A method and device for applying pre-tightening force on anchor rods

A pre-tightening force and bolt technology, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of discounted pre-tightening force for bolt installation, failure to achieve pre-tightening force, and large damage to the bolt, and achieve Improved construction efficiency, easy maintenance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

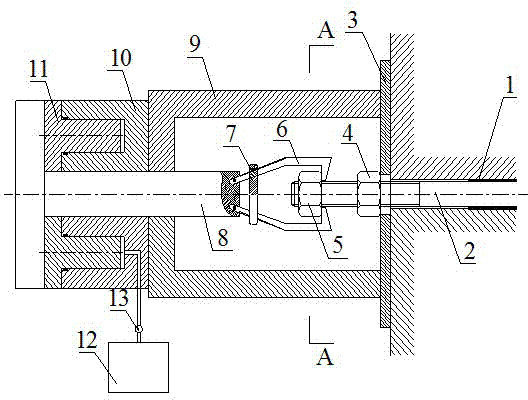

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

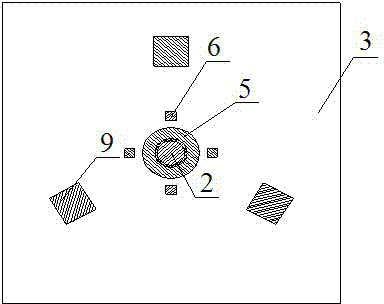

[0017] The method for applying the bolt pretightening force of the present invention: after the hole is drilled with a pneumatic rock drill, the remaining water and slag in the hole are cleaned, the anchoring agent 1 and the bolt 2 are inserted into the drilled hole, and the upper tray 3 is installed, Screw the nut 4 into the thread rolling section of the anchor rod by hand to contact the pallet 3; connect the pneumatic rock drill with the nut 4, rotate the anchor rod 2 with a small power to stir the anchoring agent 1, and unload the pneumatic rock drill after the anchoring agent 1 is solidified; Screw in a force nut 5 within 15mm in front of the anchor rod, press the tensioner shell 9 against the tray 3, the pull claw 6 of the slide rod 8 buckles the force nut 5, and push the fixing ring 7 forward to lock the pull claw 6 fixed; start the hydraulic drive de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com