Efficient water flow power generation device and water flow inner power generation method

A high-efficiency technology for hydropower generation, applied in hydroelectric power generation, safety devices, engine control, etc., can solve the problems of high investment cost and inability to be widely used, and achieve obvious results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

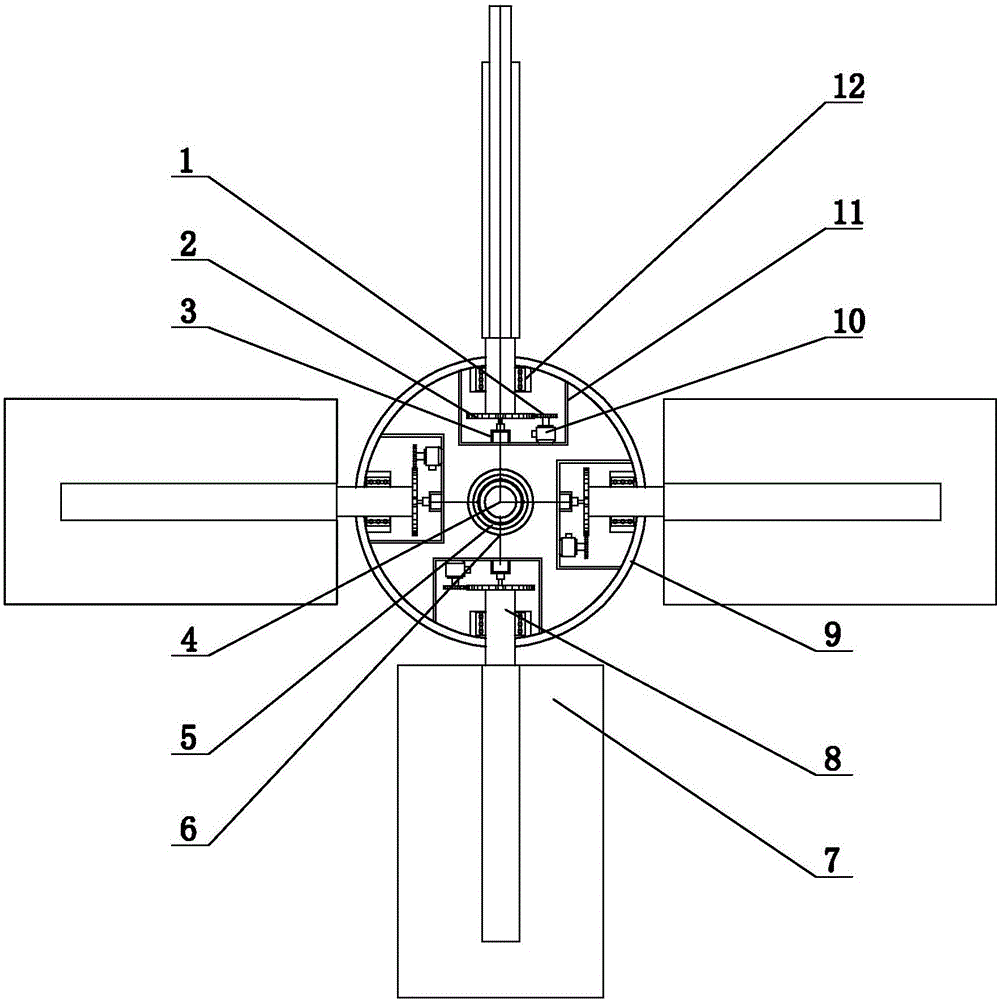

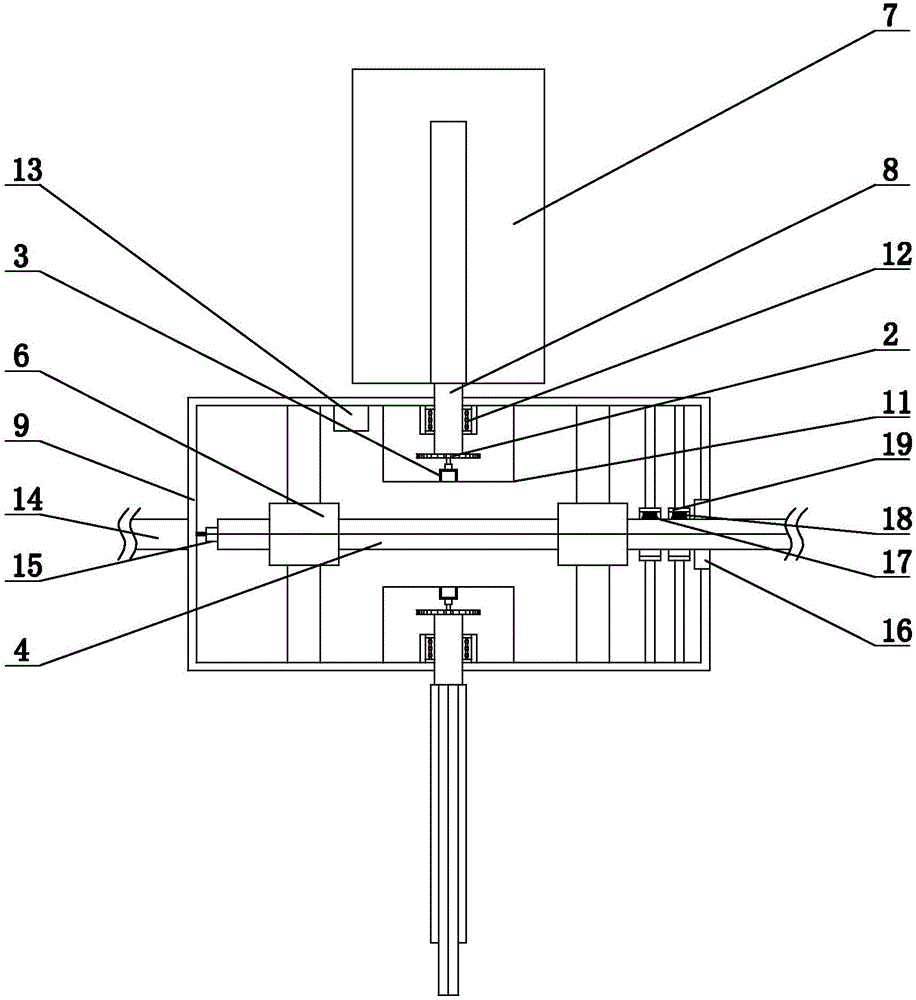

[0021] The following is a further description of the high-efficiency water flow power generation device in conjunction with the accompanying drawings:

[0022] Such as figure 1 with figure 2 As shown, the high-efficiency water flow power generation device of the present invention includes a housing 9, the housing 9 is installed on the main shaft 4, the housing 9 is provided with four fan pages 7, the fan pages 7 are provided with a rotating shaft 8, and the rotating shaft 8 is inserted into the The rotating power box 11 in the housing 9 is provided with four rotating power boxes 11 in the housing 9, and the rotating shaft 8 of each fan leaf 7 is inserted into a rotating power box 11, and the rotating power box 11 drives the fan leaf 7 to rotate through the rotating shaft 8 , the housing 9 is installed on the rotating shaft 8, and the end of the rotating shaft 8 is provided with an angle sensor A3 to measure the rotation angle of the housing 9. The housing 9 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com