Patents

Literature

273results about How to "Reliable compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

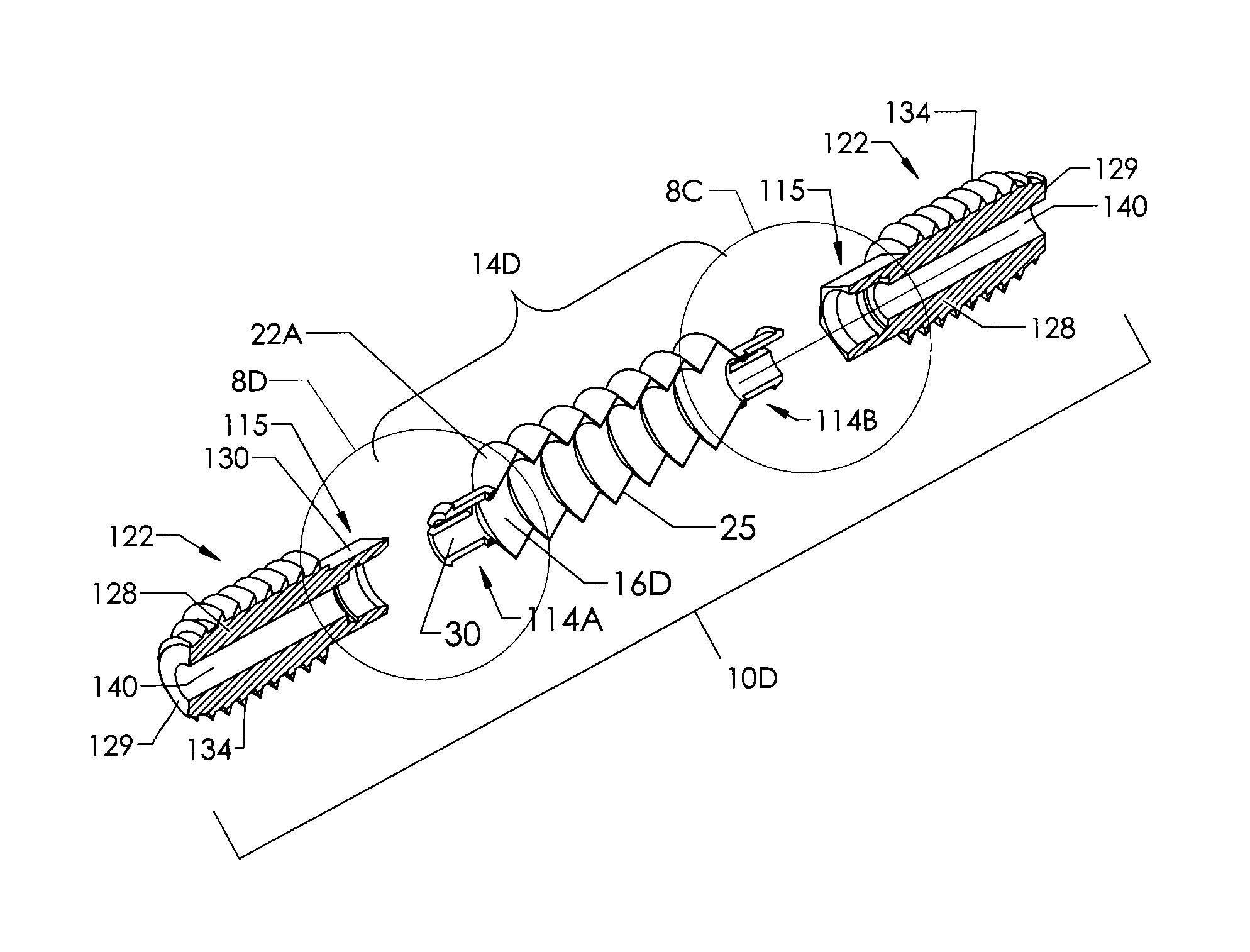

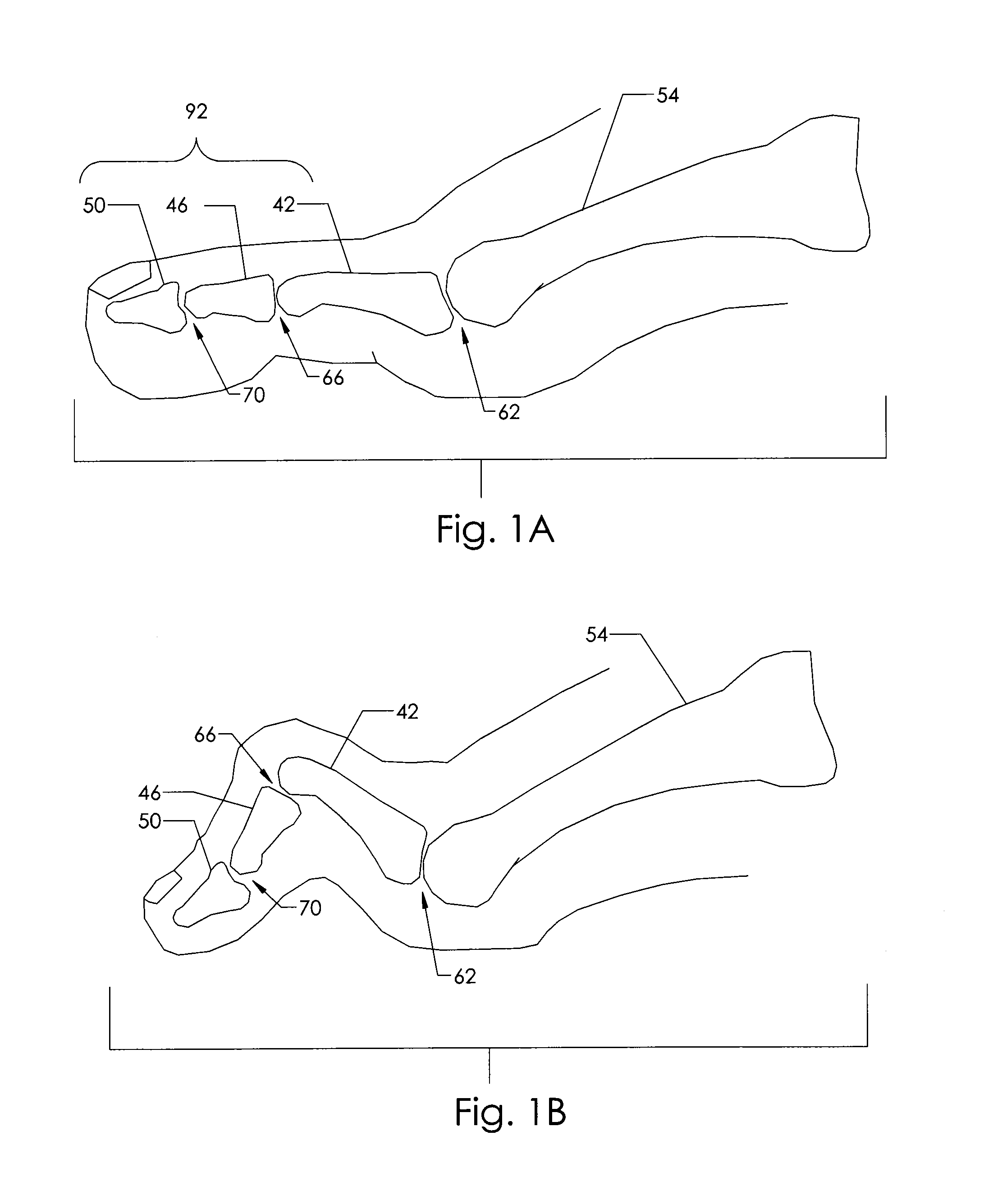

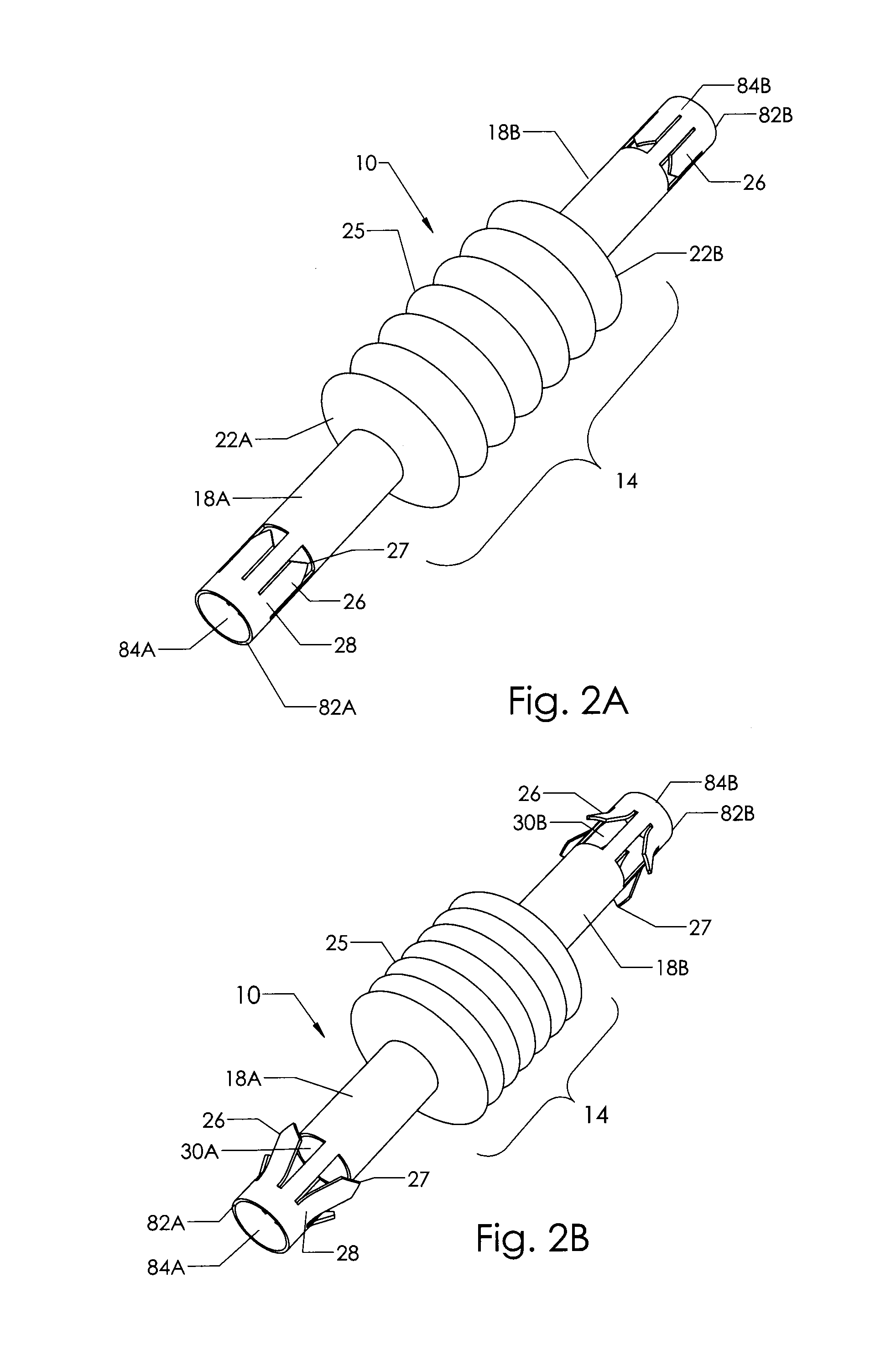

Fasteners with shape changing bellows and methods using same

ActiveUS9138274B1Avoid accidental displacementAccurate placementInternal osteosythesisFastenersShape changeMetal alloy

A fastening device having a bellows made of a material that changes shape when activated by a catalyst, and having a pleated structure that contracts from an extended state to a contracted state upon activation. The shape changing material may be a shape memory metal alloy, shape memory polymer or elastic memory composite. A method of using this fastener provides apposition and compression of abutment surfaces to join together two pieces of material, and is suitable for joining apposing bone surfaces together to heal fractures via the use of orthopedic hardware.

Owner:XTRAVERSE

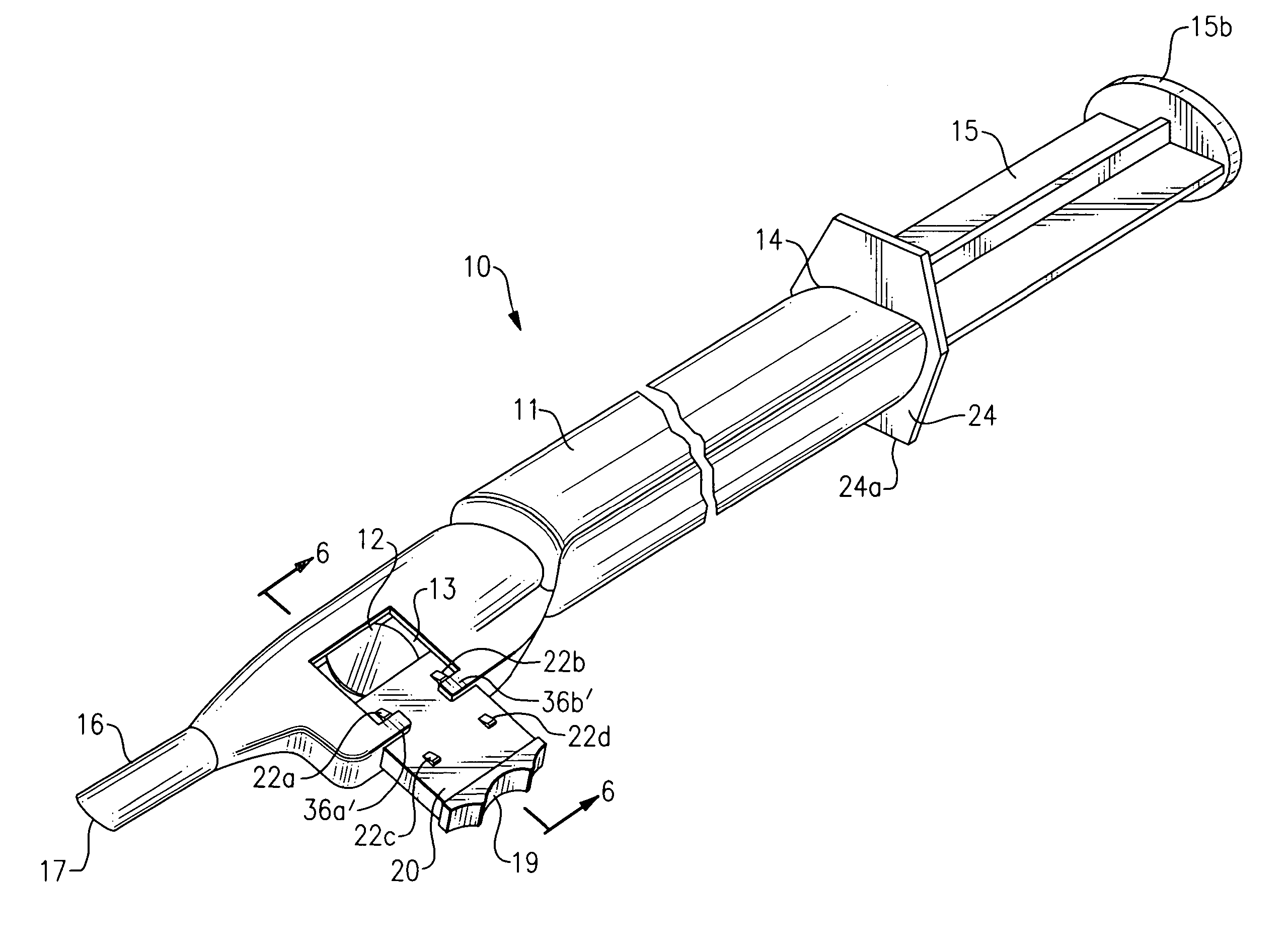

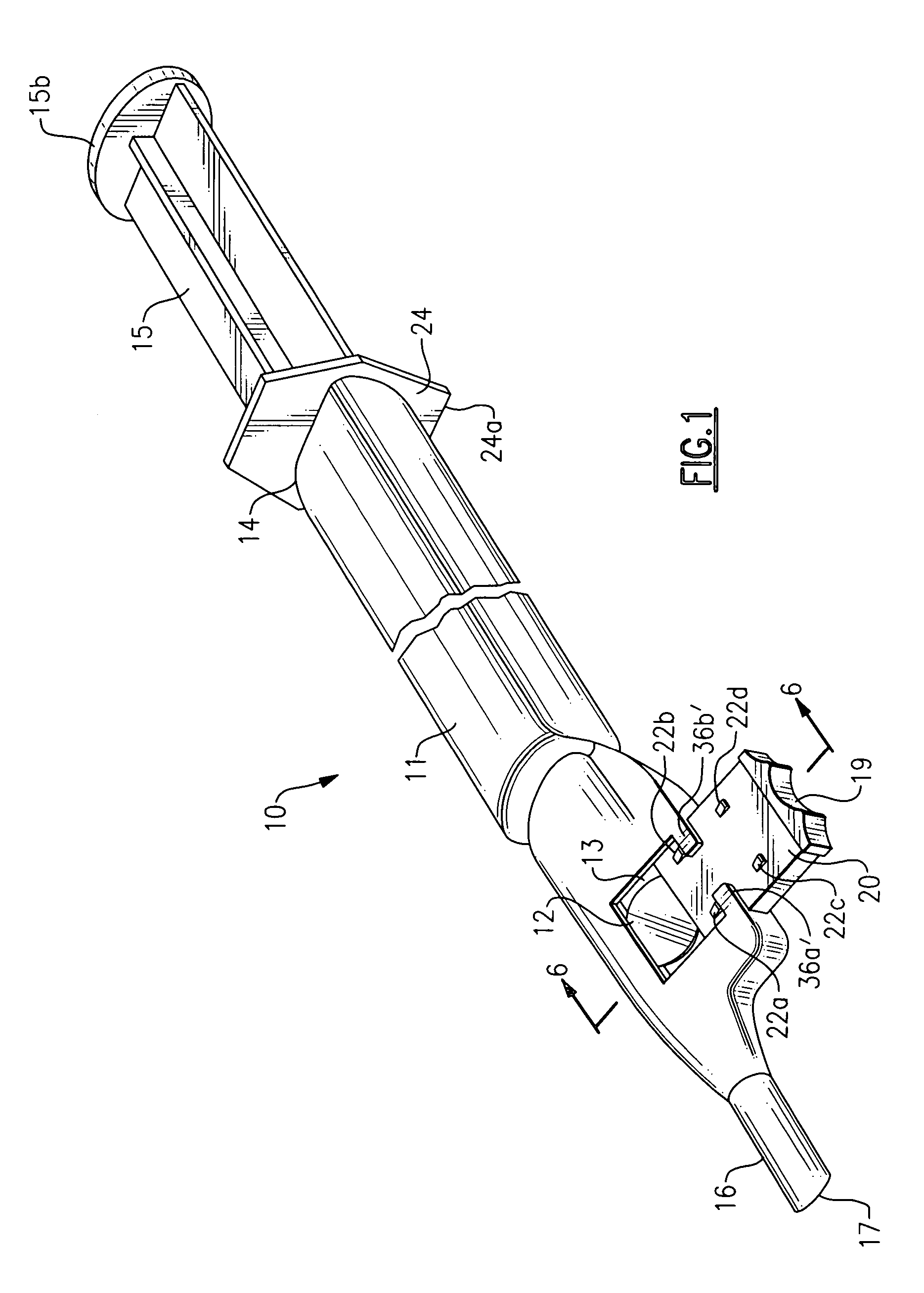

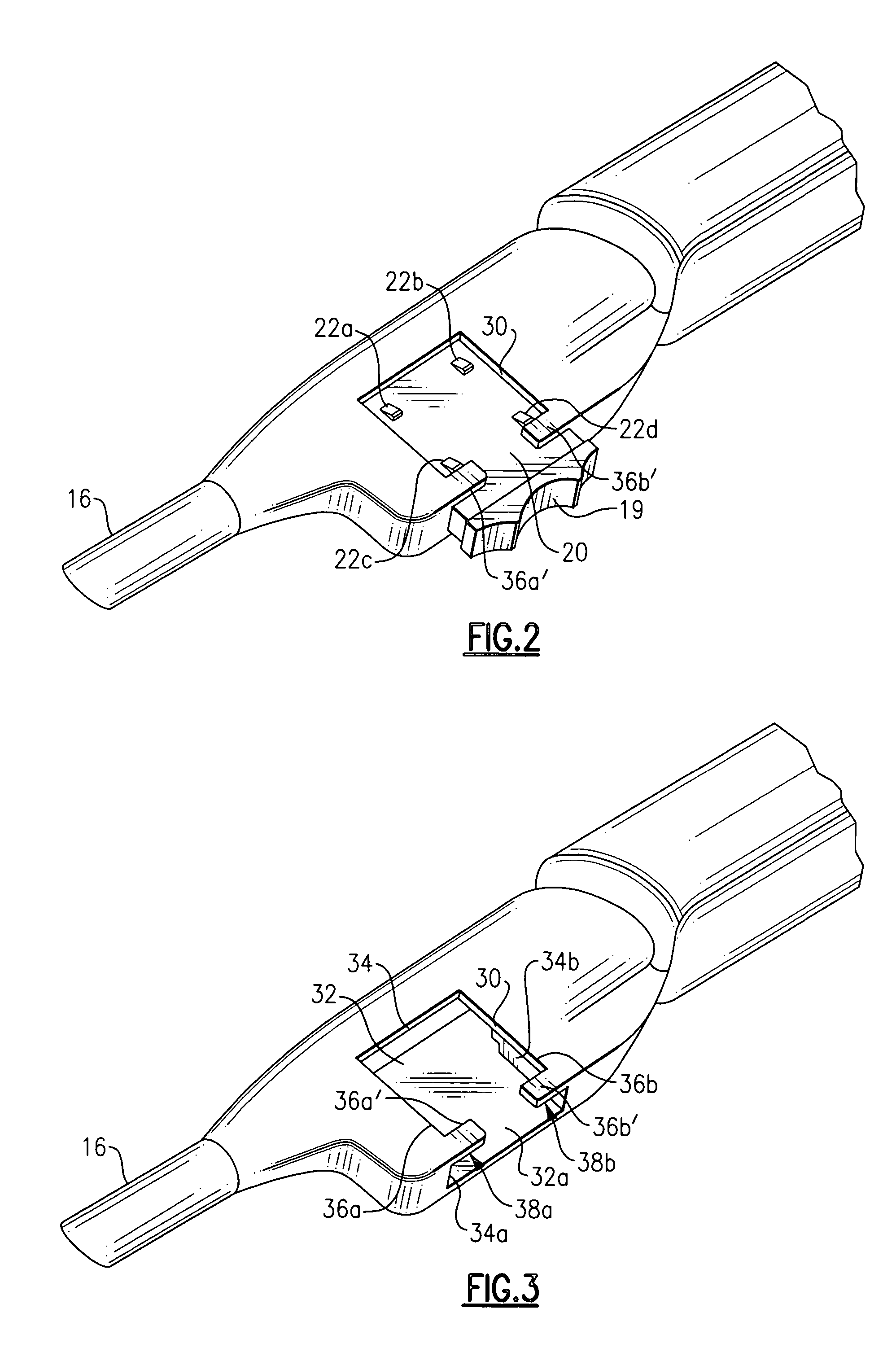

IOL injector device and method

InactiveUS20050149056A1Reliable loadReliable compressionEye treatmentIntraocular lensLocking mechanismDetent

Improved closing and locking mechanism for an IOL compressor component of an IOL injector device includes two equally spaced, sequential pairs of catches provided on a wall of the compressor for sequentially engaging with a respective pair of detents formed adjacent the compressor opening of the injector body as the compressor is moved to the closed position.

Owner:BAUSCH & LOMB INC

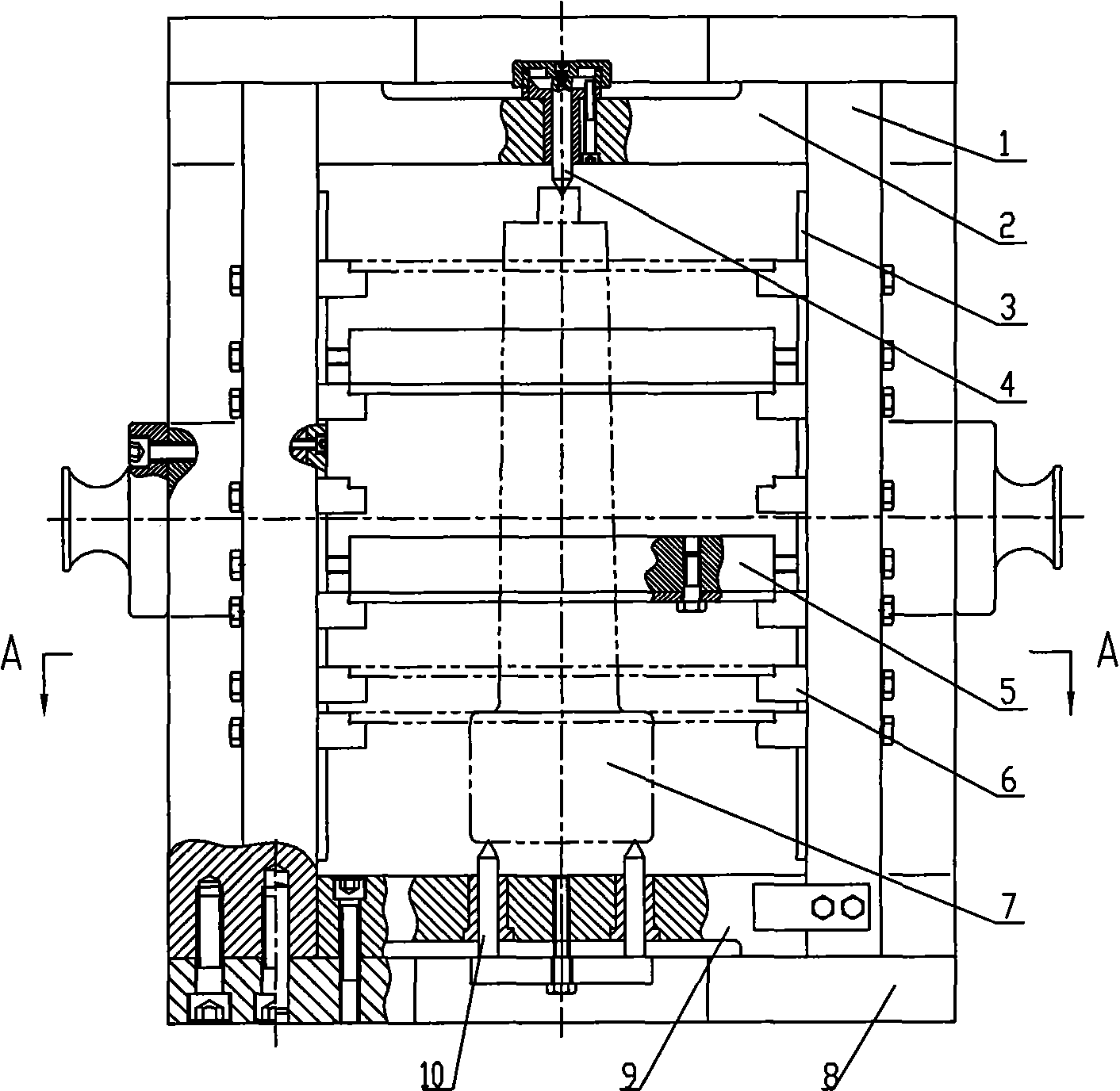

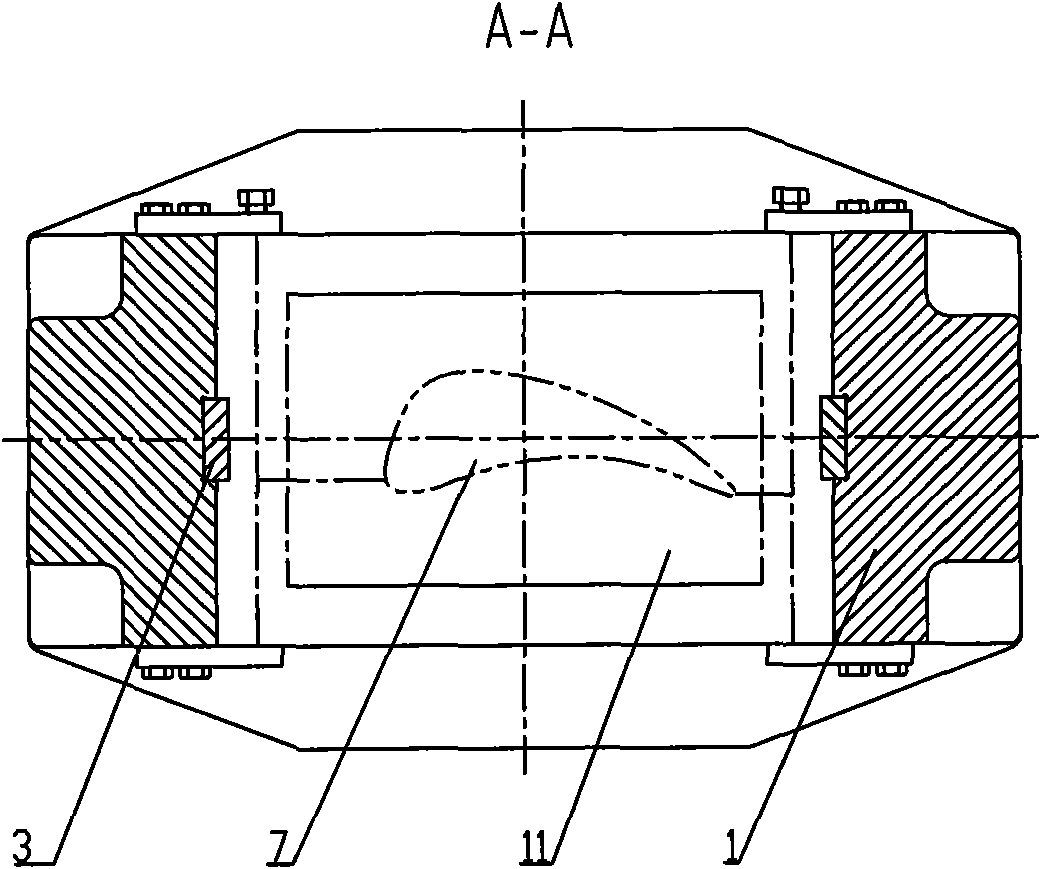

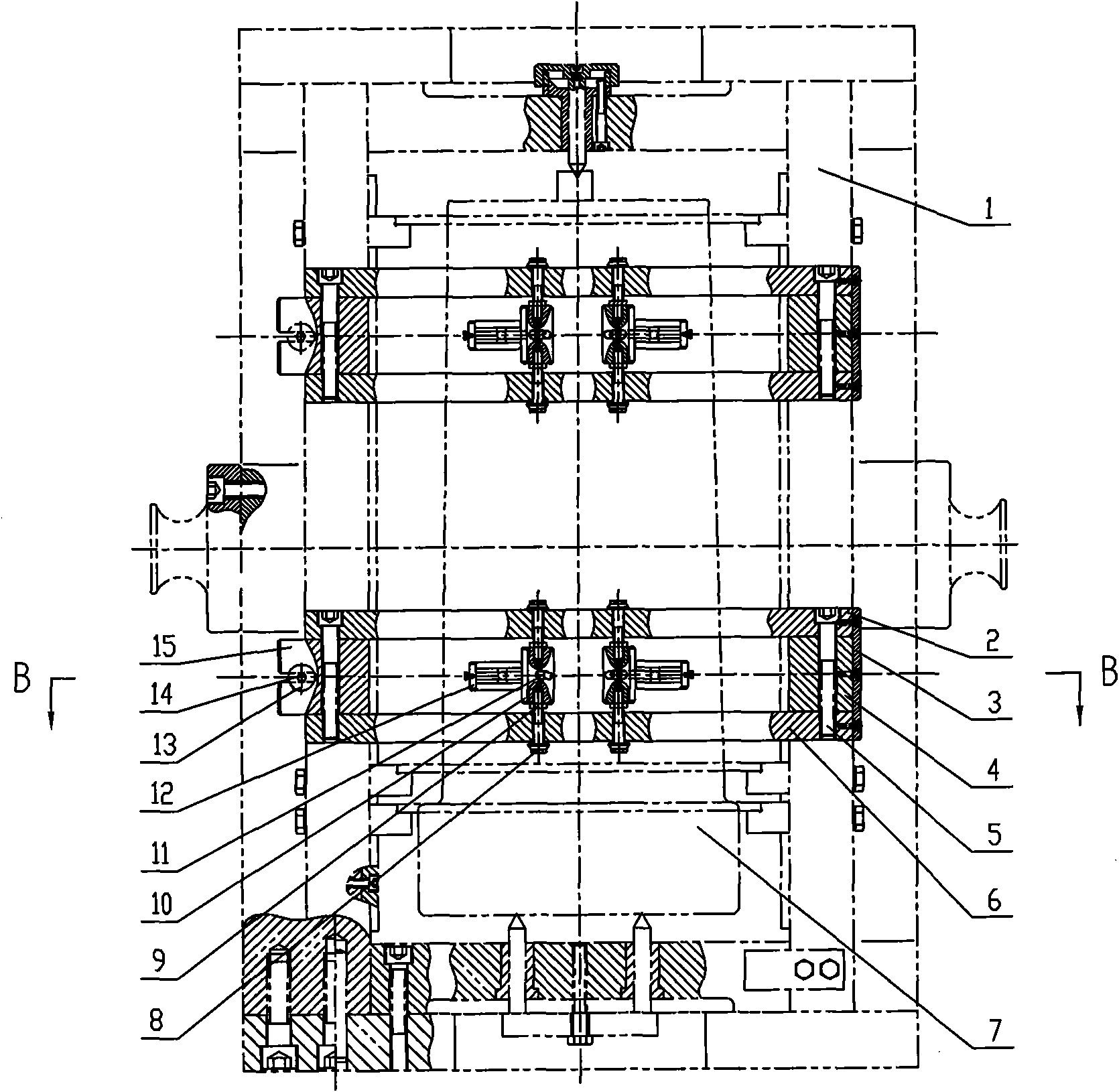

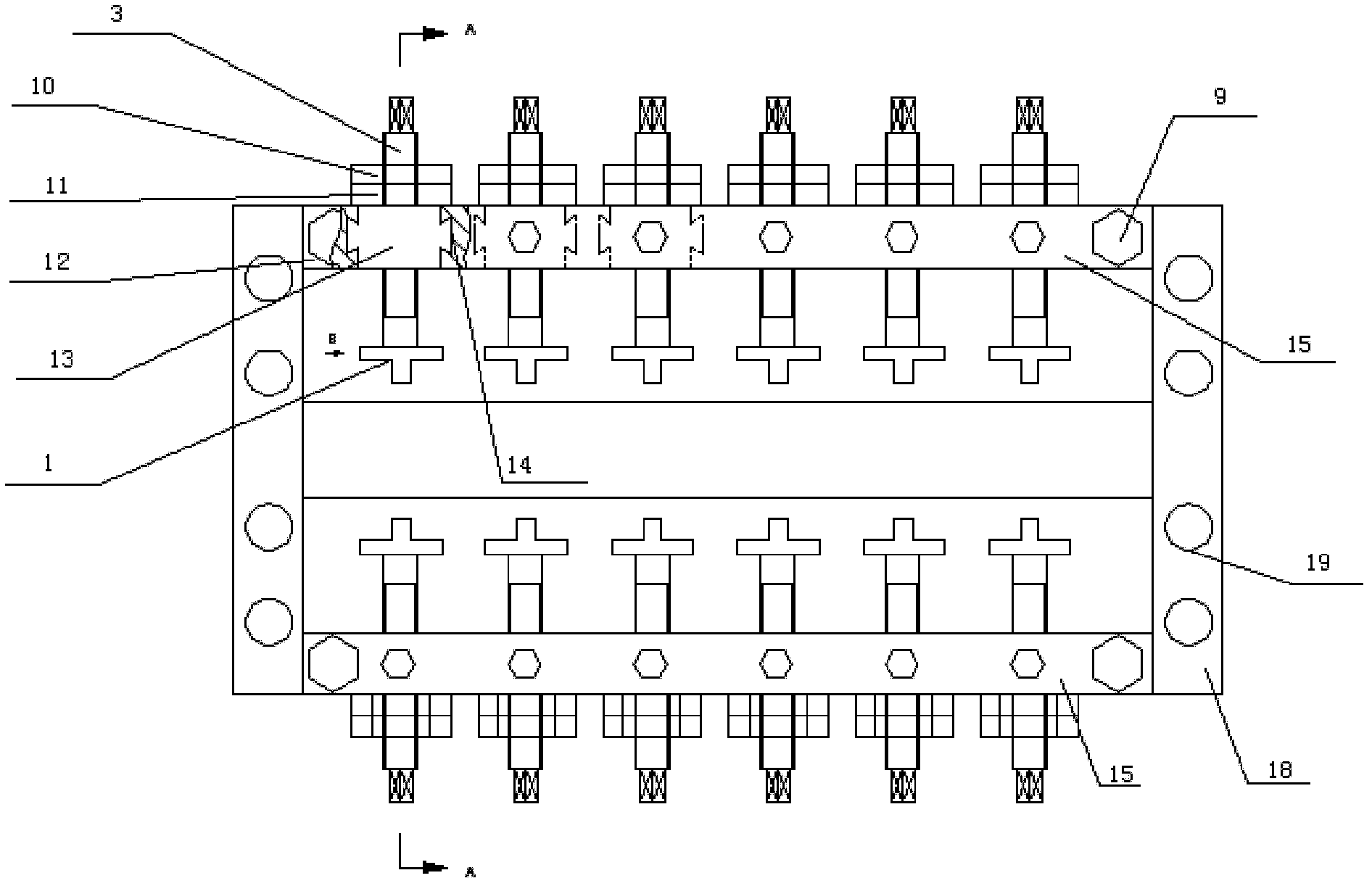

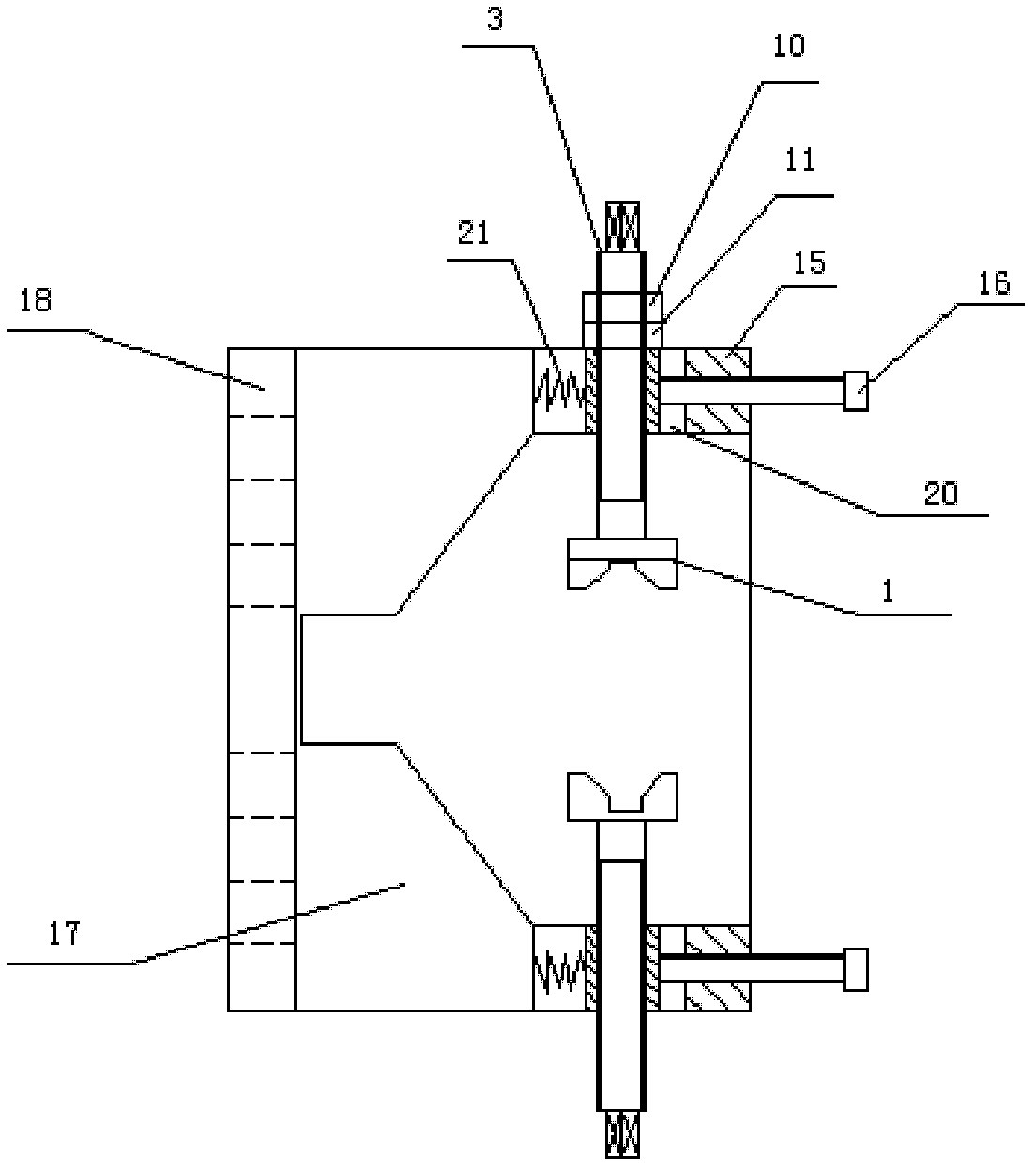

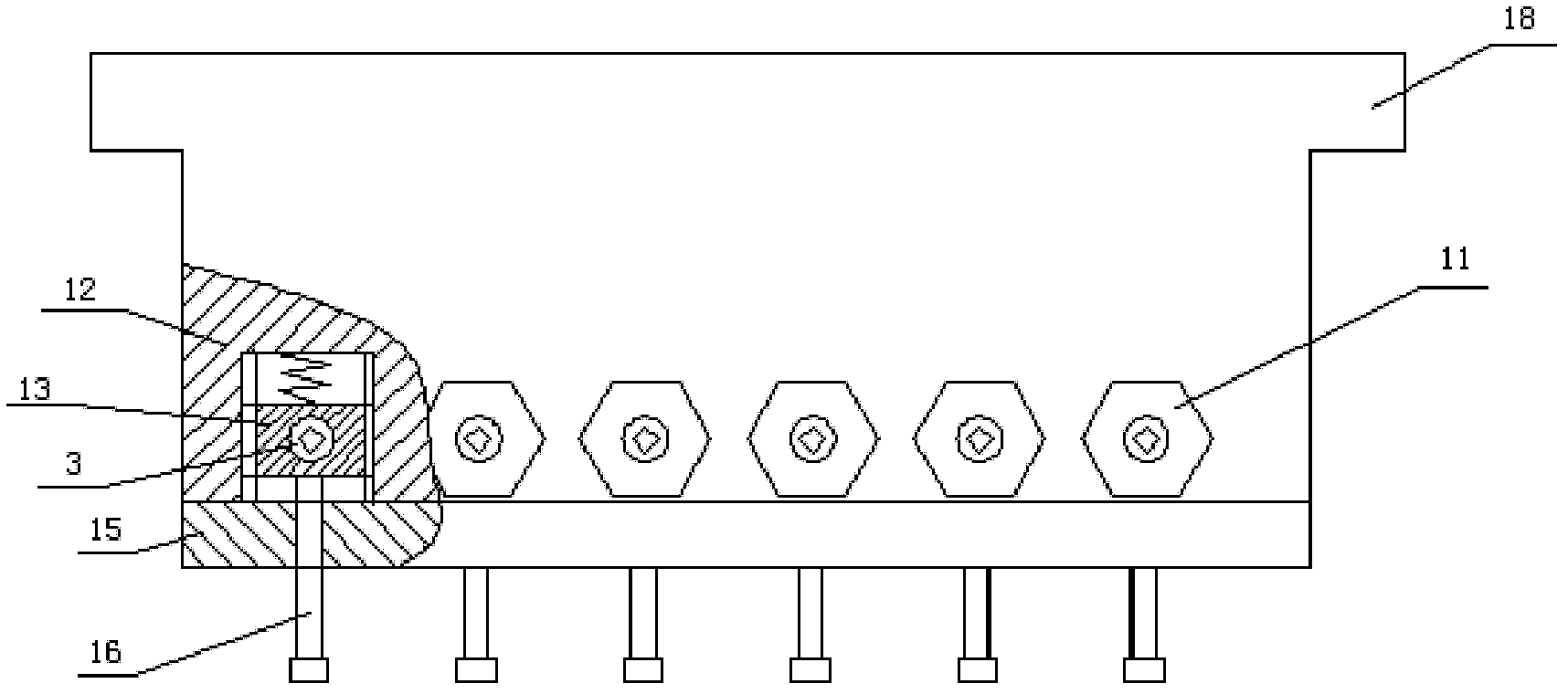

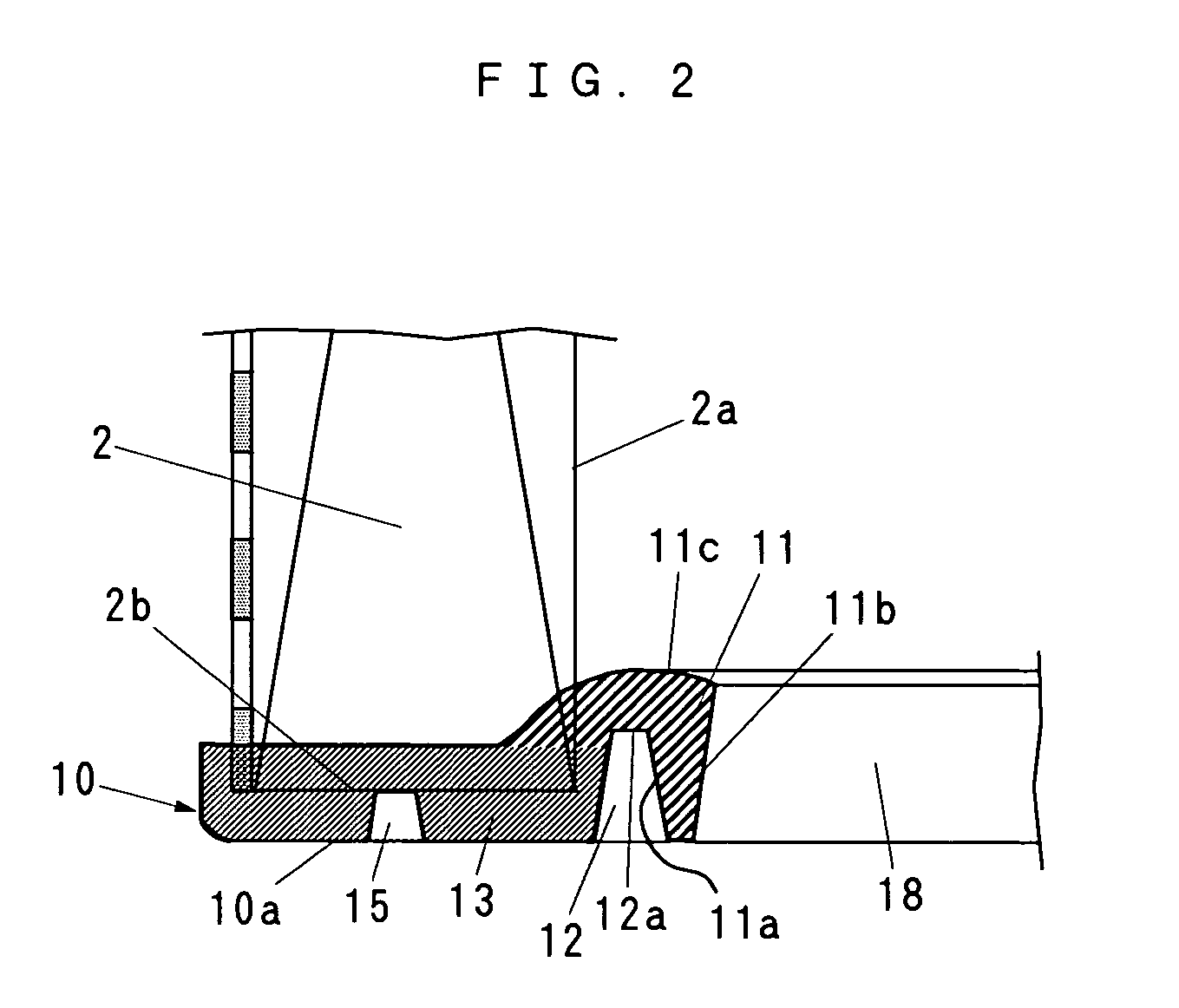

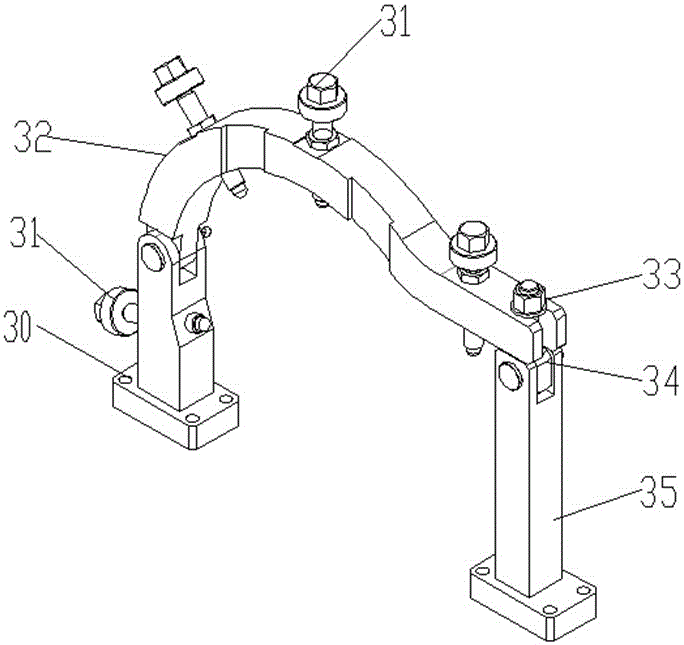

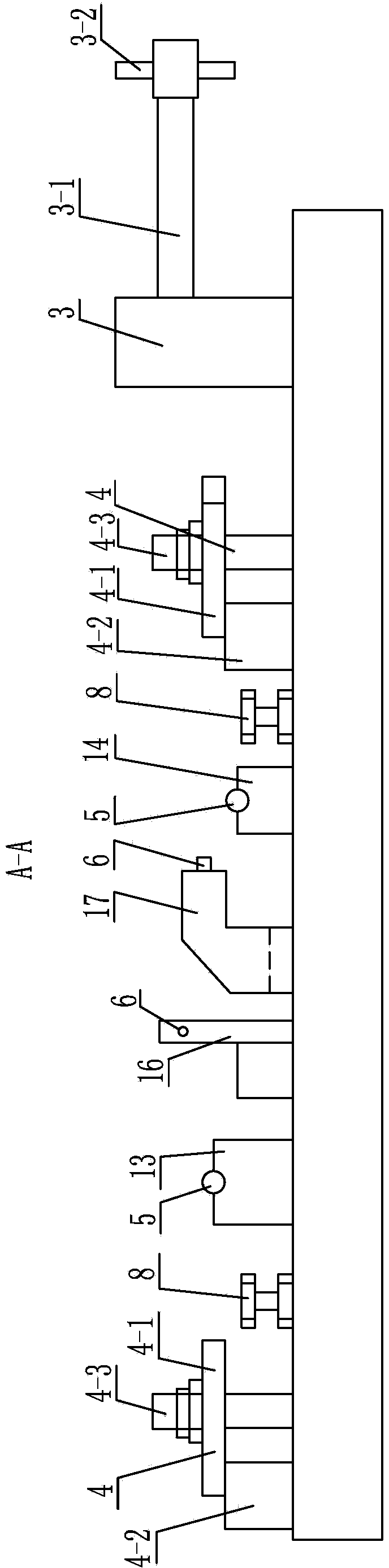

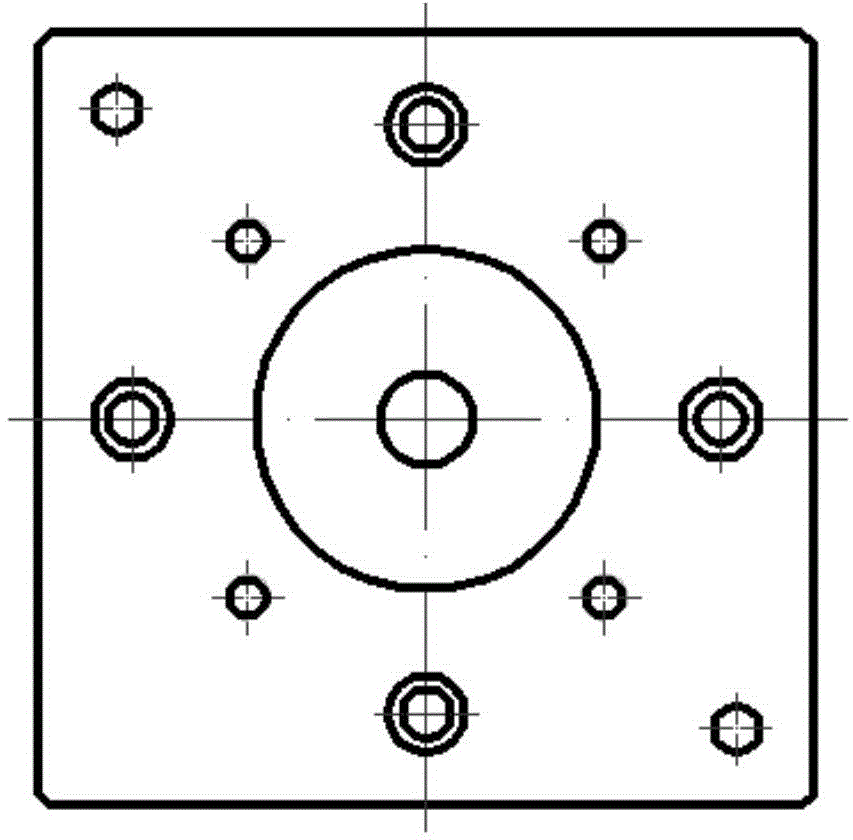

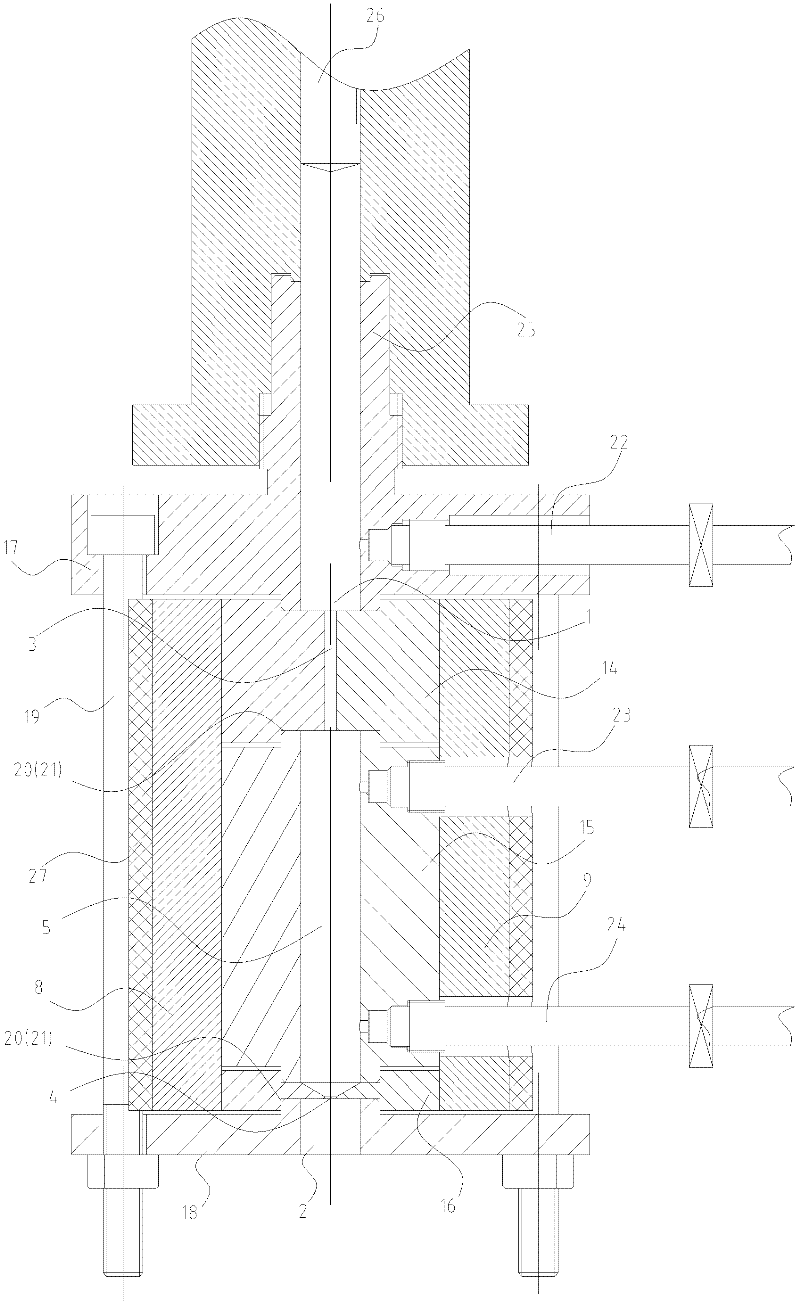

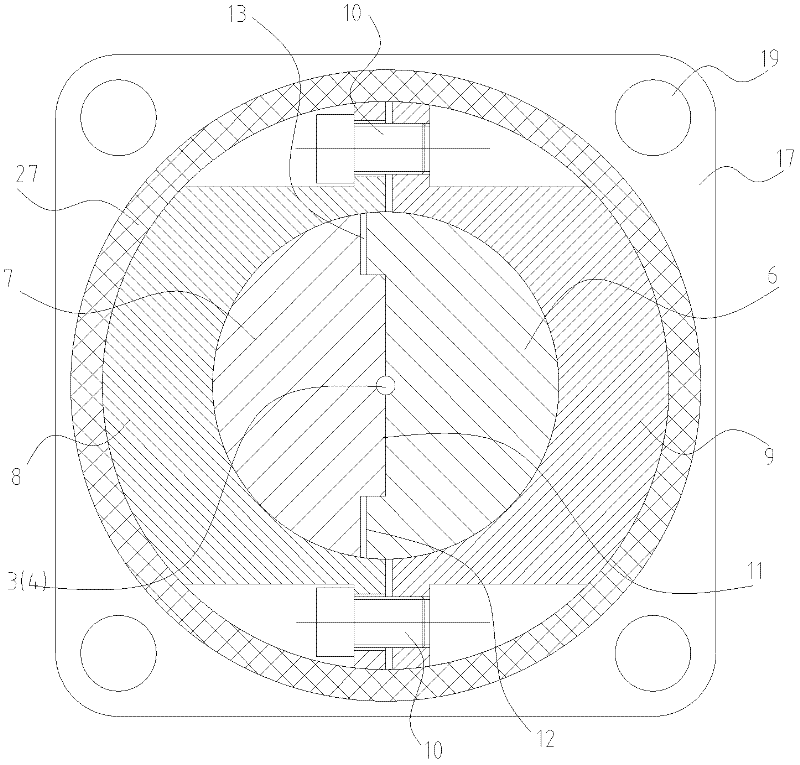

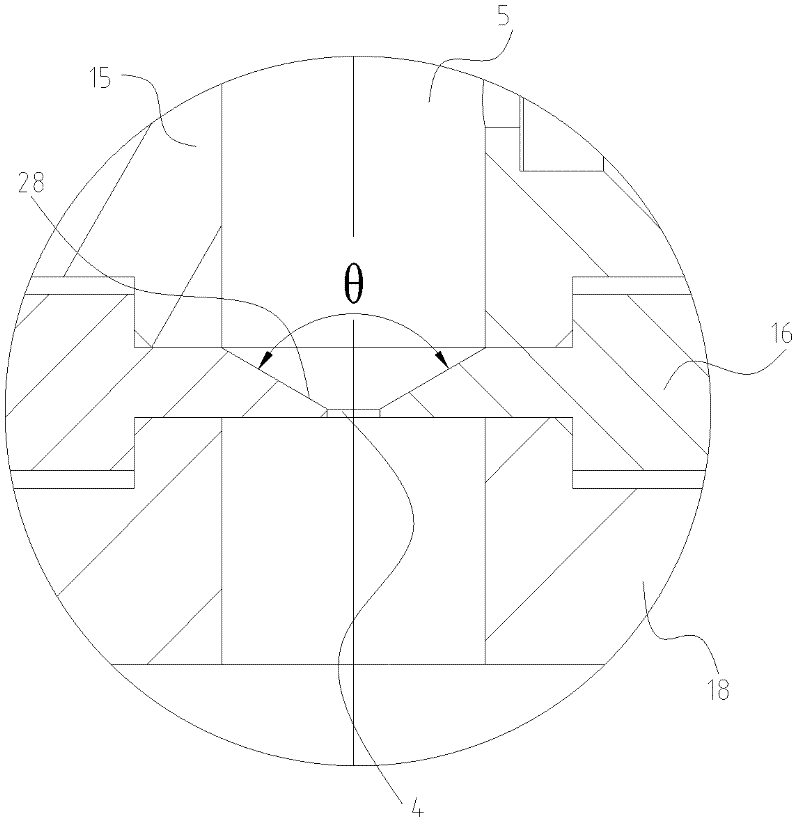

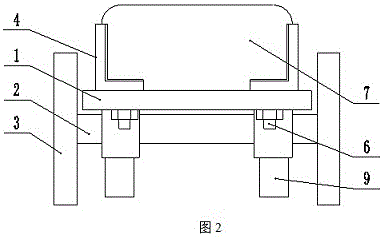

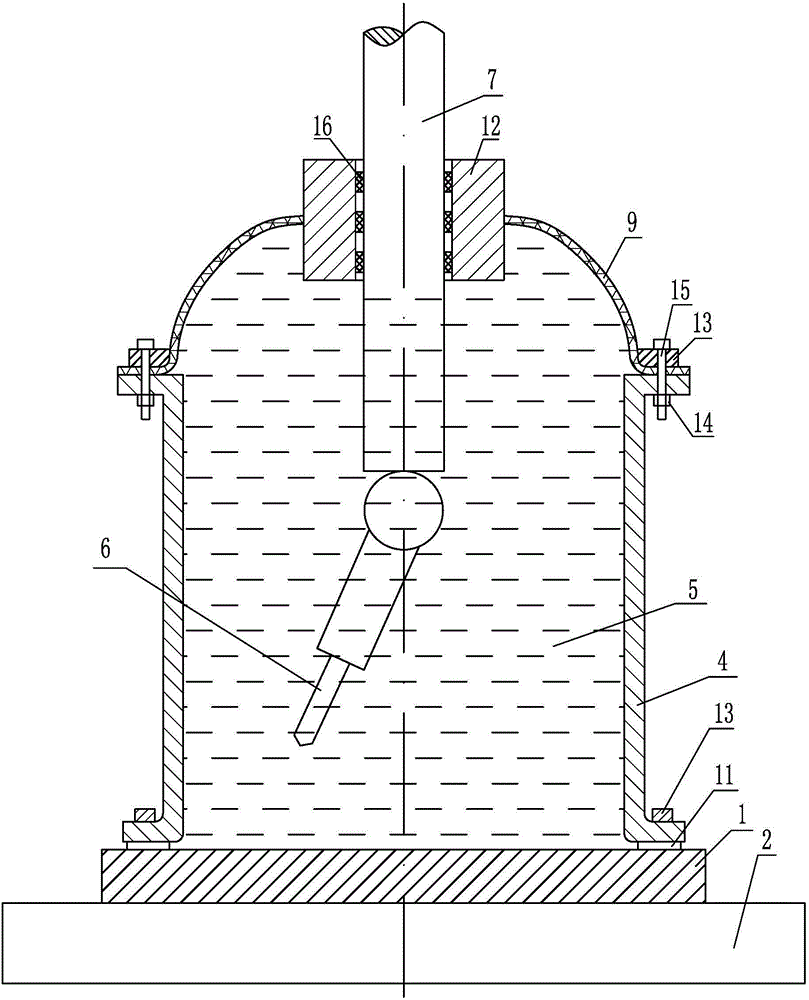

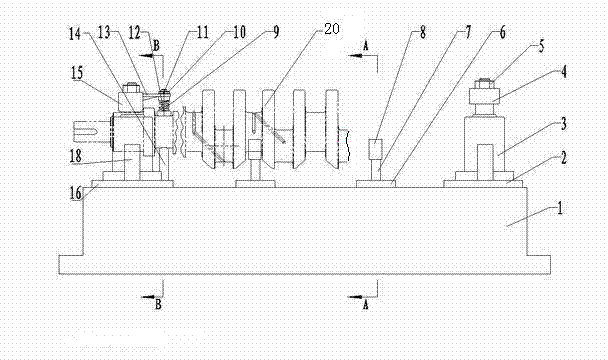

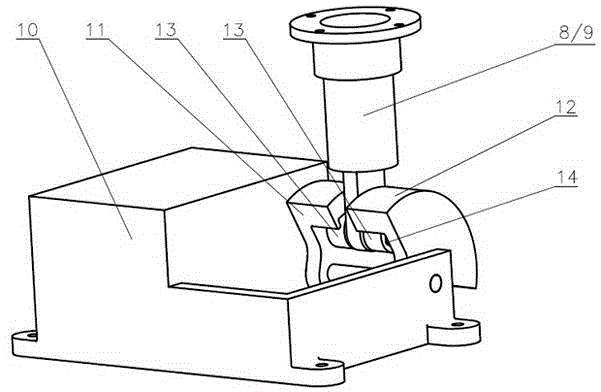

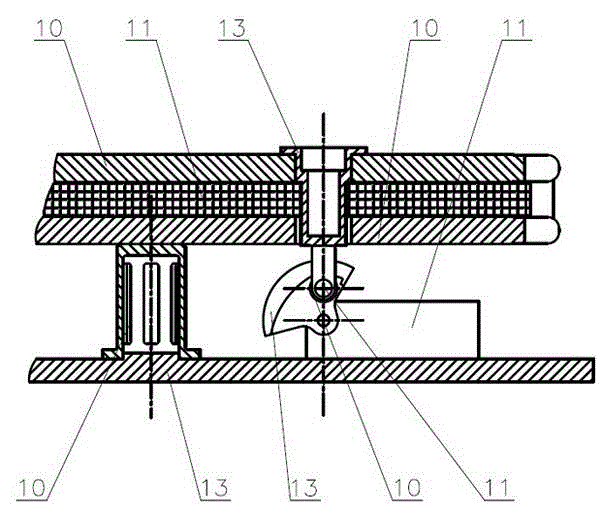

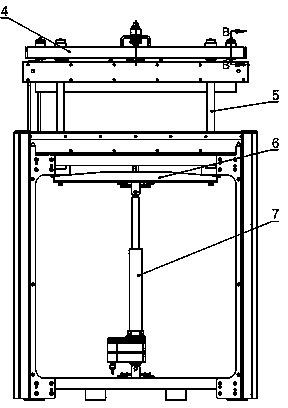

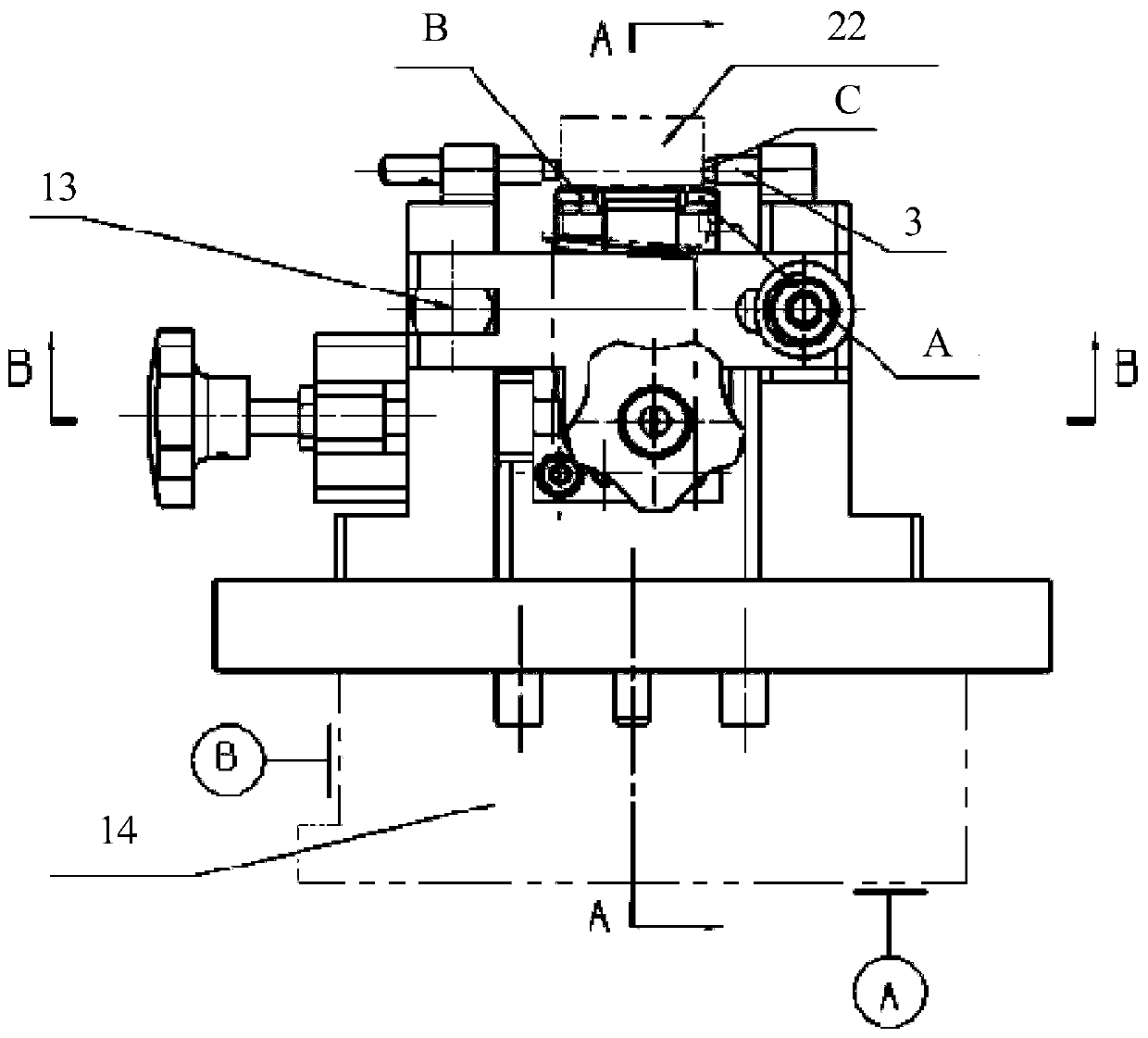

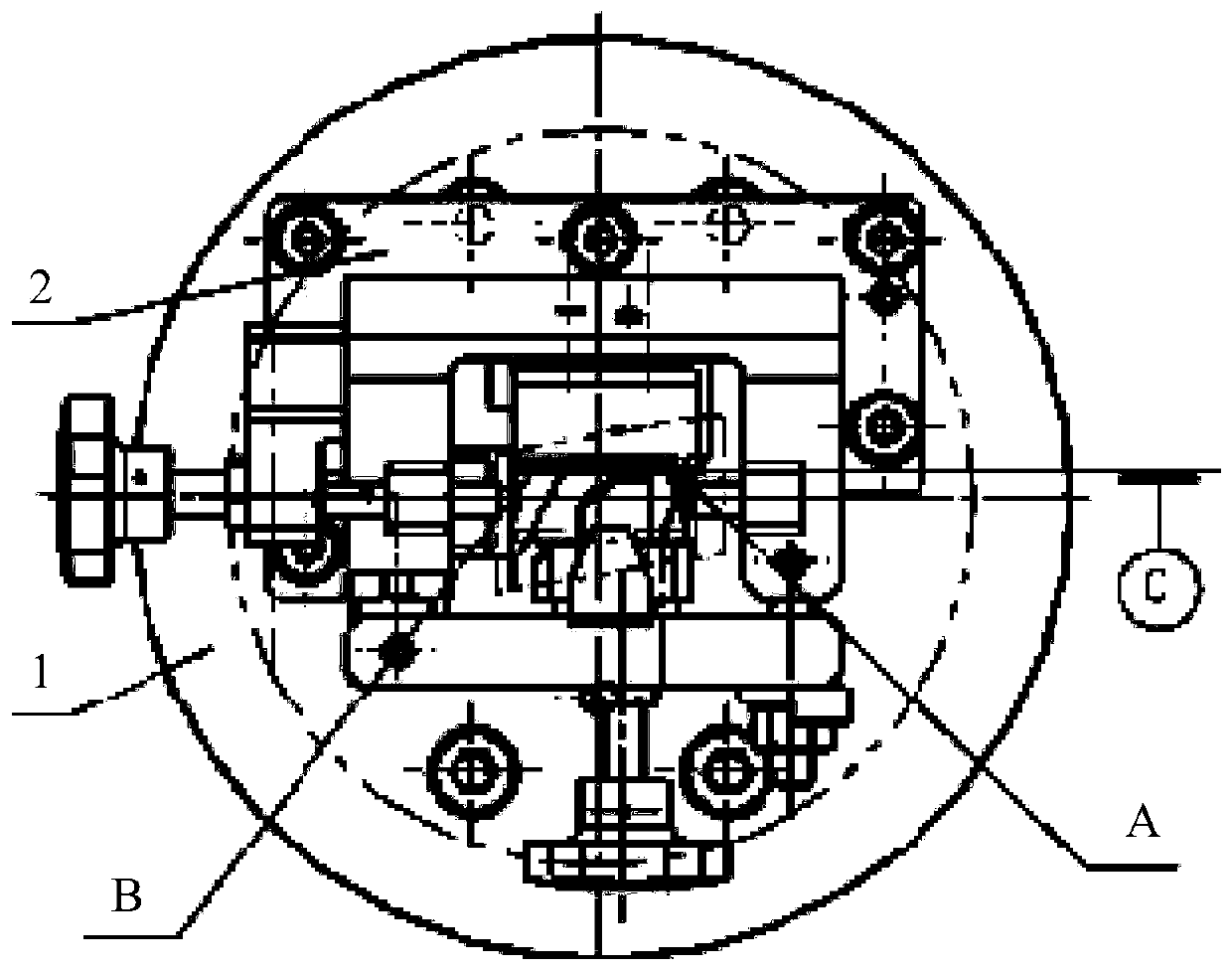

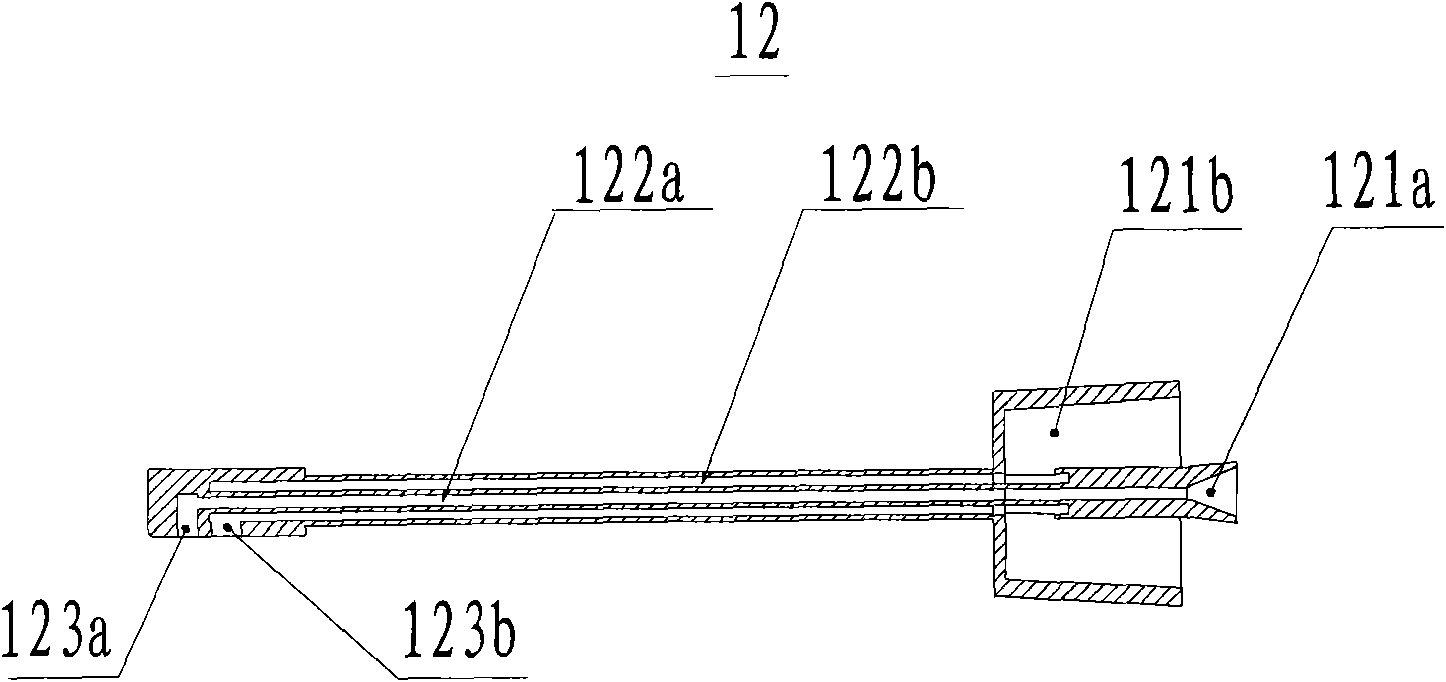

Universal hold-down mechanism of steam turbine blade drill jig

InactiveCN101791765AReliable compressionSimple structurePositioning apparatusMetal-working holdersSteam turbine bladeEngineering

The invention relates to a universal hold-down mechanism of a steam turbine blade clamp, comprising a frame composed of an upper cover plate, a lower cover plate, a left cushion block and a right cushion block, wherein the upper cover plate and the lower cover plate are respectively provided with a corresponding slide way which is provided with a plurality of notches; a universal slide block is arranged between the upper cover plate and the lower cover plate; the upper side and the lower side of the universal slide block are respectively provided with a support shaft; the support shaft on the upper side of the universal slide block is installed in the slide way in the upper cover plate; the support shaft on the lower side of the universal slide block is installed in the slide way in the lower cover plate; the universal slide block is movably connected with a pressure lever of which the axial direction is crossed with the axial direction of the support shaft; and one end of the pressure lever is provided with a pressure head. The universal hold-down mechanism comprises the slide ways, the universal slide block, the pressure lever and the pressure head, has simple structure, strong generality, low using cost and convenient operation; a blade is pressed by the pressure head; the pressure head is connected with the universal slide block which slides in the slide ways, so that the universal hold-down mechanism is flexible to adjust and has high efficiency.

Owner:WUXI AIERFU BLADE

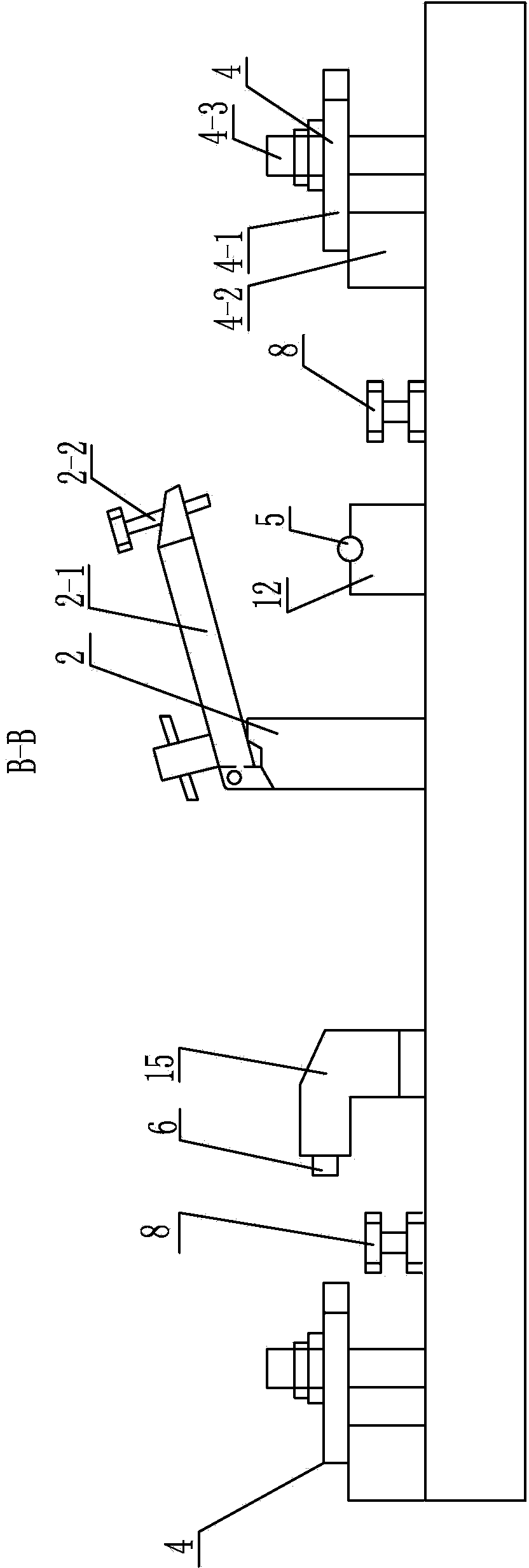

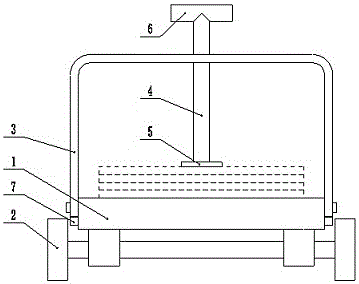

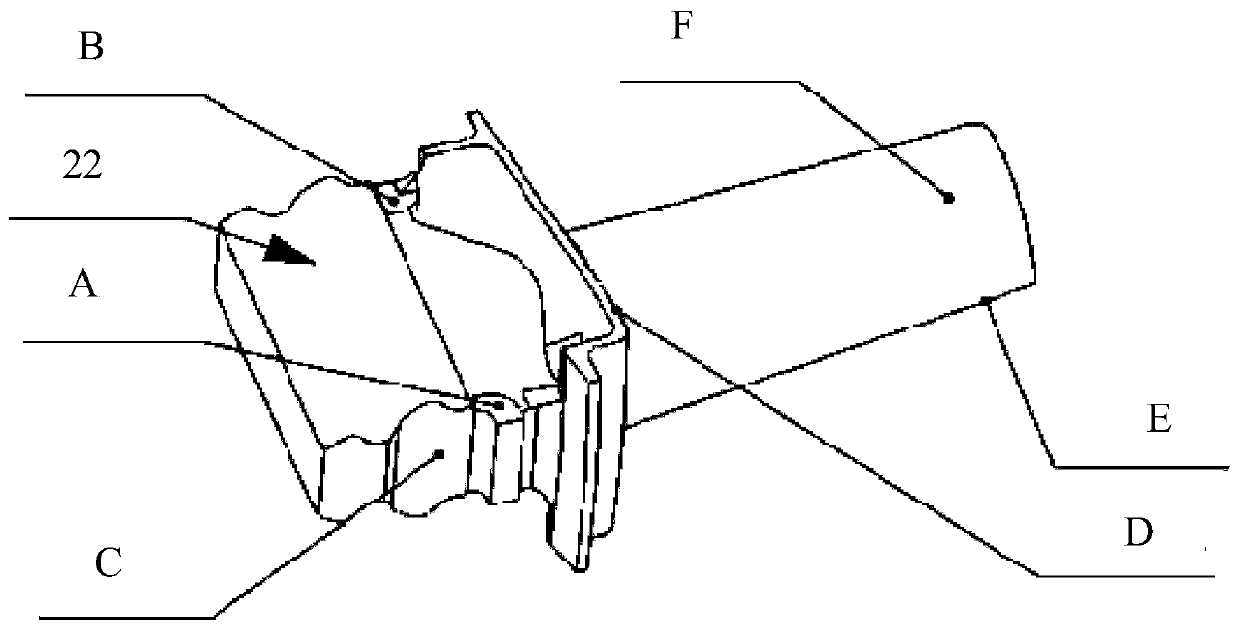

Fixture for elbows with space curves as axes

InactiveCN102581665ASimple structureEasy to usePositioning apparatusMetal-working holdersScrew threadIndustrial engineering

The invention discloses a fixture for elbows with space curves as axes. The fixture comprises a fixture main body, a supporting and adjusting mechanism and a clamping device. The fixture main body is used for fixing and consists of a fixture body and pressing edges with holes. the pressing edges are arranged at two edges of the fixture body, the fixture body and the pressing edges are integrated, the fixture body is fixed onto a worktable by bolts via the holes at the pressing edges, the supporting and adjusting mechanism consists of sliders, slider supporting guide plates, slide grooves, springs, pressure plates, adjusting bolts and fixing screws, the clamping device comprises screw stems, the screw stems are symmetrically arranged on upper end surfaces and lower end surfaces of the slider supporting guide plates and are connected with the corresponding sliders in a threaded manner, first locking nuts and second locking nuts are arranged at joints of the upper portion of the screw stems and outer end surfaces of the slider supporting guide plates, and V-shaped chucks are disposed at lower ends of the screw stems. The fixture is simple in structure and convenient in use and maintenance, can firmly and reliably compress the elbows with optional space curves as axes, and brings convenience for machining.

Owner:WUXI INST OF COMMERCE

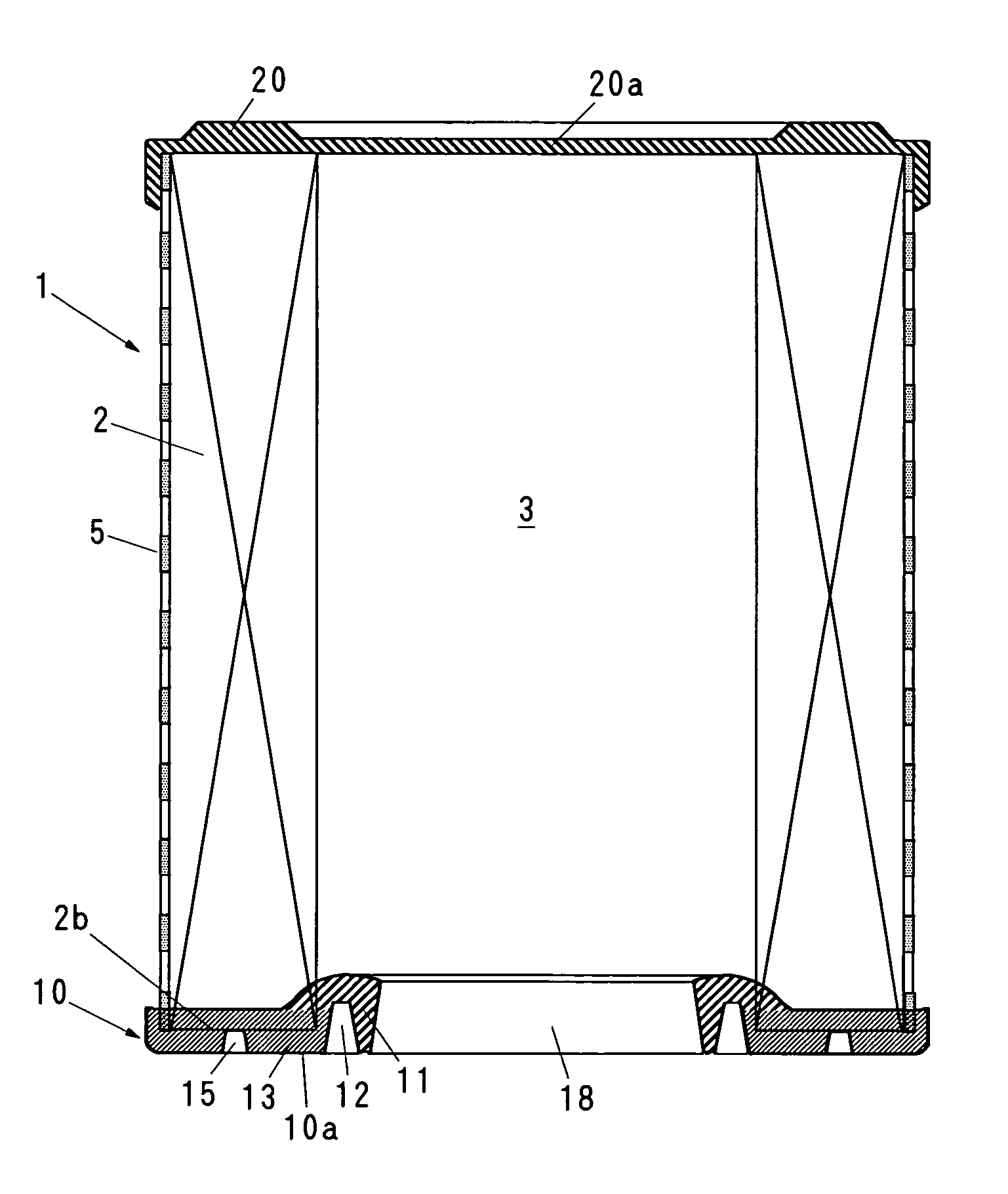

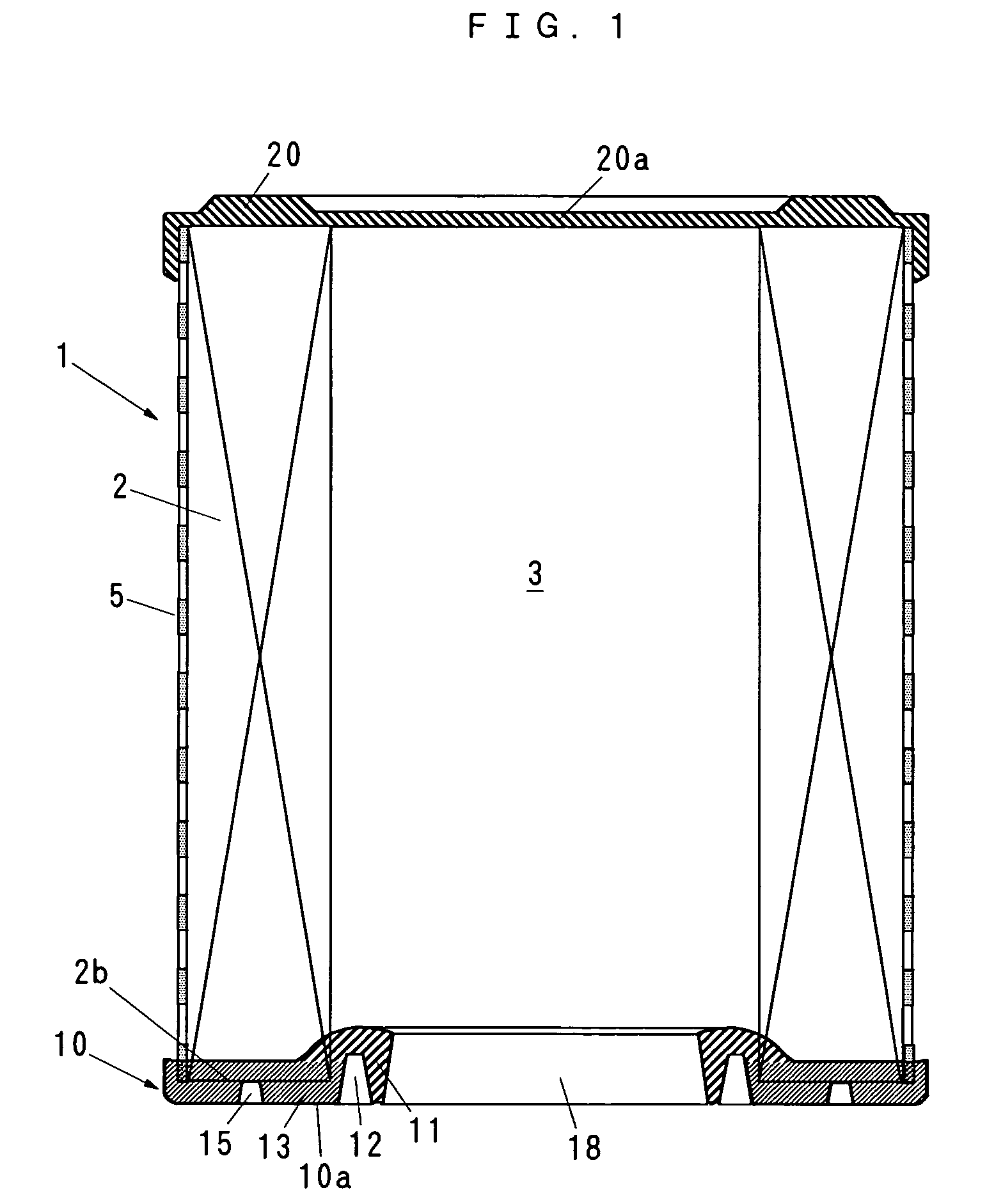

Air filter element and method of producing the same

InactiveUS7083661B2Reliable and easy to produceImprove rigidityDispersed particle filtrationCombustion-air/fuel-air treatmentComposite constructionAir filter

There is provided an air filter element which is used by fitting a central opening in its end plate on a cylindrical portion projecting into a casing, wherein the air filter element has a novel seal construction (end plate). An end plate (10) closing the end surface of a hollow cylindrical filter portion (2) includes a soft inner peripheral seal portion (11) capable of sticking to the outer surface of a cylindrical member (33) and a rigid closure portion (13) which is disposed on the outer periphery side of the inner peripheral seal portion and in which the end surface of the filter portion is embedded, the end plate being of composite construction in which the inner peripheral seal portion (11) and the closure portion (13) are integrally molded. On the outer periphery side of the inner peripheral seal portion (11), a groove (12) axially extending from an end surface (10a) of the end plate is formed along the opening. The inner peripheral seal portion (11) effects reliable center seal with respect to the cylindrical member (33), while the closure portion (13) on the outside thereof improves the rigidity of the air filter element.

Owner:TOYO ELEMENT IND

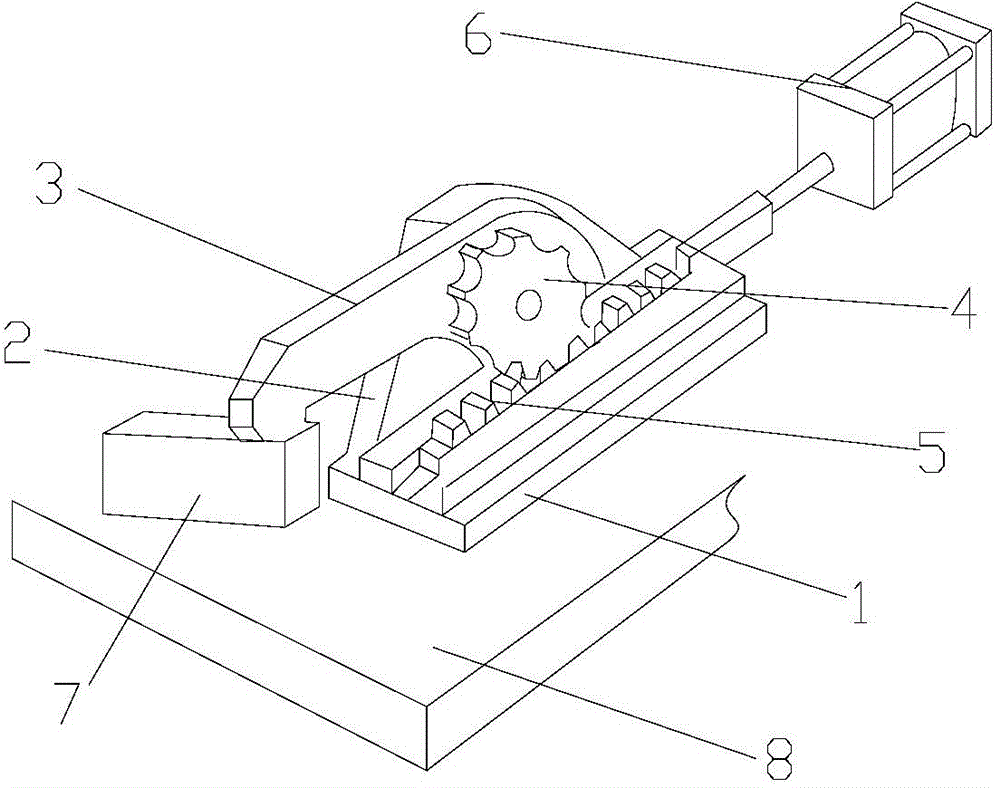

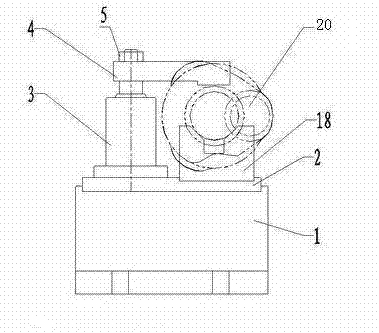

Gear transmission swinging pressing mechanism

InactiveCN104440298AHydraulic drive saves effortSimple structurePositioning apparatusMetal-working holdersHydraulic cylinderGear wheel

The invention relates to the technical field of machine tool clamps, in particular to a gear transmission swinging pressing mechanism. The gear transmission swinging pressing mechanism comprises a fixing plate, a hydraulic cylinder, a pressing plate and a gear. The fixing plate is provided with a vertical stand plate, the front end of the pressing plate is in a linear shape, and the back end of the pressing plate is in an arc shape bent downwards. The gear is fixed to the arc back end of the pressing plate and controls the pressing plate to rotate synchronously. The arc back end of the pressing plate is hinged to the stand plate. A rack meshed with the gear is arranged on the part, corresponding to the bottom of the gear, of the fixing plate and connected with the fixing plate in a sliding mode. The hydraulic cylinder is arranged on the back side of the rack. A piston rod of the hydraulic cylinder is connected with the back end of the rack and controls the forward and backward movement of the rack, clamping is quick, labor is saved, pressing is reliable due to hydraulic driving pressing, and the clamp is simple in structure and low in cost.

Owner:常州市锐金轮机械配件有限公司

Multifunctional screw turning device

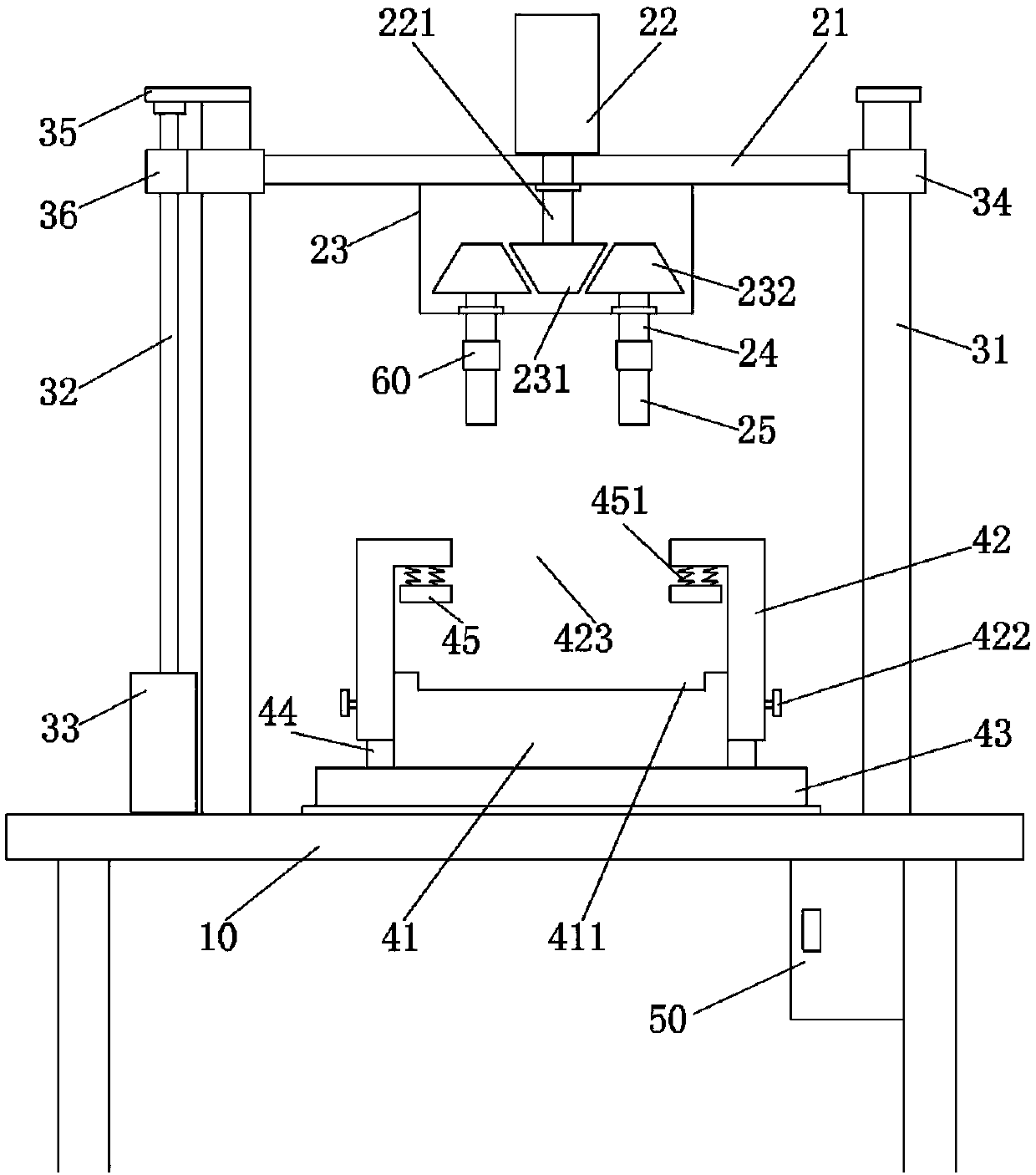

InactiveCN107717430AImprove efficiencyEnergy savingWork holdersMetal working apparatusEngineeringMotor drive

The invention discloses a multifunctional screw turning device. The multifunctional screw turning device comprises a worktable, a turning mechanism, a positioning mechanism and a control mechanism. The turning mechanism comprises a lifting fixing plate, a turning motor and a driving box; a driving bevel gear and two driven bevel gears are arranged in the driving box; the turning motor drives the driving bevel gear to rotate so as to drive the driven bevel gears; the bottoms of the driven bevel gears are fixedly connected with driven shafts; and the bottoms of the driven shafts are detachably connected with turning heads. A lifting mechanism comprises guide columns, a lifting lead screw and sliding sleeves arranged on the guide columns in a sleeving mode, and a lifting nut in engaged transmission with the lifting lead screw is arranged on the lifting lead screw in a sleeving mode and fixedly connected with the sliding sleeve on the guide column on the left side. The positioning mechanism comprises a positioning base, lifting sleeves, a horizontal sliding rail and a sliding bottom block. The multifunctional screw turning device can conduct turning operation on two screws simultaneously, parts are fixed reliably, the screw turning efficiency is high, and the screw turning quality is good.

Owner:嘉善县晓海金属制品厂(普通合伙)

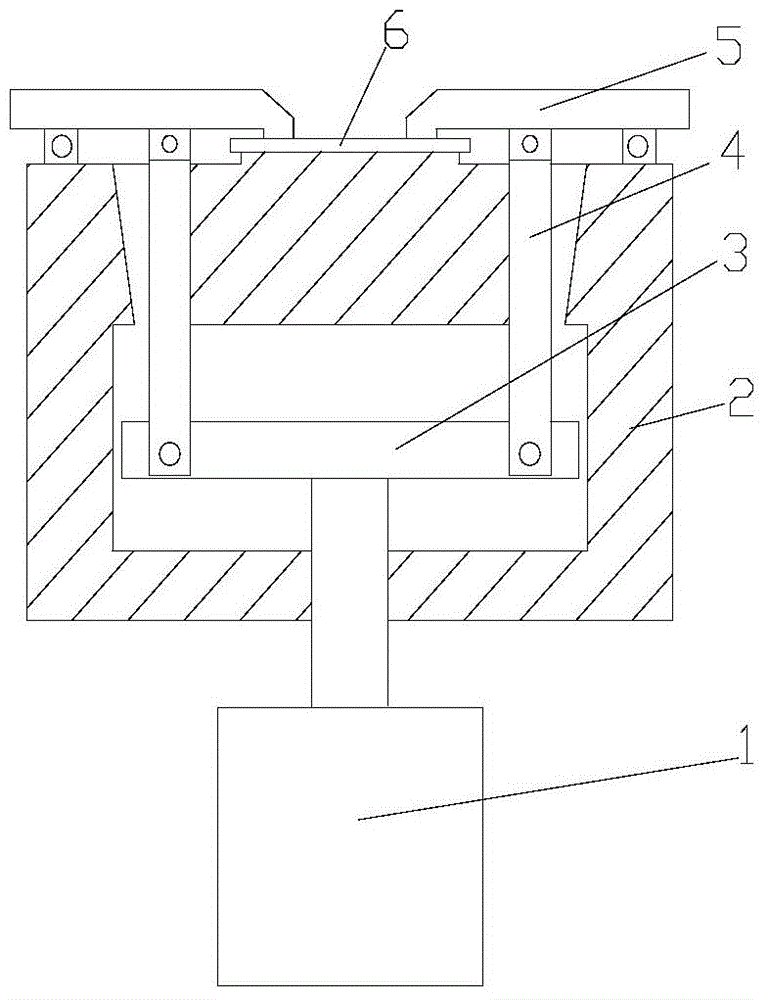

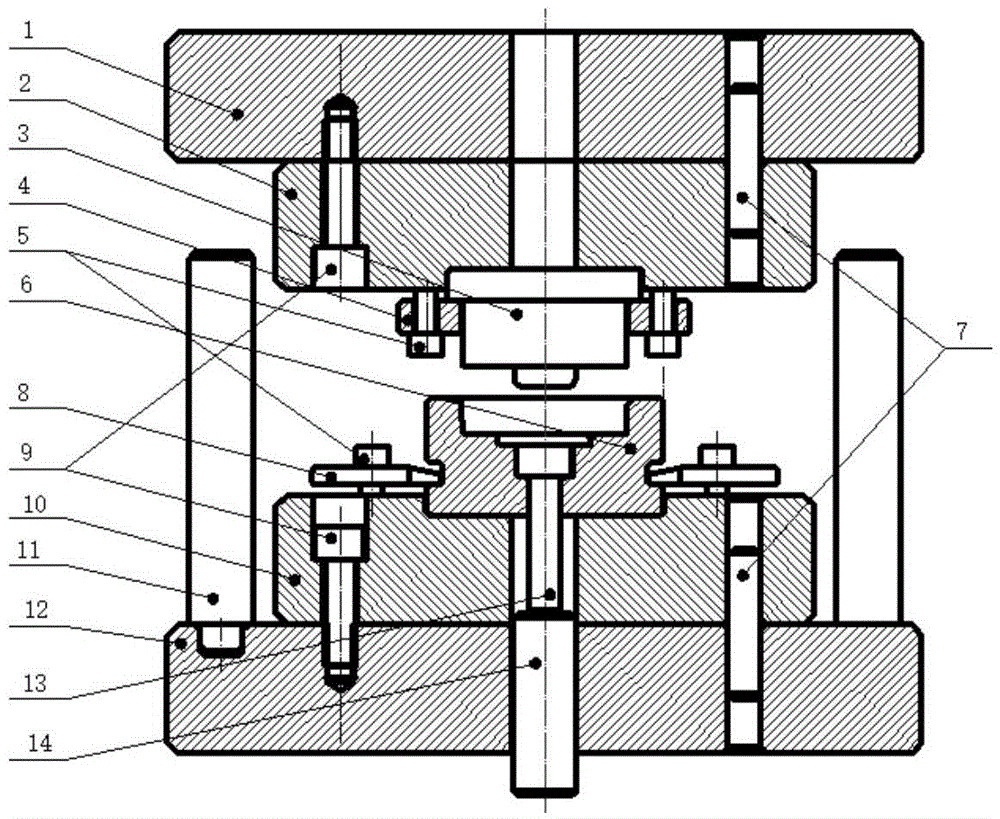

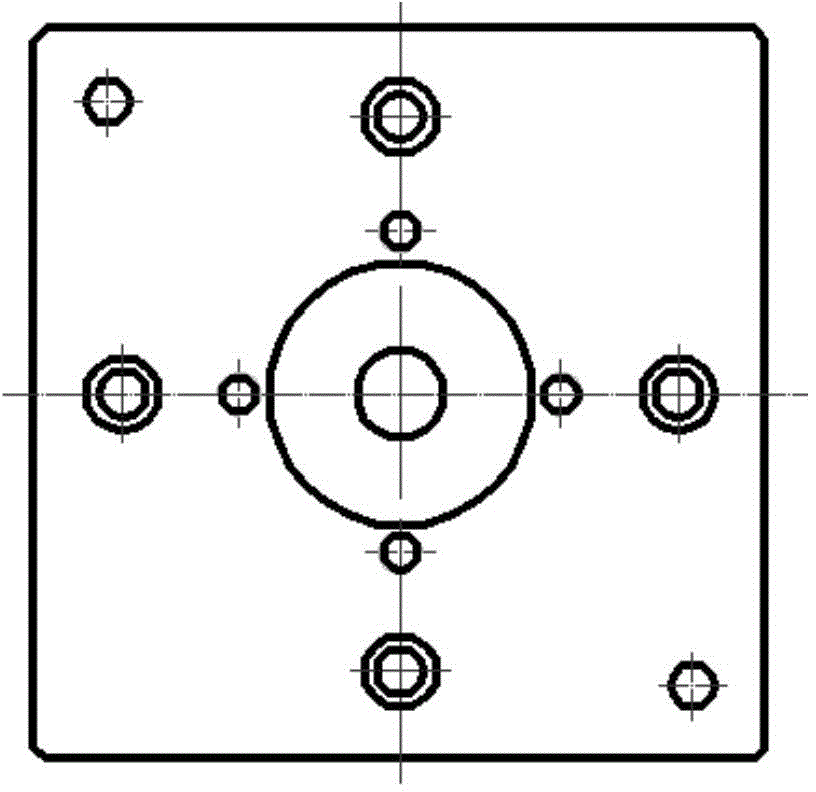

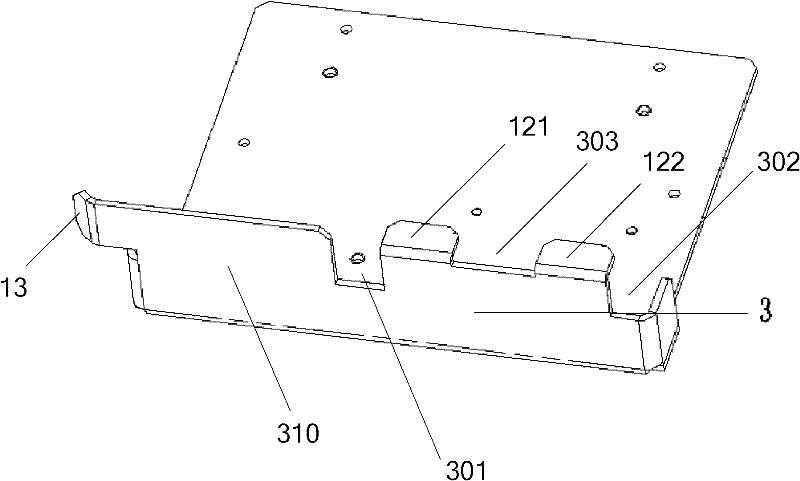

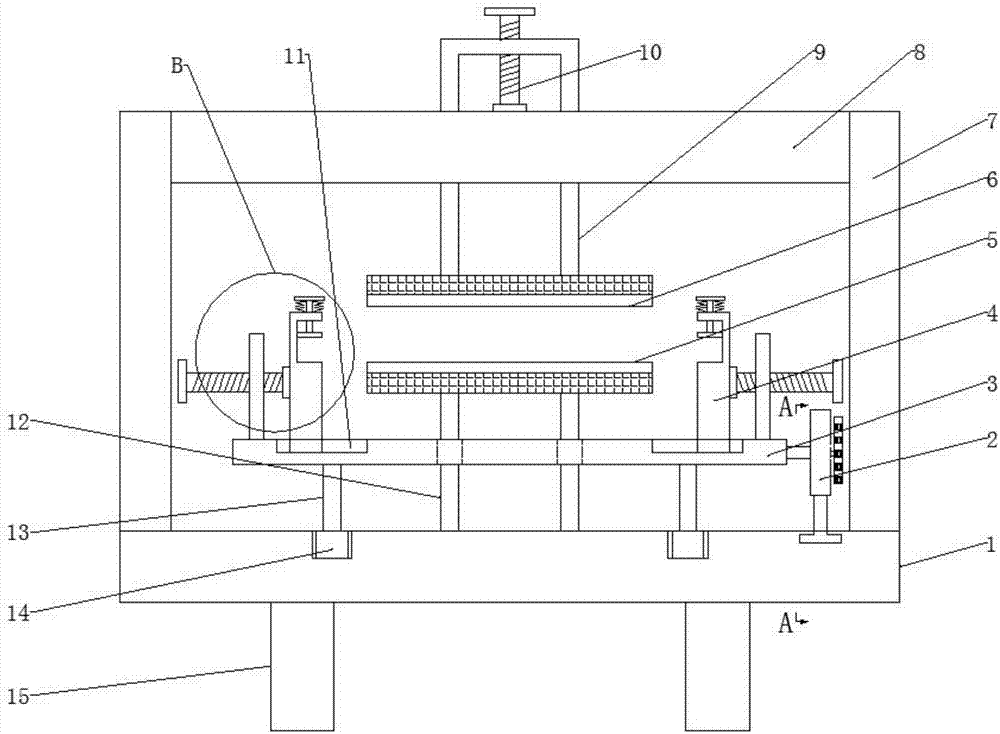

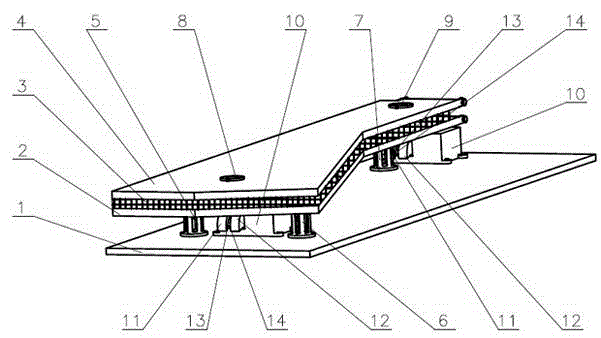

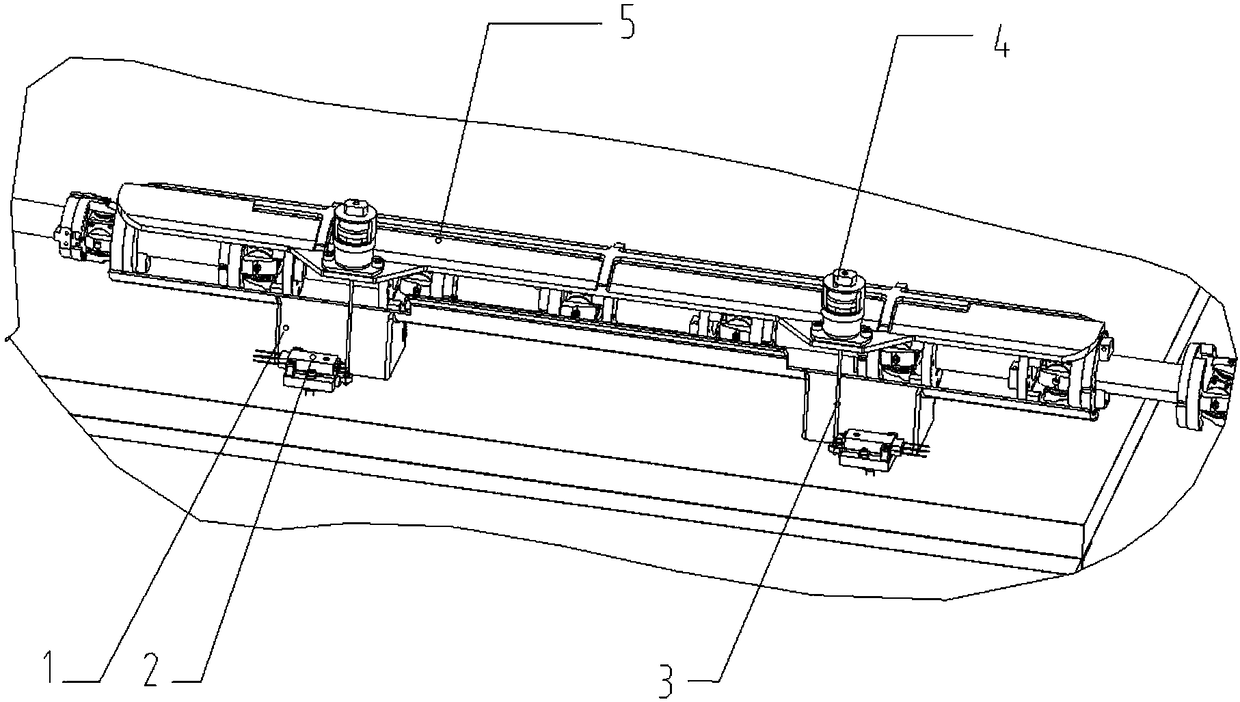

Clamp for processing gearbox body of forklift

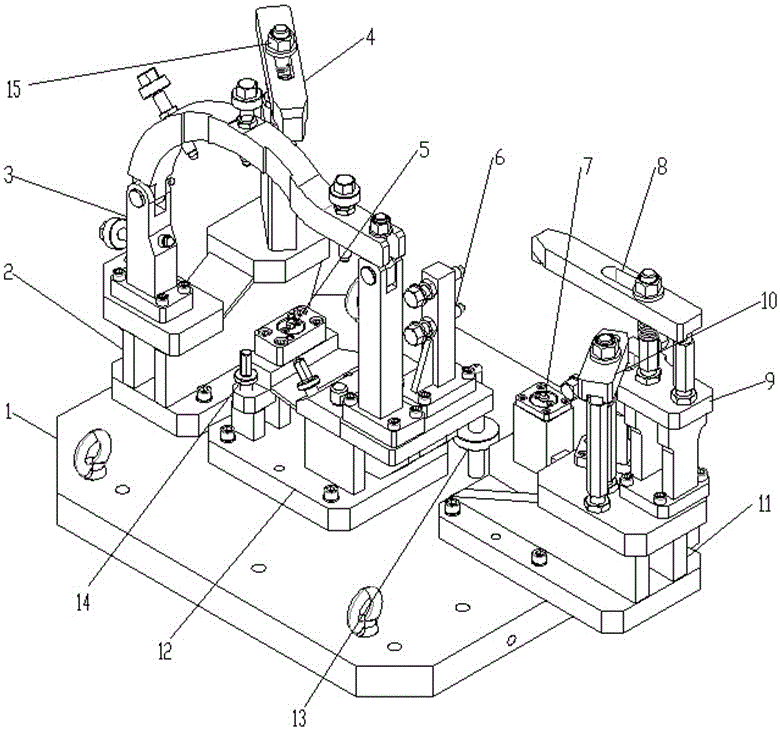

ActiveCN105149985ASolve the processing vibration problemReliable compressionPositioning apparatusMetal-working holdersEngineeringMulti point

The invention relates to a clamp for processing a gearbox body of a forklift. The specific structure of the clamp is that a left pressing plate mechanism, an intermediate mechanism and a right pressing plate mechanism are correspondingly arranged on a bottom plate, wherein a first locating pin and a second locating pin are correspondingly arranged on the bottom plate parts at two sides of the intermediate mechanism; the left pressing plate mechanism comprises an arc-shaped pressing plate and a left pressing plate; the right pressing plate mechanism comprises a locating pressing plate and a right pressing plate; one side of the gearbox body to be processed, of the forklift, is a differential housing and the other side of the gearbox body to be processed, of the forklift, is a motor mounting housing; when the clamp is put into use, the gearbox body to be processed, of the forklift, is positioned on the first locating pin and the second locating pin, the arc-shaped pressing plate and the left pressing plate are pressed to the top part of the differential housing, the right pressing plate is pressed to the top part of the motor mounting housing, and the locating pressing plate is pressed onto a lug on the motor mounting housing, so that the gearbox body to be processed, of the forklift, can be positioned and clamped. The clamp is reliable to locate and compress; the problem of vibrating in processing can be solved; the one-point compressing in the prior art is adjusted to be multi-point compressing, thereby removing the influence of human factors on the workpiece clamping effect.

Owner:ANHUI HELI CO LTD

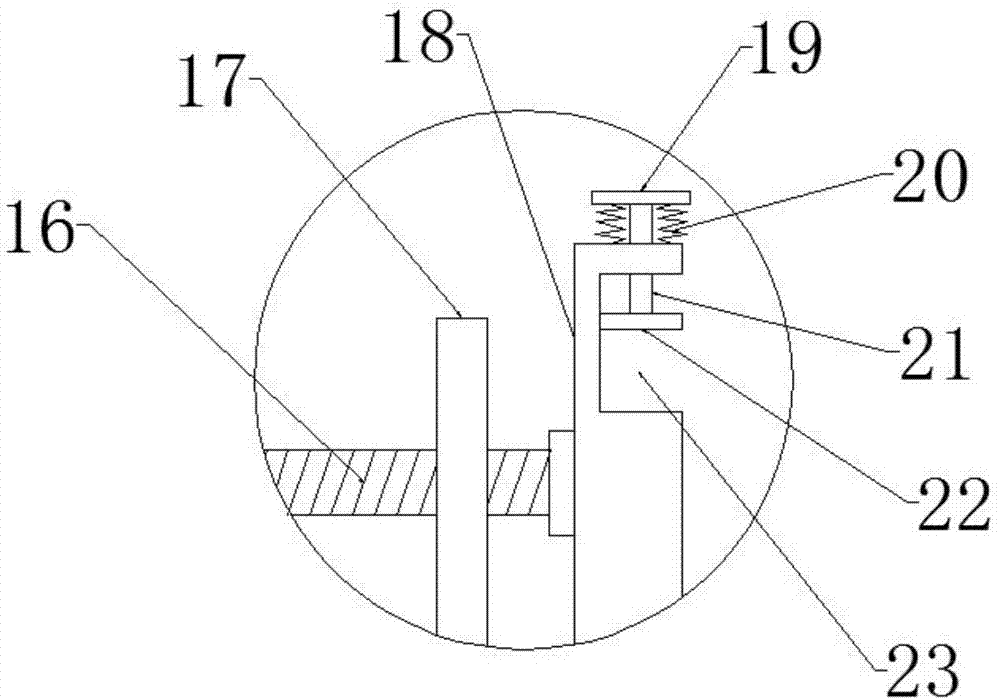

Rapidly-and-evenly-pressing pressing plate

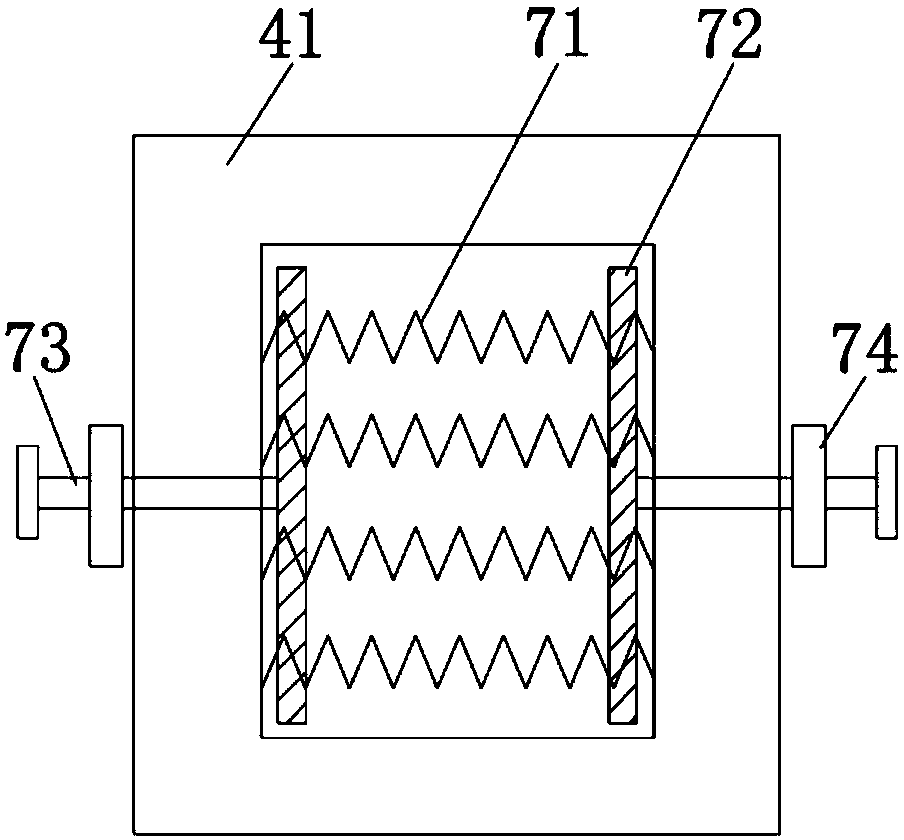

InactiveCN104440296AUniform pressing forceReliable compressionPositioning apparatusMetal-working holdersHydraulic cylinderMechanical engineering

The invention relates to the technical field of clamps, in particular to a rapidly-and-evenly-pressing pressing plate. The pressing plate comprises a base, pressing plate bodies, an identical arm lever and a hydraulic cylinder; the hydraulic cylinder is vertically arranged, a piston rod of the hydraulic cylinder upwards extends into the portion, inside the base, of the top end of the hydraulic cylinder, the middle of the identical arm lever is connected with the piston rod of the hydraulic cylinder, the number of the connecting rods and the number of the pressing plate bodies are two, the connecting rods are symmetrically arranged in the base, the bottom ends of the connecting rods are hinged to the end of the identical arm lever, and the top ends of the connecting rods extend out of the upper portion of the base to be hinged to the middles of the pressing plate bodies arranged at the top of the base, the pressing plate bodies are symmetrically arranged at the top of the base and correspond to the connecting rods, the back ends, close to the edge of the top of the base, of the pressing plate bodies are hinged to a seat, a cavity is formed in the portion, corresponding to the identical arm lever, of the interior of the base, hydraulic drive is achieved, the pressing plate bodies run at the same time to press workpieces, operation is convenient, and even pressing is achieved.

Owner:CHANGZHOU JINGYUAN NOISE CONTROL MATERIALS

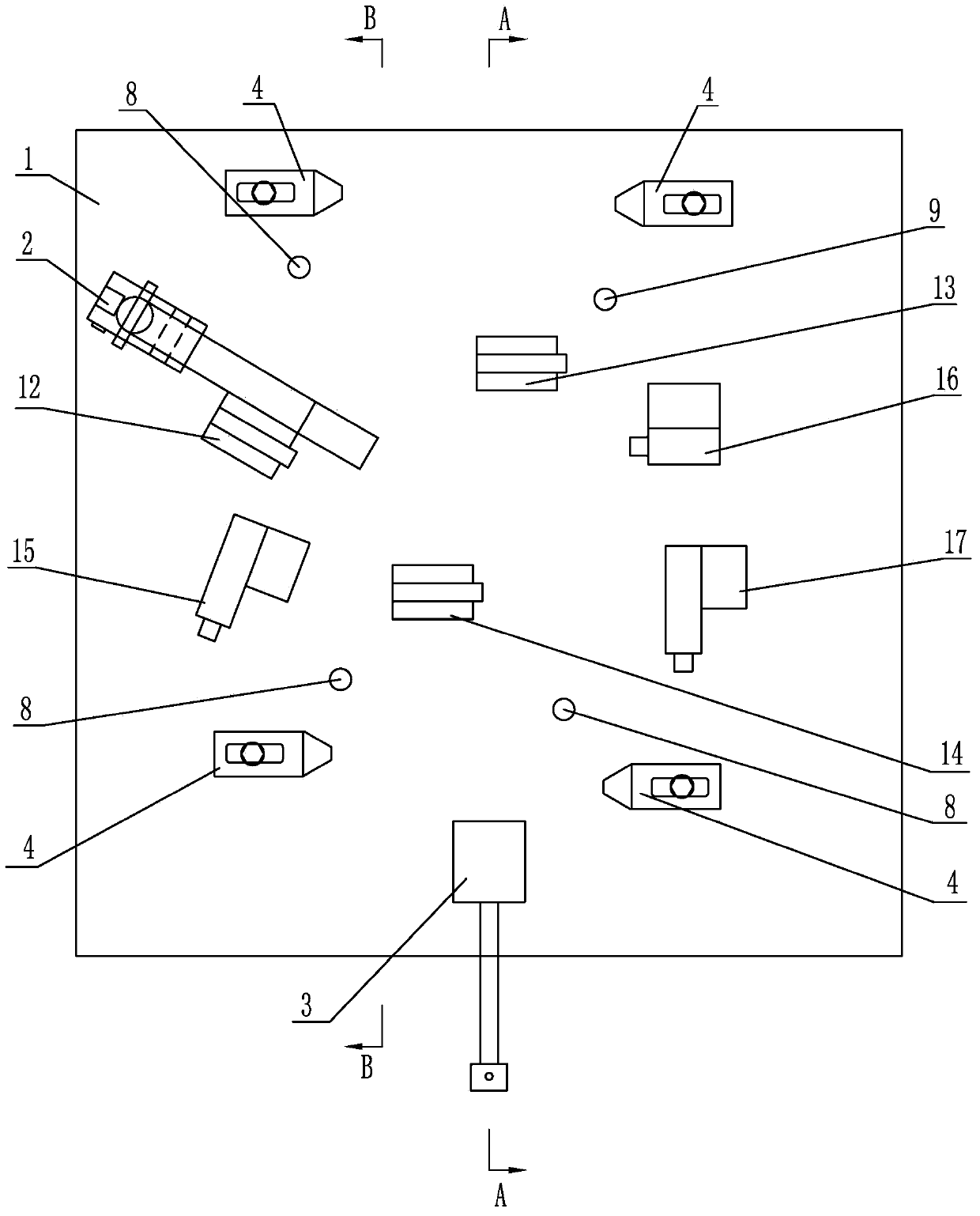

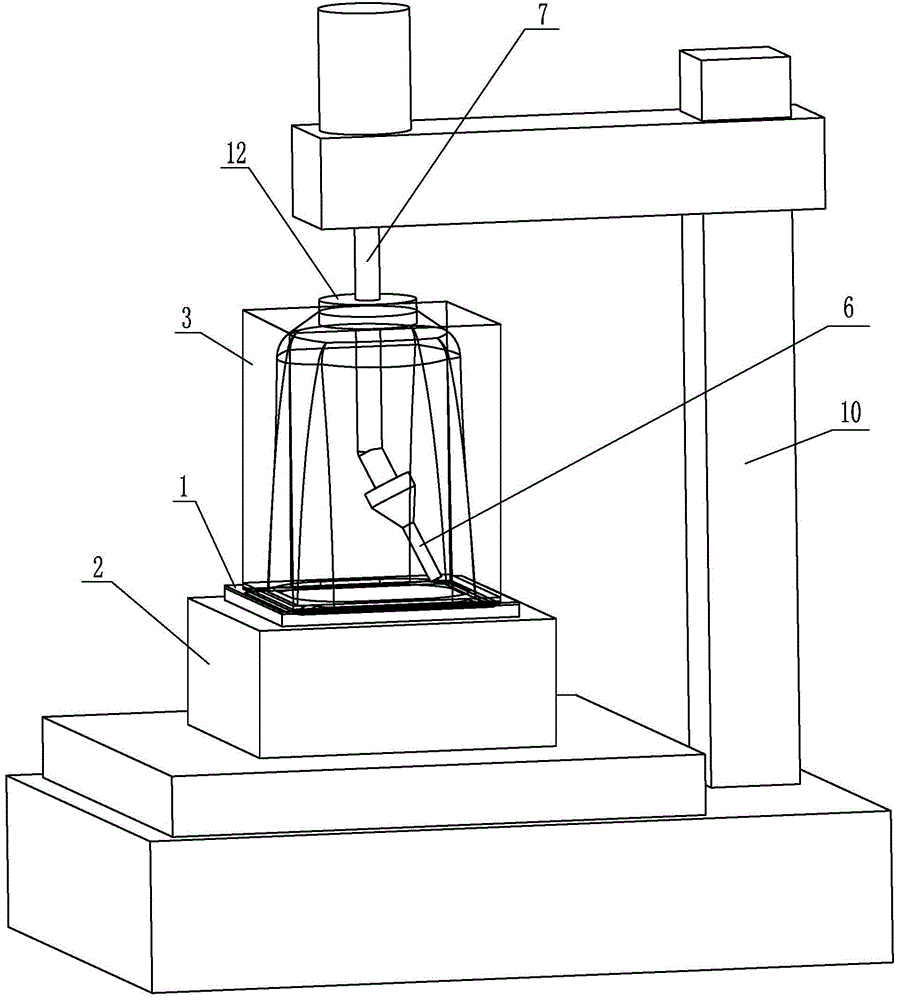

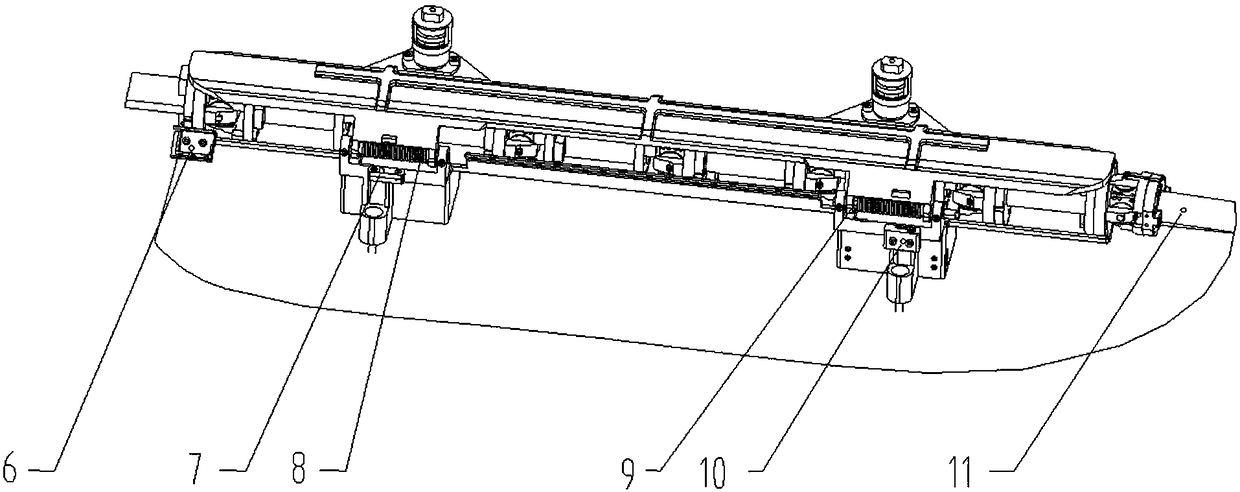

Clamping and positioning device for machining gas turbine power turbine guide vane datum face

ActiveCN104191264AImprove positionHigh geometric accuracyWork clamping meansPositioning apparatusEngineeringMachining process

The invention provides a clamping and positioning device for machining a gas turbine power turbine guide vane datum face, and relates to the clamping and positioning device. The clamping and positioning device aims to solve the problems that no special fixture device exists in the existing machining process of gas turbine power turbine guide vanes, assembling and positioning of steam passages are inconsistent with assembling and positioning of steam passage circular arcs, and the steam passages are damaged. The clamping and positioning device comprises a fixture, a first screwing device, a second screwing device, three positioning cylindrical pins, three positioning round head pins, four auxiliary lifting adjusting and supporting devices, four pressing devices and six positioning bases. The first positioning base, the second positioning base, the third positioning base, the fourth positioning base, the fifth positioning base and the sixth positioning base are correspondingly installed on the upper end face of the fixture according to the positions of six datum points for machining workblanks of the gas turbine power turbine guide vanes. The first screwing device, the second screwing device, the four pressing devices and the four auxiliary lifting adjusting and supporting devices are arranged on the upper end face of the fixture. The clamping and positioning device is used for positioning and machining of the gas turbine power turbine guide vanes.

Owner:HARBIN TURBINE +1

Forging die

InactiveCN106141056AEasy to fixHigh positioning accuracyForging/hammering/pressing machinesEngineeringFlange

The invention discloses a forging die, which belongs to the technical field of die design, and includes an upper die seat backing plate, an upper die seat, an upper die, a flange pressing plate, an inner hexagon screw, a lower die, pins, a pressing plate, bolts, and a lower die Seat, support rod, lower mold base plate, ejector rod, lower ejector rod, upper and lower mold base plate and upper and lower mold bases are first inserted into the holes of the two for positioning by pins, and then fixed and connected by bolts. The flange pressing plate is pressed on the upper mold base through the hexagon socket head screw, the support rod is fixed on the upper surface of the lower mold base backing plate, and a through hole is drilled in the middle of the lower mold base backing plate, and the lower ejector rod is installed in this hole. The upper part of the ejector pin is located in the middle hole of the lower mold base and the lower mold. The forging die disclosed by the present invention has a high position accuracy between the upper and lower mold bases and the backing plates of the upper and lower mold bases. Both the upper mold and the lower mold are Reliable fixation, easy installation and disassembly of support rods, relatively balanced force when closing molds.

Owner:CHANGLI FORGING

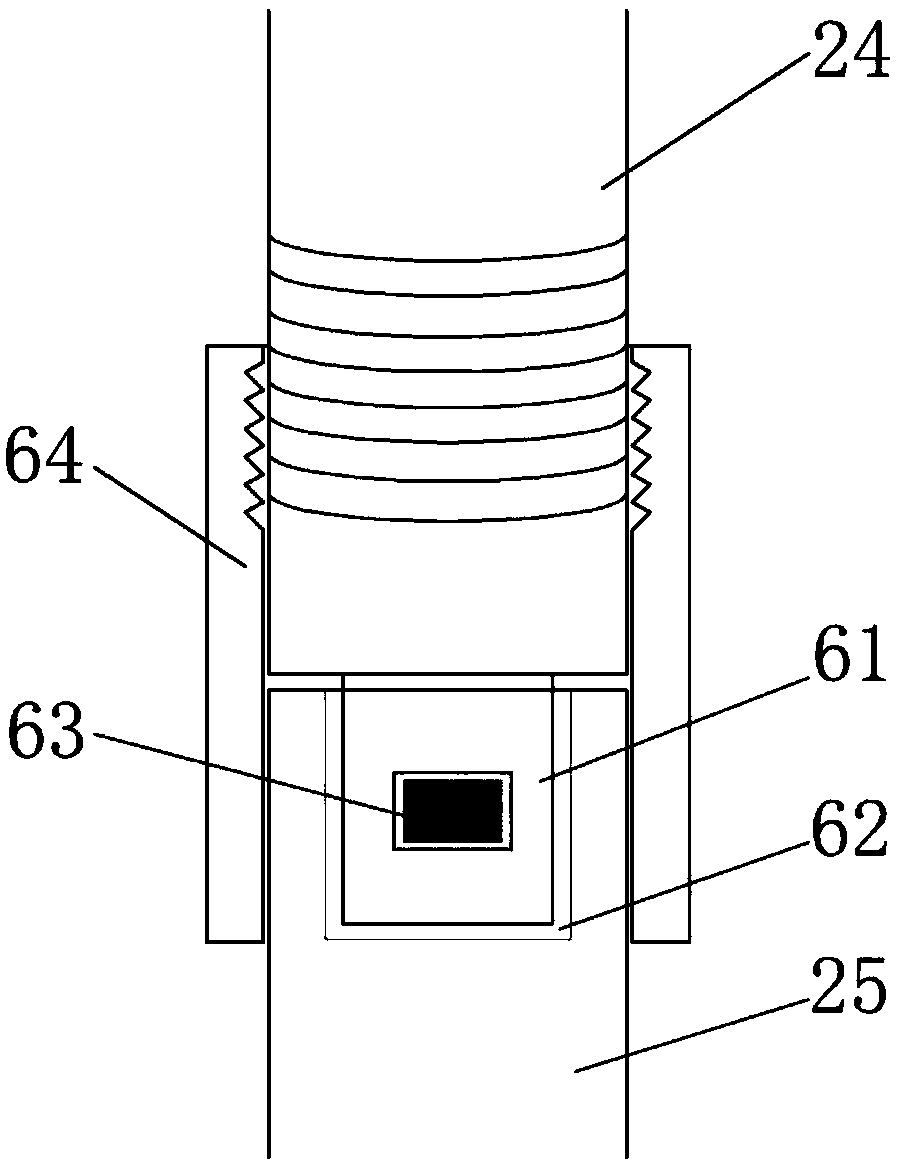

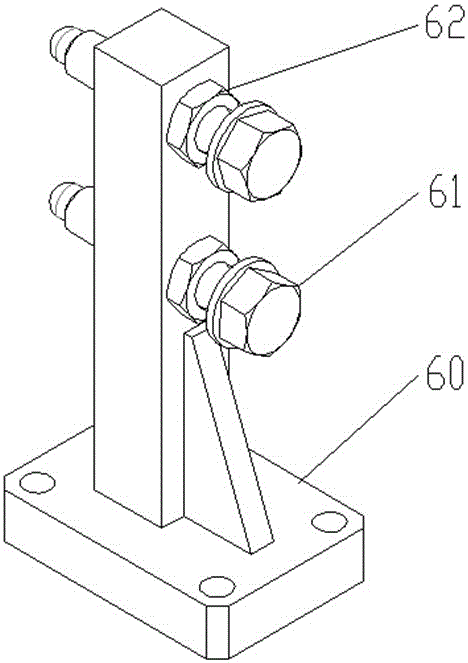

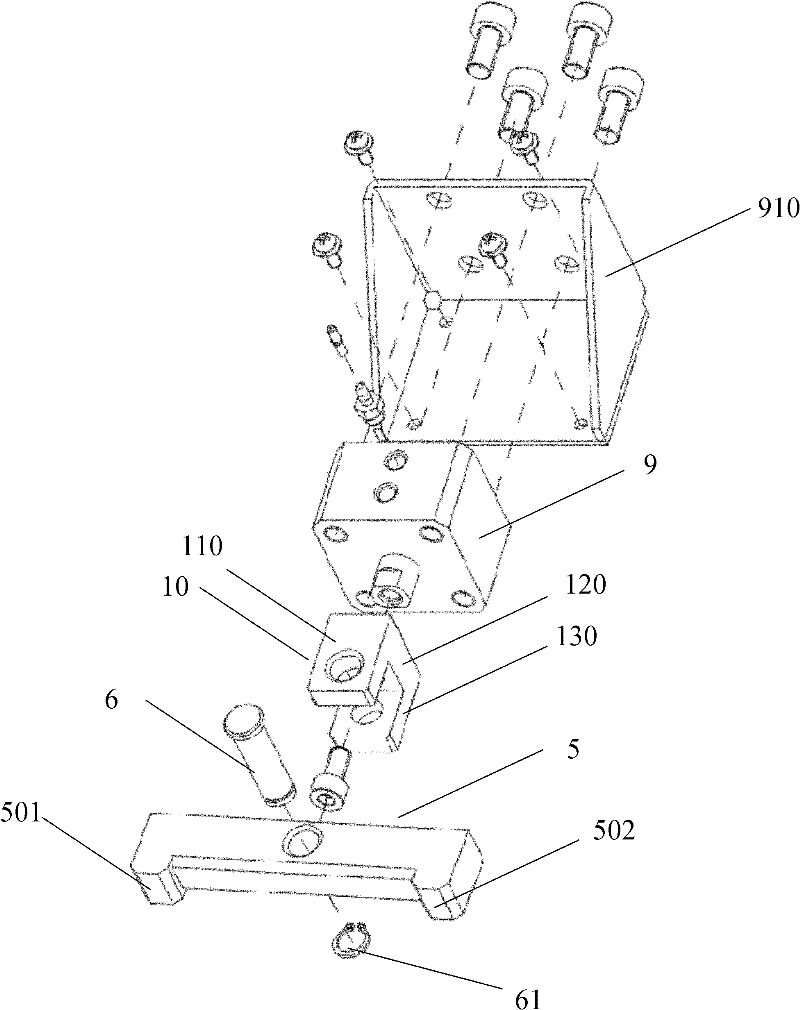

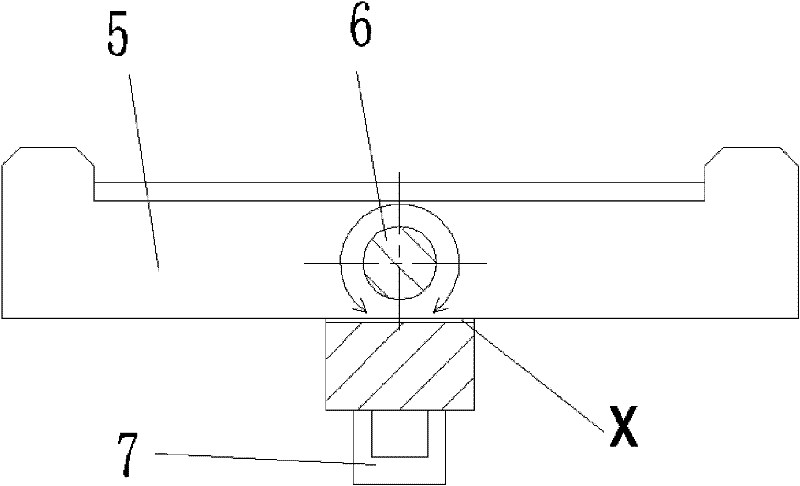

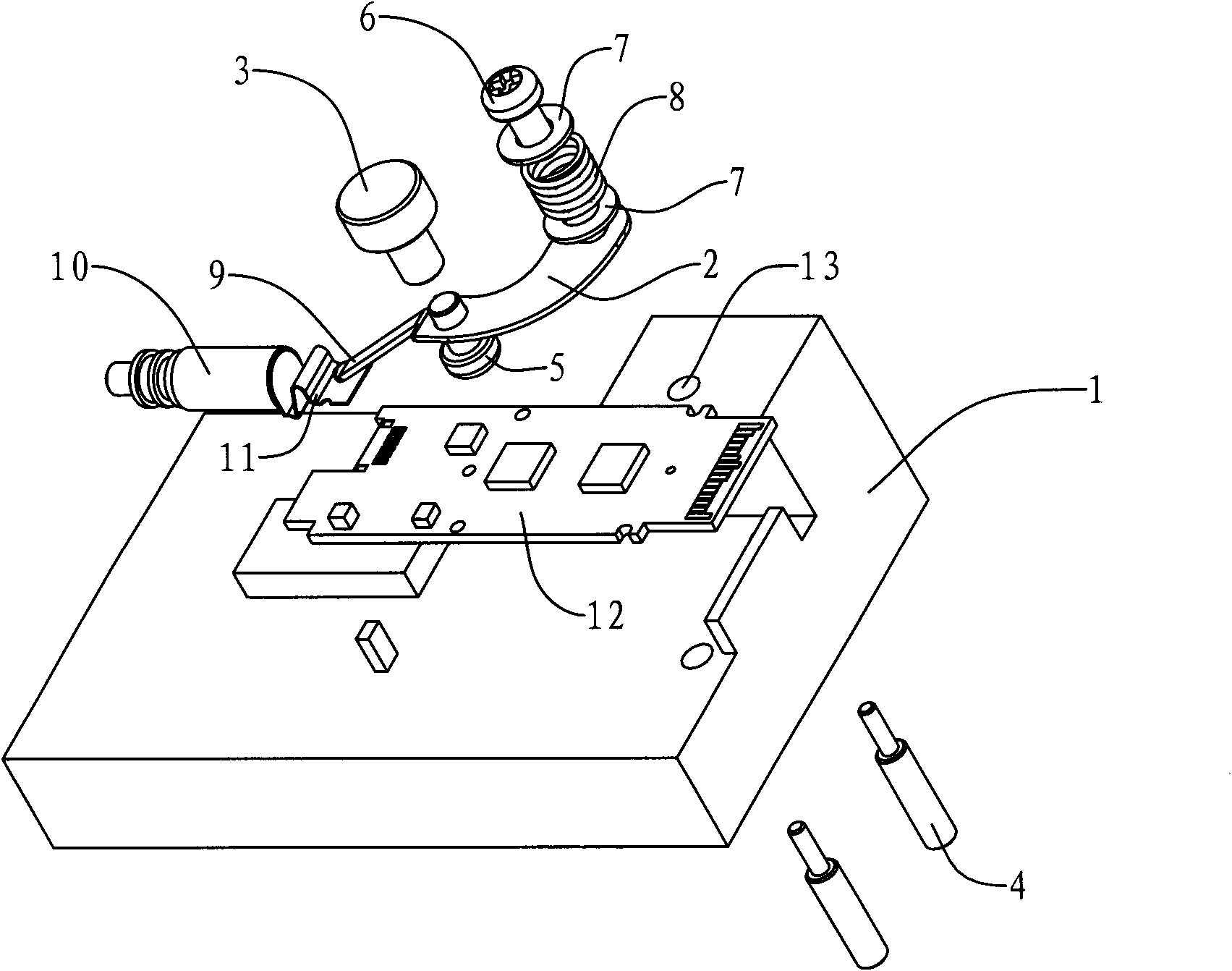

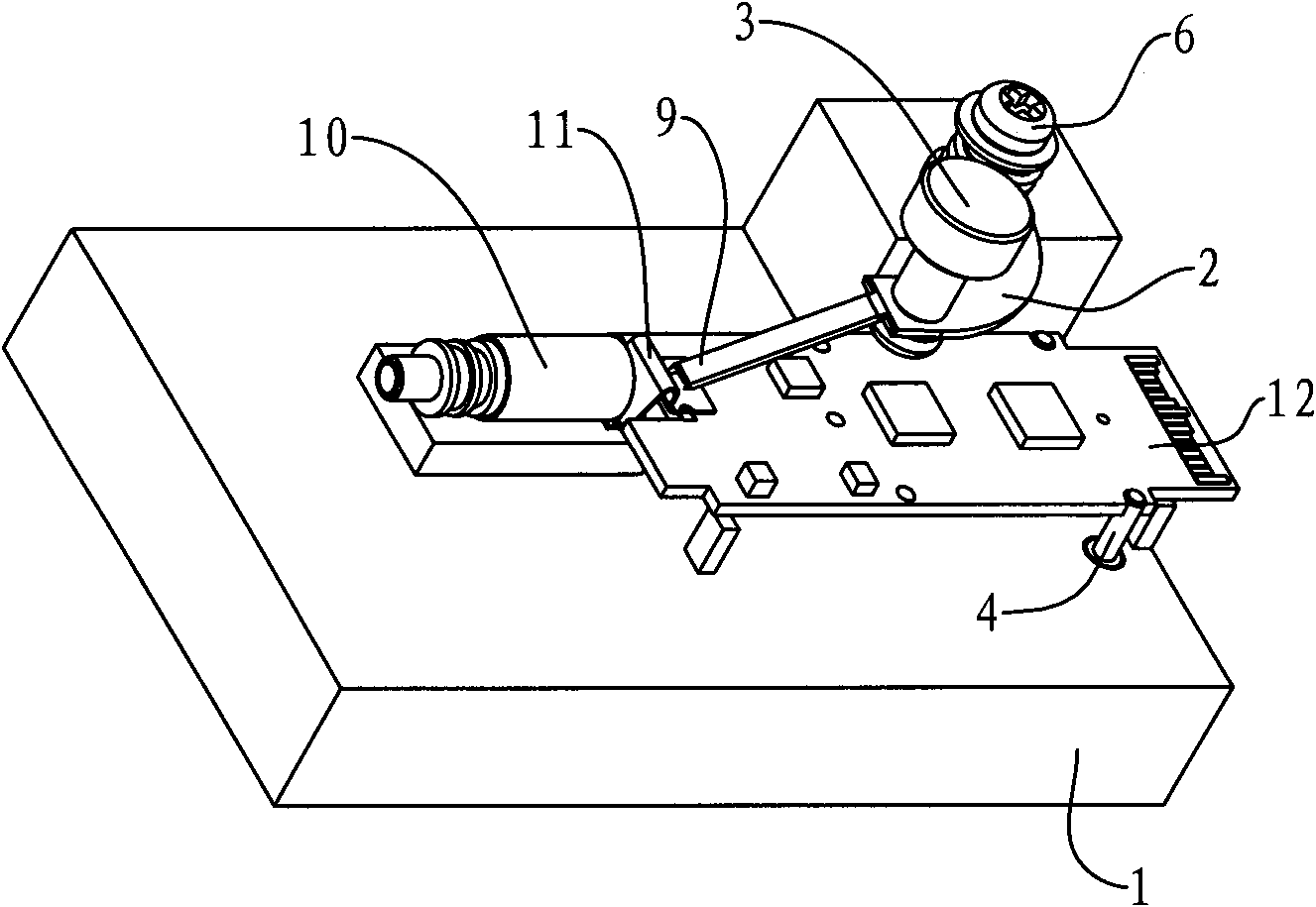

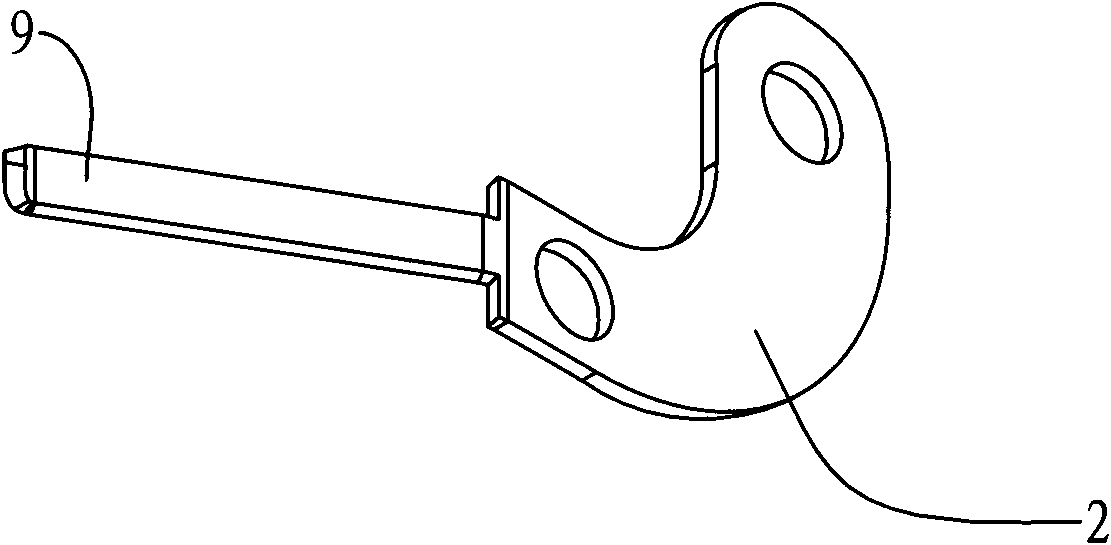

Test-tube stand fixing device and method, and blood analysis device thereof

ActiveCN102527458AReliable compressionBiological testingSupporting apparatusEngineeringElectrical and Electronics engineering

The invention discloses a test-tube stand fixing device, which comprises a baseboard, a power device, a support and a pressure block, wherein the power device is connected with the baseboard, an output shaft of the power device is connected with the support, the pressure block is connected with the support, the output shaft of the power device drives the pressure block to move towards the direction of the test-tube through the support, and the pressure block is pressed on the side wall of the test-tube when the output shaft stops moving. The output shaft of the power device is connected with the support, the support is driven by the output shaft to move, the pressure block is connected with the support, the support drives the pressure block to move, the output shaft of the power device drives the pressure block to move towards the direction of the test-tube stand through the support, thus the test-tube stand is pressed, an pressure point is close to the location of the test-tube stand, which bears an impact force, and the test-tube stand is more realizably pressed.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

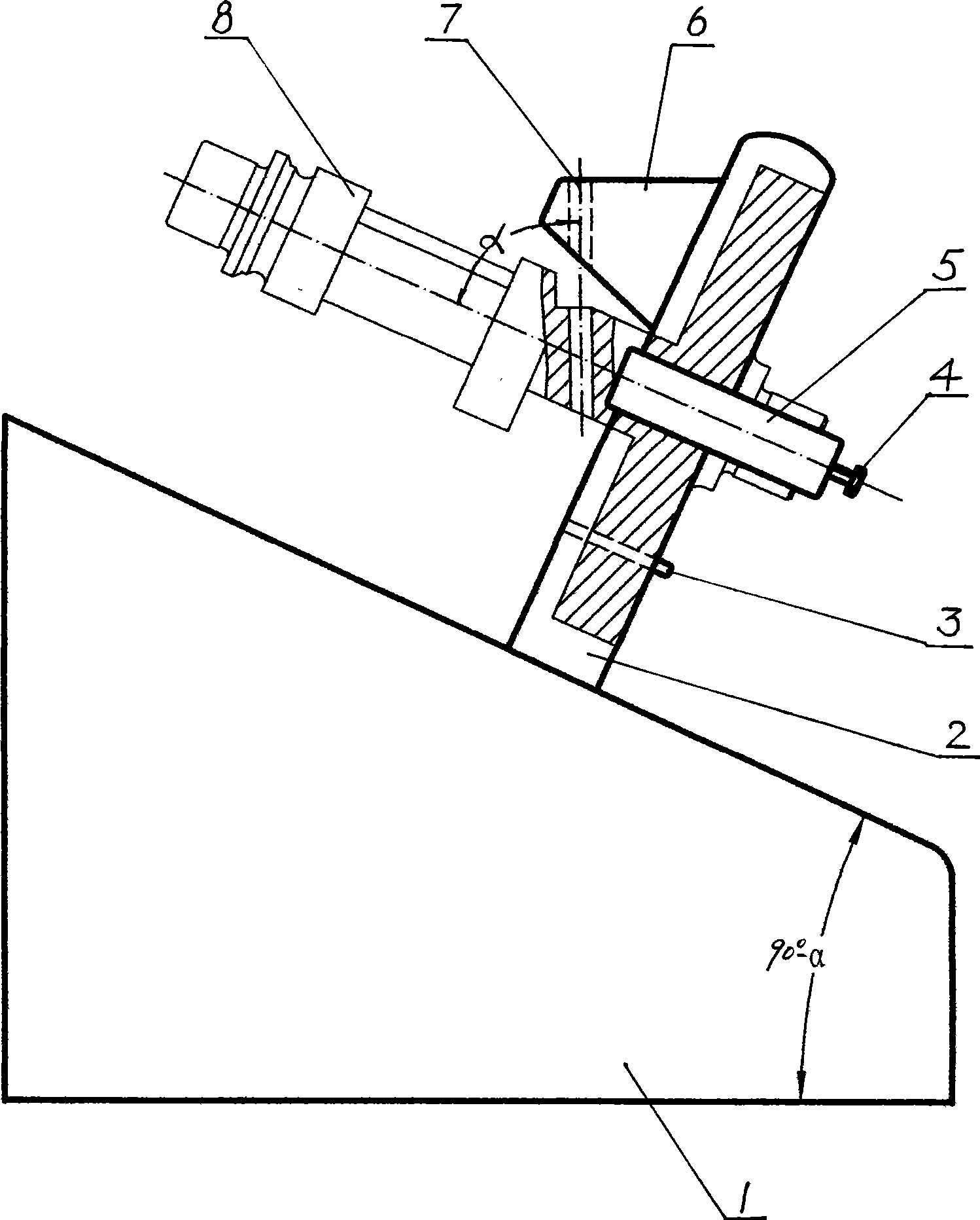

Camshaft flank hole processing clamp

InactiveCN101396795AReduce mistakesPrecise positioningPositioning apparatusBoring/drilling componentsProcessing accuracyBatch production

The invention discloses a camshaft side surface hole processing clamp; a positioning plate which forms an oblique angle Alpha with the bottom surface of a base is arranged above the base; the middle position of the positioning plate is provided with a positioning hole vertical to the positioning plate and a positioning pin which is arranged below the positioning hole; one side of the positioning plate is provided with a movable pressing plate and a pressing screw. Further improvement of the camshaft side surface hole processing clamp is characterized in that the movable pressing plate is a hook-shaped sliding pressing plate which is sheathed on the positioning plate; the positioning plate is provided with a drill sleeve which is arranged above the positioning hole. The camshaft side surface hole processing clamp is used for processing the side surface hole on the camshaft in a gasoline engine, has convenient assembly and disassembly and small positioning error, can improve the processing efficiency and processing precision and is suitable for batch production.

Owner:TAIZHOU HONGXIANG POWER MACHINERY

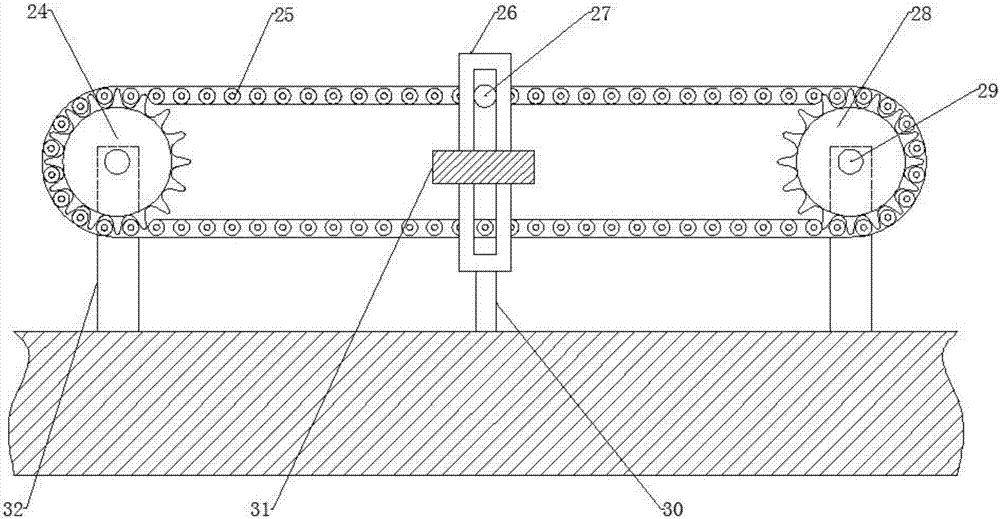

Double-faced efficient reshaping device for building decorative board

The invention discloses a double-sided high-efficiency shaping device for building decorative boards, which includes a base, a top plate, a pressing device and a movement mechanism. A working table is arranged above the base, and pressing devices are arranged on both sides of the upper part of the working table. There is a lower shaping knife between the pressing devices on both sides of the workbench, a second threaded rod is arranged in the middle of the upper part of the top plate, and an inverted U-shaped plate is spirally connected to the outside of the second threaded rod. The shaping knife is fixedly connected, and the right side of the workbench is equipped with a movement mechanism. The present invention is equipped with a pressing device to press the decorative plate, and the pressing is reliable. It is provided with a second threaded rod, an inverted U-shaped plate, an upper shaping knife and a lower The shaping knife can adapt to different thicknesses of decorative panels, and can perform double-sided shaping, which improves work efficiency. It is equipped with a movement mechanism to drive the worktable to move left and right, and the upper and lower shaping knives can repeatedly shape the upper and lower surfaces of the decorative panels. , The plastic effect is better, the labor load of the workers is reduced, and the work efficiency is improved.

Owner:吴秀女

Capillary rheometer and method for measuring rheological properties of polymer materials

ActiveCN102507383AEliminate biasImprove comparabilityDirect flow property measurementCapillary channelEngineering

The invention discloses a capillary rheometer and a method for measuring rheological properties of polymer materials. The capillary rheometer comprises a charging barrel, wherein the front end of the charging barrel is provided with a feed port, and the rear end of the charging barrel is provided with a discharging port. A first capillary channel, a material flowing pipeline and a second capillary channel are arranged in the charging barrel, and the feed port is communicated with the discharging port sequentially through the first capillary channel, the material flowing pipeline and the second capillary channel. The cross-sectional area of the material flowing pipeline is larger than that of the first capillary channel and the second capillary channel. The method can simultaneously measure shearing rheological parameters and extensional rheological parameters of the polymer materials. During measuring polymer composite materials, the method can avoid the influence of artificial factors, reduce the errors in measurement for several times, and increase the accuracy of measurement.

Owner:SOUTH CHINA UNIV OF TECH

Ring-disk electrode

InactiveCN1789996AGuaranteed coaxialityReduce runoutMaterial electrochemical variablesCurrent noiseDiffusion

The invention discloses a ring-disk electrode body in the electrochemical analysis measuring electrode domain, which is characterized by the following: setting the ring and disk electrode at the axle and two bottoms at the same plane with macromolecular material insulating ring and adhesion layer between them; embedding the ring electrode in the end part of ring union body; connecting the ring union body with the screw of ring guide rod with guide matching face; contacting the disk electrode roof and the probe in the hole of disk guide rob bottom stickly; setting the ring and disk guide rod at the same axle with insulation sleeve and compacting by nut; setting the protection lid and sealing ring on the bottom of electrode body. The invention is applied to detect the diffusion coefficient and electrochemical parameter with large insulation resistance between ring and disk and small contact resistance in the signal guide system, which reduces the current noise and utility lifetime.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

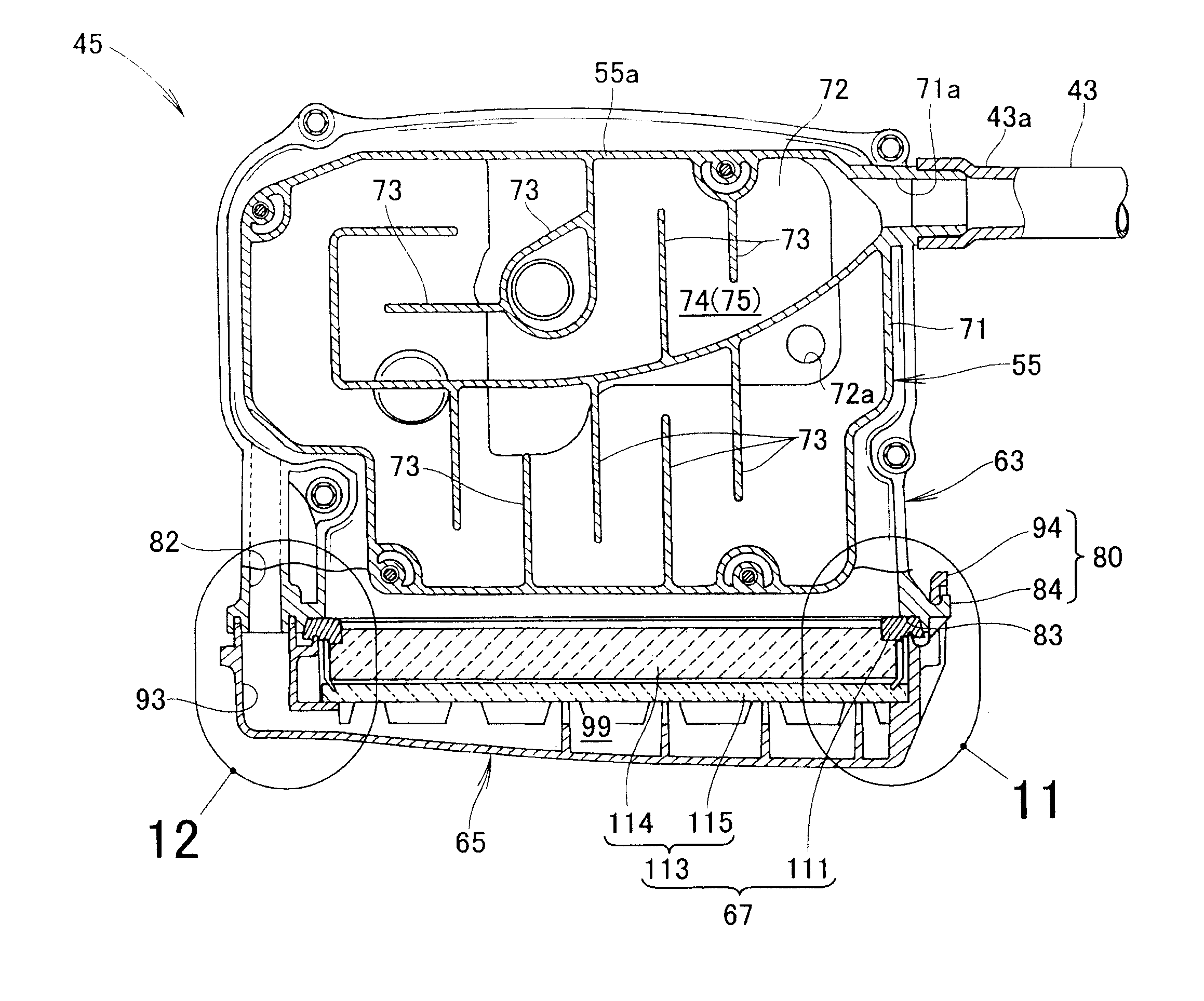

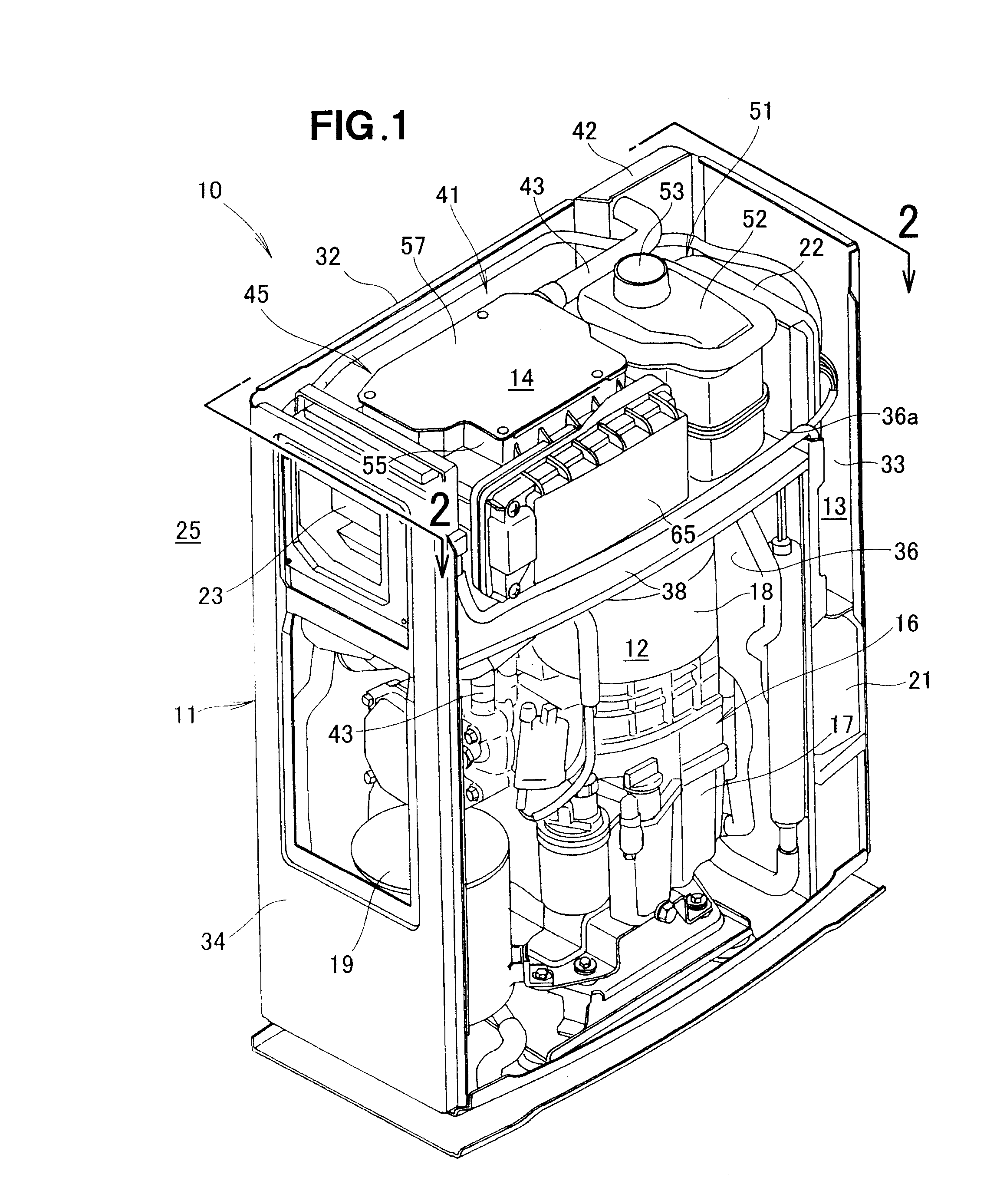

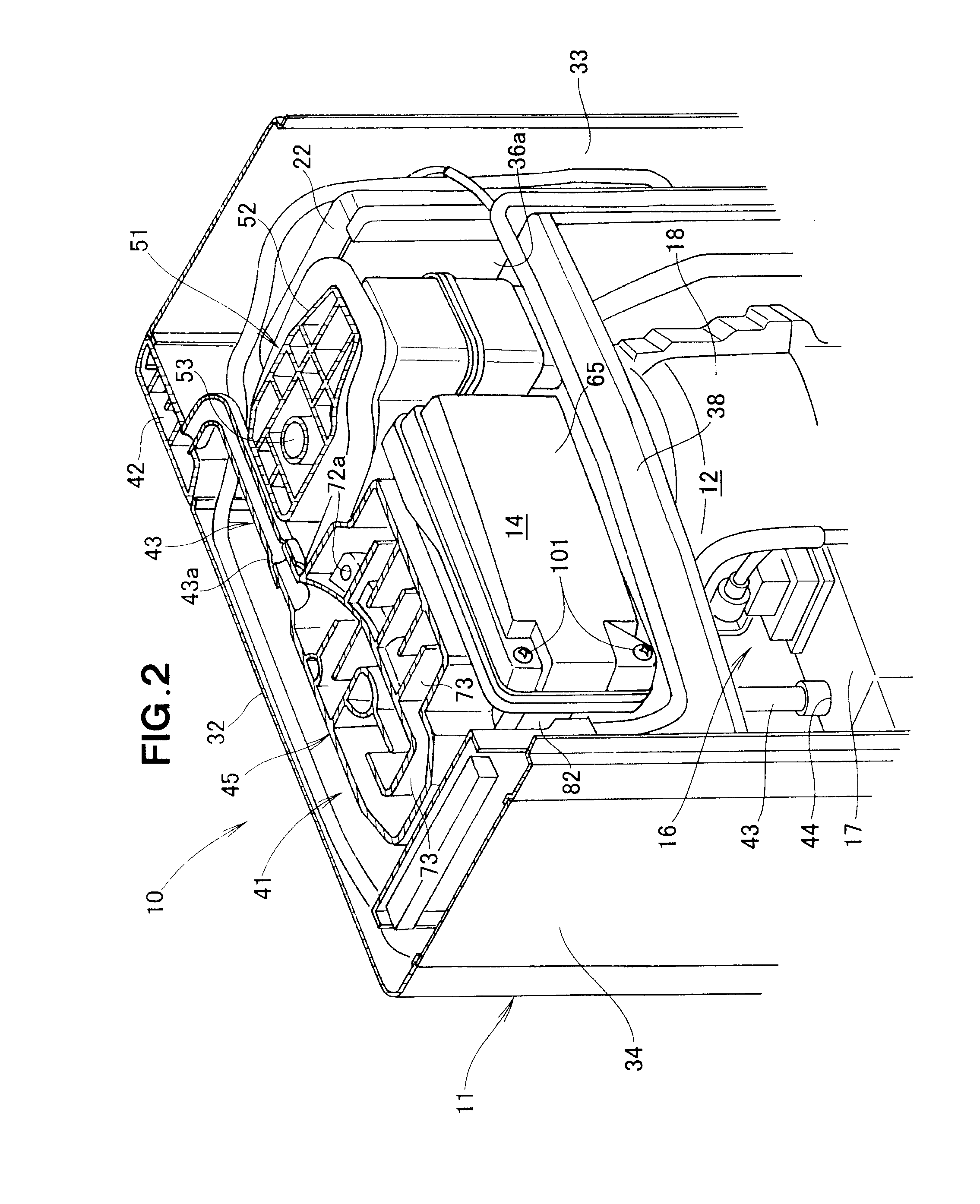

Air cleaner device

ActiveUS20120186207A1Good adhesionEasy detachmentDispersed particle filtrationUsing liquid separation agentEngineeringTime-Consuming

An air cleaner device whereby the number of component parts is reduced and the filter element can be maintained and inspected without a time-consuming procedure. The air cleaner device includes: a support part provided to a cleaner case and having a fitting ingress at a region on the opposite side thereof from the cover; and a pivot provided to the cover and having a convex part capable of fitting in the fitting ingress of the support part. A hinge part for connecting the cover to the cleaner case so that the cover can open and close is formed by the support part and the pivot by fitting of the convex part in the fitting ingress.

Owner:HONDA MOTOR CO LTD

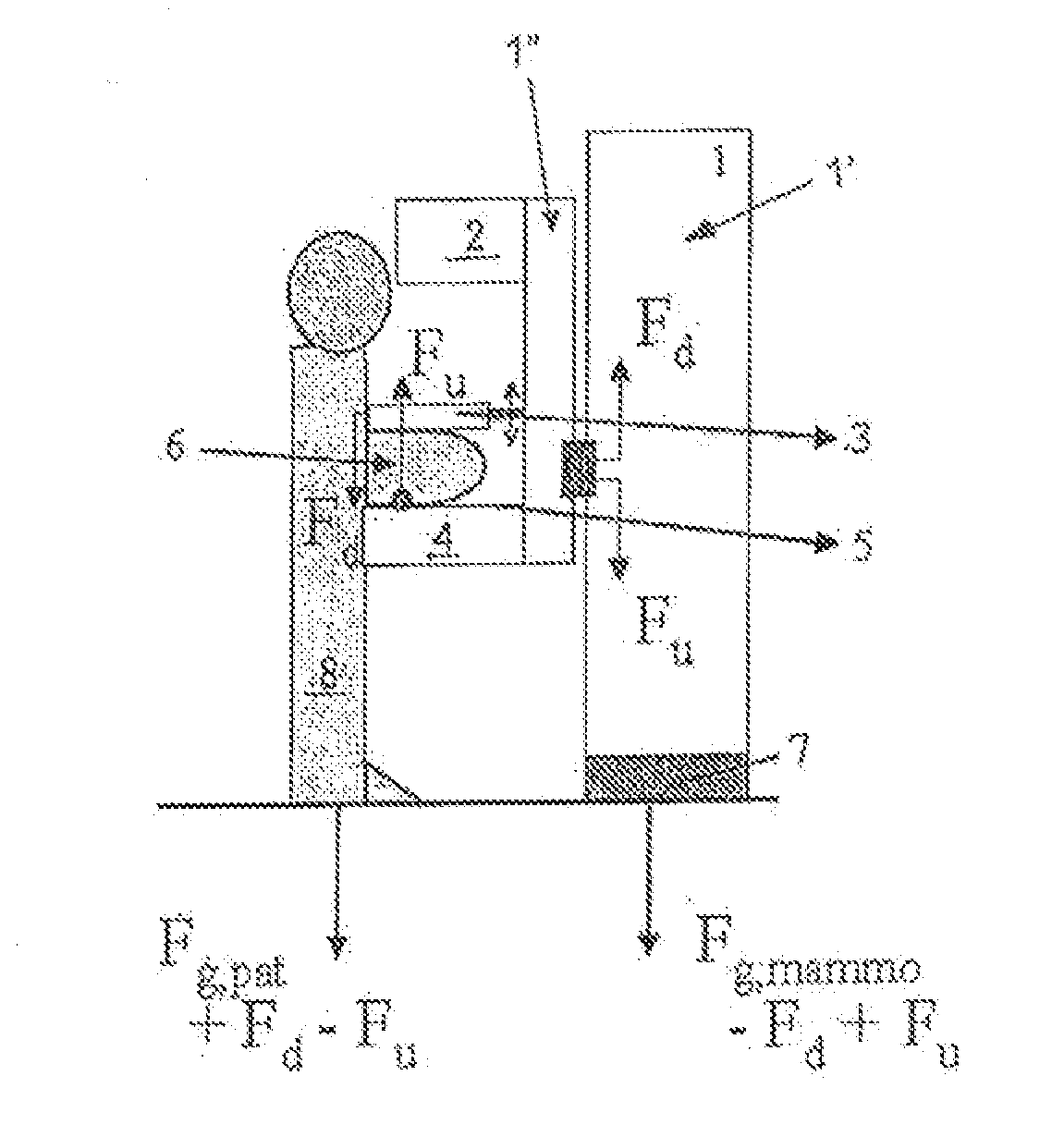

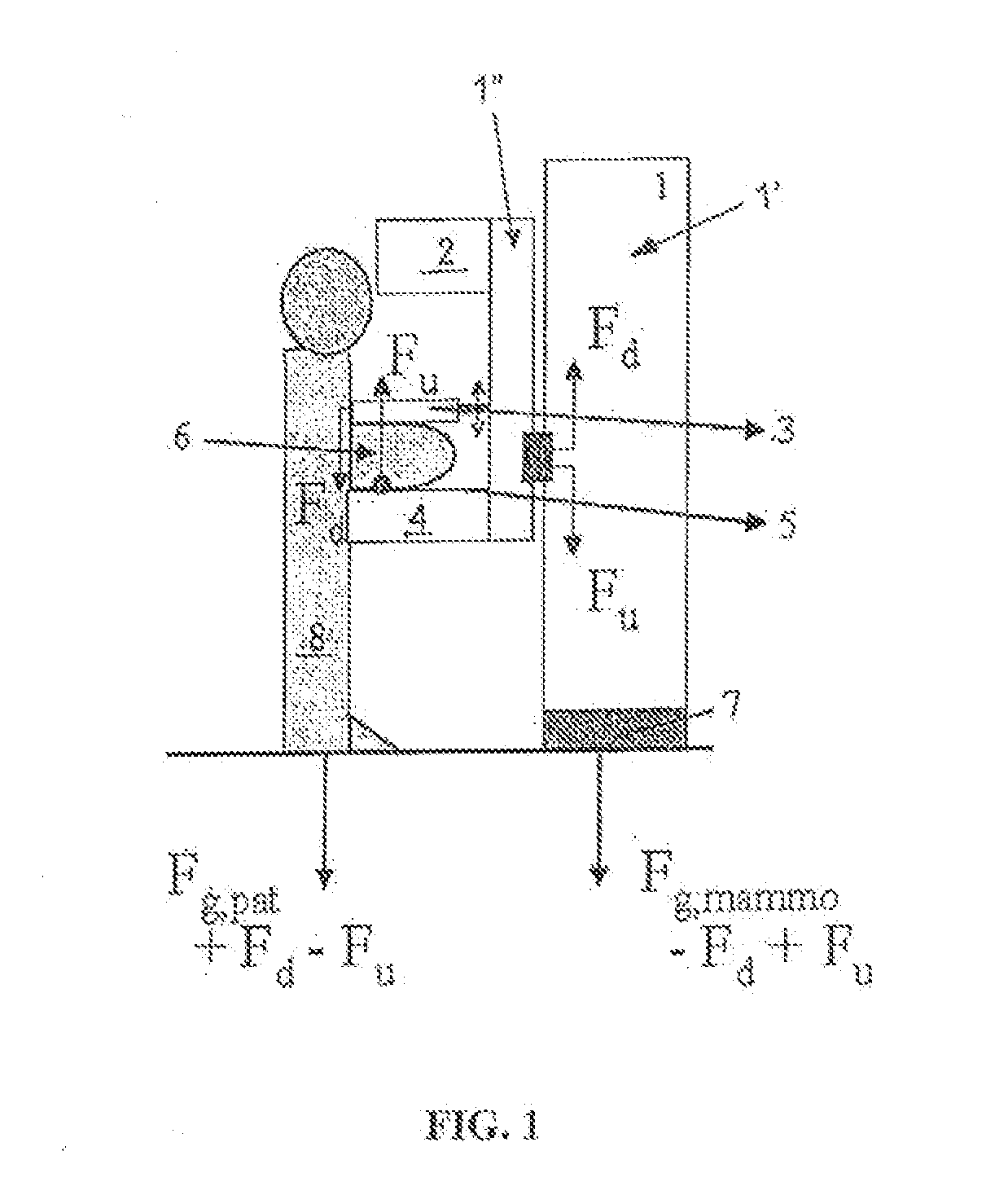

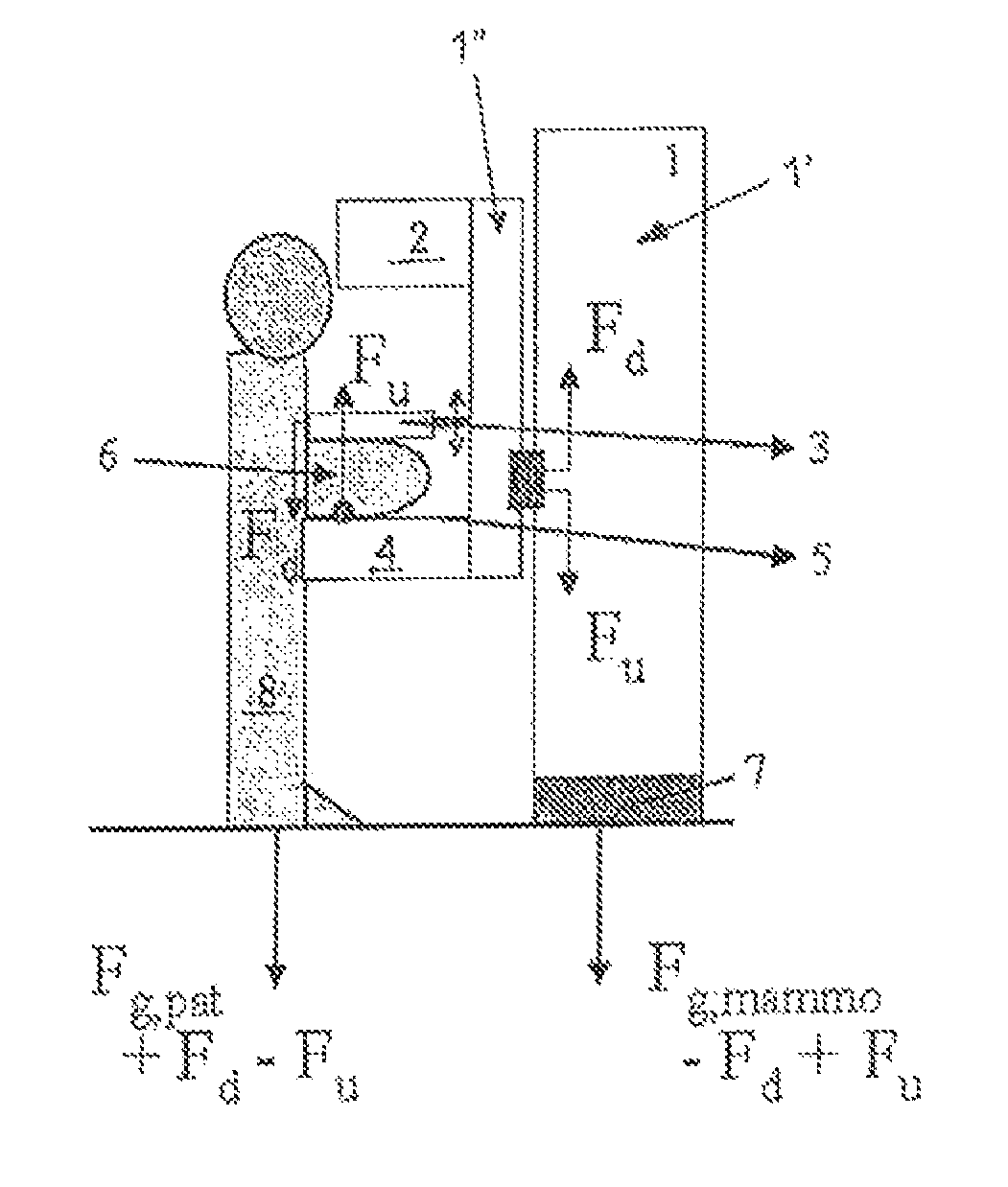

Mammography Apparatus and Method to Adjust or Tune the Mechanical Settings of Such a Mammography Apparatus

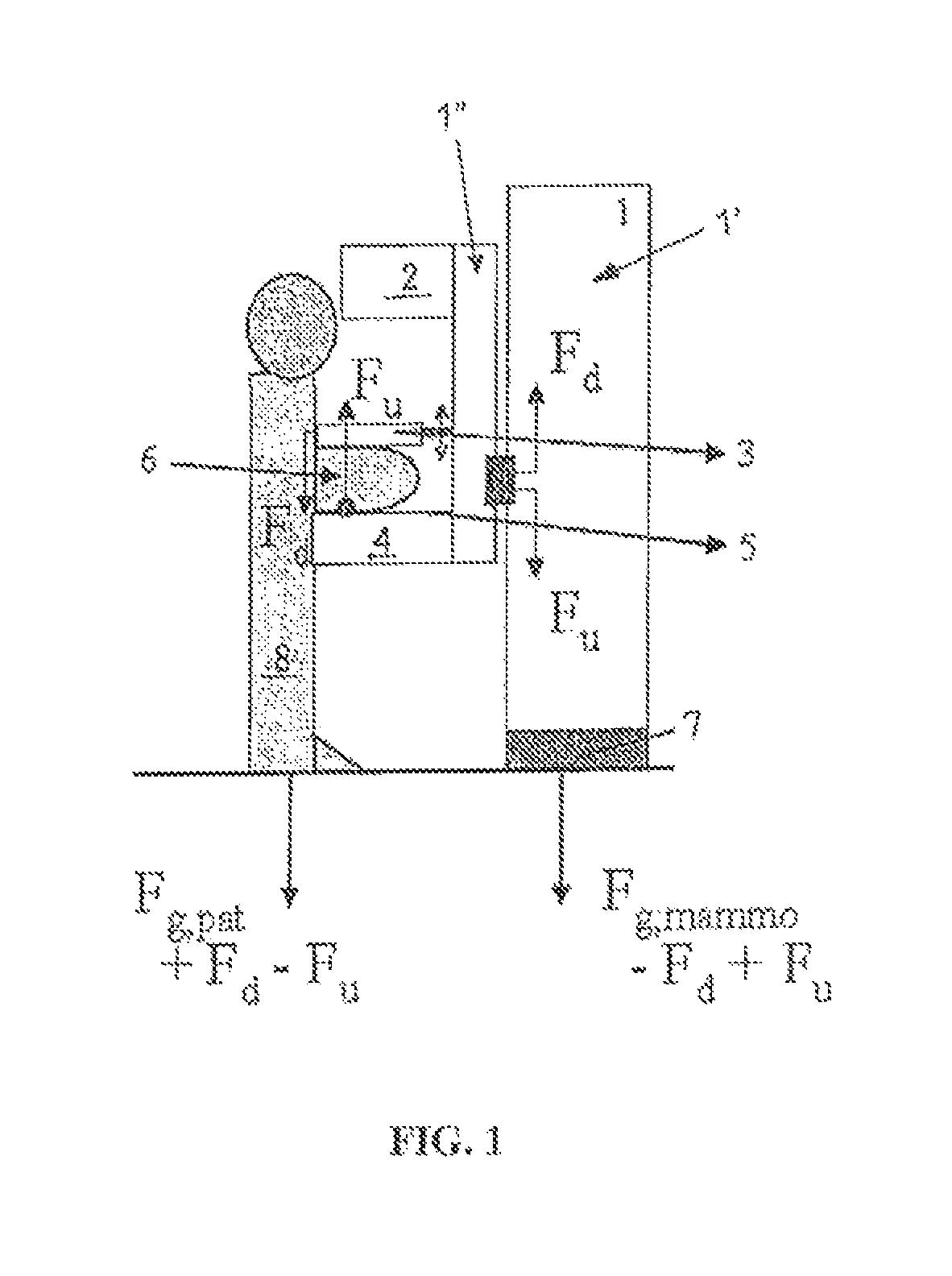

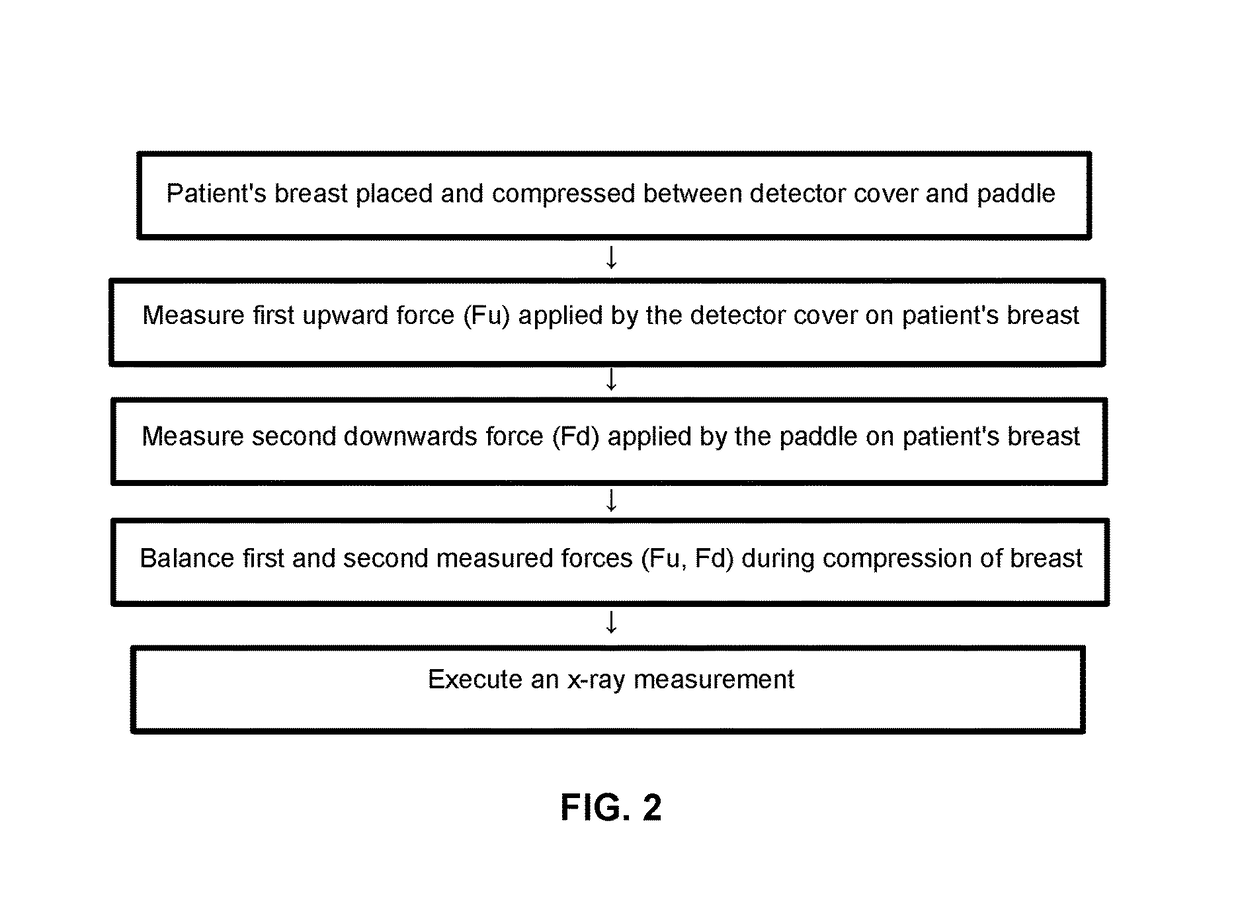

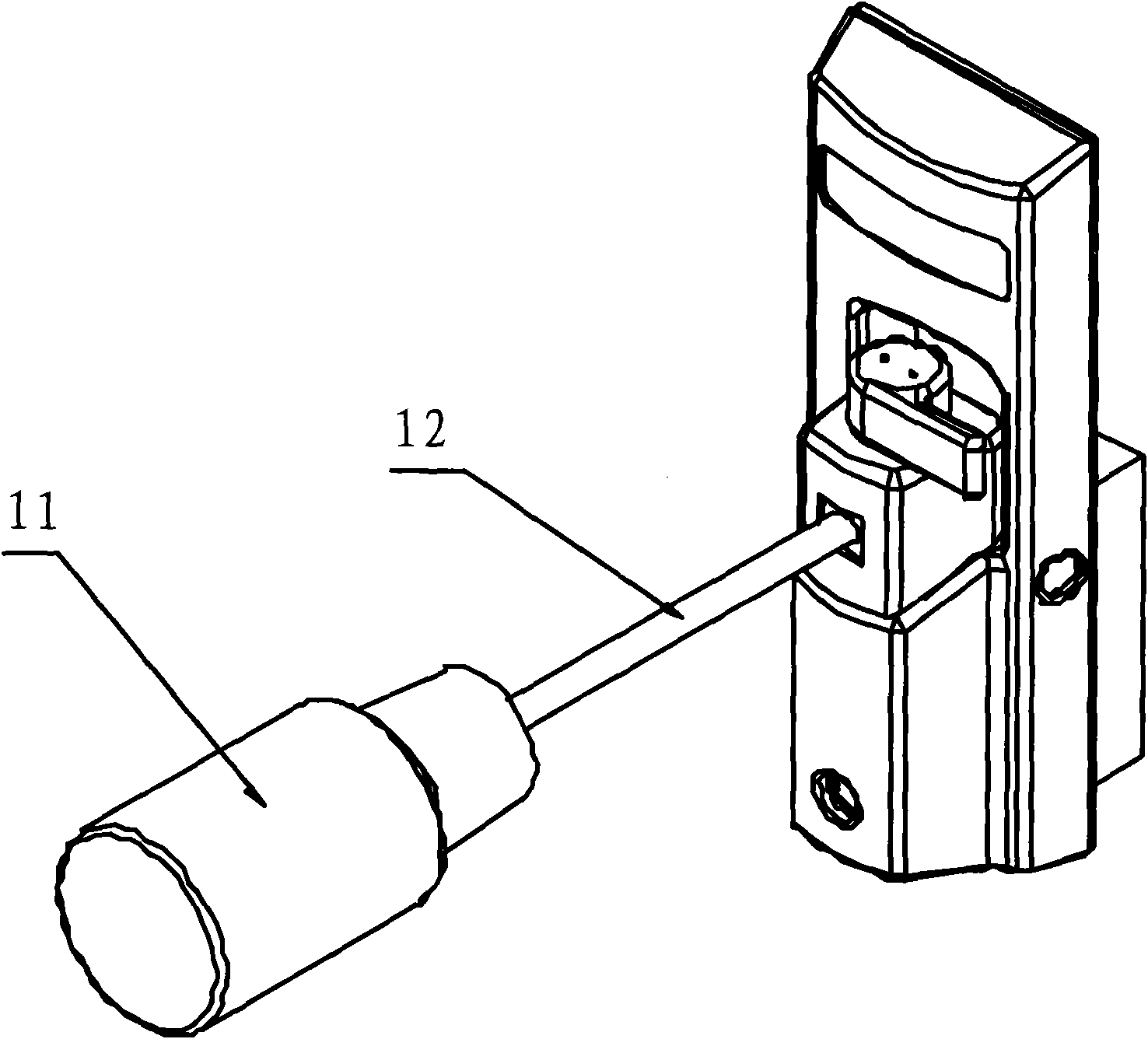

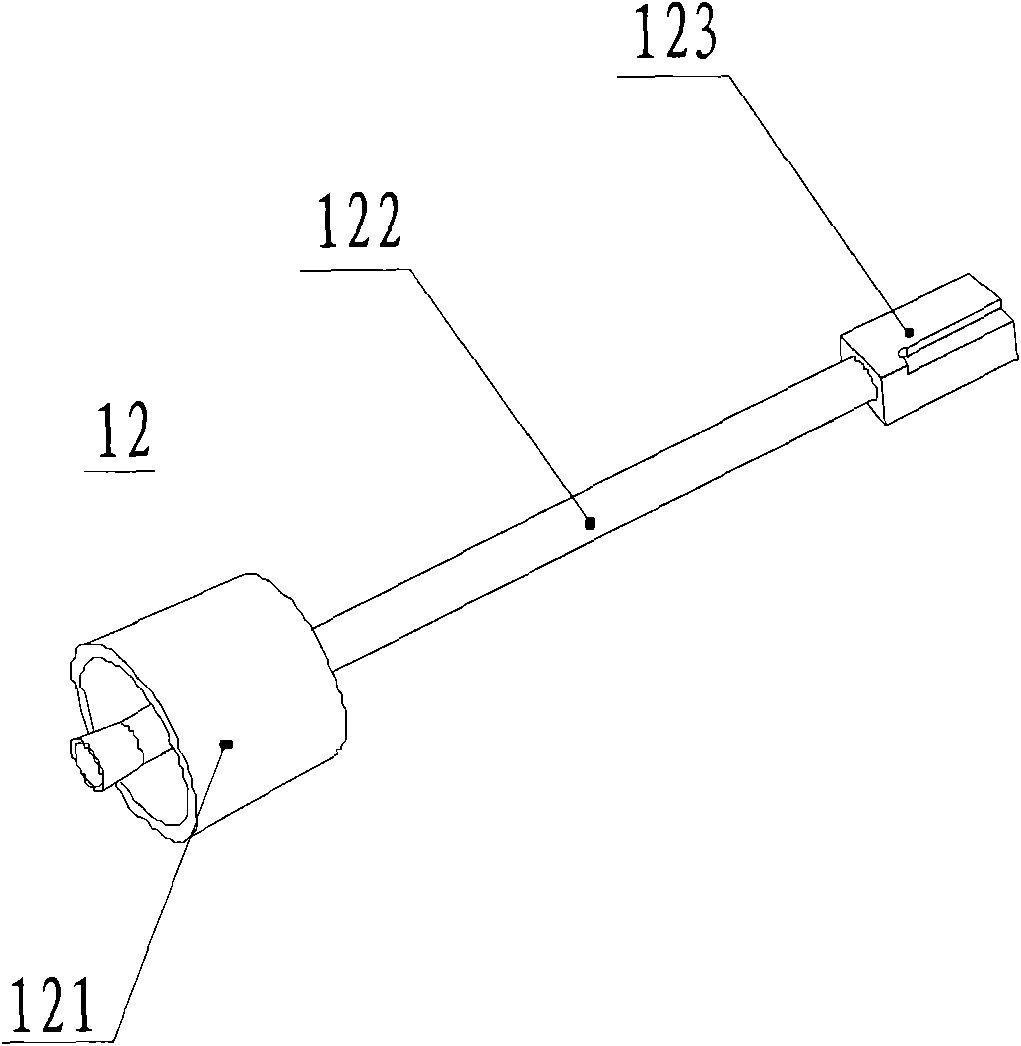

ActiveUS20150043711A1Low experience requirementImprove repeatability and reliabilityMedical imagingPatient positioning for diagnosticsX-rayMammography

A method to adjust or tune mechanical settings of a mammography apparatus comprising an x-ray source, a paddle and a detector with a detector cover, wherein before executing an x-ray measurement a patient's breast is placed and compressed between the detector cover and the paddle, wherein prior to the x-ray measurement reaction forces between the mammography apparatus and the patient's breast are minimized. The invention relates further to a mammography apparatus comprising an x-ray source, a paddle and a detector with a detector cover, which apparatus is provided with at least one weighing means to measure the downwards forces exerted by (the part of) the apparatus above the weighing means towards the ground.

Owner:DALSA

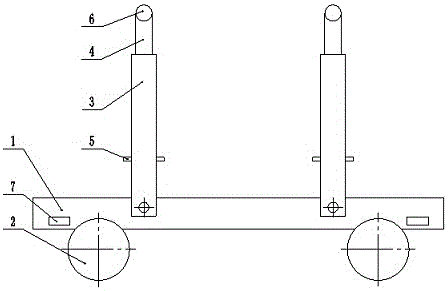

Steel plate transport car

InactiveCN106143564AAvoid letting goWon't slipSupporting partsVentilationAgricultural engineeringInverted u

The invention discloses a steel plate transport car and belongs to the field of transport machinery. The steel plate transport car comprises a bearing plate and a steel plate fixing mechanism. Two car wheel axles are arranged at the bottom of the bearing plate. Car wheels are mounted at the two ends of each car wheel axle correspondingly. The steel plate fixing mechanism comprises a swing frame and a screw. The swing frame is of an inverted-U-shaped structure, and the two ends of the swing frame are connected with the two side faces of the bearing plate correspondingly. A threaded hole is formed in the top of the swing frame. The lower end of the screw penetrates through the threaded hole of the swing frame and then extends into the inner side of the swing frame. The steel plate transport car can conveniently and rapidly transport steel plates, the single time steel plate transport amount is large, the steel plates are fixed during transport and prevented from slipping off and causing danger, and the reliability is high; and meanwhile, defects of functions of existing transport cars are overcome, and the effect that people are always in a favorable environment can be ensured.

Owner:MAANSHAN JINCHAO RUBBER TECH R&D TECH CO LTD

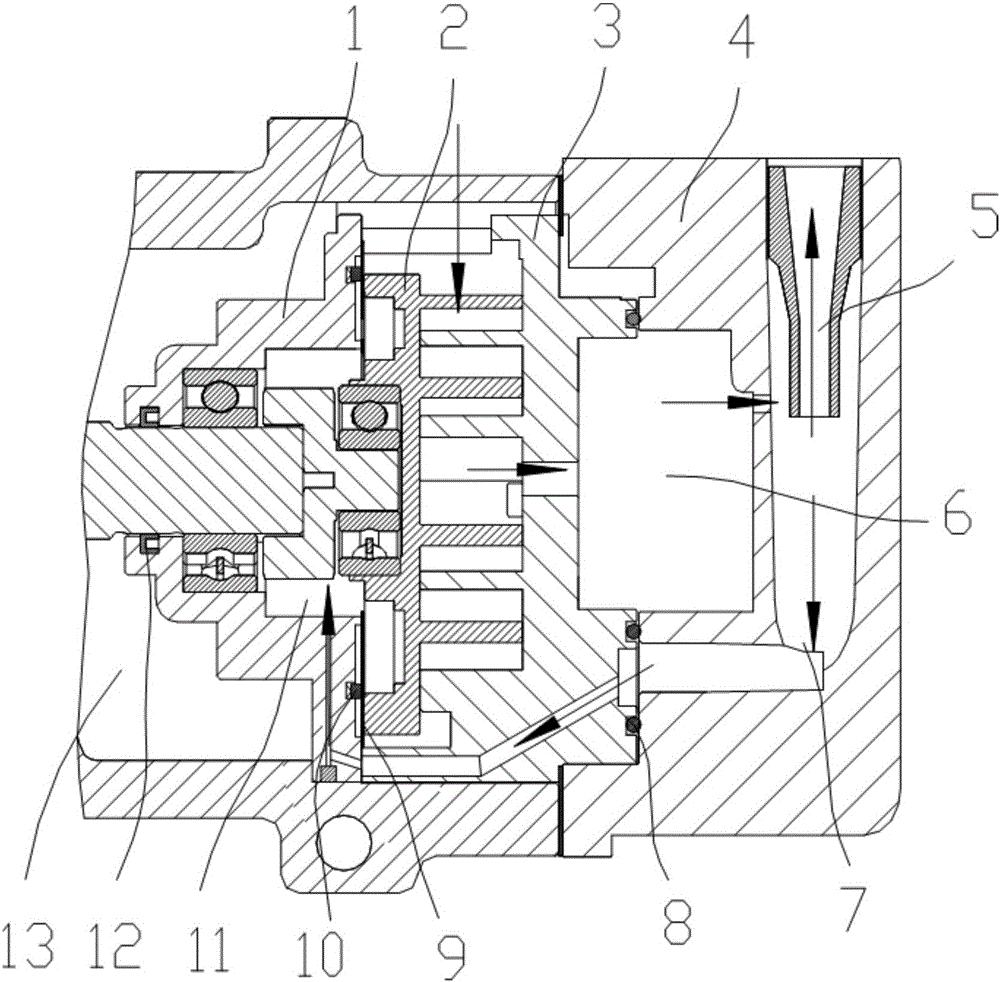

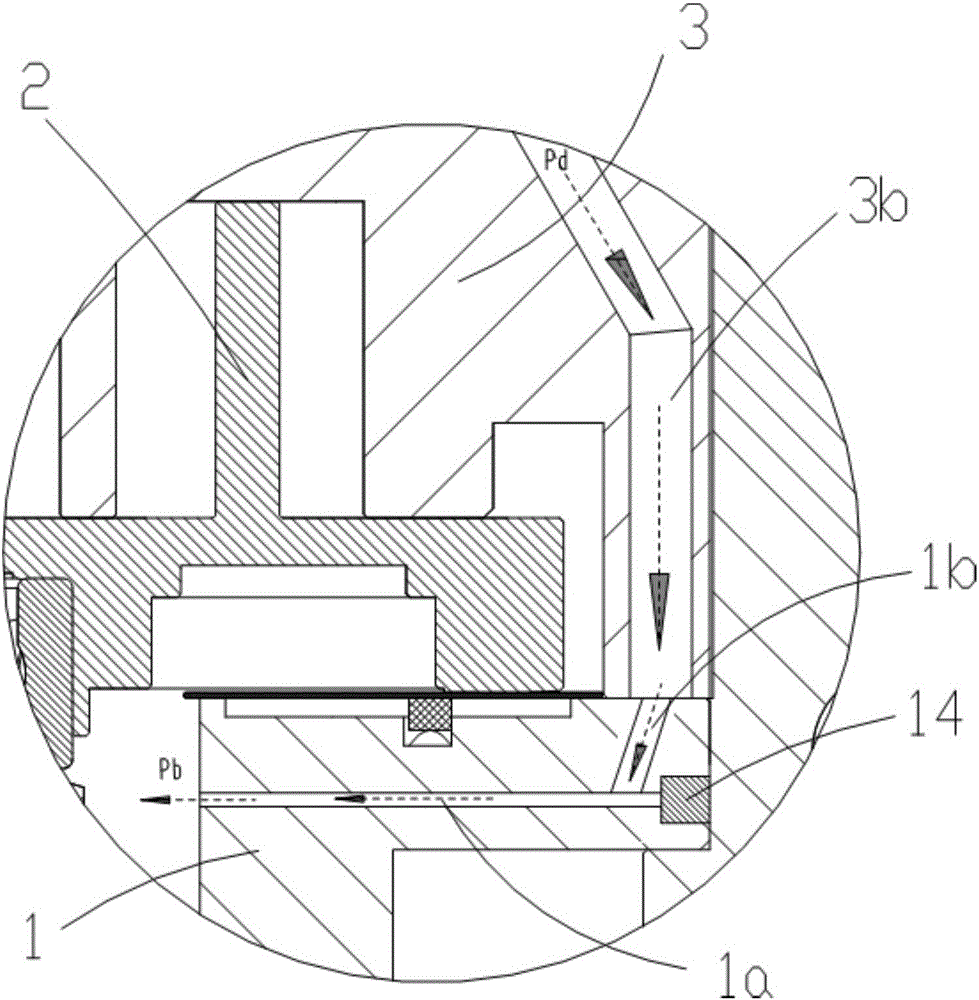

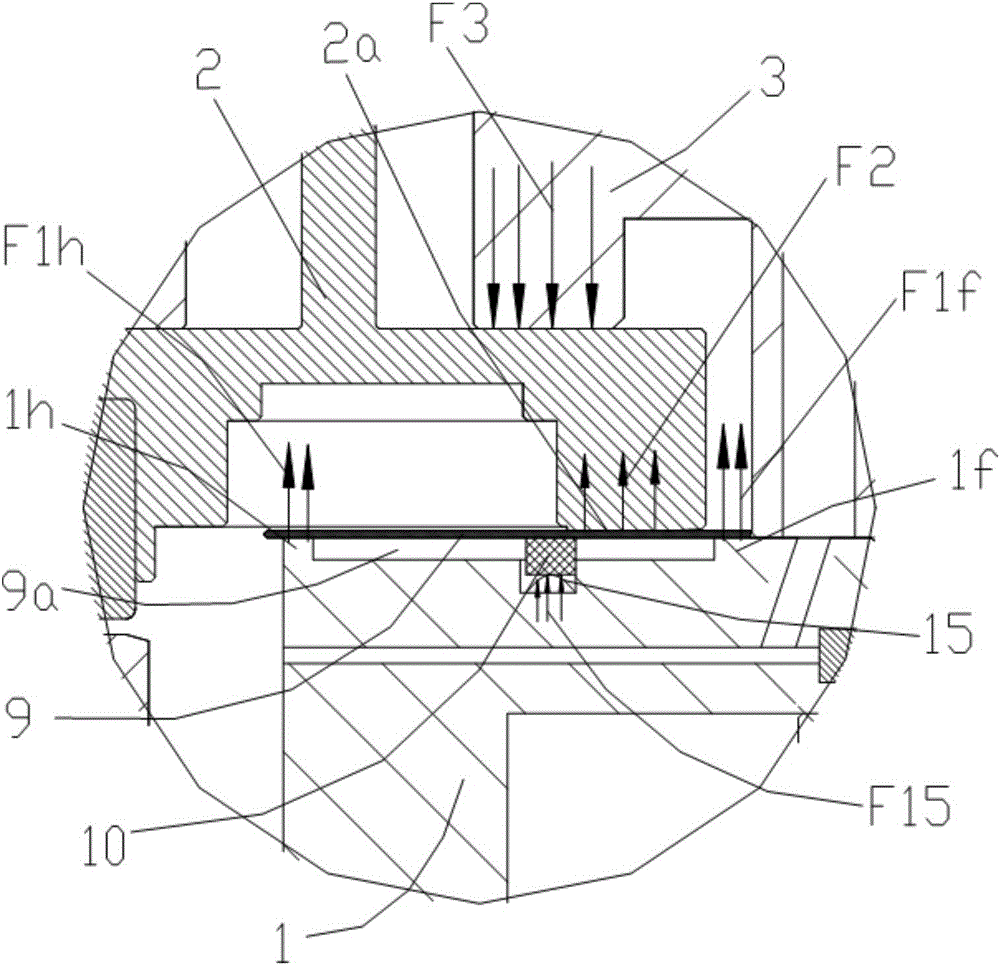

Scroll compressor

ActiveCN105840504AImprove processing strengthIncrease the difficulty of the processRotary piston pumpsRotary piston liquid enginesEngineeringScroll compressor

The invention discloses a scroll compressor. The scroll compressor comprises an upper support and an upper cover, wherein the upper support and the upper cover are connected. A movable scroll plate is arranged in the upper support and in the upper cover. A static scroll plate is coaxially arranged on the side, close to the upper cover, of the movable scroll plate. An elastic circular ring is coaxially arranged on the side, close to the upper support, of the movable scroll plate. The upper support is provided with an inner supporting part and an outer supporting part, wherein the inner supporting part and the outer supporting part are matched with the elastic circular ring. A suspended part is formed between the inner supporting part and the outer supporting part. A back pressure sealing groove is formed in the bottom face of the suspended part. A back pressure sealing ring tightly attached to the elastic circular ring is arranged in the back pressure sealing groove. A back pressure cavity and an air sucking cavity which communicate with the suspended part are formed in the upper support. An exhaust cavity communicating with the back pressure cavity is formed in the upper cover. A compression cavity communicating with the air sucking cavity and the exhaust cavity is formed between the movable scroll plate and the static scroll plate. The scroll compressor is sufficient and reliable in sealing effect, and the technology difficulty of a sealing structure of the scroll compressor is low.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

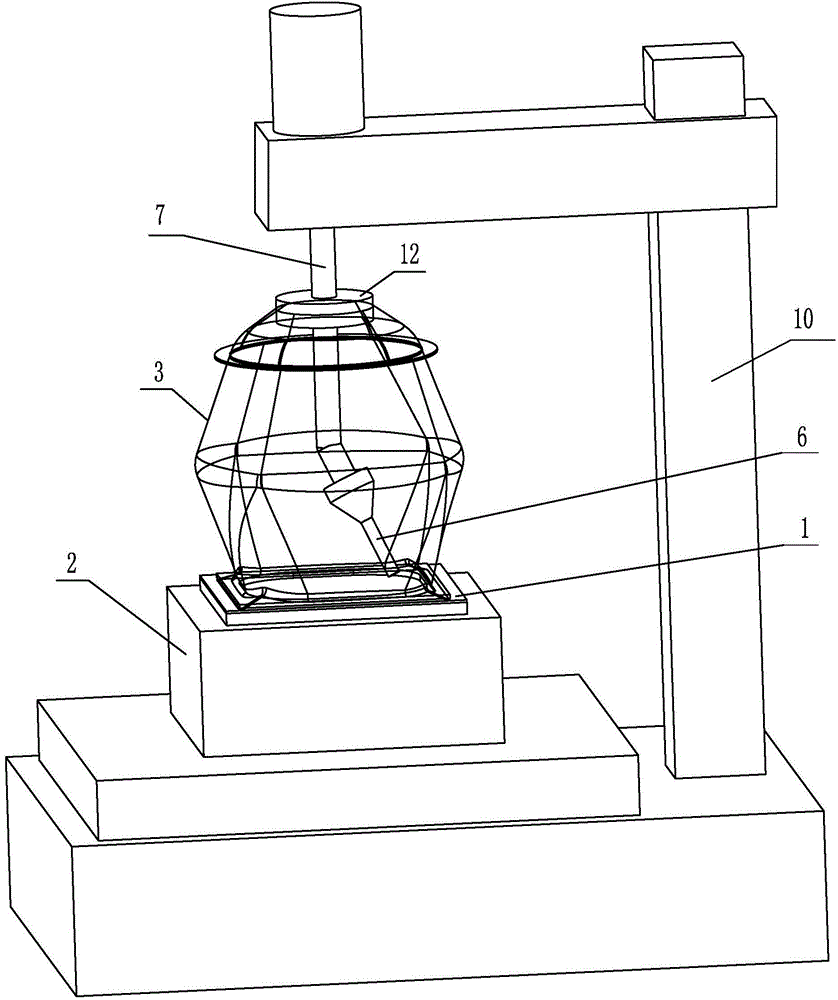

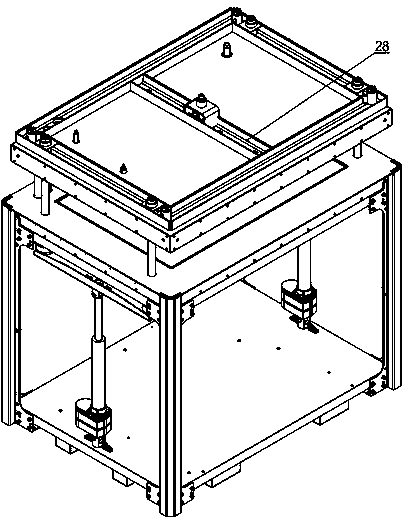

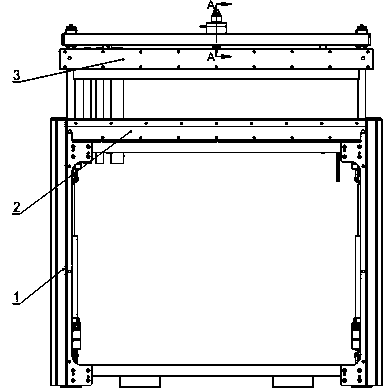

Pressure-assistant thin-wall blank precise processing method

ActiveCN104889763APress evenlyReliable compressionWork clamping meansPositioning apparatusThin walledEngineering

The invention discloses a pressure-assistant thin-wall blank precise processing method, relating to a precise processing method of a thin-wall blank and solving the problem that the shape and size precision of the final part cannot be guaranteed as an existing cutting processing method and device cannot avoid complex deformation or movement of large-size thin-wall blank during the cutting process. The method comprises the main steps of: step 1, placing a to-be-cut blank on a support molding bed and positioning the blank; step 2, placing a pressure medium cavity on the to-be-processed blank; step 3, filling a medium with the pressure medium cavity; step 4, cutting the to-be-cut blank by utilizing a cutting tool placed inside the pressure medium cavity to obtain a finally needed part; step 5, removing pressure in the pressure medium cavity, moving away the cutting tool and the pressure medium cavity and taking the part out. The pressure-assistant thin-wall blank precise processing method is used for precise processing of the thin-wall blank.

Owner:HARBIN INST OF TECH

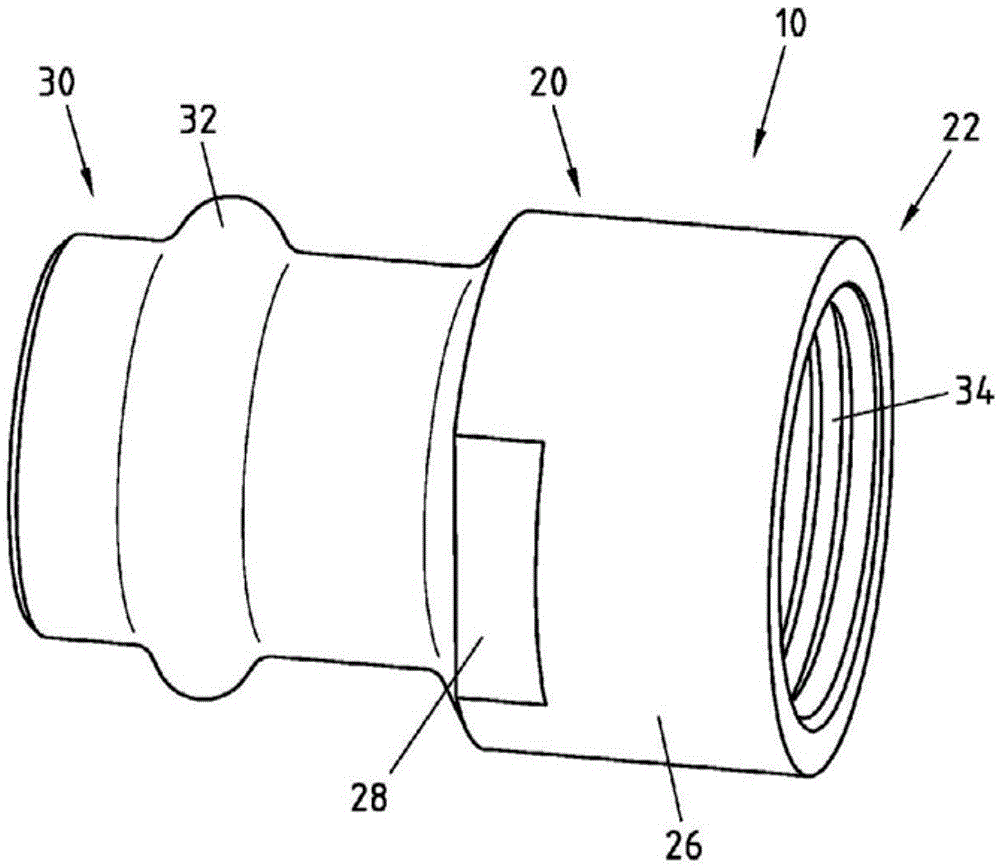

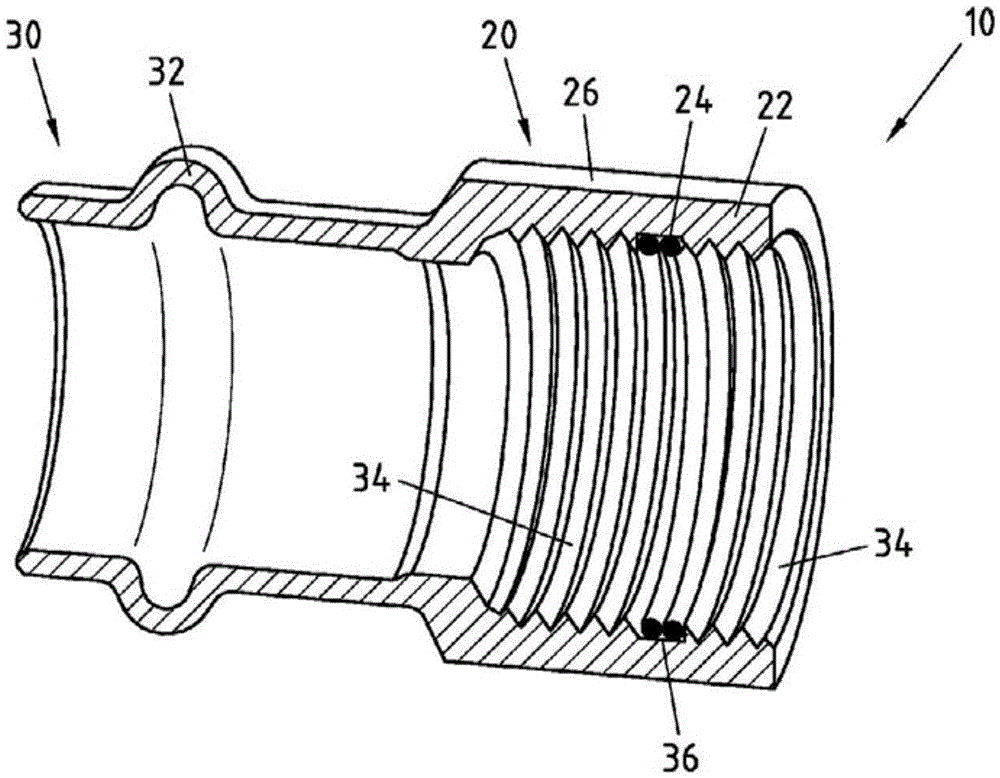

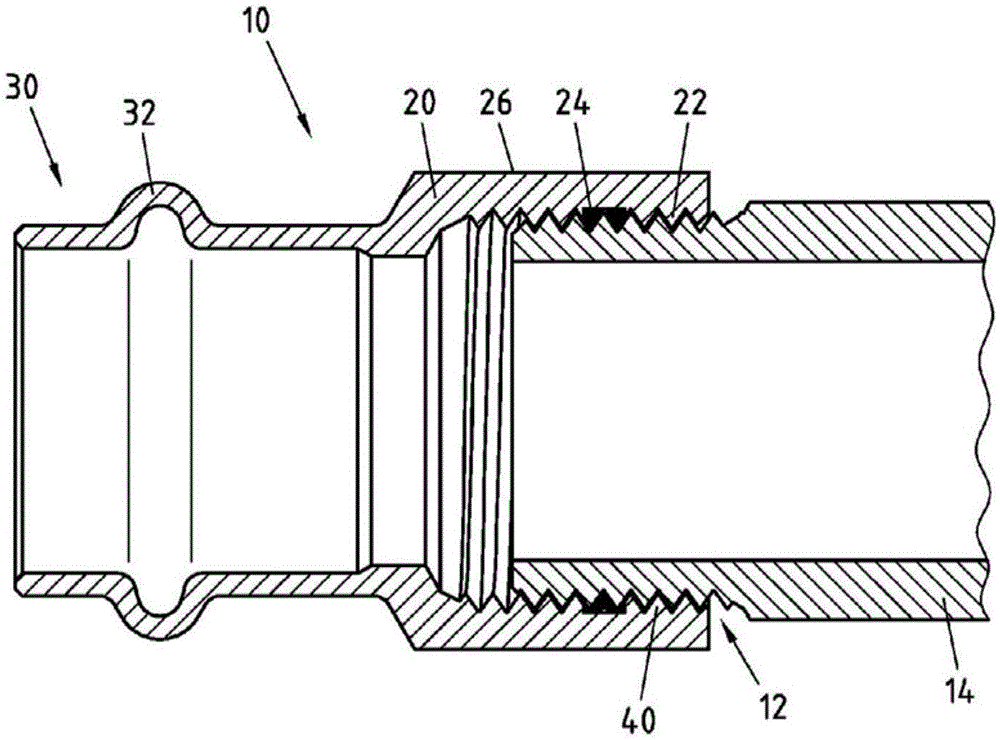

Press fitting for a threaded connection and method for attaching a fitting to a threaded connection

ActiveCN105659017AAvoid chippingImprove sealingRollersNon-disconnectible pipe-jointsScrew threadWater pipe

The invention relates to a fitting for attaching to a threaded connection of a pipe, in particular a water pipe, with a basic body (20), with a threaded portion (22) and with a sealing body (24, 50, 56; 62) arranged on the threaded portion (22), in which the technical problem of simplifying the attachment to a threaded connection of a pipe and configuring the attachment to be more reliable at the same time is solved in that the basic body (20) has a pressing surface (26, 66) on the side situated opposite to the threaded portion (22). The invention also relates to a method for attaching a fitting to a threaded connection of a pipe.

Owner:VIEGA TECH GMBH & CO KG

Device soft belt welding fixture

InactiveCN101913007ALight structureReasonable welding processWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a device soft belt welding fixture which comprises a base and a compression spring leaf, wherein one end of the compression spring leaf is hinged on the base through a screw, and the other end is the free end. The device soft belt welding fixture has lightweight structure, reasonable welding process step, simple and convenient use, compact actions, reliable compression and high production efficiency. The connection between a device and a circuit board completed by adopting the device soft belt welding fixture has accurate positioning, firmness, reliability and high finished product rate.

Owner:WUHAN TELECOMM DEVICES

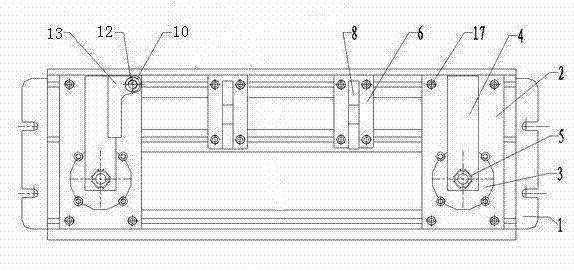

Automatic clamping device for milling crankshaft key groove

InactiveCN103111884AAvoid bruisesSimple structureMilling equipment detailsPositioning apparatusTurn angleEngineering

The invention relates to an automatic clamping device for milling a crankshaft key groove. A base of the automatic clamping device for milling the crankshaft key groove is provided with a right pressing base plate, a left pressing base plate and pre-support base plate. The right pressing base plate and the left pressing base plate are respectively provided with a turn angle air cylinder and a support V-shaped block, and the upper end of each turn angle air cylinder is correspondingly connected with a right pressing arm and a left pressing arm. The left pressing base plate is further provided with a connecting rod neck limit block, and a connecting rod neck pressing block support arm is fixed on the left pressing arm. A connecting rod neck pressing block is installed on the connecting rod neck pressing block support arm. A pre-support air cylinder is installed on the pre-support base plate, and is provided with a pre-support V-shaped block. The automatic clamping device for milling the crankshaft key groove is simple in structure and convenient to use, supporting and locating can be adjusted according to the length of a crankshaft to be processed, locating and pressing are reliable, and the damage of a crankshaft journal can be effectively avoided, and the automatic clamping device for milling the crankshaft key groove is ideal.

Owner:TIANRUN IND TECH CO LTD

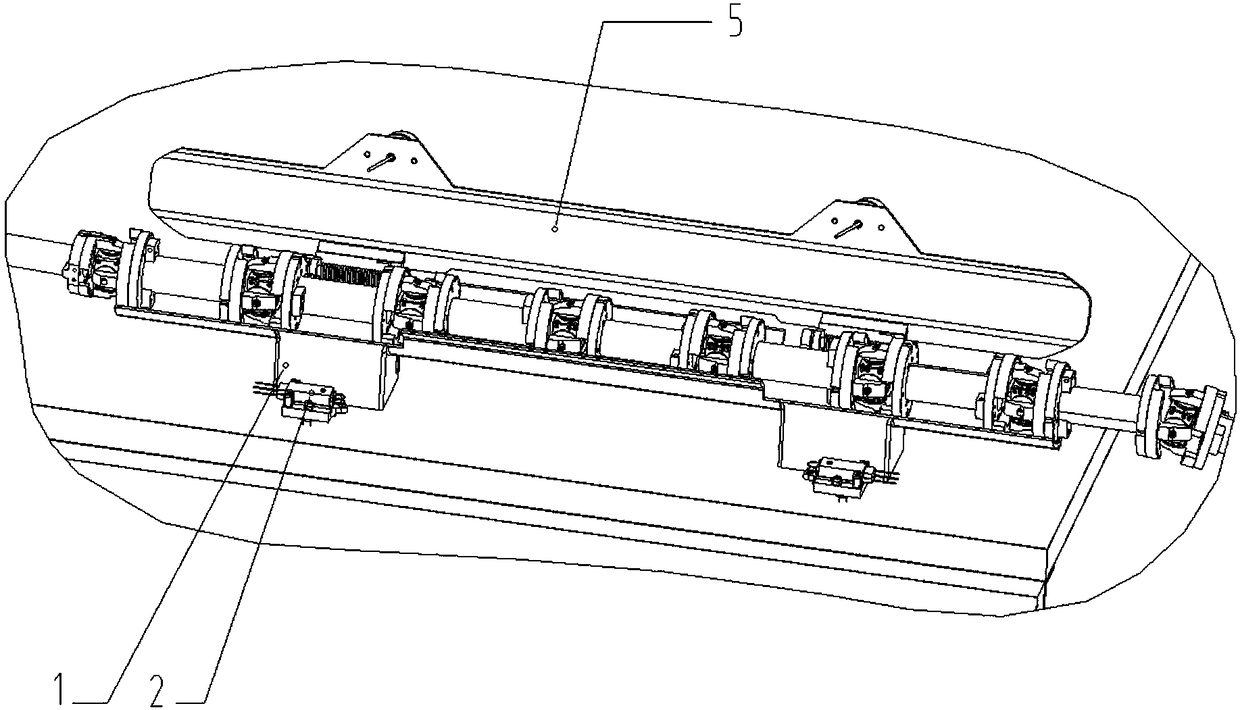

Flexible solar wing compaction and release device

ActiveCN104908979ANot destroyedLift fixed constraintsCosmonautic power supply systemsEngineeringHeight difference

The invention provides a flexible solar wing compaction and release device. The compaction and release device mainly consists of a driving end, a driven end and a support piece, wherein a driven piece is fixed with a movable plate; a roller on the driven piece rolls in a wedged compaction wheel of the driving end; and the movement of the movable plate to a fixed plate is realized through the height difference of the wedged compaction wheel to press a buffer material of a flexible wing to generate compaction force. After the compaction is in place, the movement trajectory of the wedged compaction wheel is an arc trajectory; and the roller of the driven end cannot automatically slide to reduce the compaction force. Before a solar wing is unfolded in orbit, the compaction and release device actively moves to release the fixed restraint between the movable plate and the fixed plate, so that the movable plate is smoothly unfolded under the driving of an unfolding mechanism. The device can repeatedly press and release the flexible solar wing, and is simple in structure and reliable in compaction. In addition, the support force is provided between the flexible solar wing and a cabin body by multiple support points, and the compaction force is provided by multiple locking points, so that the compaction and release device is high in bearing capacity.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Plasma flat plate instant freezer

ActiveCN104075539AReliable compressionDomestic cooling apparatusLighting and heating apparatusAerospace engineering

The invention discloses a plasma flat plate instant freezer which comprises an upper cooling plate and a lower cooling plate. The lower cooling plate is fixed at the upper end of a body frame part. A lifting mechanism is fixed on the body frame part. An upper lifting frame of the lifting mechanism corresponds to the lower cooling plate. The upper cooling plate is hung on the bottom face of the upper lifting frame. A pressure adjustable mechanism is arranged between the upper cooling plate and the four corners of the upper lifting frame. The hung upper cooling plate structure is used, the pressure of the upper cooling plate structure has certain floating amount, so that during the process that the upper cooling plate goes down and presses a plasma bag with the lower cooling plate, when blood bags of the same specification have tiny difference, through a floating structure of an upper cooling plate component, even force is exerted between a lower cooling plate component and the upper cooling plate component, and the fact that each plasma bag is pressed reliably is guaranteed.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER

Space flexible arm pressing releasing mechanism for wire fuse unlocking

The invention provides a space flexible arm pressing releasing mechanism for wire fuse unlocking, and belongs to the technical field of the space flexible arm pressing releasing mechanism. The space flexible arm pressing releasing mechanism comprises a fixed base, a wire fuse unlocking device, a pressing cover plate, a position detecting micro switch, phenyl silicone rubber sheets, torsion springs, hinge pins and limiting micro switches. Before launching, locking machines of the wire fuse unlocking device is adjusted, and proper pre-tightening force is applied to the pressing cover plate through stays to press a space flexible arm against the fixed base. After orbit injection, a command is sent from the ground, a cutter of the wire fuse unlocking device is energized, and a resistance wireof the cutter is rapidly heated to melt the stays. The space flexible arm pressing releasing mechanism for wire fuse unlocking is reliable in pressing and adopts the wire fuse unlocking device as a pressing and unlocking tool, the structure is simple, the relatively accurate pre-tightening force can be applied, and the assembly and adjustment are convenient; and no impact or vibration is generatedwhen unlocking, the space flexible arm can be protected from being damaged by the vibration shock load during launching, and the space flexible arm pressing releasing mechanism for wire fuse unlocking is suitable for the occasion in which the locking force of the space flexible arm is not required too much.

Owner:HARBIN INST OF TECH +1

Positioning device and method for blade machining

The invention discloses a positioning device and method for blade machining. The positioning device comprises an adapter plate, a supporting block, an AB point positioning block, a C point positioningpin, a D point positioning pin and an EF point positioning block. The AB point positioning block, the C point positioning pin, the D point positioning pin and the EF point positioning block are all installed on the supporting block. Moving auxiliary positioning is added, a hinge pressing mechanism is adopted, and the head and the body of the blade are pressed and operated respectively; the positioning device is novel and compact in structure, accurate in positioning, reliable in pressing, fixed in pressing position, convenient in operation, and rigid enough, the blade body is prevented from being scratched; a scheme of directly adopting a blank reference point for positioning when the turbine working blade is used for processing the tenon is realized; the machining auxiliary procedures are reduced, the cost is reduced, the machining period is shortened, the machining efficiency is improved, meanwhile, the utilization rate of the grinding wheel is increased, the design and manufacturing cost is low, the turbine working blade tenon machining requirement is completely met, and meanwhile referential experience is provided for similar problems.

Owner:AECC AVIATION POWER CO LTD

Mammography apparatus and method to adjust or tune the mechanical settings of such a mammography apparatus

ActiveUS9826950B2Low experience requirementImprove repeatability and reliabilityMedical imagingPatient positioning for diagnosticsX-rayMammography

A method to adjust or tune mechanical settings of a mammography apparatus comprising an x-ray source, a paddle and a detector with a detector cover, wherein before executing an x-ray measurement a patient's breast is placed and compressed between the detector cover and the paddle, wherein prior to the x-ray measurement reaction forces between the mammography apparatus and the patient's breast are minimized. The invention relates further to a mammography apparatus comprising an x-ray source, a paddle and a detector with a detector cover, which apparatus is provided with at least one weighing means to measure the downwards forces exerted by (the part of) the apparatus above the weighing means towards the ground.

Owner:DALSA

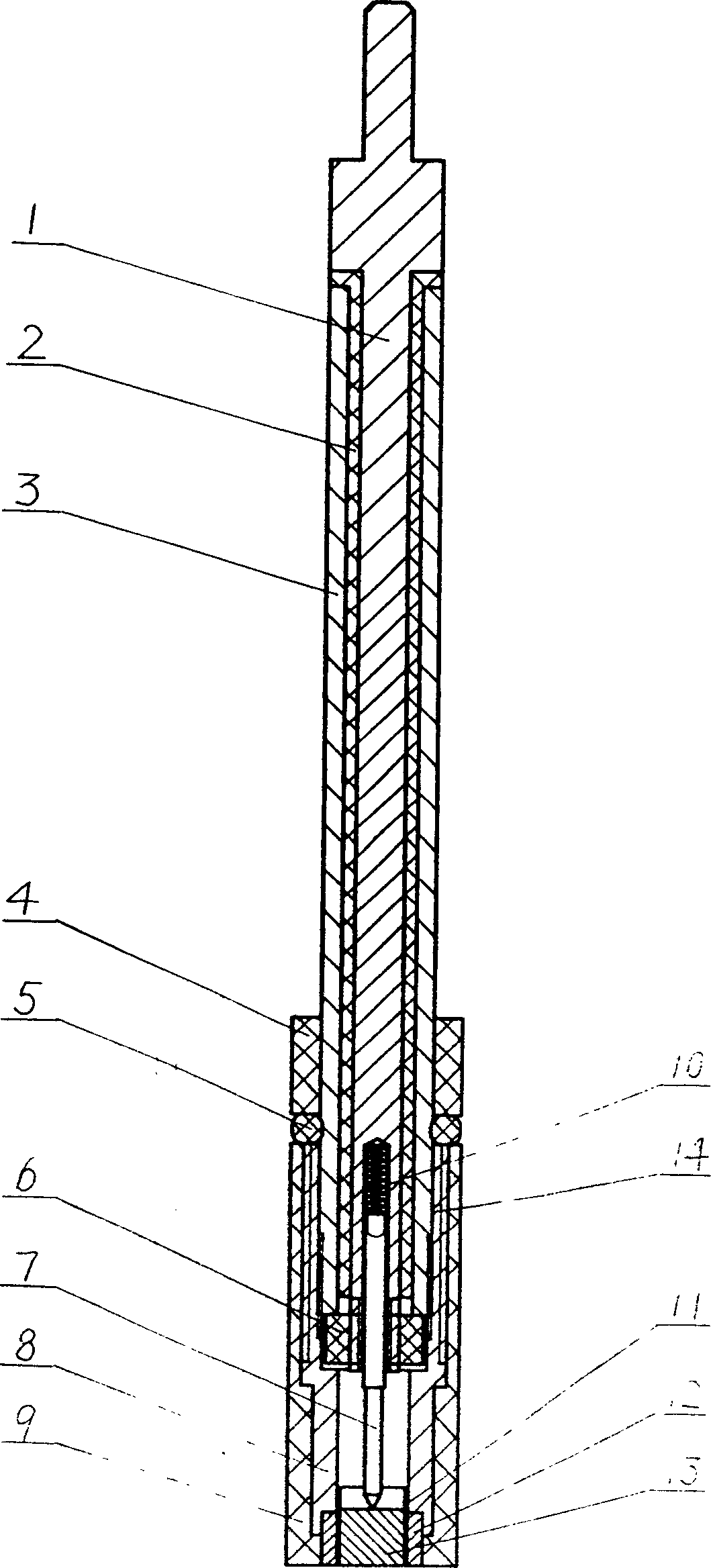

Injection device of anesthetic vaporizer

The invention discloses an injection device of an anesthetic vaporizer, which comprises an injection seat, a transition sleeve and a compressing mechanism, wherein the injection seat is used for being connected with an anesthetic vaporizer main body and is provided with a filling port; the transition sleeve is hermetically mounted on the filling port of the injection seat and is provided with a plug hole for the plugging of a plug-in adapter or an injection port sealing pin, the circumferential wall of the plug hole is previously provided with at least two pin holes, and each pin hole is matched with a positioning pin of one corresponding plug-in adapter; and the compressing mechanism is arranged above the transition sleeve and is used for compressing the plug-in adapter or the injection port sealing pin. In the injection device of an anesthetic vaporizer, the different combinations of the positions of the positioning pin and the transition sleeve can realize the composite applicationof multiple anesthetics, and the additional compressing mechanism can realize zero leakage in the injection process. Besides, based on the matching between a cam and a pin, the compressing mechanism realizes the functions of reliable compression and release prevention.

Owner:BEIJING AEONMED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com