Device and method for measuring pretightening force of bolt

A bolt pre-tightening force and bolt technology, which is applied in the direction of measuring torque/torsion force during tightening and the measurement of the property force of piezoelectric devices, can solve the problem of inconvenient measurement of bolt elongation and insufficient accuracy of bolt pre-tightening force. and other problems, to achieve the effect of convenient and fast measurement, accurate results and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention will be further described in detail below with reference to the drawings and embodiments, but it is not used as a basis for any restriction on the invention.

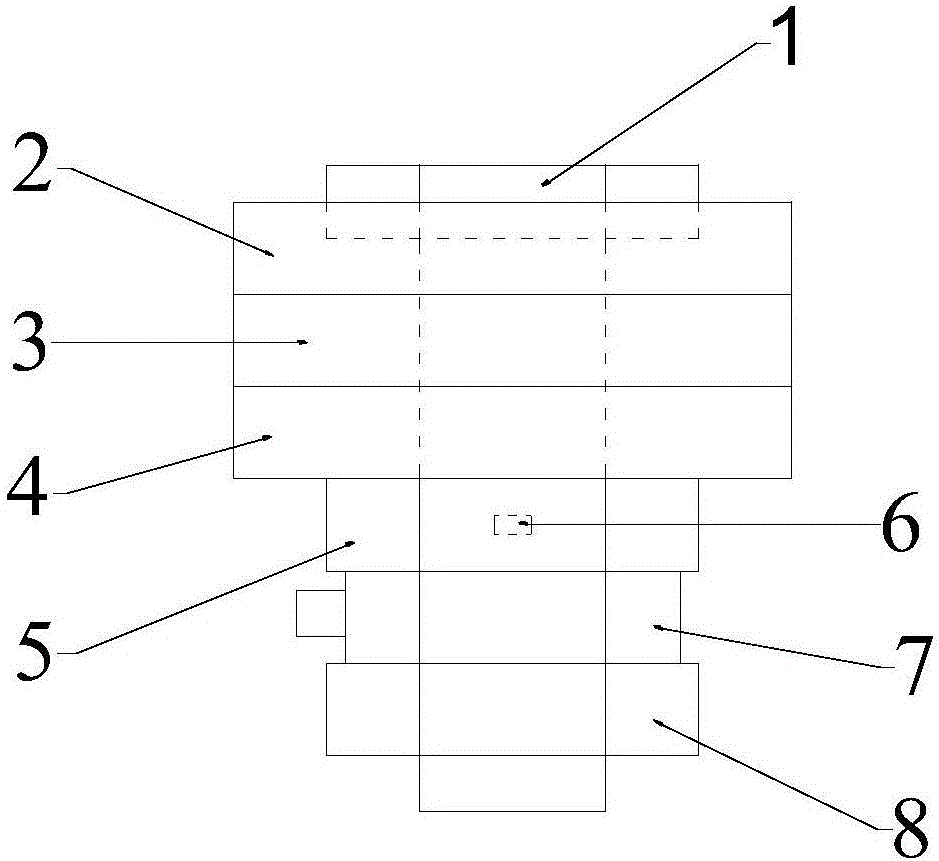

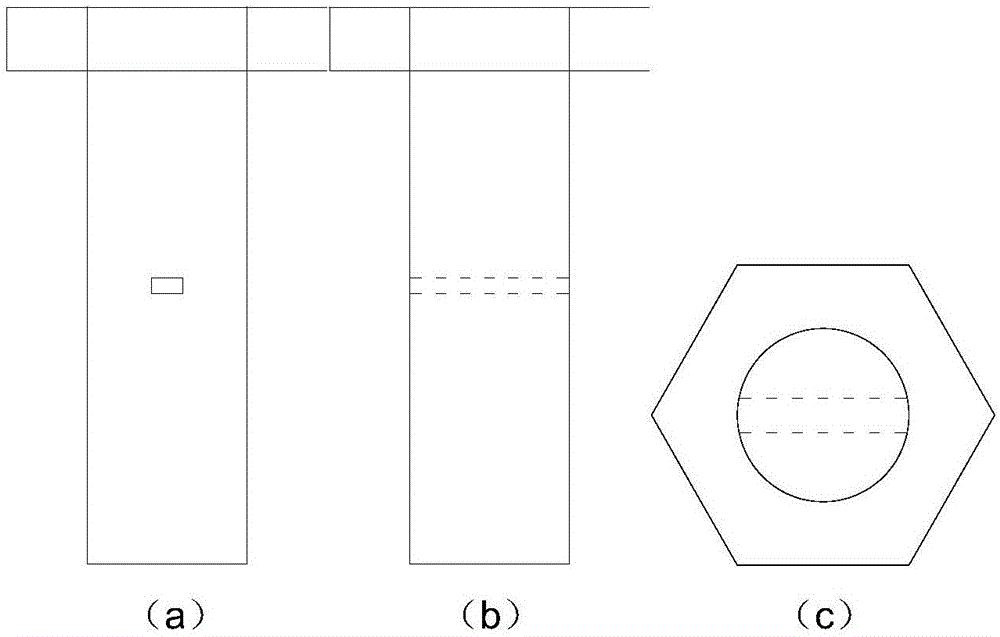

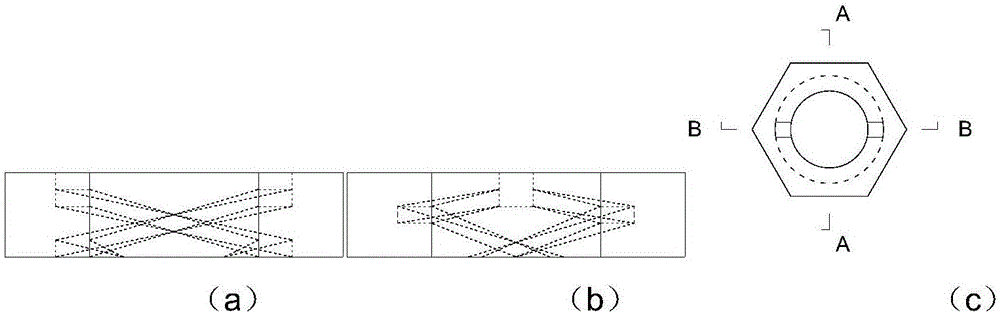

[0051] Such as figure 1 As shown, the device of the present invention for measuring the pre-tightening force of a bolt includes a bolt with a hole 1, and a temporary compression piece I2, a temporary compression piece II3, and a temporary compression piece Ⅱ3, which are stacked on the bolt 1 with a hole and overlapped in sequence from top to bottom. Pressure piece Ⅲ 4, special nut 5, pressure tester 7 and nut 8; the reserved hole on the holed bolt 1 extends out of the temporary pressure piece Ⅲ 4, and the pin 6 is horizontally inserted into the reserved hole of the holed bolt 1 along the hole The two side walls of the bolt 1 extend, so that the pin 6 extends out of the bolt 1 with a hole in the same radial direction on both sides. The reserved groove on the special nut 5 sleeved on the holed bolt 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com