Rocker arm mechanism

A technology of rocker mechanism and rocker body, which is applied in the direction of mechanical equipment, combustion engine, engine control, etc. It can solve the problems of not being able to use the engine, not being able to stop the engine cylinder and braking, and difficult to calibrate, so as to achieve the lock pin stroke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

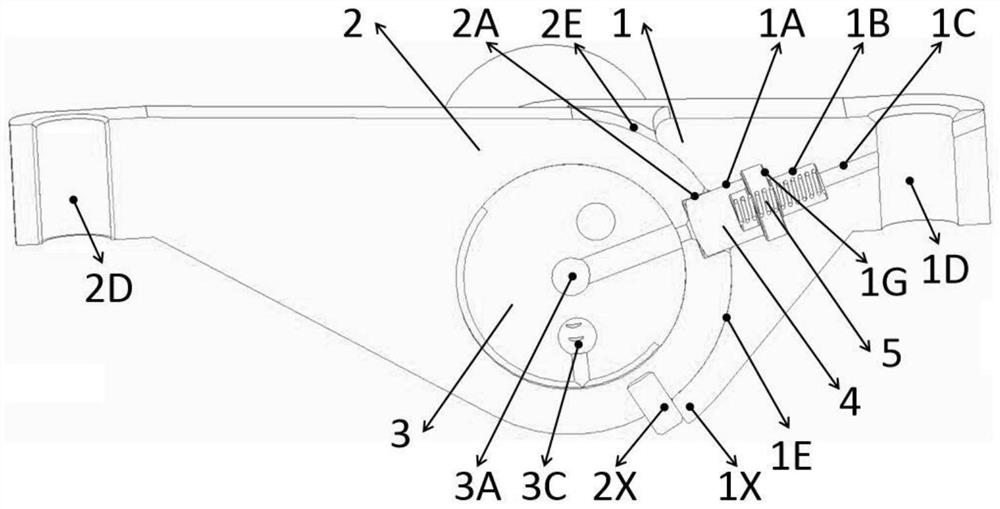

[0059] The rocker arm mechanism includes a first rocker arm body 1, a second rocker arm body 2, a rocker arm shaft 3, and a locking assembly;

[0060] The first rocker body 1 is provided with a first lock pin hole 1A, a spring hole, an emptying hole 1C, a first transmission end 1D, a first mating surface 1E, a first installation hole 1F, and a first rocker body switching limit surface 1X;

[0061] The second rocker arm body 2 is provided with a second locking pin hole 2A, a second transmission end 2D, a second mating surface 2E, a second mounting hole 2F, and a second rocker arm body switching limit surface 2X;

[0062] A control oil passage is set on the rocker arm shaft 3;

[0063] The locking assembly at least includes a lock pin 4 and a lock pin spring 5;

[0064] The first rocker arm body 1 forms an axial hinge relationship with the rocker arm shaft 3 through the first installation hole 1F, and the first installation hole 1F and the corresponding surface of the rocker a...

Embodiment 2

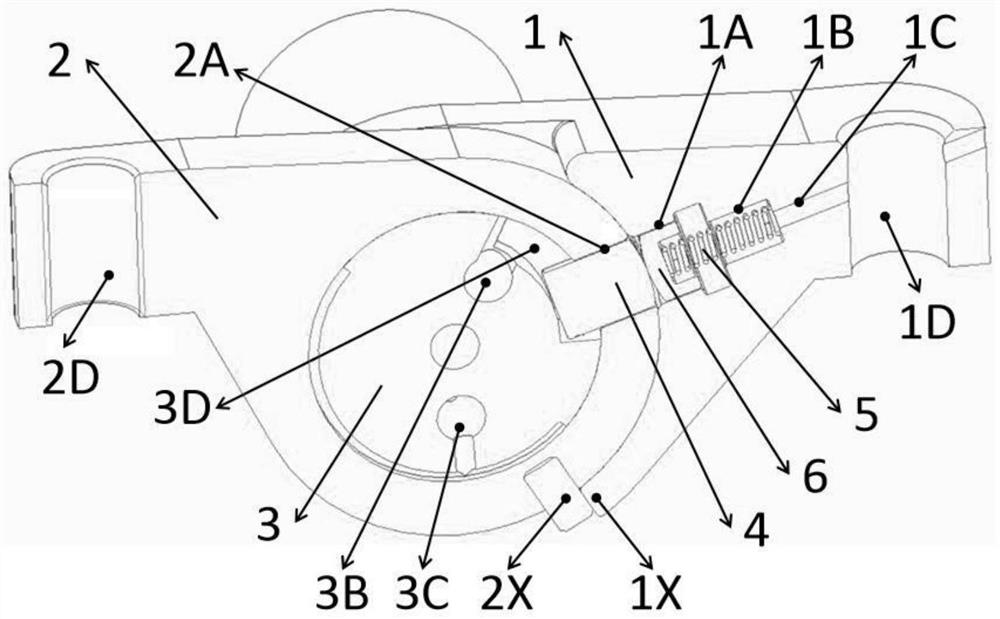

[0070] Embodiment 2 (switch type normally locked rocker arm mechanism):

[0071] Combined with the content of the above-mentioned Embodiment 1, the rocker mechanism is a normally locked rocker mechanism, the lock pin 4 is arranged in the first lock pin hole 1A, the lock pin 4 is in direct contact with the lock pin spring 5, and the lock pin 4 is in contact with the first lock pin 4. Pin hole 1A is a pair of fittings;

[0072] When the control oil passage is connected to the high pressure oil, the lock pin 4 is completely inside the first rocker arm body 1, and the first rocker arm body 1 and the second rocker arm body 2 are not locked by the lock pin 4; when the control oil passage is connected to the low pressure oil When the oil is connected, the lock pin 4 is in the first rocker arm body 1 and the second rocker arm body 2 at the same time, and the first rocker arm body 1 and the second rocker arm body 2 are locked by the lock pin 4;

[0073] In other preferred embodiments,...

Embodiment 3

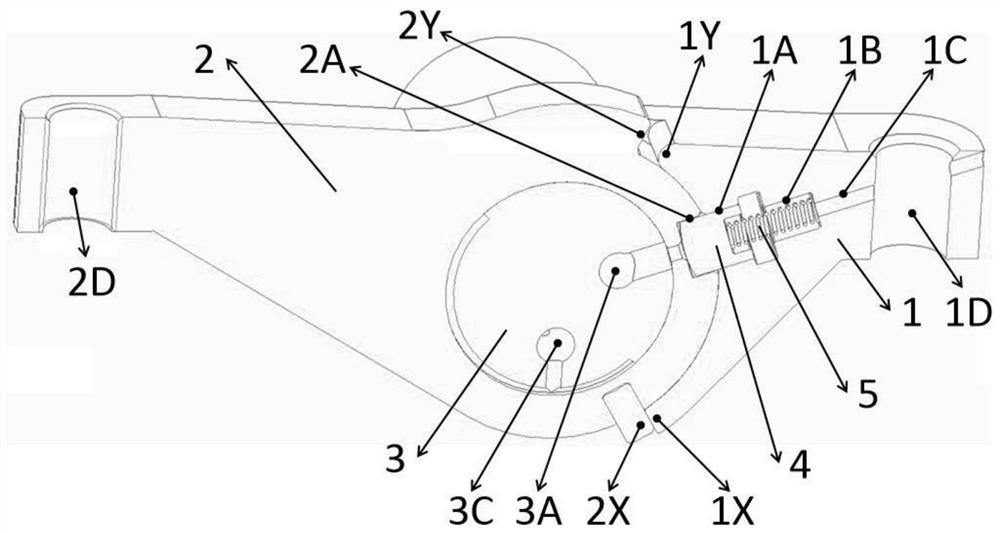

[0077] Embodiment 3 (half-switch type normally locked rocker arm mechanism):

[0078] The difference from the above-mentioned Embodiment 2 is that the first rocker arm body 1 is added with a first rocker arm body working limit surface 1Y, and the second rocker arm body 2 is added with a second rocker arm body working limit surface 2Y; When the first rocker body 1 and the second rocker body 2 are not locked by the lock pin 4, the first rocker body working limit surface 1Y and the second rocker body working limit surface 2Y restrict the first rocker body 1 and the second rocker body The relative swing amount of the two rocker arm bodies 2 .

[0079] Specifically, the working principle is as follows: For the semi-switch type normally locked rocker arm mechanism, when the control oil passage is connected to the high-pressure oil, the lock pin completely enters the first rocker arm body, and when the first rocker arm body and the second rocker arm body are on the Before the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com