Camshaft flank hole processing clamp

A side hole and camshaft technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of side hole processing accuracy, low efficiency of clamping methods, and unsuitable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

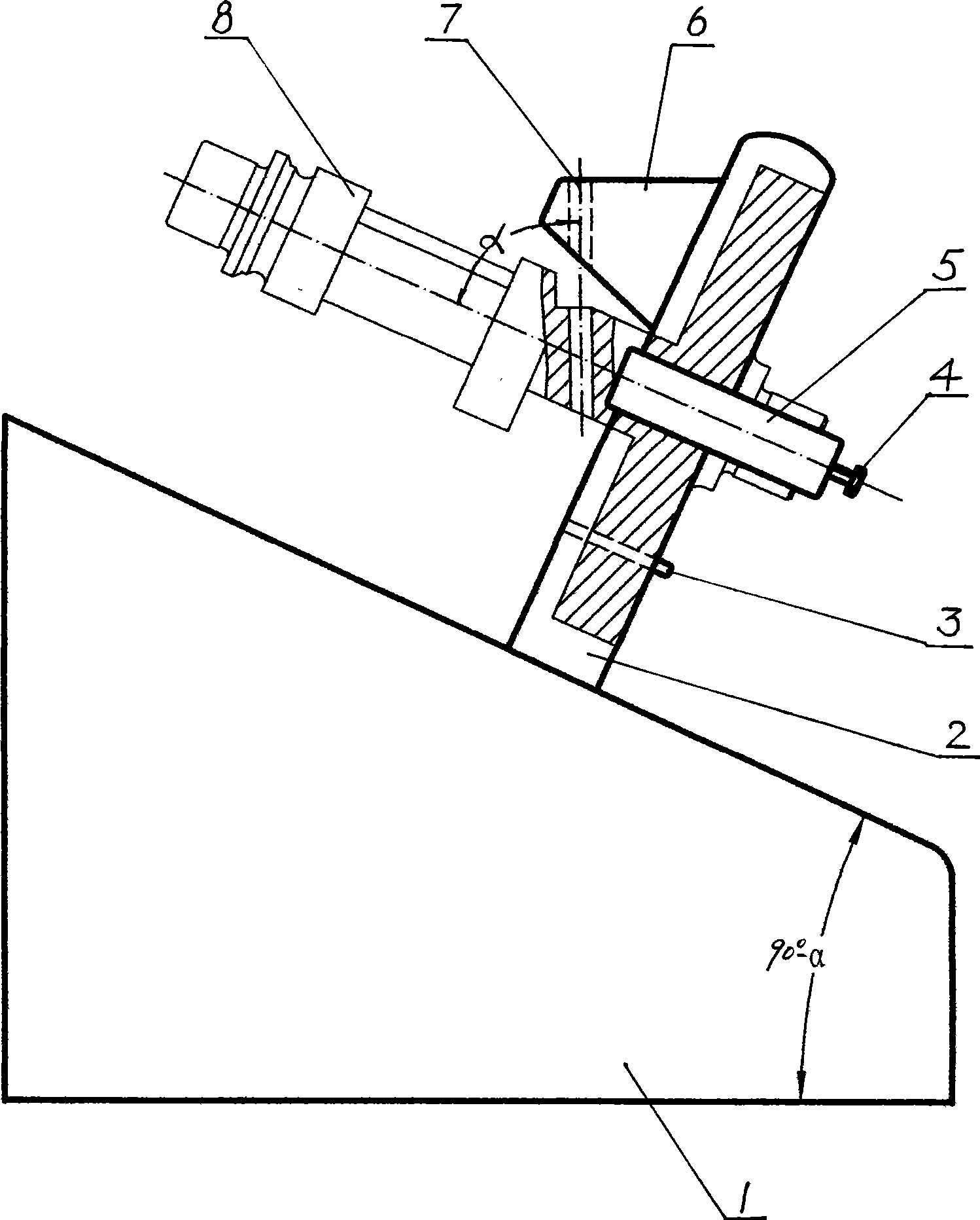

[0008] Referring to the accompanying drawings, the upper plane of the base 1 forms an inclination angle of 90°-α with the bottom plane, where α is the angle between the side hole on the camshaft 8 and the axis of the camshaft, and the positioning plate 2 fixed on the upper plane of the base is perpendicular to the upper Plane, forming an oblique angle α with the bottom plane of the base, the middle part of the positioning plate has a positioning hole perpendicular to the positioning plate and a positioning pin 3 below the positioning hole, the end surface of the positioning hole forms an oblique angle α with the bottom plane of the base, and 5 sets of hook-shaped sliding pressure plates On the positioning plate, it can move up and down, the pressing plate is provided with a compression screw 4, the positioning plate is provided with a drill sleeve 6 above the positioning hole, and the drill sleeve has a guide hole 7 perpendicular to the bottom plane of the base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com