Plasma flat plate instant freezer

A technology of quick freezer and flat plate, which is applied in lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve the problems of large energy consumption of cold plate under moving and uneven force on plasma bags, and achieve the effect of reliable compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

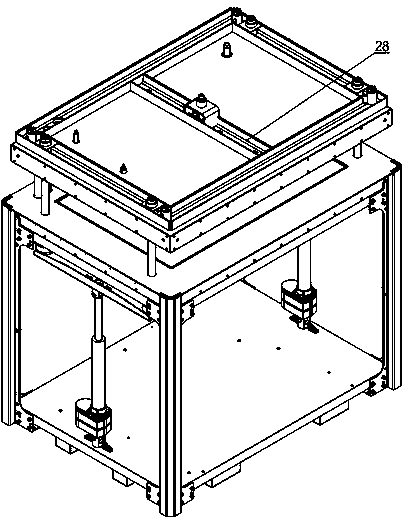

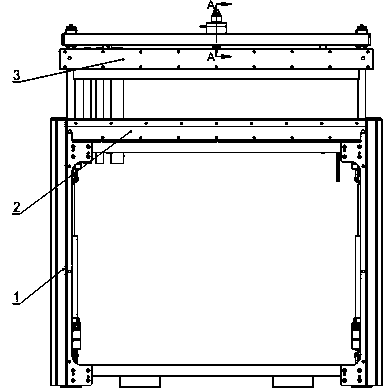

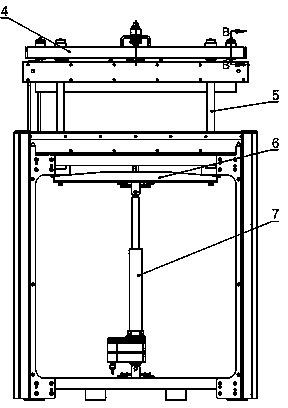

[0016] The plasma plate quick-freezing machine of the present invention includes an upper cold plate 3 and a lower cold plate 2, the lower cold plate 2 is fixed on the upper end of the main body frame part 1, and the lifting mechanism for realizing the rising and falling of the upper cold plate in this embodiment includes an upper lifting frame 4 , guide post 5, crossbeam 6 and electric push rod 7, the upper lifting frame 4 is a rectangular frame structure, the center is provided with a load-bearing beam 28, four guide posts 5 are symmetrically arranged on the parallel sides of the rectangular frame, and two guide posts on the same side 5 is connected with the same beam 6, the beam 6 is connected with the electric push rod 7, and the electric push rod 7 is fixed on the base of the main frame part 1. The upper lifting frame 4 of the lifting mechanism corresponds to the lower cold plate 2, and the upper cold plate 3 is suspended on the bottom surface of the upper lifting frame 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com