ribbon 34 can be used by This passes through the inside of the mandrel 71, inserts the locking pin 32 so that this end of the webbing 34 is stuck in the first bar-shaped groove 7101 of the mandrel 71 and cannot be pulled out, and the other end of the webbing 34 passes through in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com