Two-stage slide valve electro-hydraulic servo valve driven by giant magnetostrictive actuator

A giant magnetostrictive and electro-hydraulic servo valve technology, which is applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of small stroke and small flow rate of servo valve control, and achieve high driving power and control The effect of large flow and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

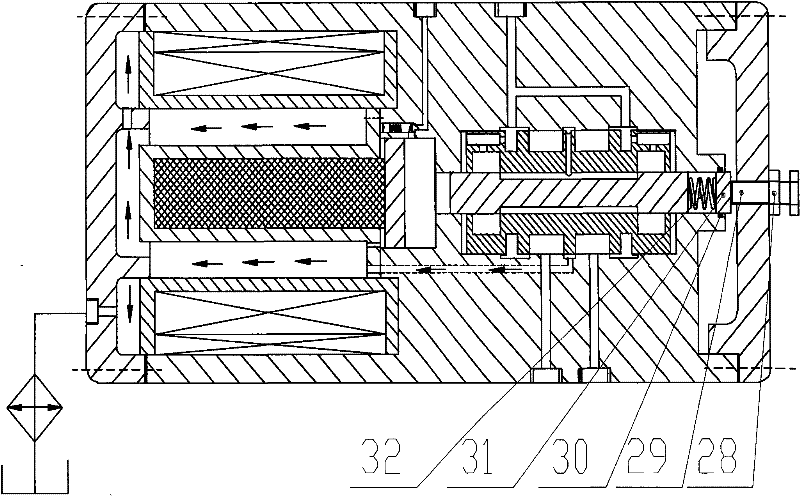

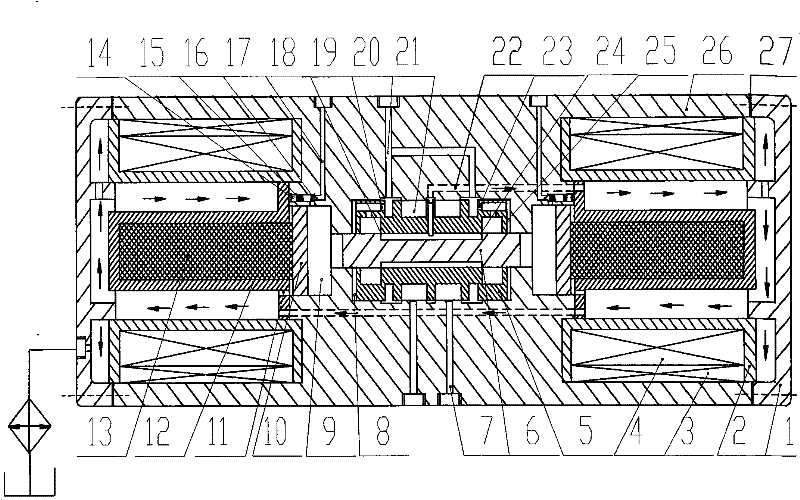

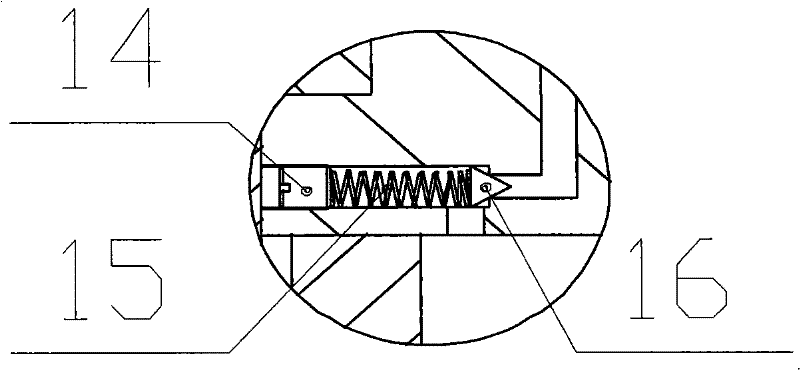

[0026] Such as figure 1 , 2, 3, 4, 5, and 6, the new two-stage slide valve electro-hydraulic servo valve is divided into a single giant magnetostrictive actuator drive (such as figure 1 shown) and double giant magnetostrictive actuator drive (such as figure 2 Shown) two structural forms, the two-stage spool type electro-hydraulic servo valve driven by a single giant magnetostrictive actuator is planned to install a giant magnetostrictive actuator and a micro-displacement amplifier on one side of the spool valve, Install the spool valve reset device (such as Figure 4 shown). The two-stage slide valve electro-hydraulic servo valve driven by double giant magnetostrictive actuators is planned to install giant magnetostrictive actuators and their micro-displacement amplifiers on both sides of the slide valve, and the slide valve pilots are driven by giant magnetostrictive actuators. The spool is used to replace the traditional two-stage slide valve electro-hydraulic servo valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com