Locknut pushing pre-tightening system

A locking nut and jacking technology, applied in the direction of nuts, threaded fasteners, screws, etc., can solve the problems of slow drop of friction force of thread pair, difficult control of pre-tightening force, loosening failure, etc. Preload control, precise preload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

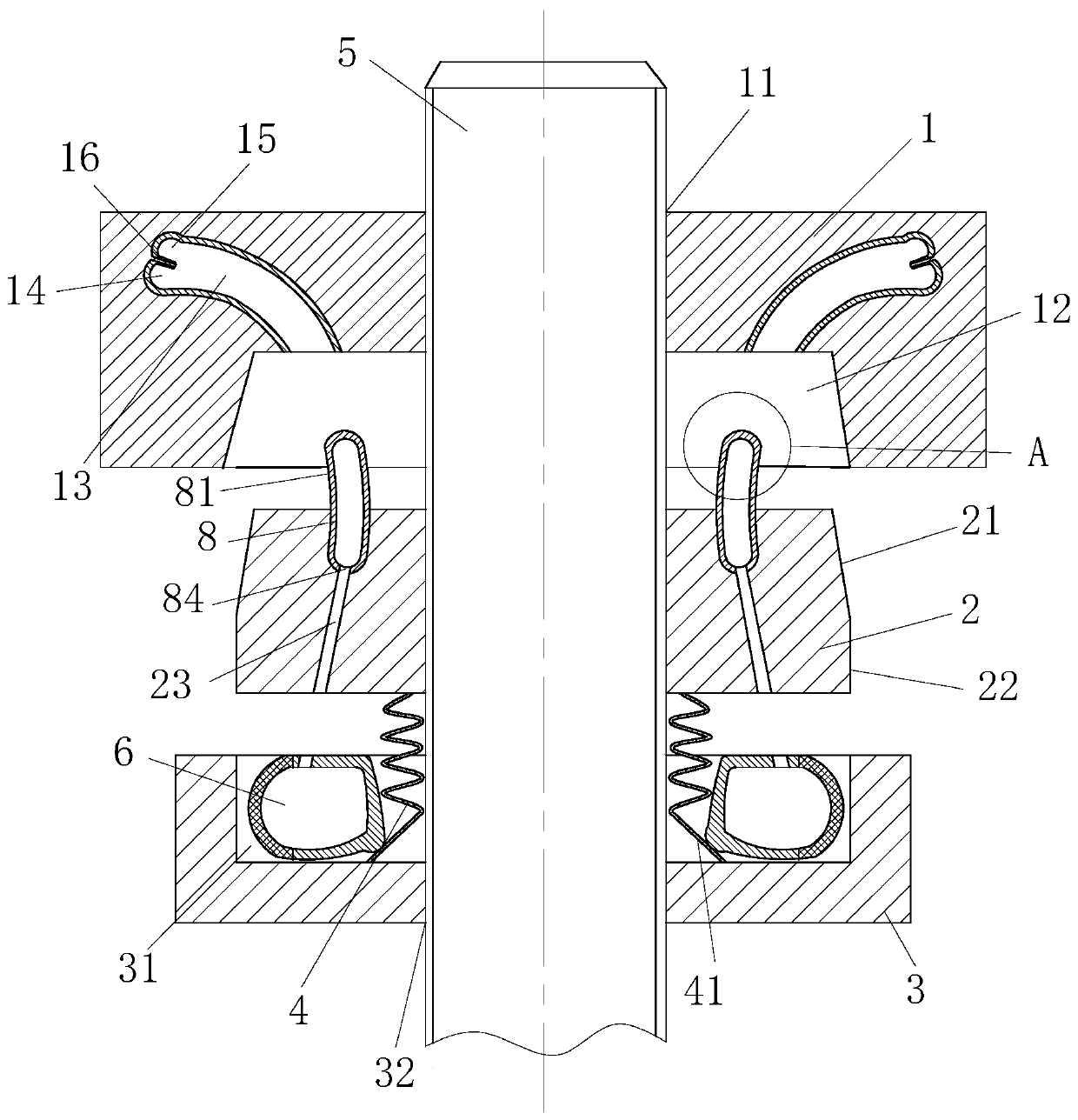

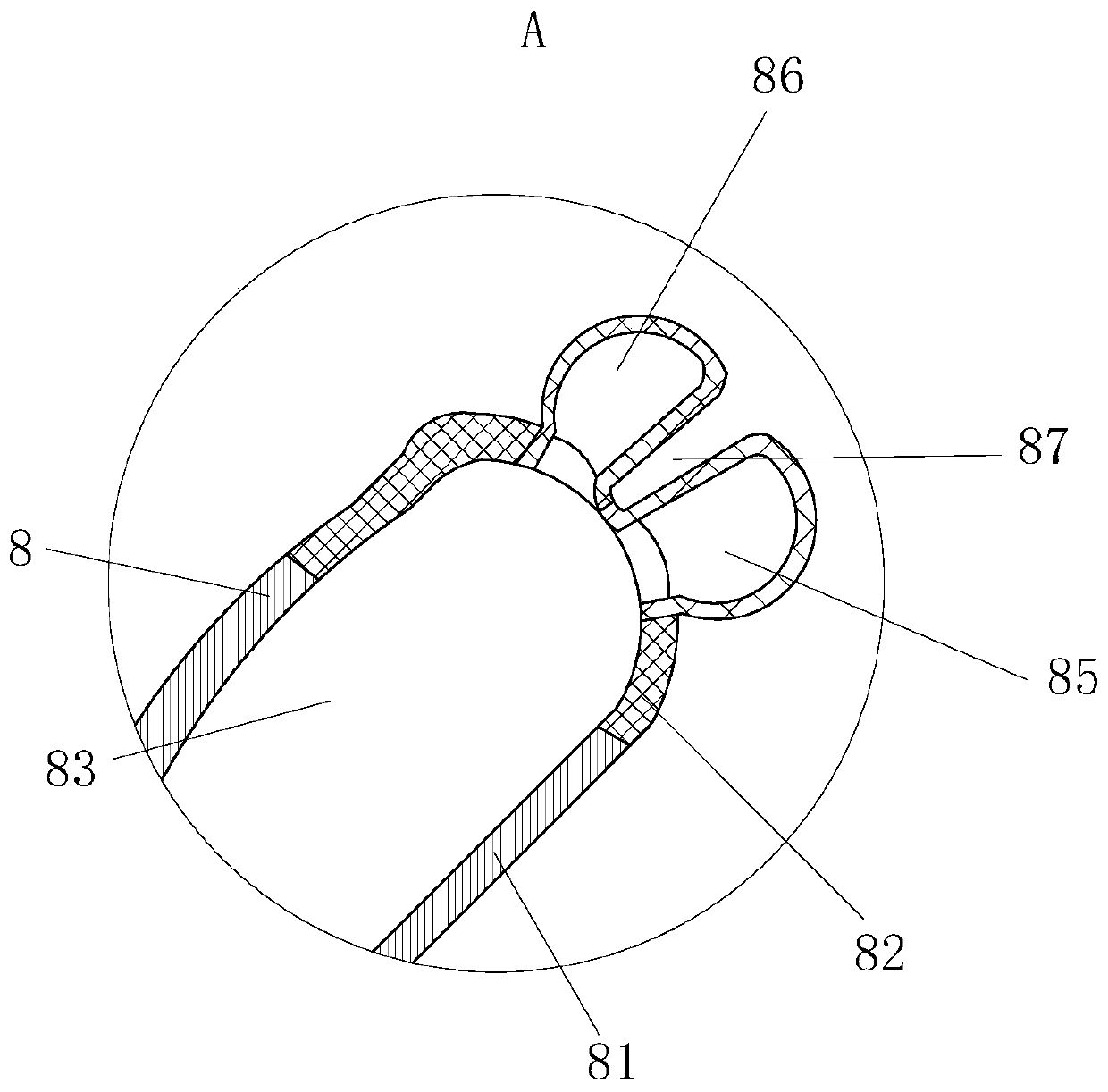

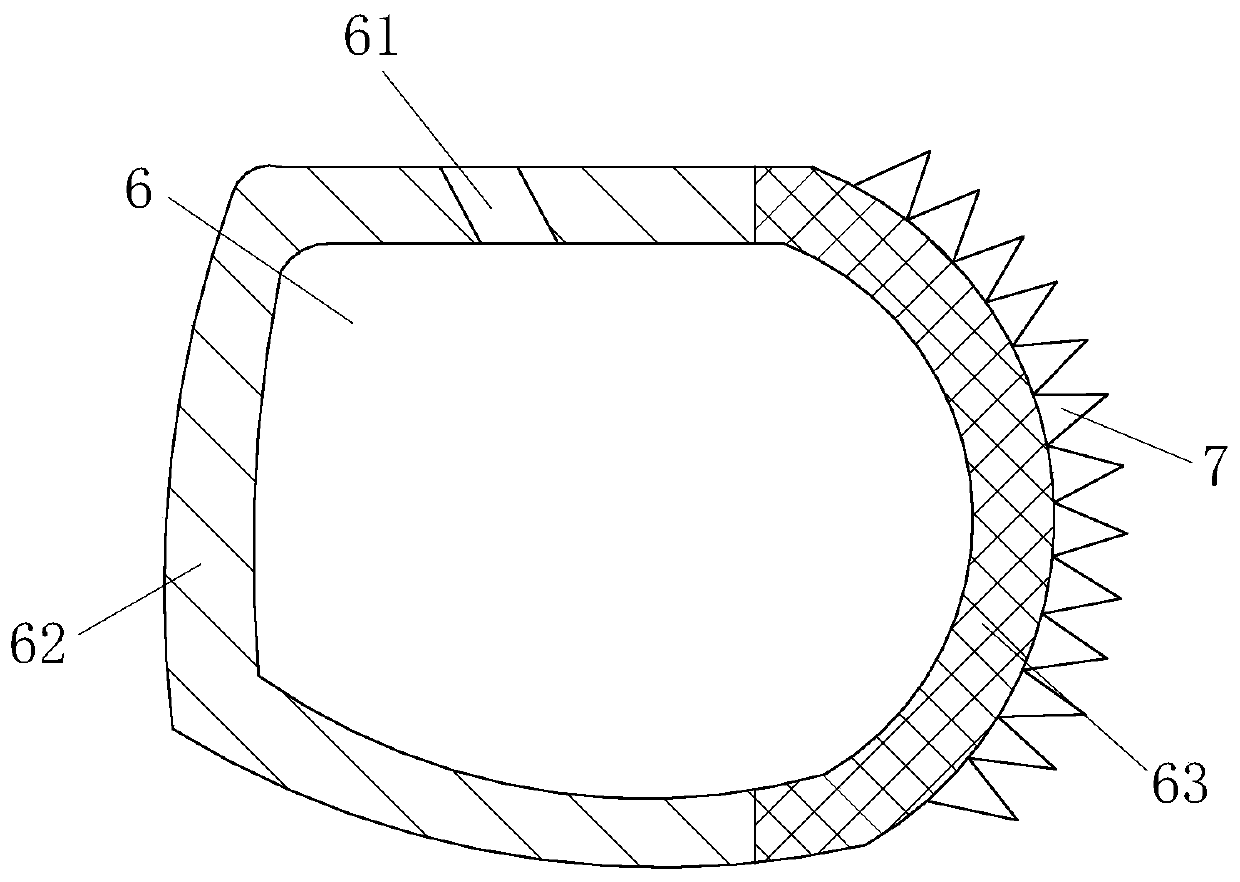

[0023] As an embodiment of the present invention, an elastic airbag 6 is arranged in the installation groove 31, and an exhaust hole 61 is opened on the elastic airbag 6; an elastic metal sheet 62 is arranged on one side of the elastic airbag 6, and elastic The other side of the airbag 6 is provided with an elastic rubber sheet 63; the bottom end of the push spring 4 is provided with a beveled surface 41, and the beveled surface 41 is in contact with the elastic metal sheet 62; , the push spring 4 will be compressed, and the beveled surface 41 at the bottom end of the push spring 4 will open outwards, and then the elastic metal sheet 62 on the side of the elastic air bag 6 will be squeezed, and the extruded elastic air bag 6 will press against the top. The push slide 2 generates a reverse preload, thereby improving the accuracy of the preload of the push preload system.

[0024]As an embodiment of the present invention, a flexible fleece 7 is provided on the outside of the ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com