Electromagnetic fixture

A technology of electromagnetic clamps and electromagnets, which is applied in the directions of clamping, manufacturing tools, and supports, can solve the problems of inability to guarantee the quality of workpiece processing, heavy labor for operators, and low efficiency, and achieves simple structure, good clamping effect, The effect of increasing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

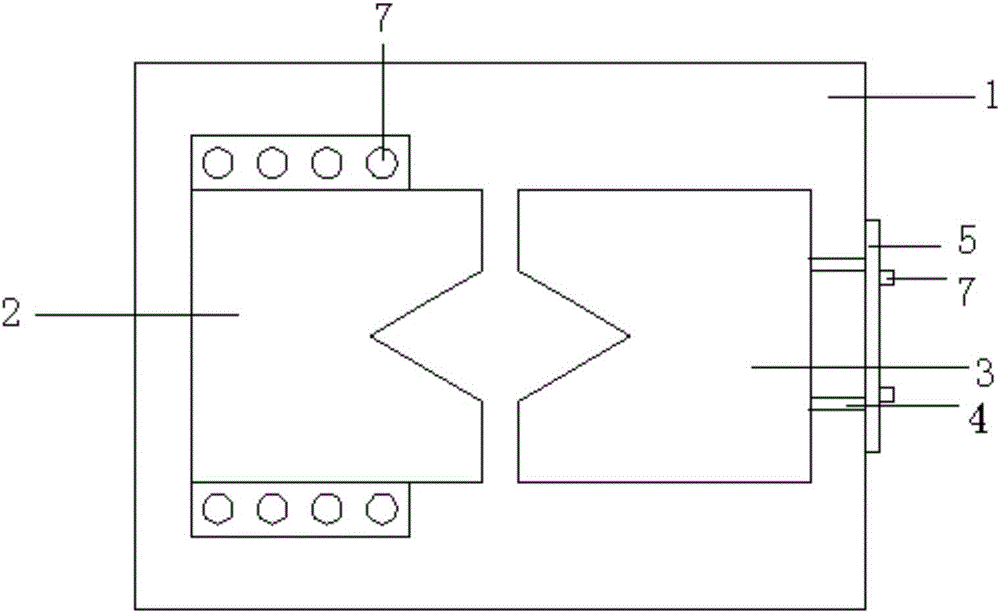

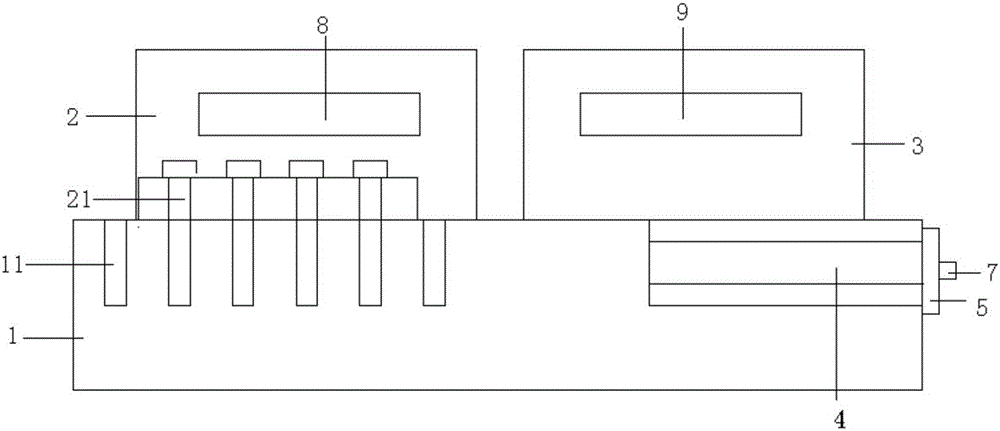

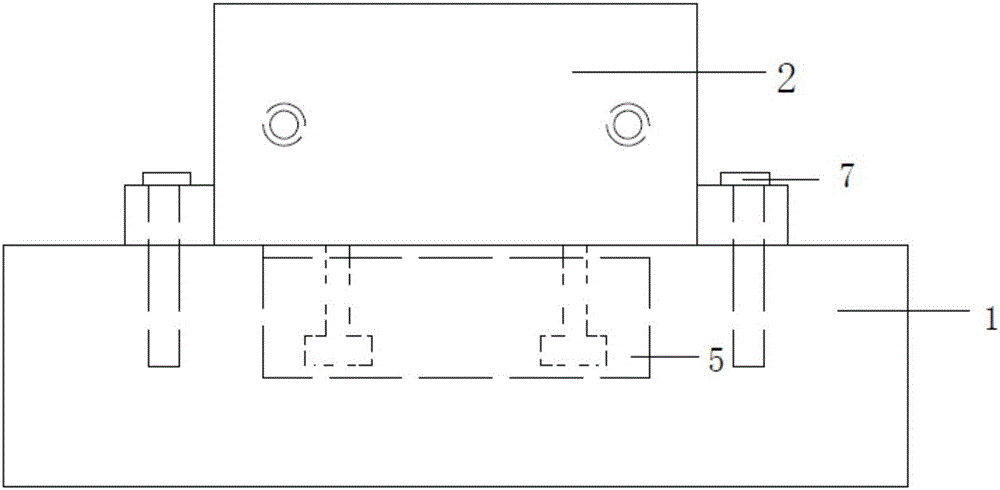

[0030] refer to Figure 1 to Figure 7 , an electromagnetic clamp, including a base 1, the base 1 is oppositely provided with a left clamping part 2 and a right clamping part 3 that are detachably engaged with each other, and the left clamping part 2 and the right clamping part 3 are engaged There is an accommodating space for the workpiece; the left clamping part 2 is detachably connected to the base 1, and the right clamping part 3 is slidably connected to the base 1; the left clamping part Both the holding part 2 and the right holding part 3 have a cavity, and a controller is arranged in the cavity, and a first electromagnet 8 is arranged in the cavity of the left holding part 2. The cavity of the right clamping part 3 is provided with a second electromagnet 9, the winding direction of the coil of the first electromagnet 8 and the second electromagnet 9 is opposite, and the first electromagnet 8 and the second electromagnet 9 are both connected to a controller, and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com