Automatic clamping device for milling crankshaft key groove

An automatic clamping and crankshaft key technology, applied in positioning devices, clamping, milling machine equipment, etc., can solve the problems of long pressing time, poor processing versatility, and high labor intensity of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

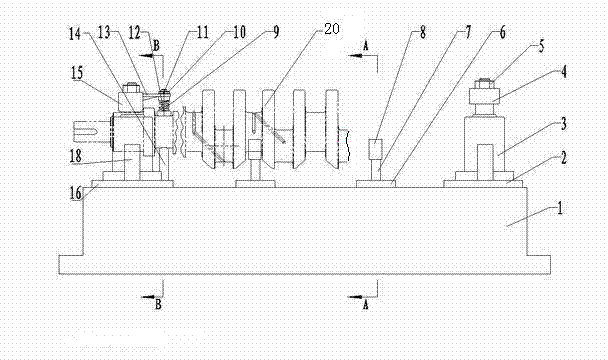

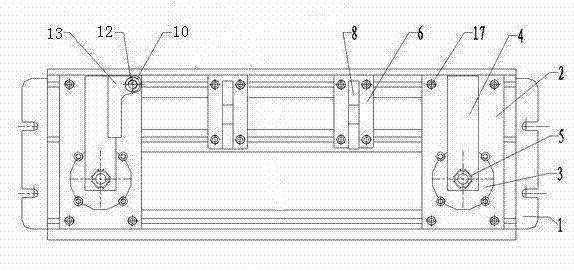

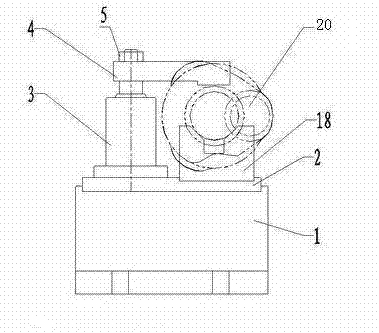

[0020] The present invention will be described and illustrated in detail below in conjunction with the accompanying drawings.

[0021] From figure 1 , figure 2 It can be seen from the figure that an automatic clamping device for milling crankshaft keyways is provided with a base 1 on which a right compression base plate 2, a left compression base plate 16 and two pre-support base plates 6 in the middle are installed.

[0022] The base 1 of the present invention is provided with a groove, and the right compression base plate 2 and the left compression base plate 16 are rectangular plate-shaped structures, and the lengths of the right compression base plate 2 and the left compression base plate 16 are the same as the concave grooves on the base 1. The width of the groove is the same, and the right pressing base plate 2 and the left pressing base plate 16 are installed in the groove. Three longitudinal T-shaped grooves are arranged in the groove of the base. The right compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com