Bidirectional angular contact thrust ball bearing assembly

A thrust ball bearing and angular contact technology, applied in the field of bearings, can solve the problems of difficult guarantee of combined installation accuracy, increase in the structural size of bearing brackets, and high requirements for the accuracy of bearing seat holes, so as to reduce cumulative installation errors, high support rigidity, and high positioning The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

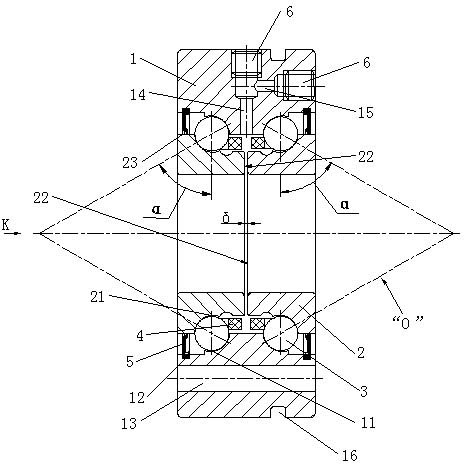

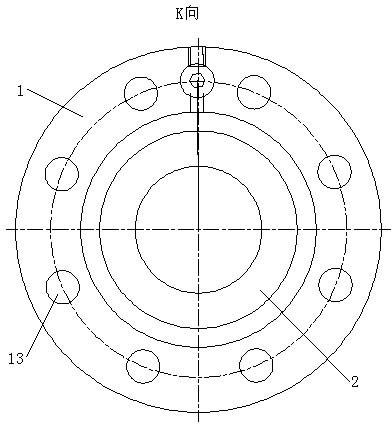

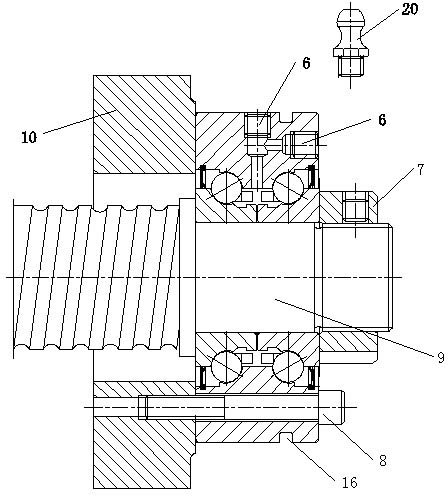

[0016] A two-way angular contact thrust ball bearing assembly, which includes a single thick-walled outer ring 1 with a "convex" cross-section, two inner rings 2, two rows of steel balls 3, two cages 4, two sealing rings 5 and Two oil filling plugs 6 are respectively provided with an outer channel 11 and an inner channel 21 for installing a row of steel balls 3 on both sides of the inner wall of the outer ring 1 and the inner outer walls of the two inner rings 2. The two cages 4 are respectively Keep a row of steel balls and divide them evenly along the circumference, inject grease between the two rows of cages 4 and the contact between the steel balls and the channel; the sealing ring 5 is set on the outer wall 23 outside the inner ring 2 and the outer ring 1 Between the grooves 12 on the inner wall; the narrow end faces 22 of the two inner rings 2 face each other and leave a preload adjustment gap δ, forming a double-row angular contact thrust ball bearing with the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com