Numerically-controlled machine tool electric spindle adopting integrated bearings

An electro-spindle and bearing technology, applied in the field of numerical control, can solve the problems of unreasonable setting of electro-spindle, affecting processing quality, etc., and achieve the effects of reducing vibration and noise, uniform distribution, and avoiding improper matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

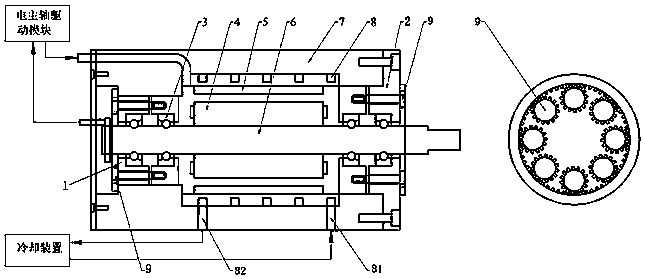

[0022] An embodiment of the present invention provides an electric spindle of a CNC machine tool using integrated bearings, such as figure 1 As shown, it includes: left bearing seat 1, right bearing seat 2, angular contact ball bearing 3, rotor winding 4, stator winding 5, main shaft 6, housing 7, cooling tank 8, bearing preload linkage device 9.

[0023] A cooling tank 8 is arranged inside the housing 7 , and the cooling tank 8 is connected to the cooling device through a cooling tank inlet 81 and a cooling tank outlet 82 . A stator winding 5 is sheathed inside the casing 7, and the stator winding 5 is connected to the electric spindle drive module through a power adapter. The main shaft 6 is provided with a rotor winding 4, which is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com