a precision chuck

A kind of chuck, precise technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of high manual operation requirements, unfavorable remote control manipulator operation, difficult operation, etc., and achieve the precision of the clamp structure. , Easy remote control operation, simple effect of preloading operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

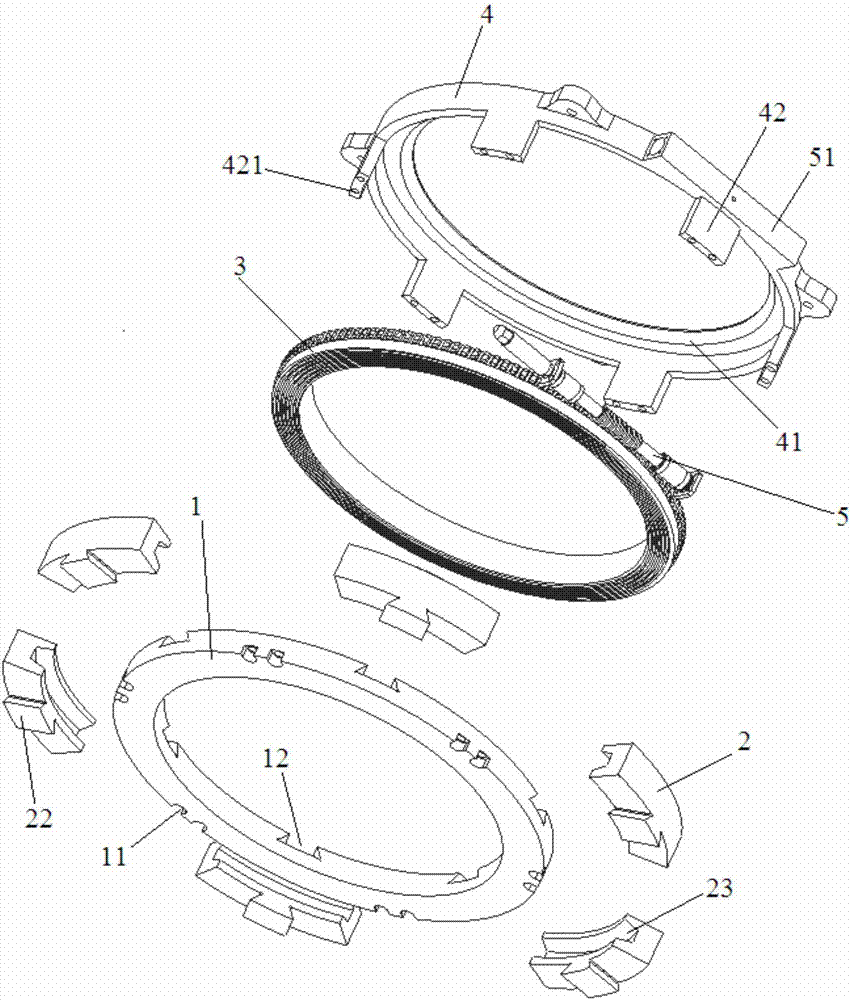

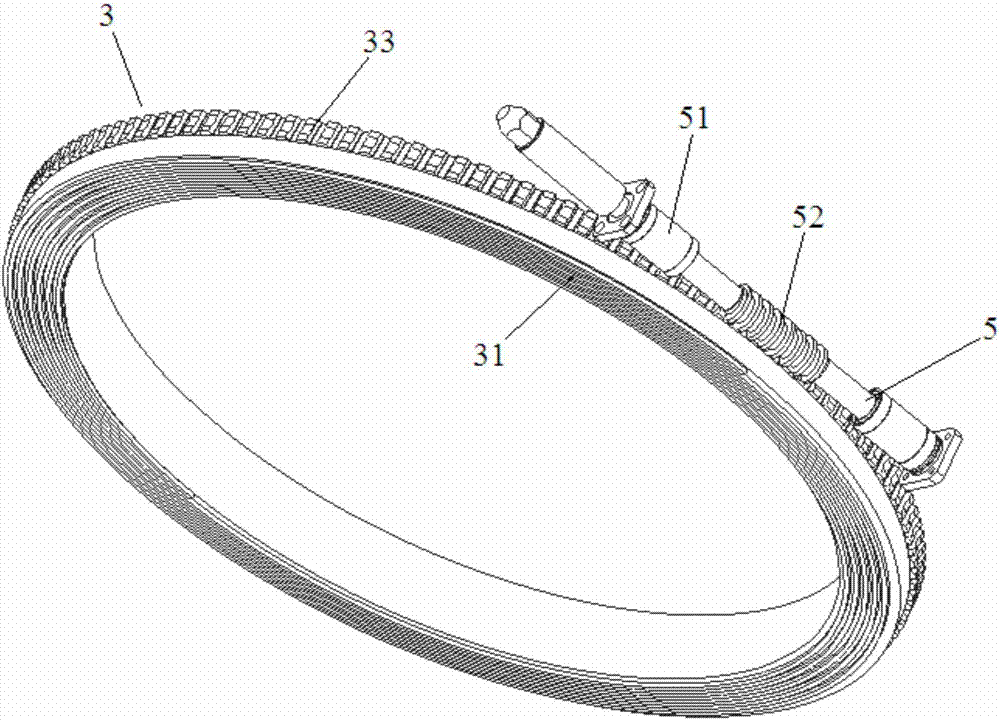

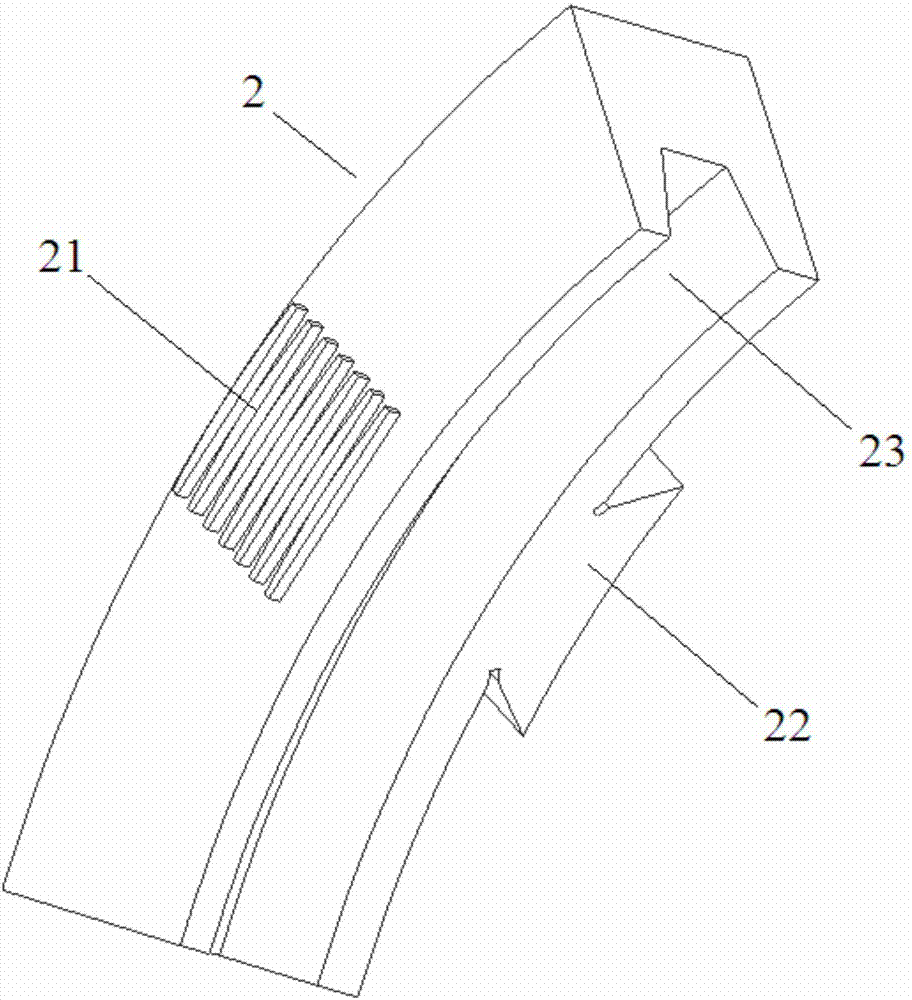

[0027] The precision chuck given in this embodiment is as figure 1 As shown, it includes a fixed ring 4 , a guide ring 1 , and a threaded turntable 3 , a clamping flap 2 and a worm 5 arranged between the fixed ring 4 and the guide ring 1 . An annular cavity is formed on the inner circumference of the fixed ring 4, and the threaded turntable 3 is accommodated in the cavity and can rotate in the cavity. An annular edge 41 is formed on the inner wall of the fixed ring 4 away from the guide ring 1, and the annular edge 41 extends radially inward along the fixed ring, so that the diameter of the end of the fixed ring 4 facing the guide ring 1 is greater than that of the end away from the guide ring 1; The side wall of the ring 4 facing the opening on one side of the guide ring 1 is provided with a plurality of fixed ears 42 extendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com