Flexible wire drive device

A driving device and flexible technology, applied in the direction of transmission device, linear motion axis, passive exercise equipment, etc., can solve the problems of easy winding of flexible wires and affecting the safety of the system, and achieve high driving power, short overall structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] The flexible silk of this embodiment adopts flexible silk.

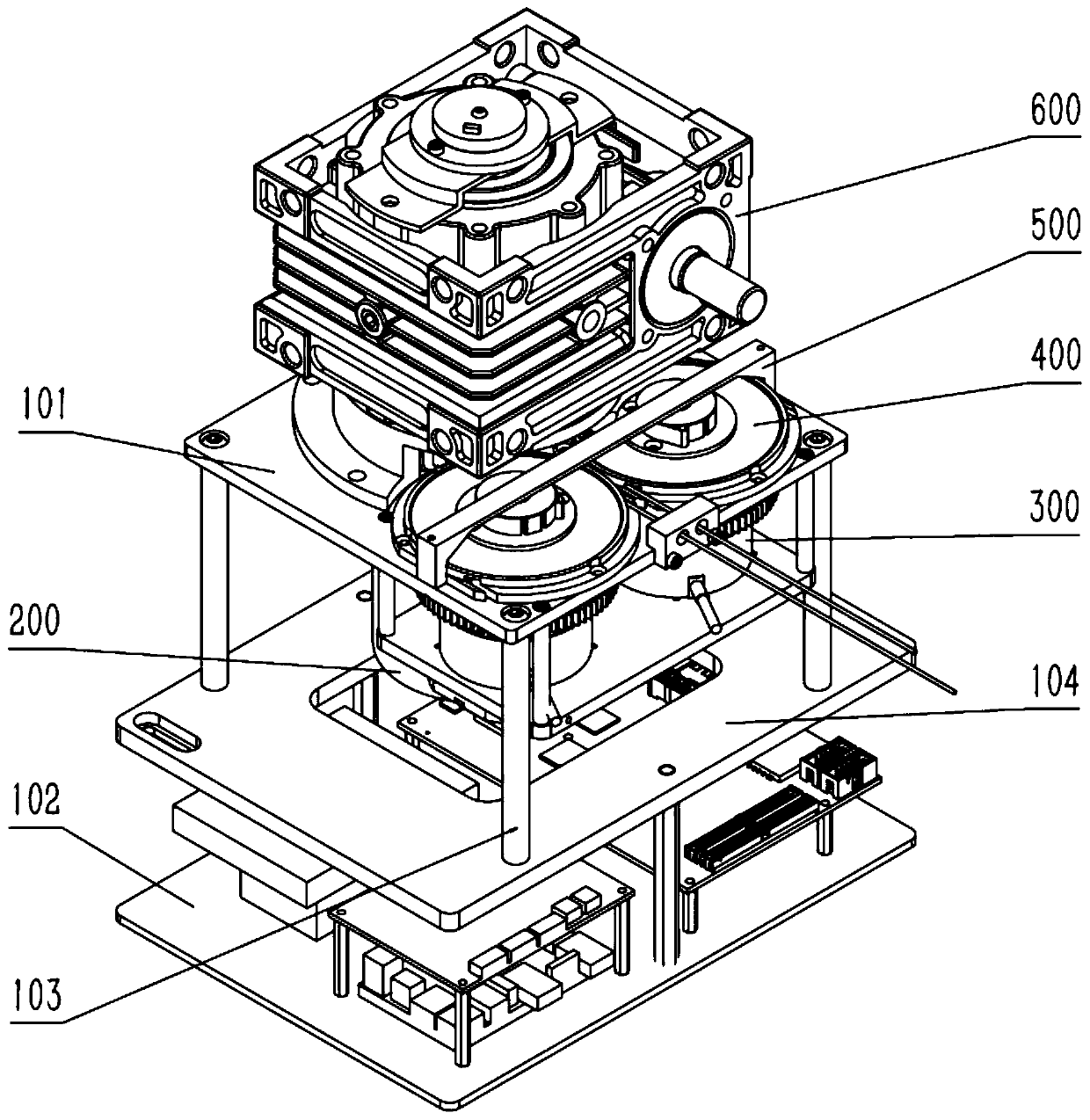

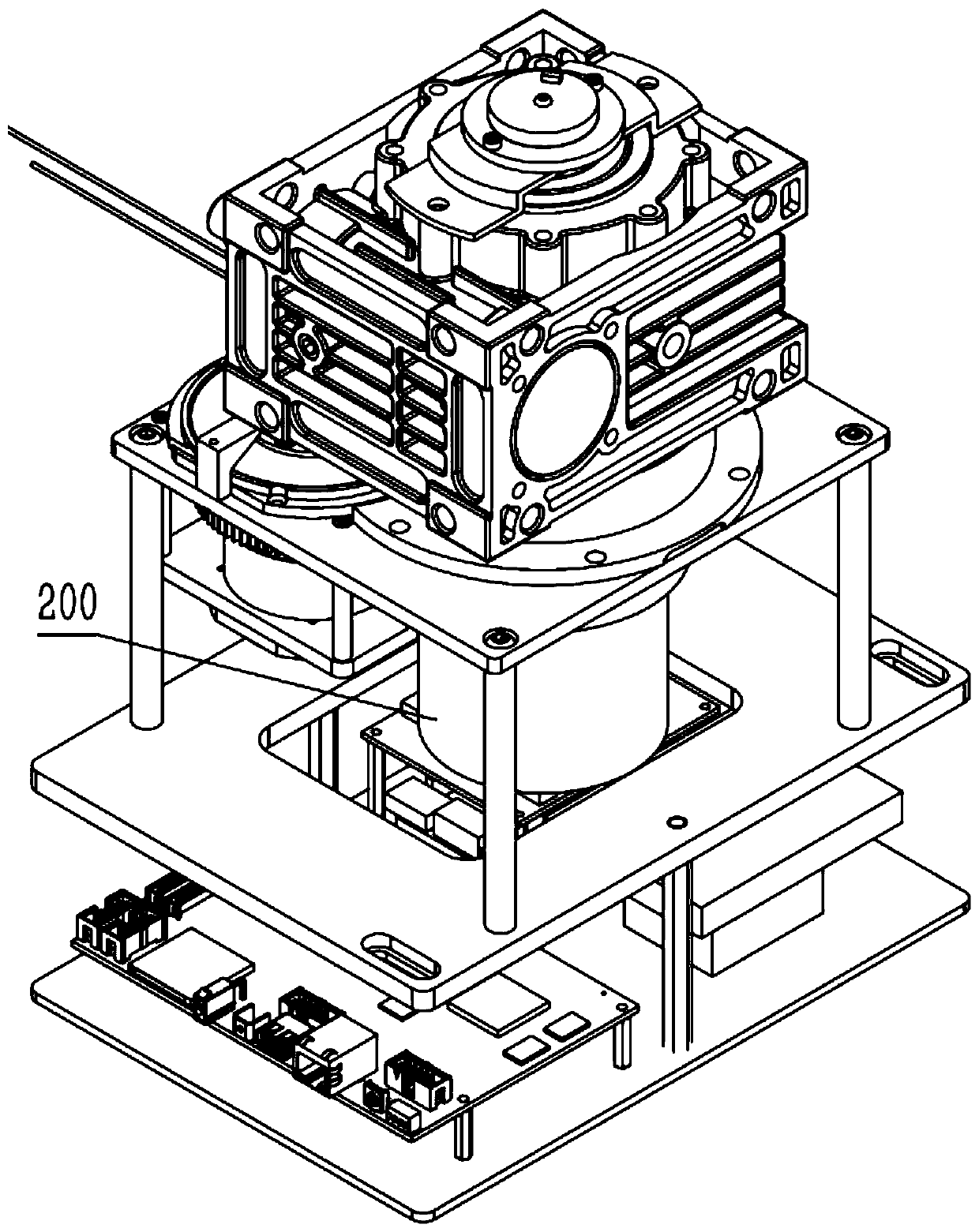

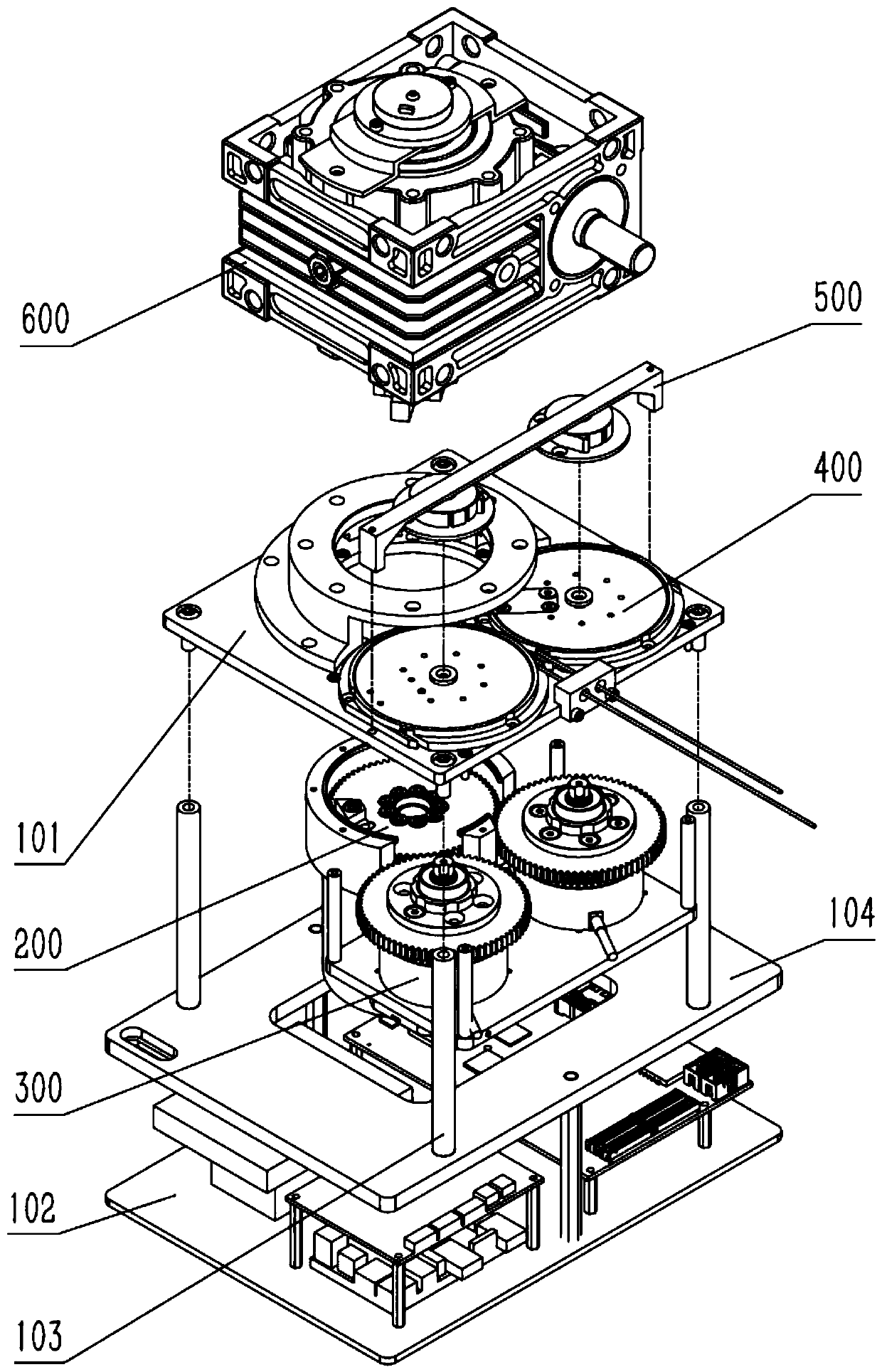

[0076] Such as figure 1 , figure 2 As shown, the device is a flexible wire driving device with a clutch, the double flexible wire can be controlled separately, and the elastic device is pre-tightened, and the stroke can be adjusted. The flexible wire driving device mainly includes a reduction motor mechanism 200, a clutch mechanism 300 , the flexible wire rope wheel mechanism 400 , the elastic pretensioning device 500 , the deceleration limit mechanism 600 , and the total mounting plate 101 .

[0077] Such as Figure 4 As shown, the reduction motor mechanism 200 includes a motor reduction unit 201 , a torque adapter plate 202 , a driving gear 204 and an adapter ring 205 . The motor deceleration unit 201 already includes components such as a DC motor, a harmonic decelerator, and an encoder. The motor reduction unit 201 is transferred and fixed on the general mounting plate 101 through an adapter ring 205 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com