Precise pre-tightening bolt

A pre-tightening bolt, accurate technology, applied in the direction of screws, threaded fasteners, measuring devices, etc., can solve the problems of large pre-tightening force error, inconvenient pre-tightening, and inability to judge whether the pre-tightening of bolts is loose, etc., to achieve accurate pre-tightening tightening and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

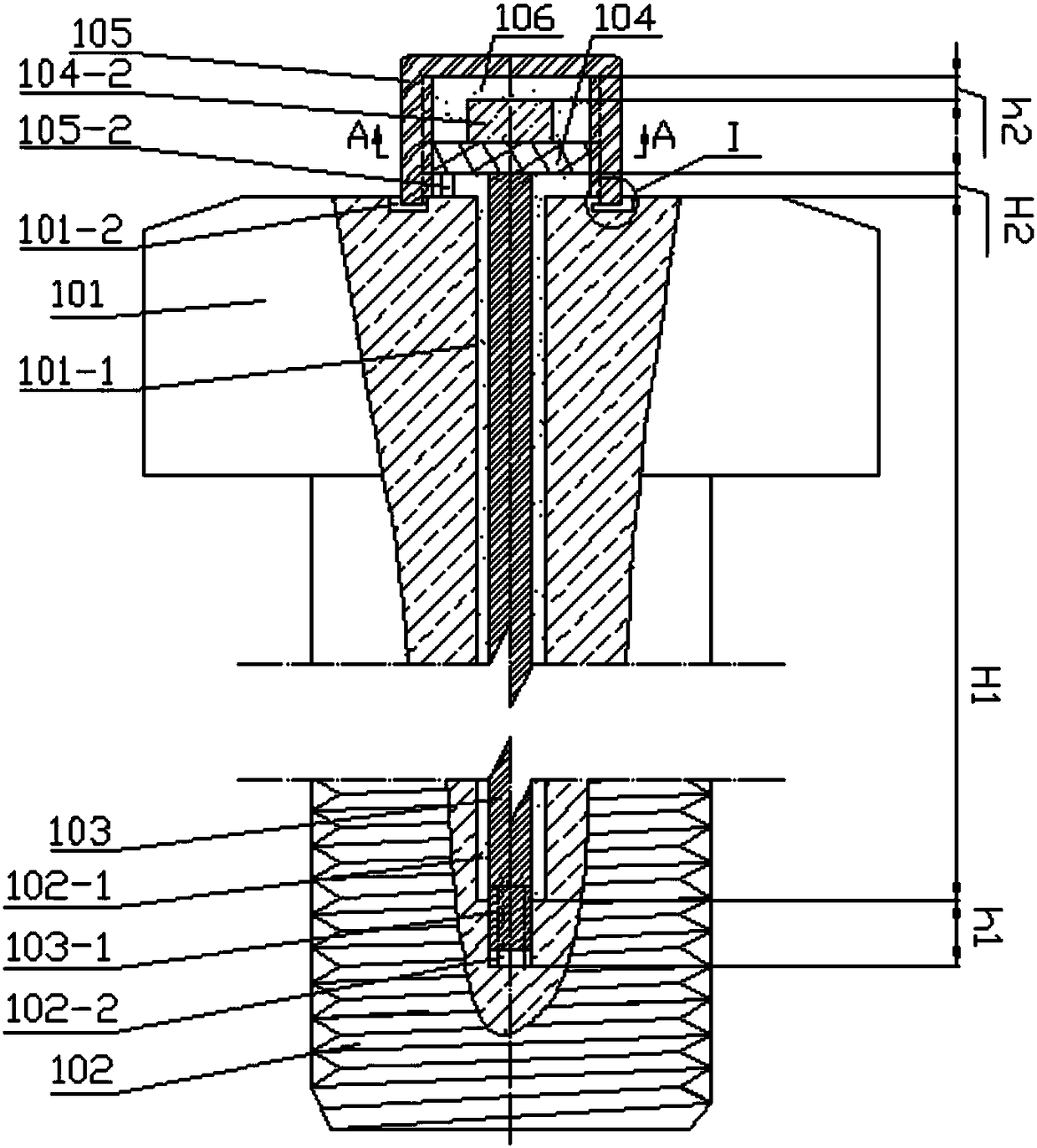

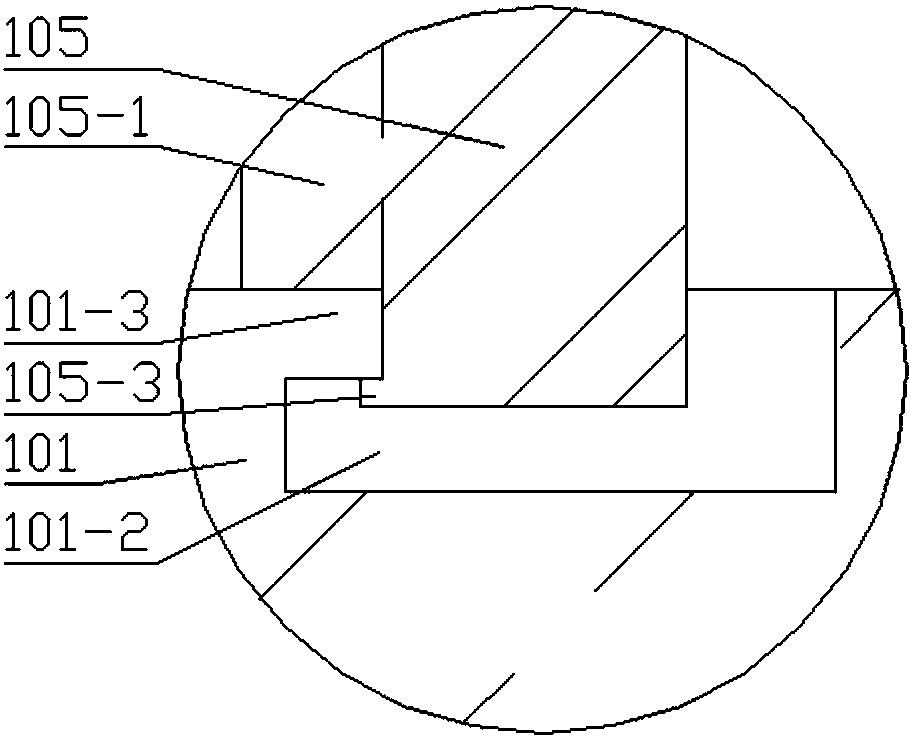

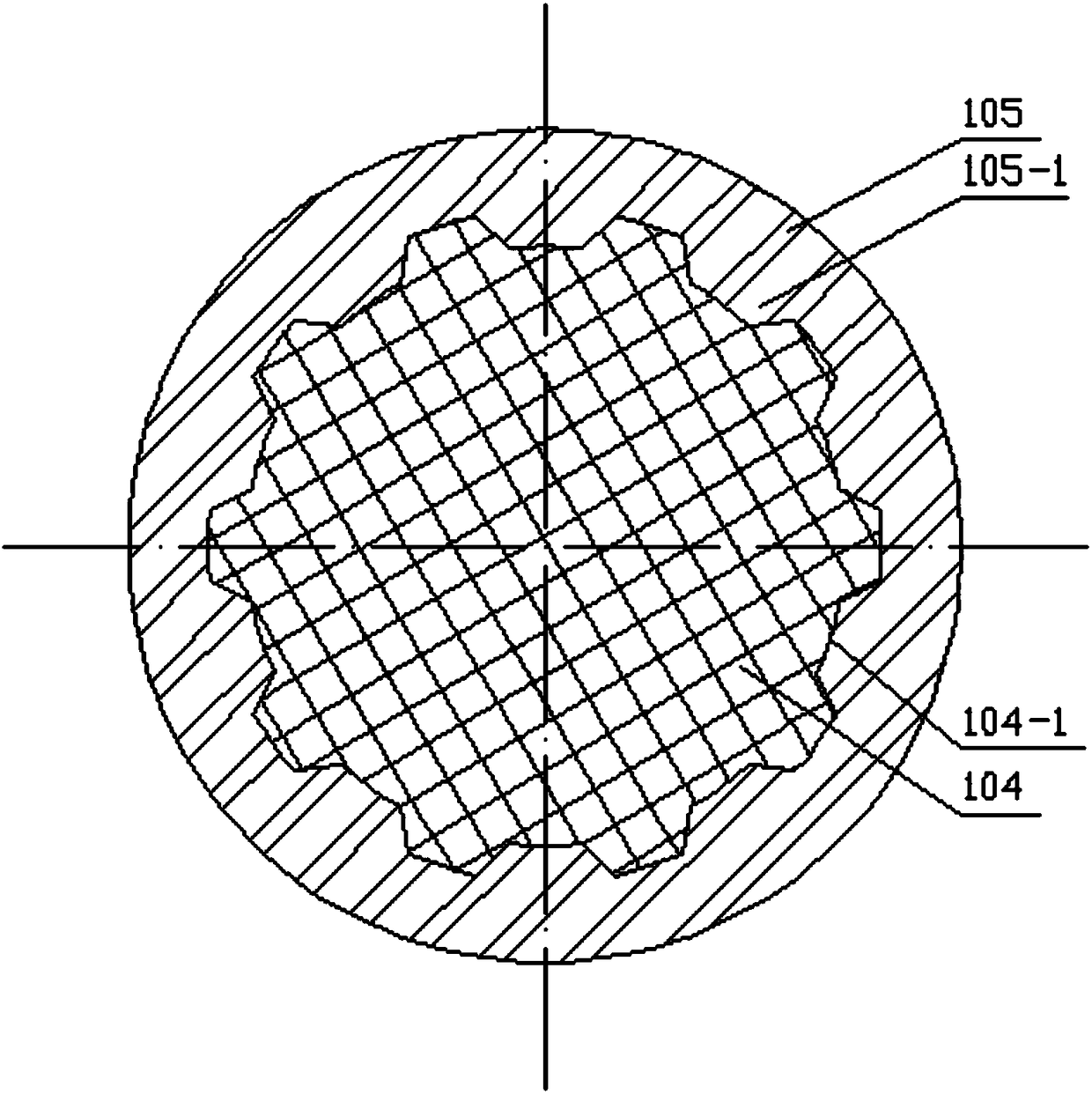

[0021] like figure 1 and figure 2 As shown, a precision pre-tightened bolt includes a head 101 , a screw 102 , a mandrel 103 , an indicator wheel 104 , an indicator cap 105 and grease 106 .

[0022] One end of the screw rod 102 has no threads, and the other end of the screw rod 102 is provided with threads. A blind hole 102-1 is provided on the end surface of the screw rod 102 without thread. The head 101 is provided with a through hole 101-1 having the same diameter as the blind hole 102-1. One end without thread on the screw rod 102 is fixed with the hexagonal head 101 .

[0023] The mandrel 103 is disposed in both the through hole 101-1 and the blind hole 102-1. The bottom of the blind hole 102-1 is close to the threaded end of the screw rod 102, the bottom of the blind hole 102-1 is provided with a threaded hole 102-2, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com