Patents

Literature

49results about How to "Improve processing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

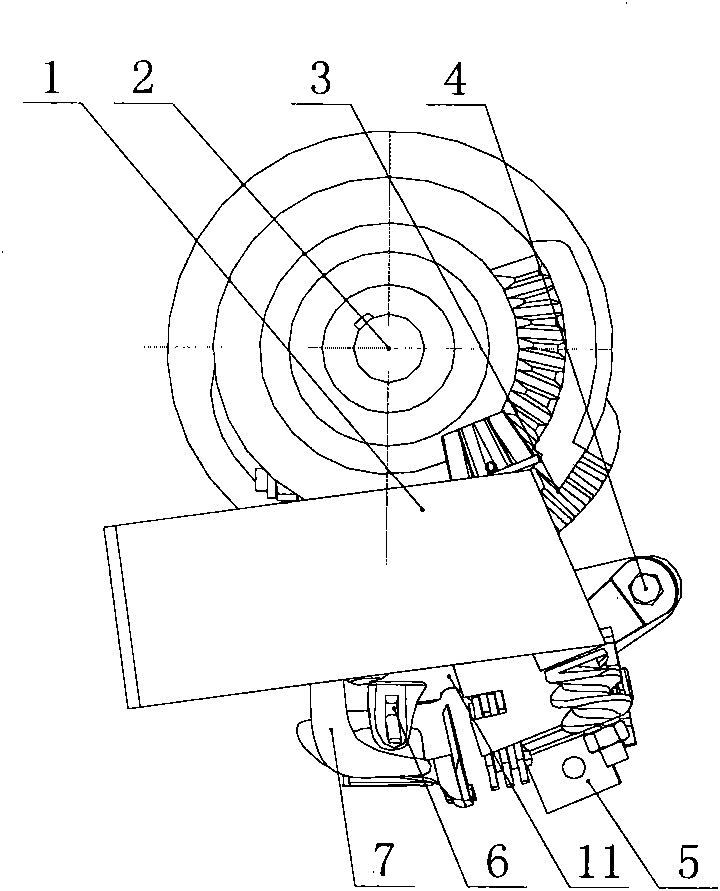

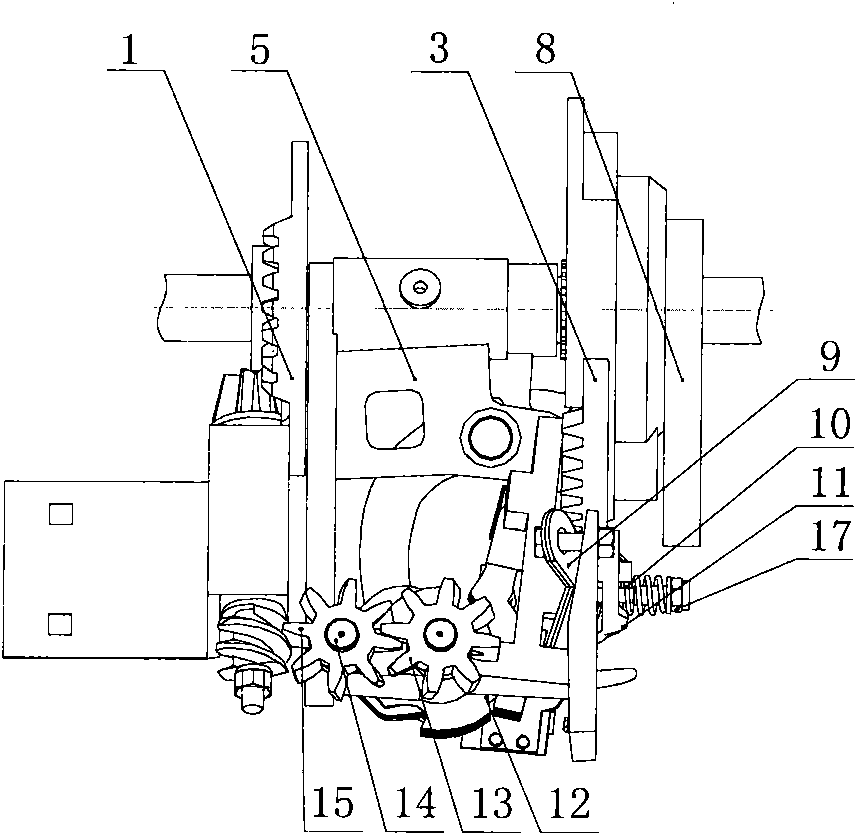

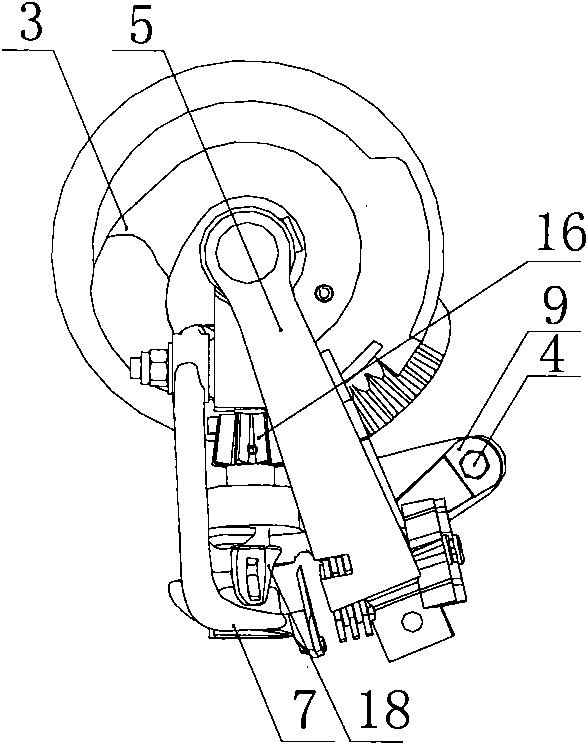

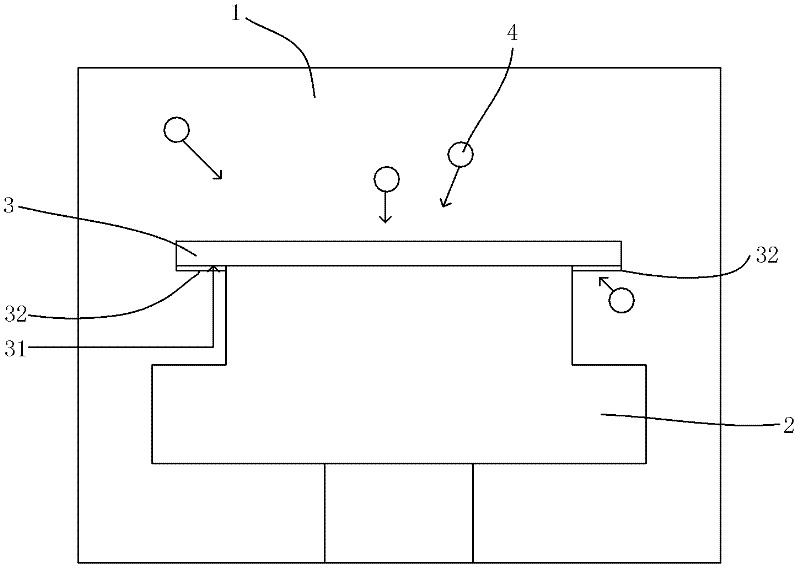

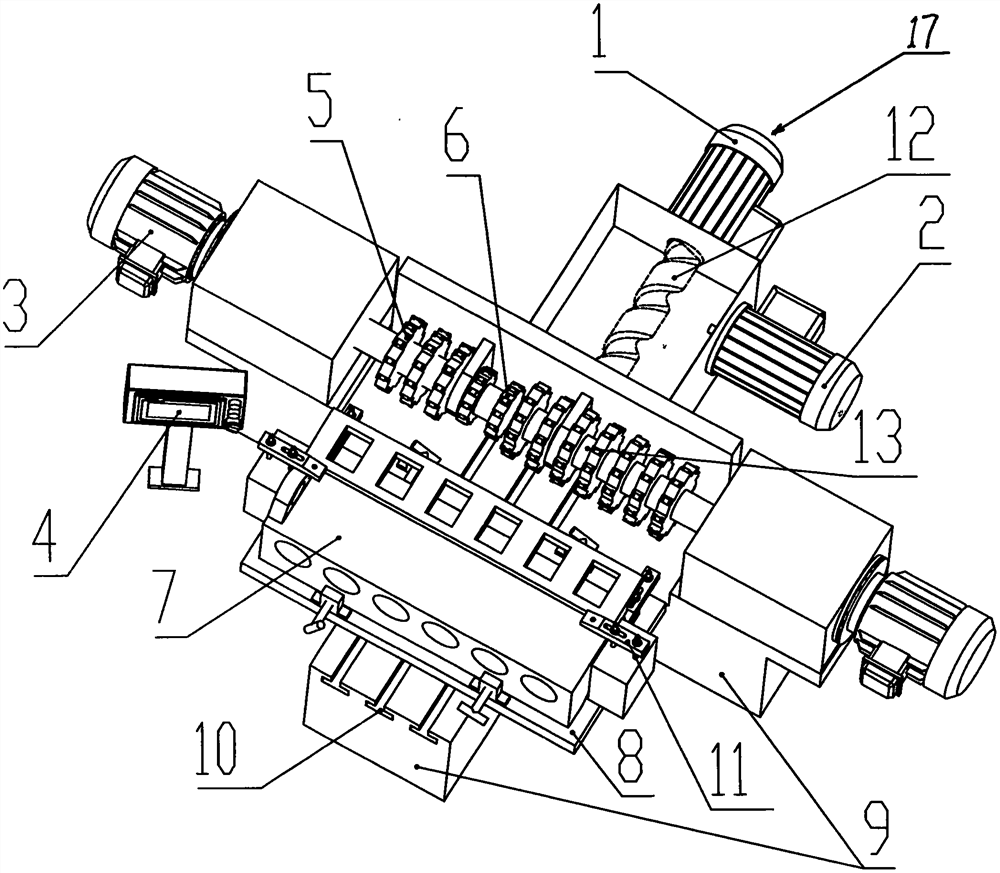

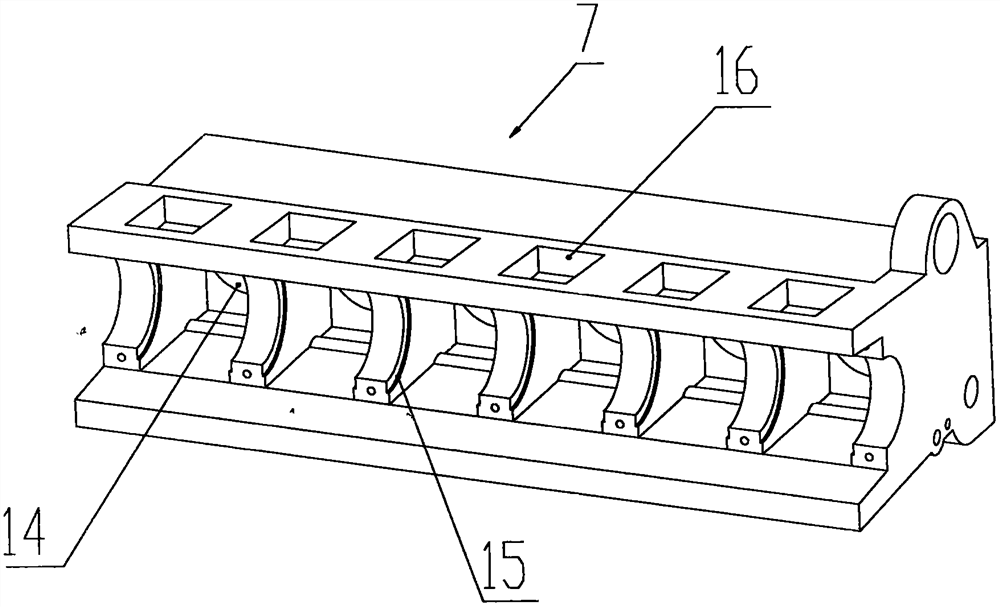

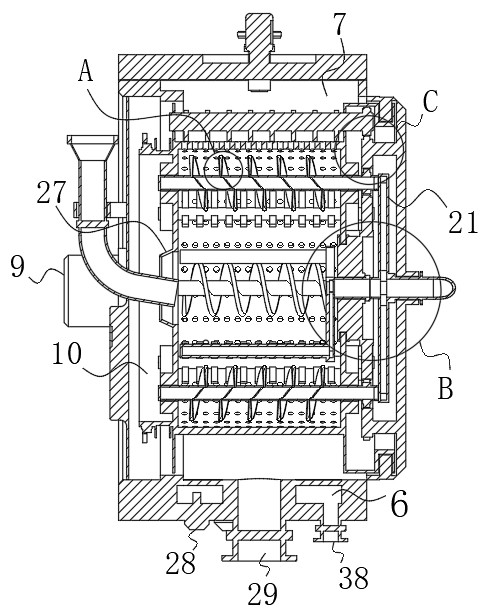

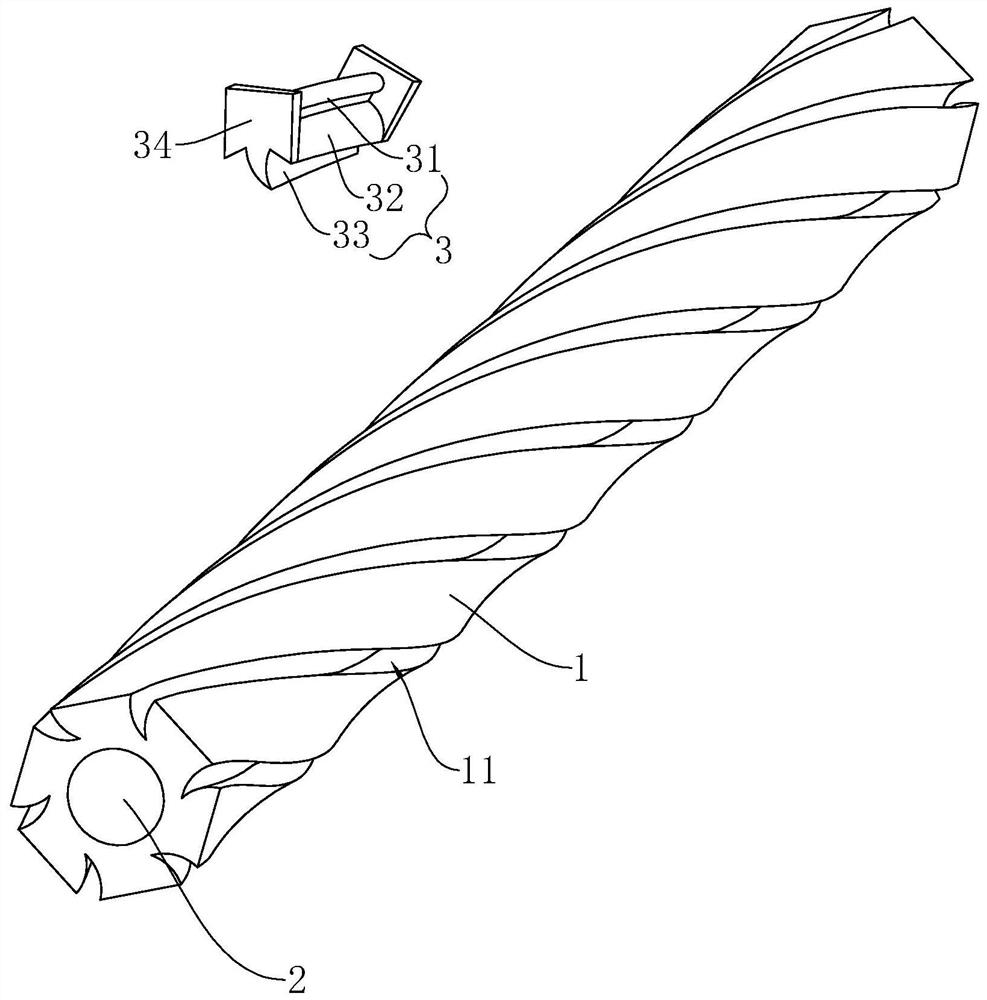

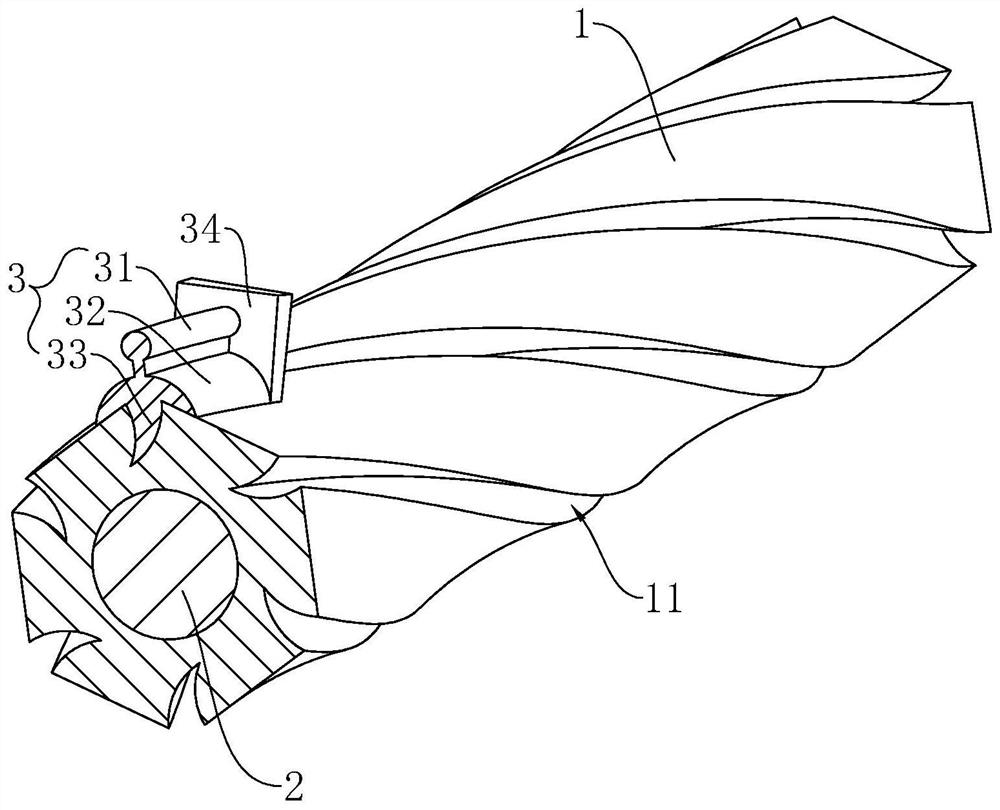

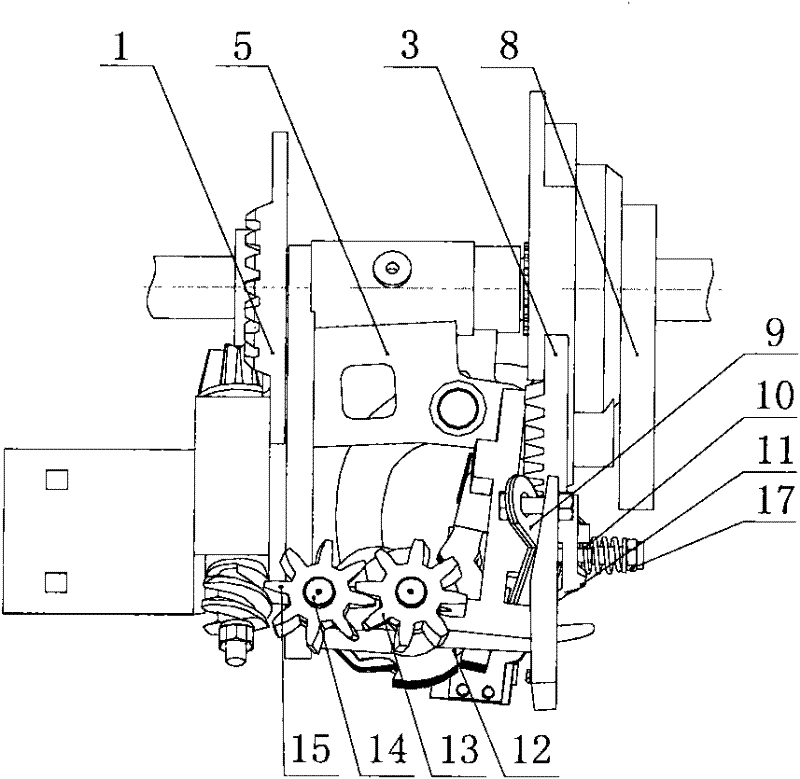

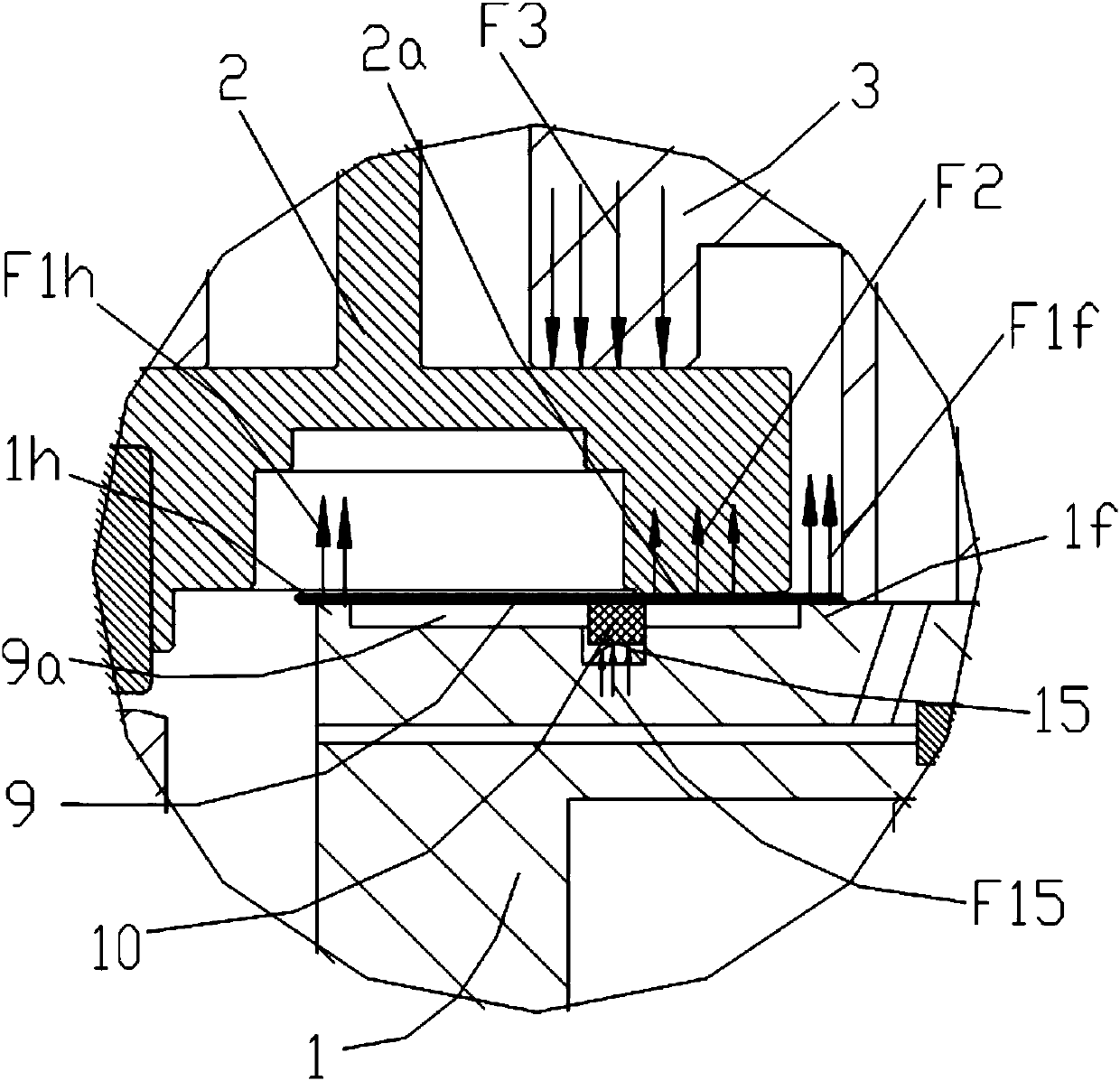

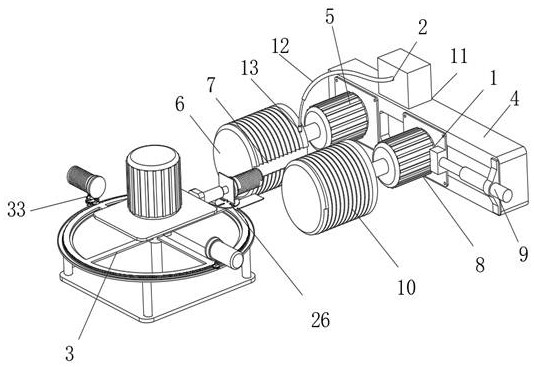

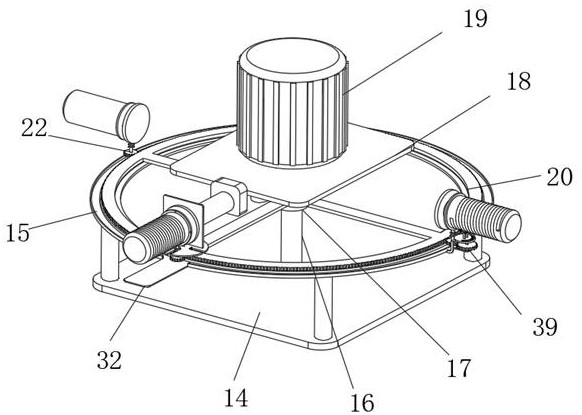

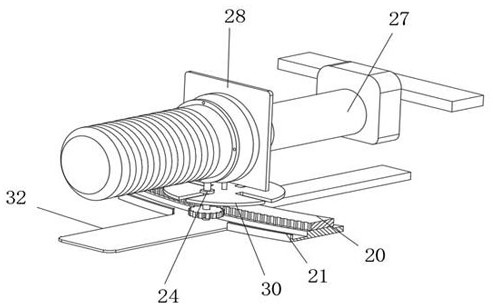

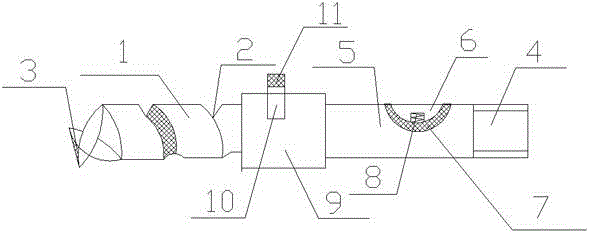

Split knotter

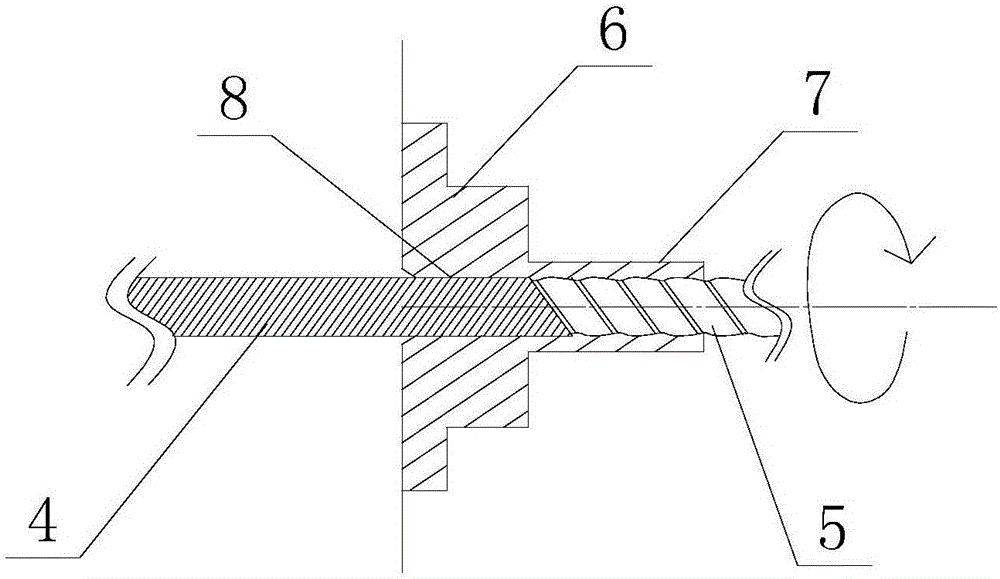

InactiveCN101953259ALower replacement costsReduce manufacturing costsHarvestersBalingDrive shaftEngineering

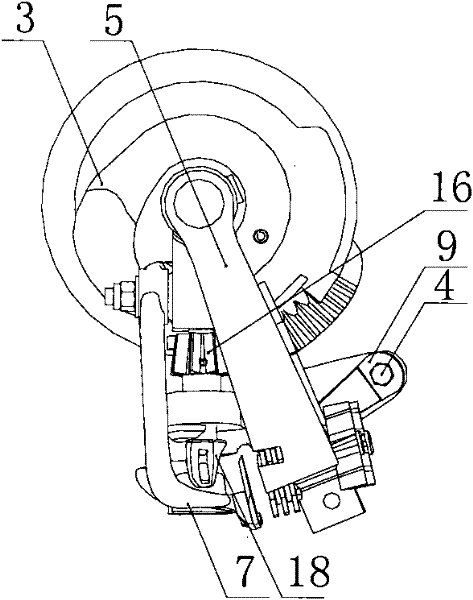

The invention relates to a split knotter which belongs to the field of agricultural mechanical equipment. A drive shaft is installed in a shaft hole I of a main installation frame; a rope clamping drive mechanism and a split drive disk mechanism are coaxially installed at both ends of the drive shaft; a cam swinging rod is installed on a shaft hole III of the main installation frame, and the cam swinging rod and the split drive disk mechanism form a cam mechanism; the rope clamping mechanism and a rope clamping right helical gear are coaxial and are installed on a shaft hole V of the main installation frame; a rope clamping left helical gear is installed on a shaft hole VI of the main installation frame; an olecranon intermittent gear and an olecranon tongue are axially connected with an olecranon shaft respectively and installed on a shaft hole II of the main installation frame; and the olecranon tongue and the main installation frame form a small cam mechanism. Key mechanisms of the invention are formed by combining split parts, thereby reducing the processing deformation of integrated parts and the manufacture and maintenance cost of a press baler, being beneficial to the adjustment of relative positions during assembly, overcoming the defect of replacing the whole part due to the damage of a structure, prolonging the service life of the knotter and enhancing the processing strength of the parts.

Owner:CHINA AGRI UNIV

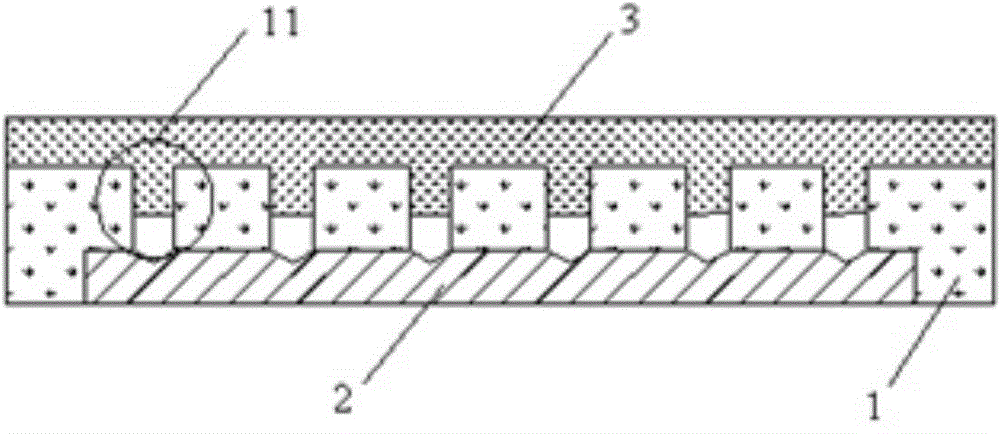

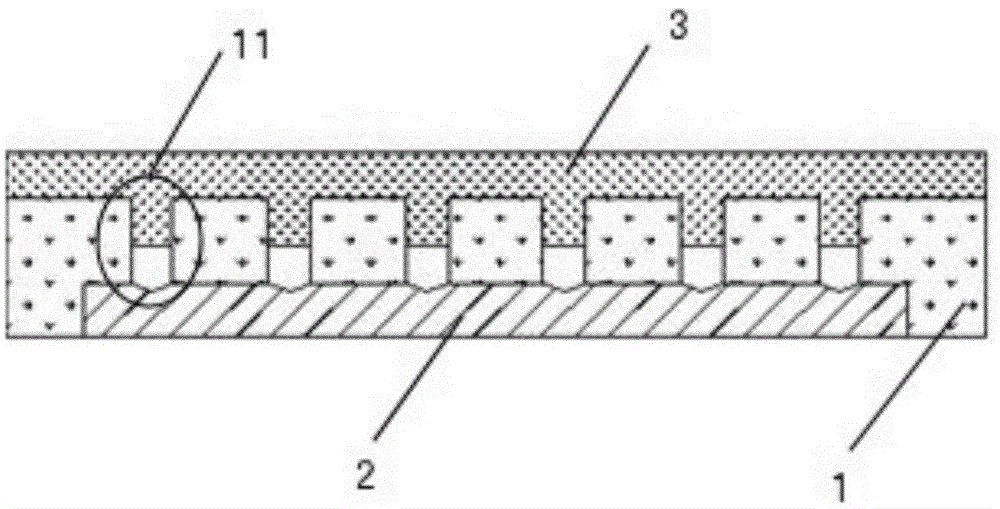

Communication equipment metal shell and preparation method thereof

InactiveCN105530782AImprove processing strengthImprove the decorative effectMetal casingsMetal layered productsEngineeringMetal substrate

The invention discloses a communication equipment metal shell and a preparation method thereof. The communication equipment metal shell comprises a metal substrate, slits and a plastic support layer, wherein the plastic support layer covers at least one part of the inner surface of the metal substrate; the slits run through the metal substrate and do not run through the plastic support layer; and the section shapes of the parts, located on the plastic support layer, of the slits are one or more of an inverted cone, an arc shape, a rectangle and an inverted trapezoid. The slits of the communication equipment metal shell disclosed by the invention do not deform and the communication equipment metal shell has smooth consistency in appearance.

Owner:BYD CO LTD

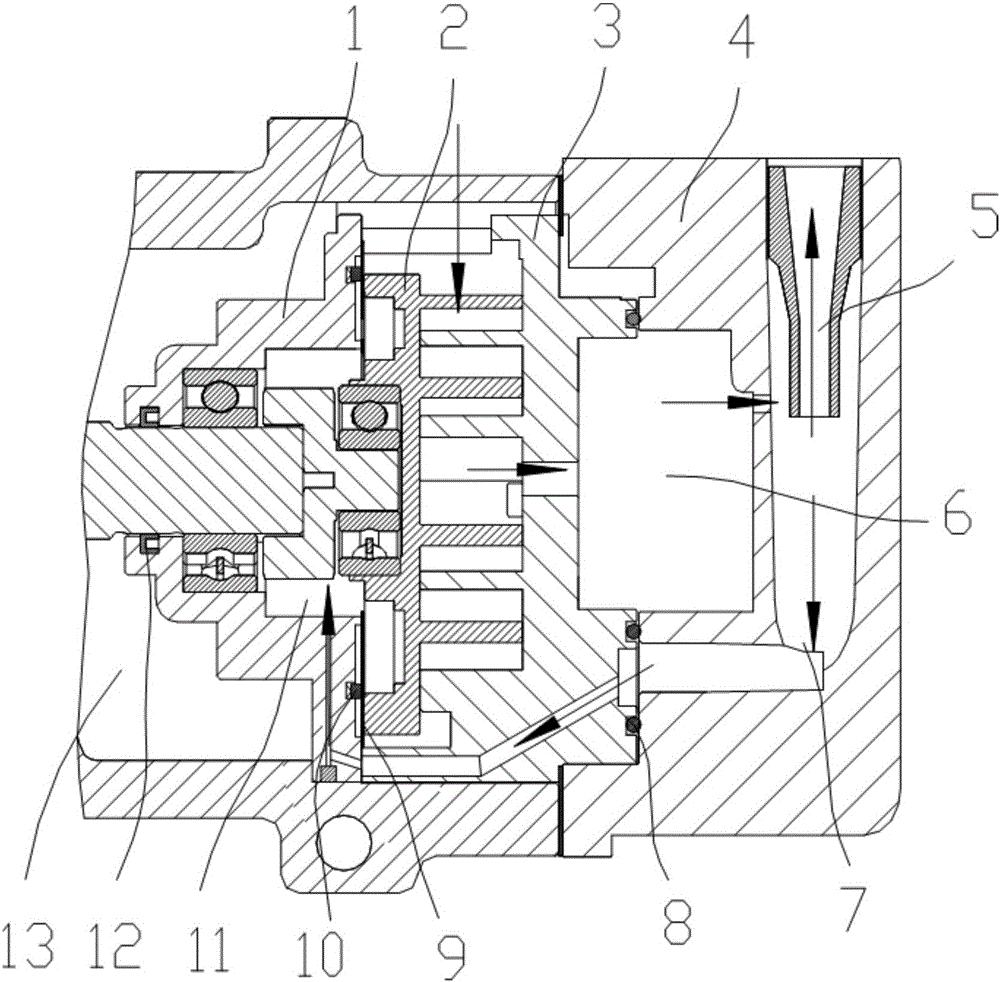

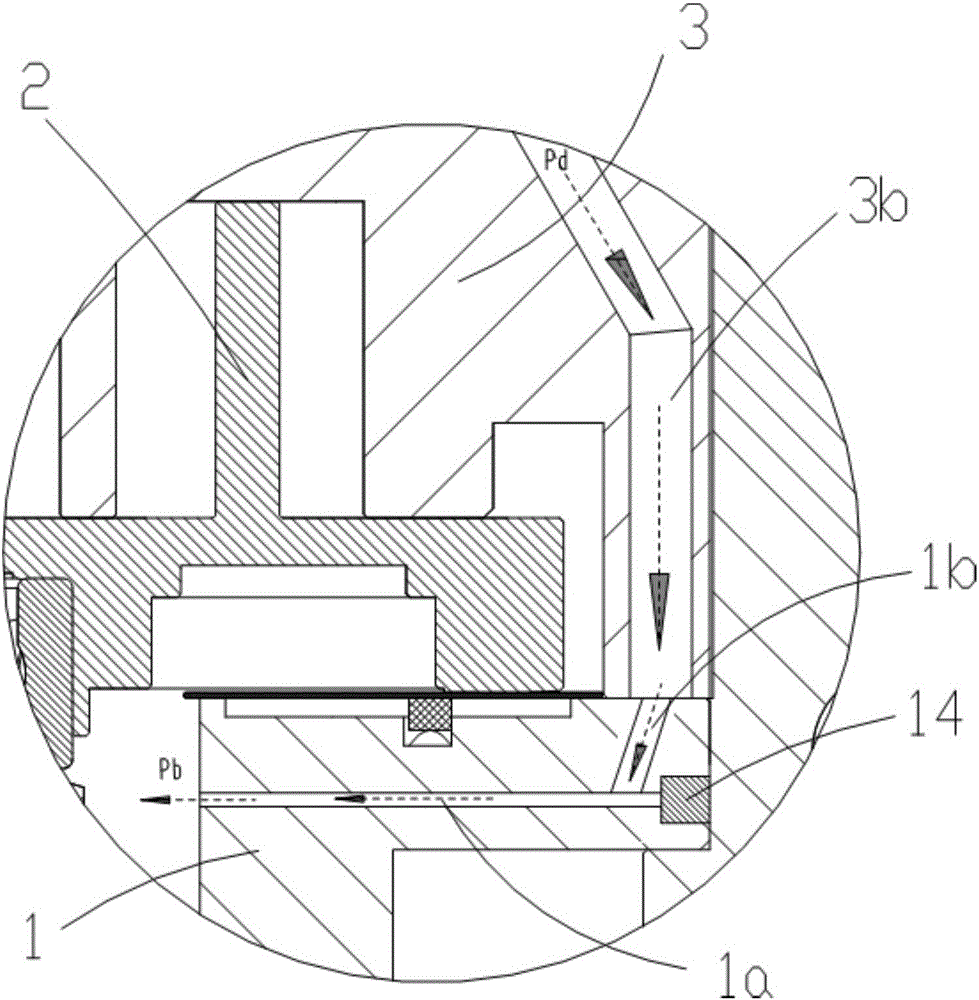

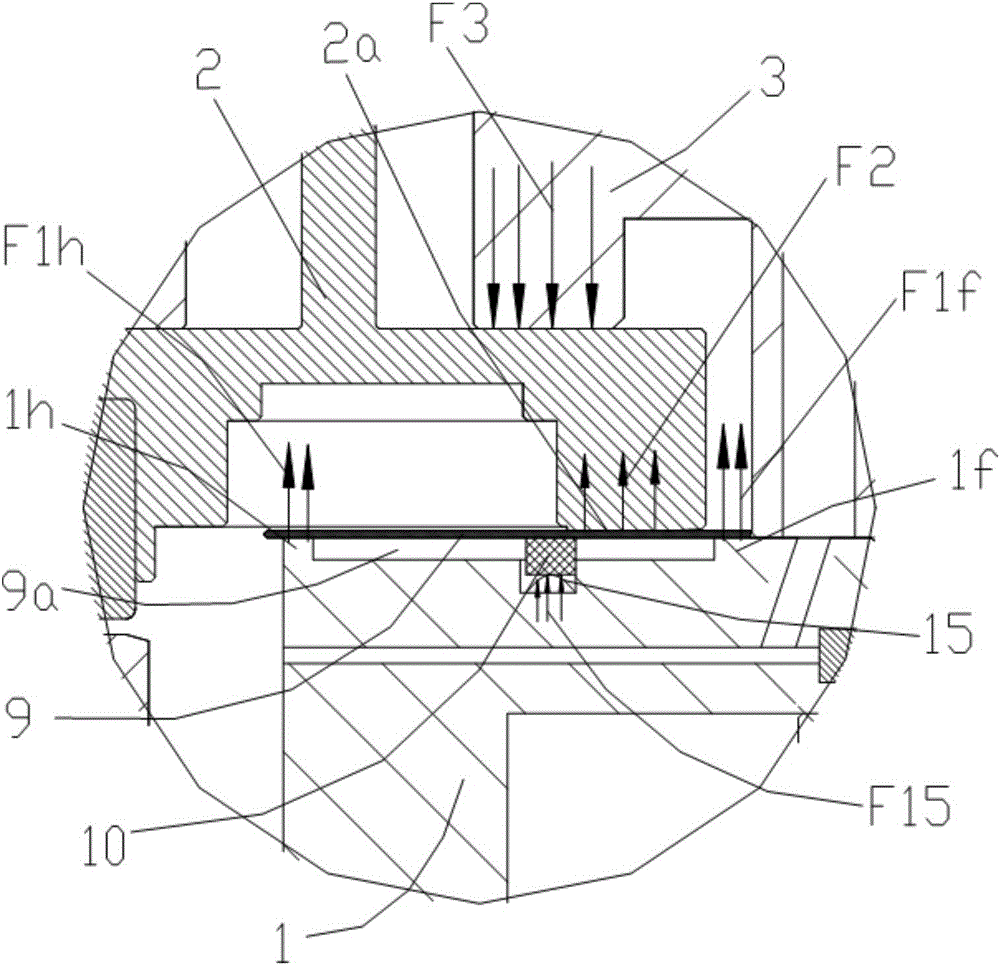

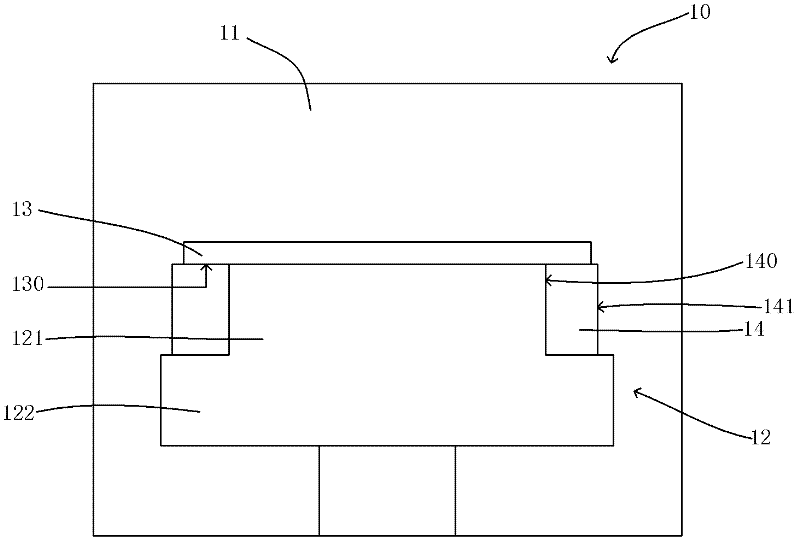

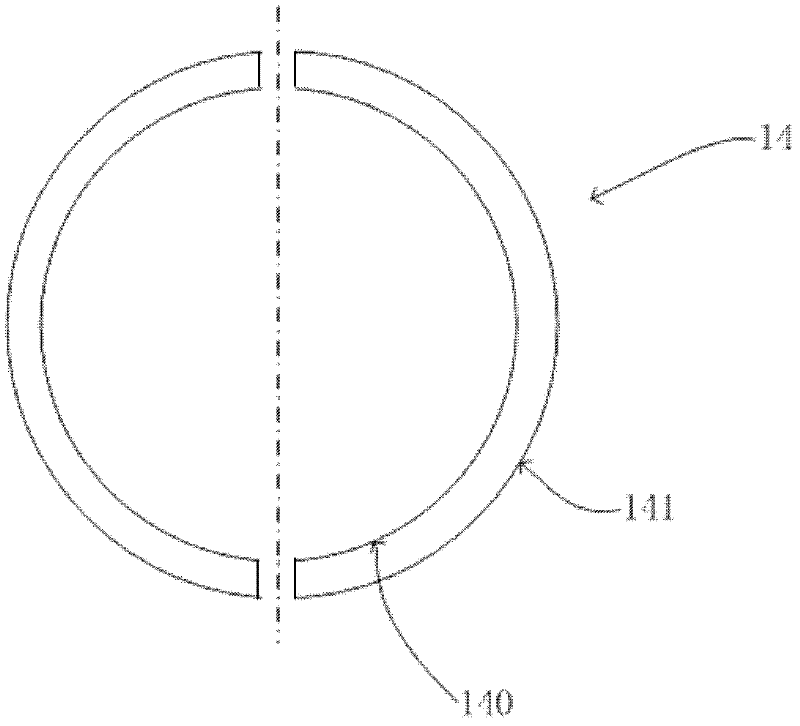

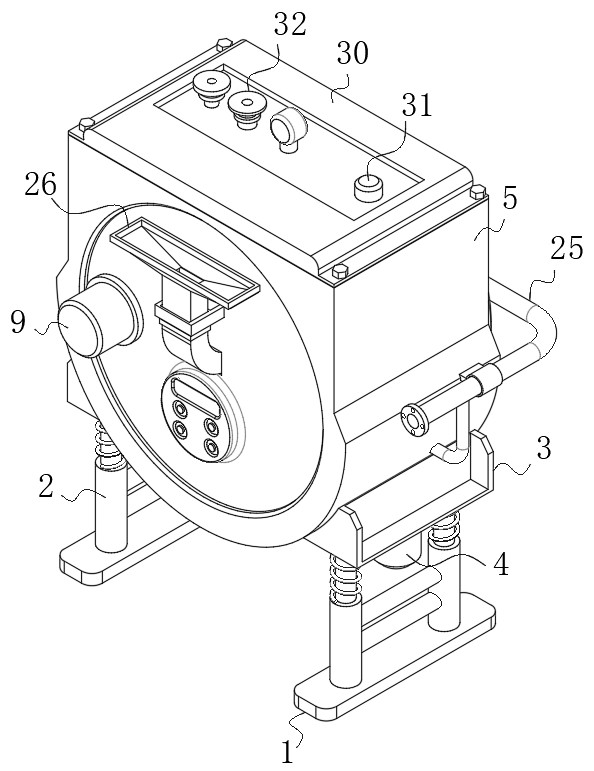

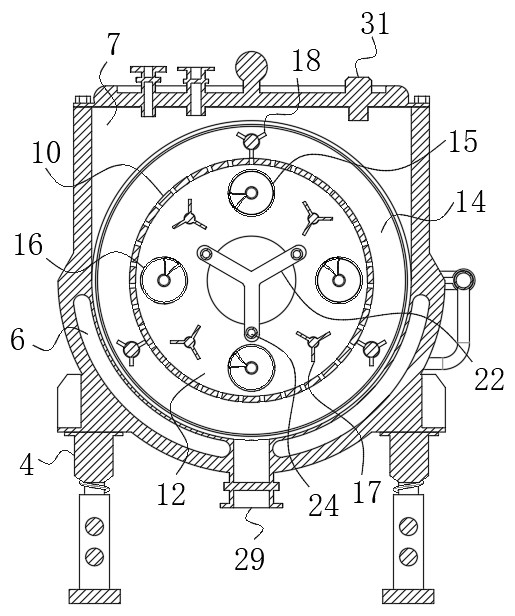

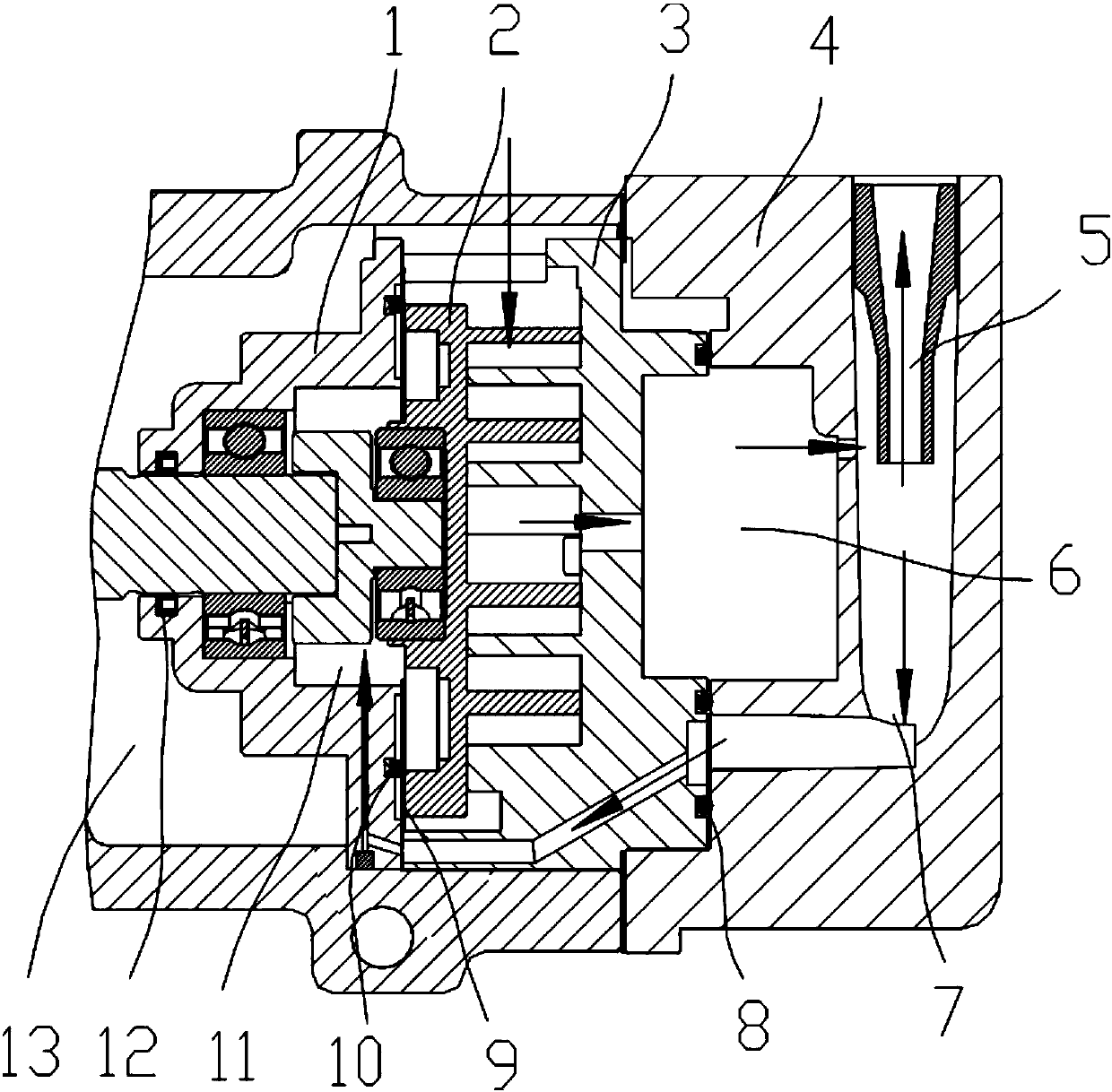

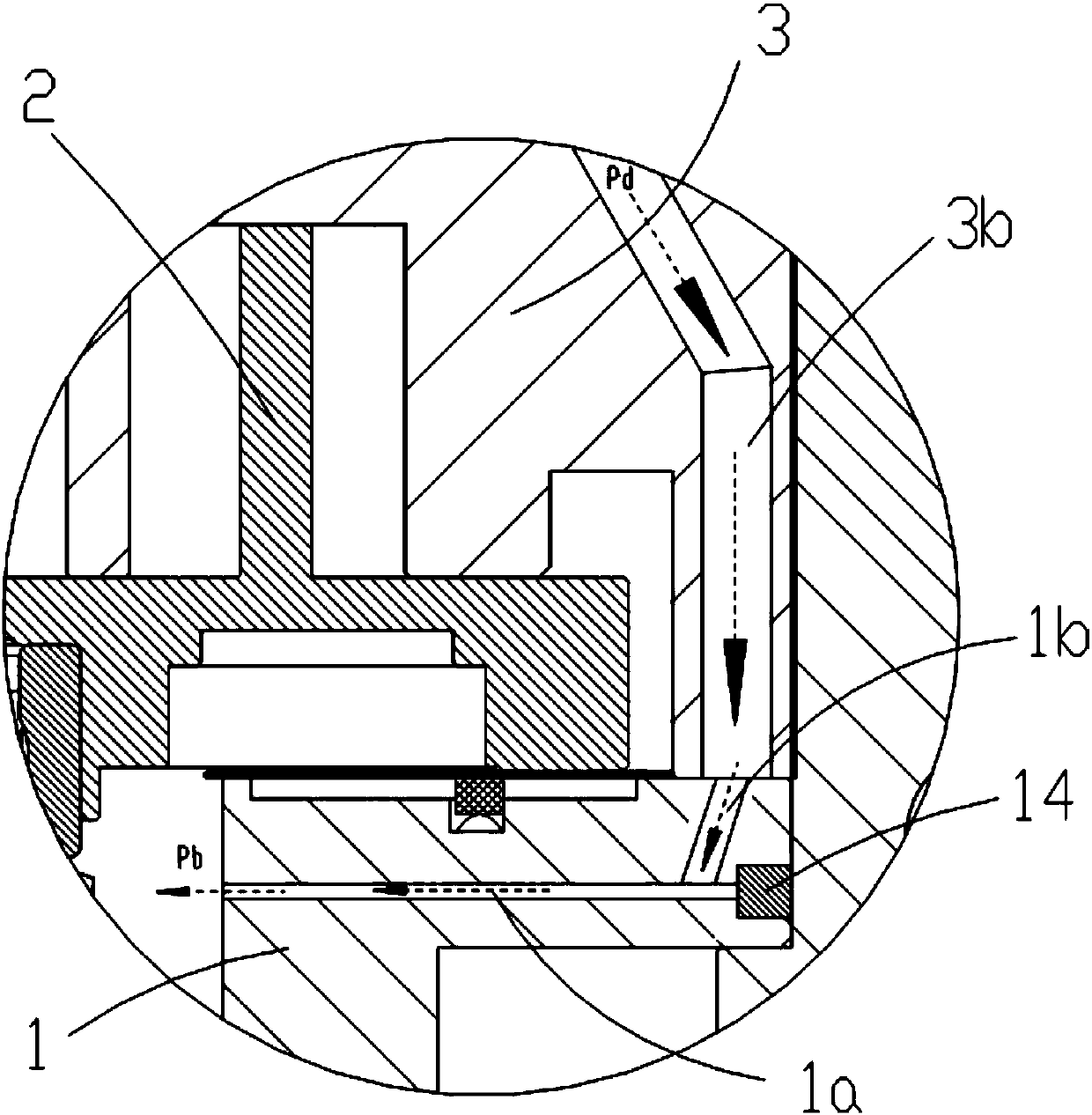

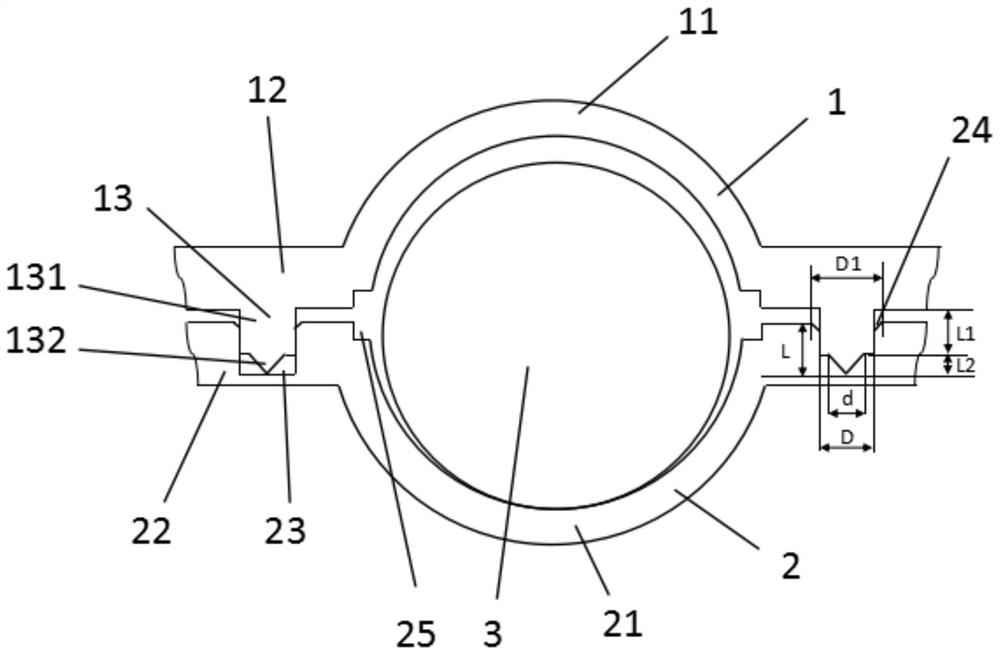

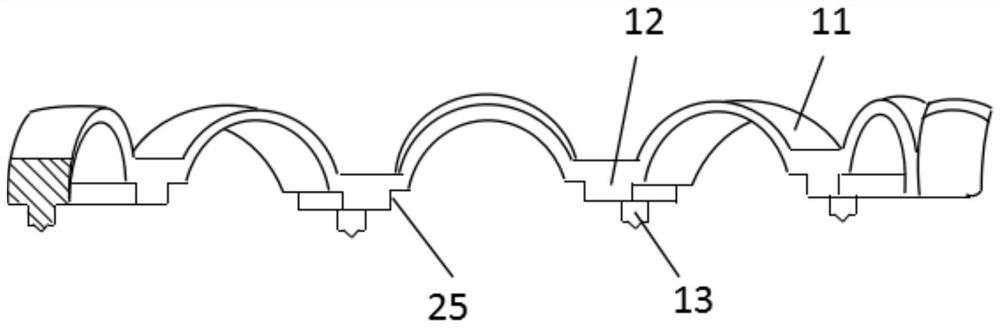

Scroll compressor

ActiveCN105840504AImprove processing strengthIncrease the difficulty of the processRotary piston pumpsRotary piston liquid enginesEngineeringScroll compressor

The invention discloses a scroll compressor. The scroll compressor comprises an upper support and an upper cover, wherein the upper support and the upper cover are connected. A movable scroll plate is arranged in the upper support and in the upper cover. A static scroll plate is coaxially arranged on the side, close to the upper cover, of the movable scroll plate. An elastic circular ring is coaxially arranged on the side, close to the upper support, of the movable scroll plate. The upper support is provided with an inner supporting part and an outer supporting part, wherein the inner supporting part and the outer supporting part are matched with the elastic circular ring. A suspended part is formed between the inner supporting part and the outer supporting part. A back pressure sealing groove is formed in the bottom face of the suspended part. A back pressure sealing ring tightly attached to the elastic circular ring is arranged in the back pressure sealing groove. A back pressure cavity and an air sucking cavity which communicate with the suspended part are formed in the upper support. An exhaust cavity communicating with the back pressure cavity is formed in the upper cover. A compression cavity communicating with the air sucking cavity and the exhaust cavity is formed between the movable scroll plate and the static scroll plate. The scroll compressor is sufficient and reliable in sealing effect, and the technology difficulty of a sealing structure of the scroll compressor is low.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

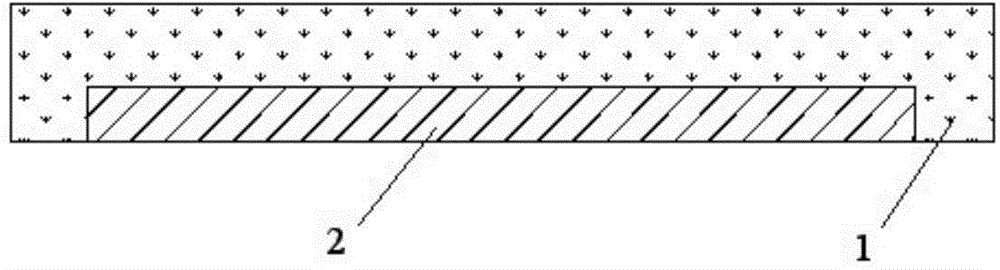

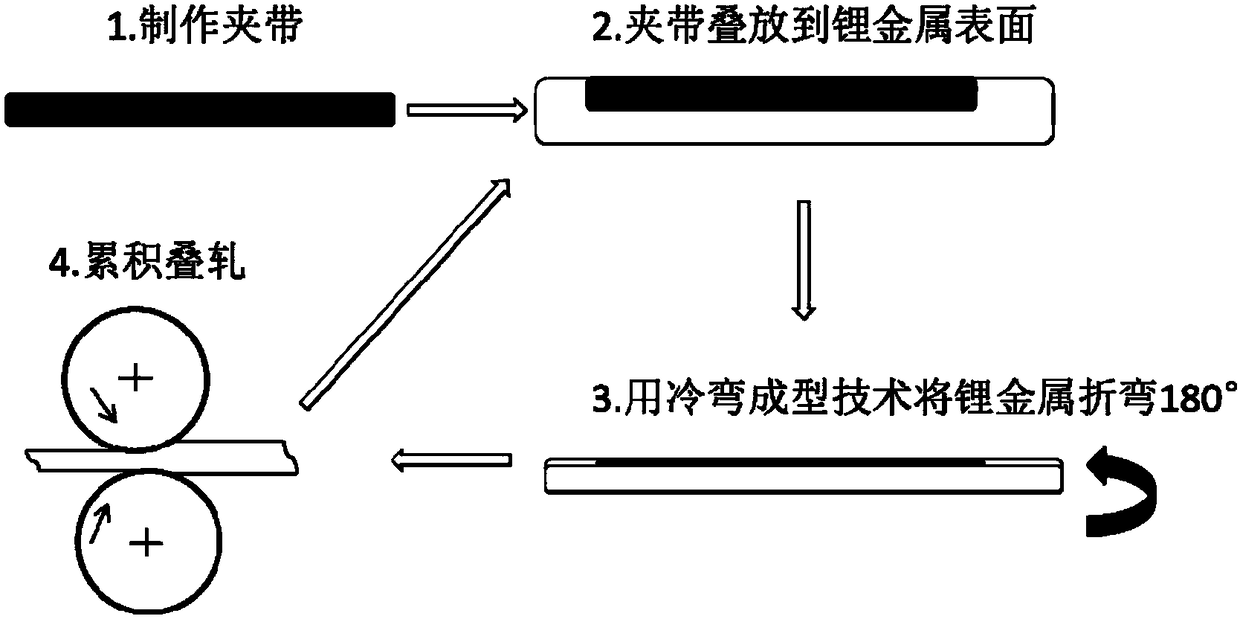

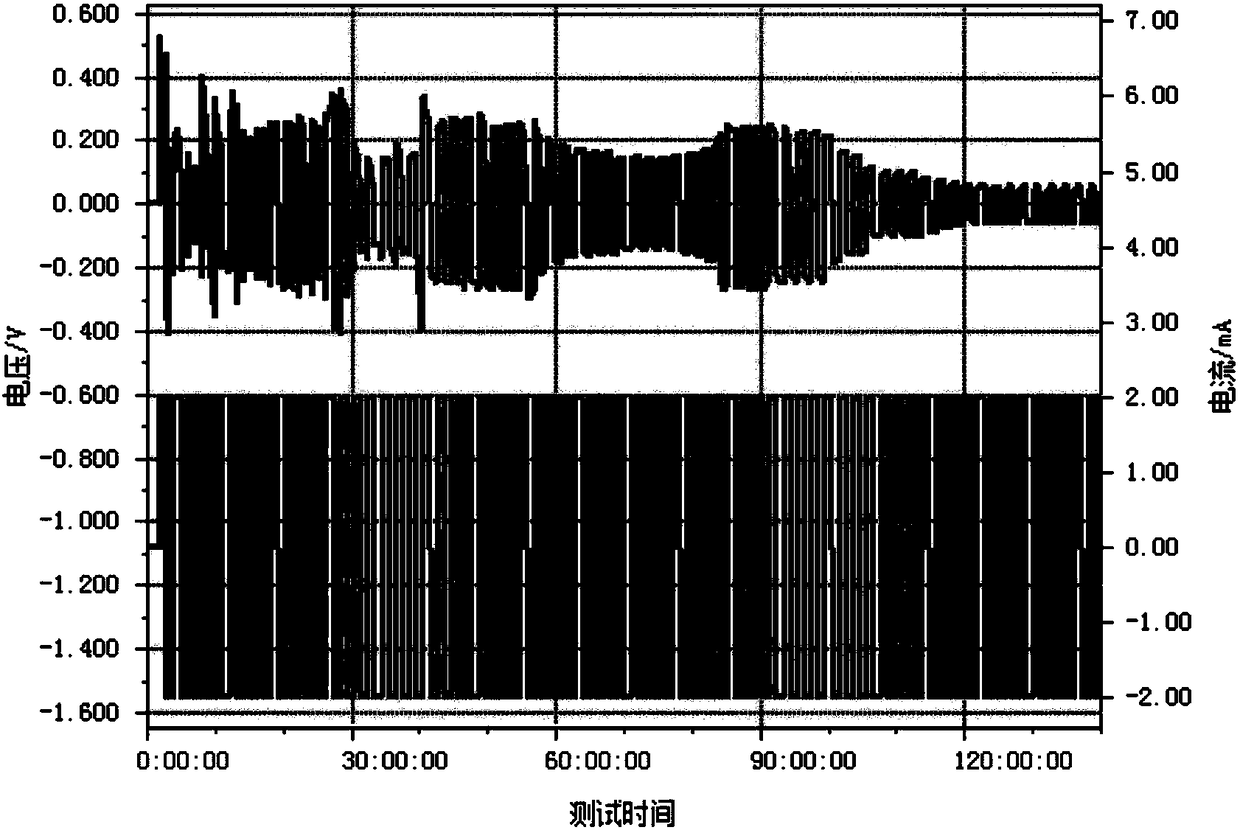

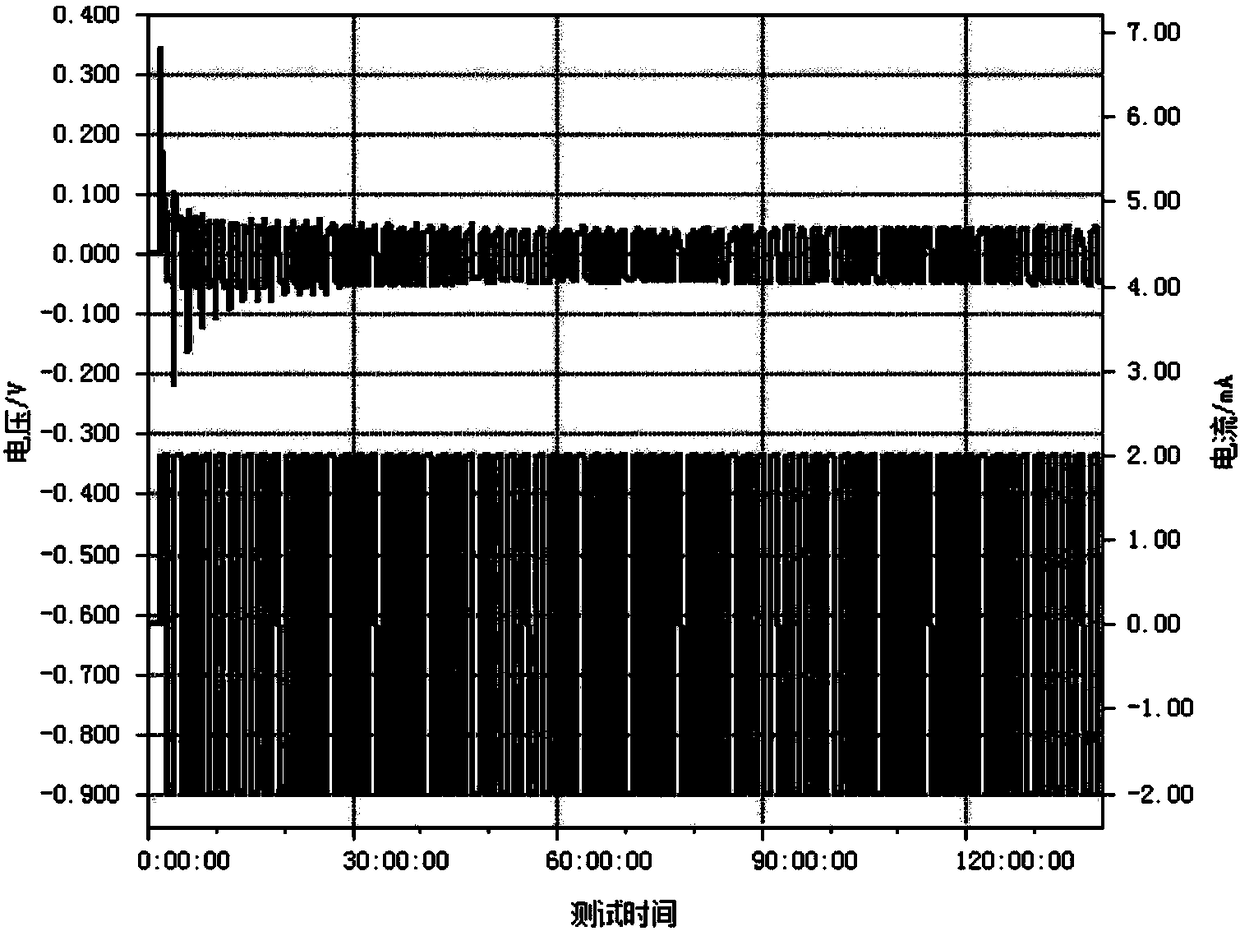

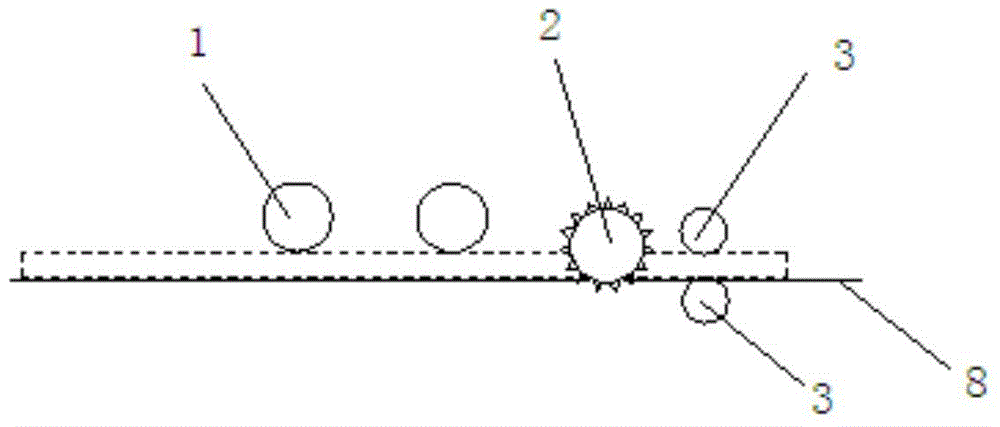

Preparation method of composite metal lithium negative electrode

InactiveCN108598358AEvenly distributedEnsure consistencyElectrode rolling/calenderingSecondary cellsPolymer adhesiveInorganic materials

The invention provides a preparation method of a composite metal lithium negative electrode. The preparation method comprises the steps of pasting an inorganic material with a polymer adhesive to forma layered clamping tape; laying the clamping tape on a surface of lithium metal, bending the lithium metal for 180 degrees in a width direction by a cold roll formation technology to form a lithium / clamping tape / lithium composite structure; and performing rolling, pressing with deformation quantity by 20-50% to obtain a composite material rolled in one time, and repeating the step for 3-20 timesto obtain the composite metal lithium negative electrode material with a multi-layer structure. By the method, the lithium deposition morphology is improved, lithium dendrites growth is suppressed, sothat the cycle property and the safety of the battery are improved, and industrial and continuous production of the composite metal lithium negative electrode can be achieved.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

Hollow spherical carbon nitride coated copper-based fuel cell catalyst and preparation method

InactiveCN108281675AGood effectImprove mechanical propertiesCell electrodesSpherical shapedCopper oxide

The invention relates to the field of preparation of fuel cell catalysts and discloses a hollow spherical carbon nitride coated copper-based fuel cell catalyst and a preparation method. The preparation method comprises the following preparation process: (1) adding copper powder into melamine and carbon tetrachloride; carrying out solvent thermal reaction to prepare spherical graphite-phase carbonnitride coated copper colloid; (2) adding a pore-forming agent and a binding agent into the prepared colloid; after coating an electrode, carrying out heat treatment and annealing to prepare the hollow spherical carbon nitride coated copper-based fuel cell catalyst, wherein the hollow spherical carbon nitride coated copper-based fuel cell catalyst is prepared from the components in parts by weight: 93 to 96 parts of the colloid, 3 to 5 parts of the pore-forming agent and 1 to 2 parts of the binding agent. Compared with a common carbon nitride type catalyst, the fuel cell catalyst provided by the invention has the advantages that copper / copper oxide particles are compounded with carbon nitride, the catalytic activity is good, the mechanical property and processing property are good and theperformance is stable; a porous structure is formed and the specific surface area is large; the hollow spherical carbon nitride coated copper-based fuel cell catalyst has an extremely good applicationprospect in proton exchange membrane fuel cells.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

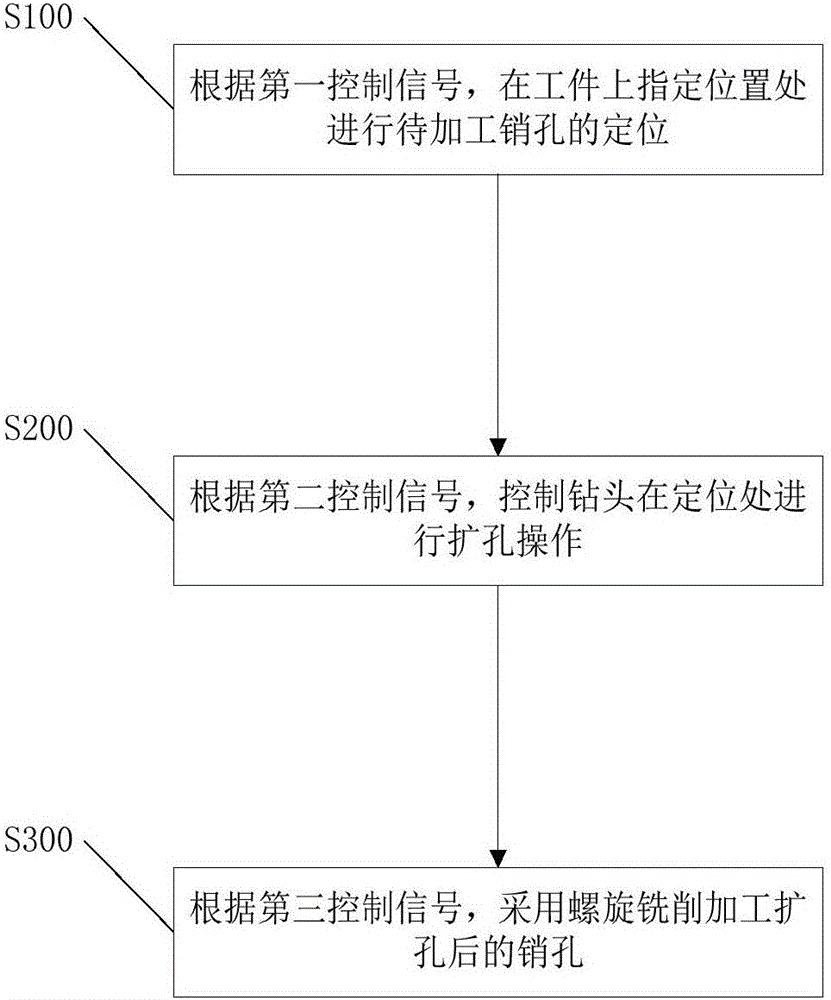

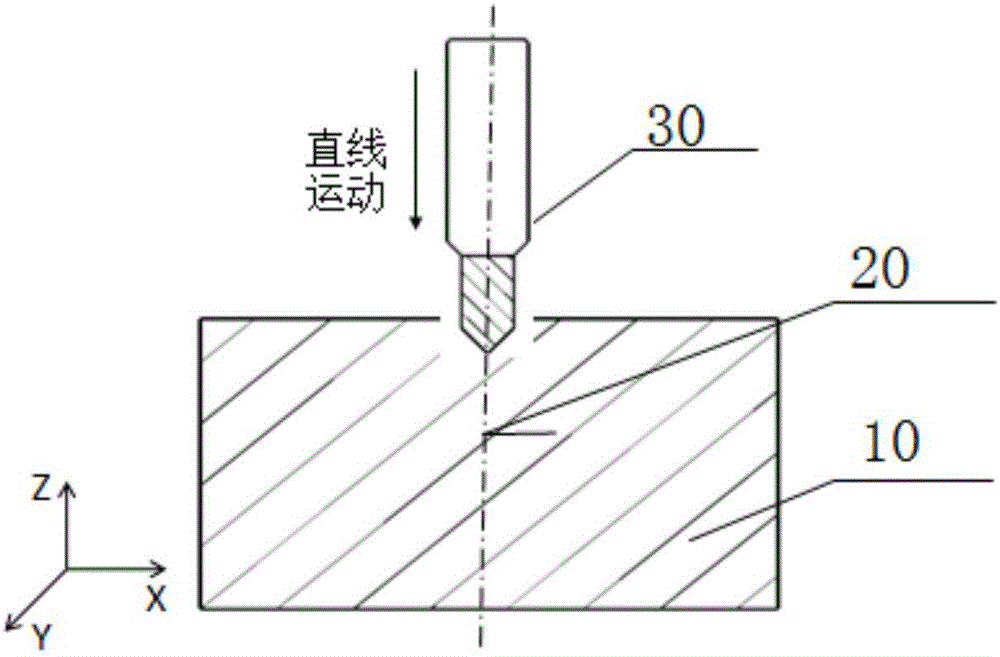

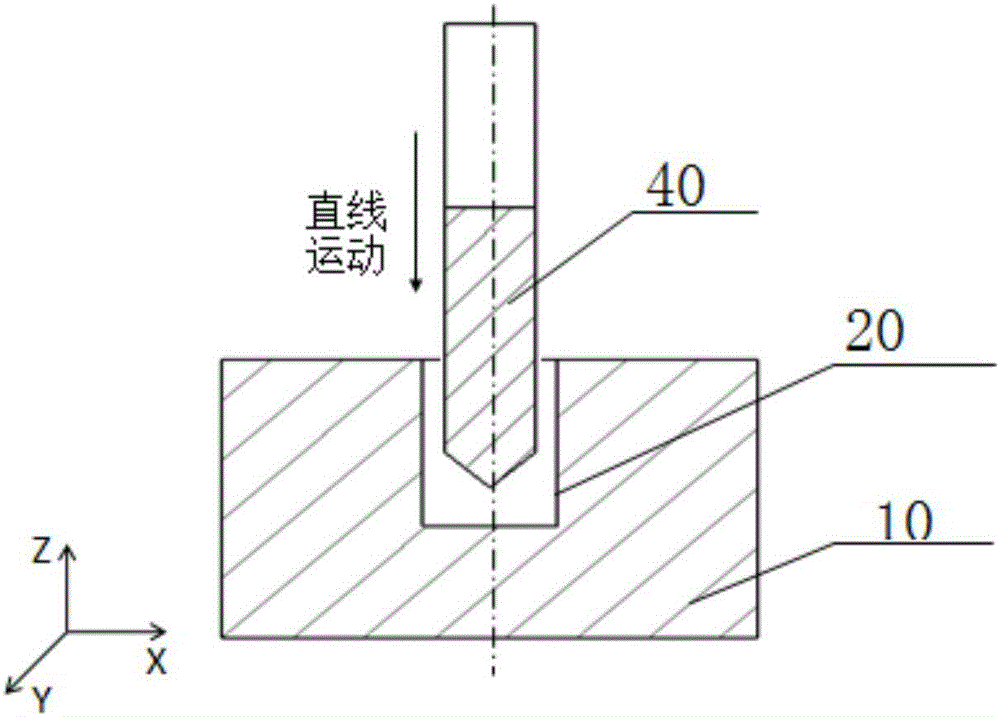

Machining method for small-diameter positioning pin hole

InactiveCN106584030AImprove processing qualityImprove processing strengthBoring/drilling machinesProcessing accuracyDrill bit

The invention relates to a machining method for a small-diameter positioning pin hole. The machining method comprises the following steps that according to a first control signal, a pin hole to be machined is positioned in the designated position of a workpiece; according to a second control signal, a drill bit is controlled to carry out reaming operation at the positioning position; and according to a third control signal, the reamed pin hole is machined through helical milling. According to the technical scheme, the machining quality and strength of the pin hole are effectively improved, machining precision is improved, and meanwhile the surface roughness of the pin hole is effectively reduced.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Machining process of small transmission gear shaft of full-automatic roller washing machine

InactiveCN102922246AMeet the continuityImprove machining accuracyMetal-working apparatusMachining processForging

The invention discloses a machining process of a small transmission gear shaft of a full-automatic roller washing machine; in the machining process, through once cold forging pre-forming and once cold forging gear extrusion, the continuity of gear forms at two ends of the small gear shaft can be very well satisfied and the machining precision and strength of a product are enhanced, so that the service life of the product is prolonged; moreover, material usage can be also reduced, the efficiency is increased and the cost is reduced.

Owner:SHANGHAI DONGFU COLD FORGING MFG

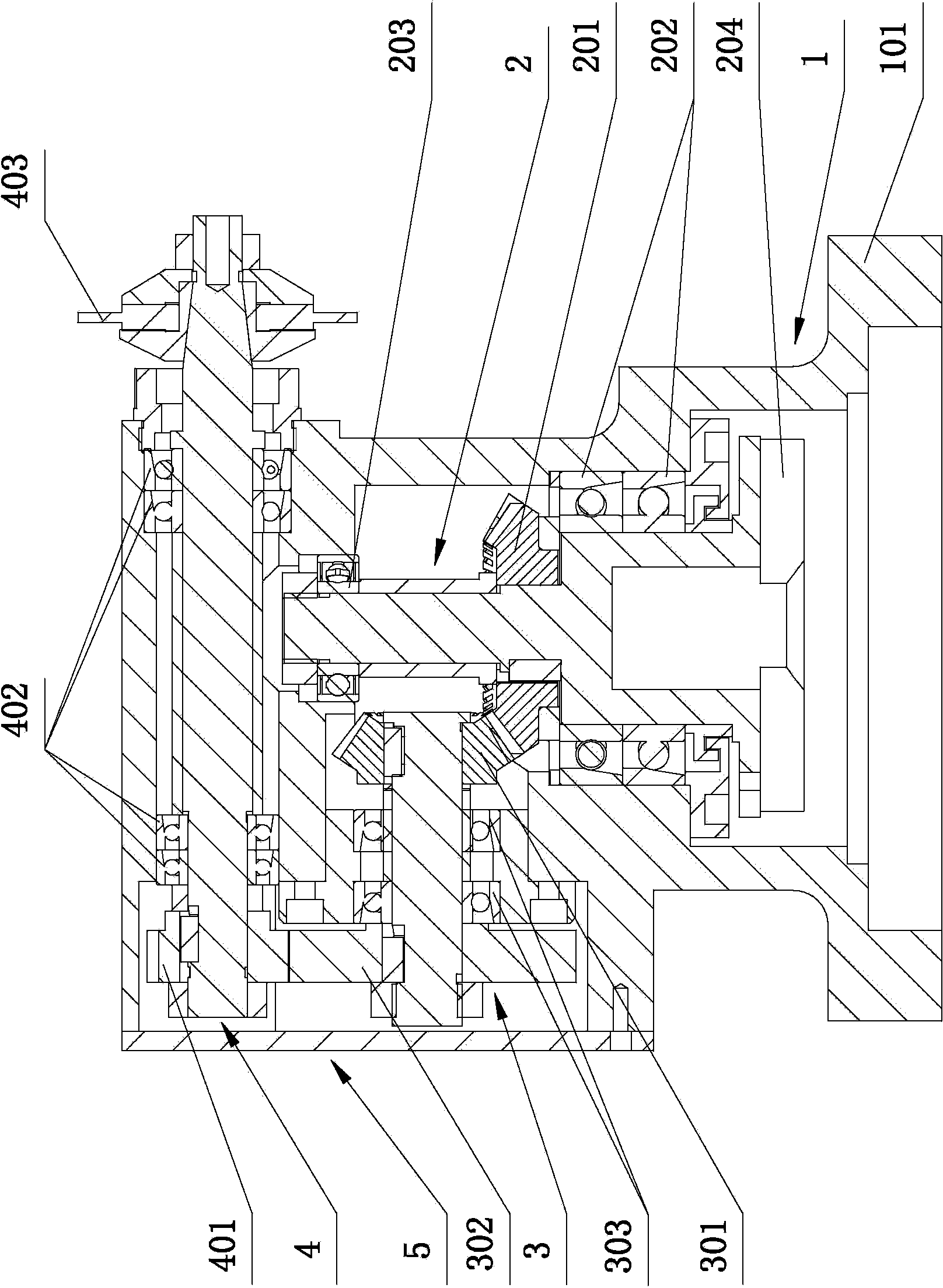

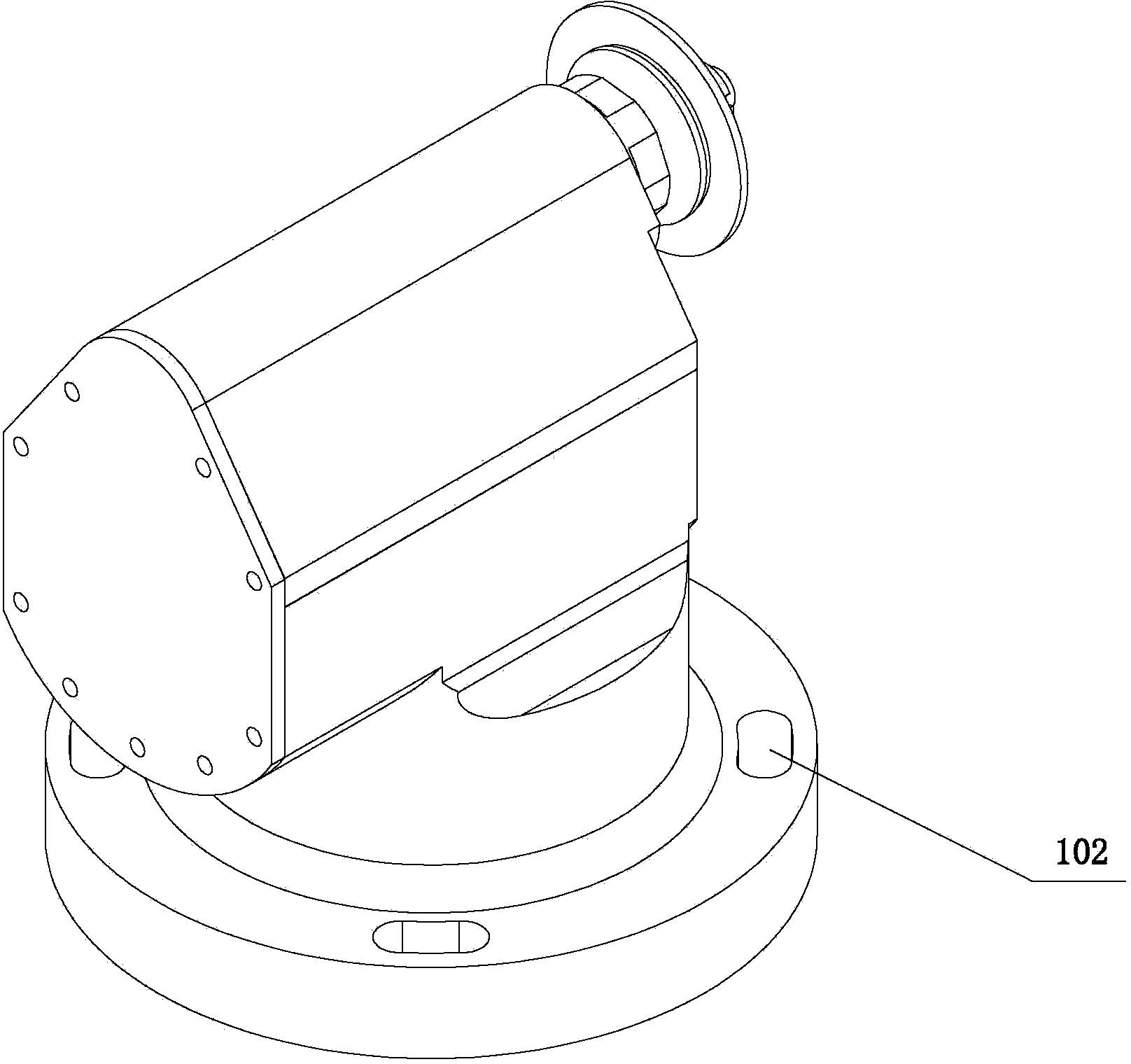

Saw blade right-angle head

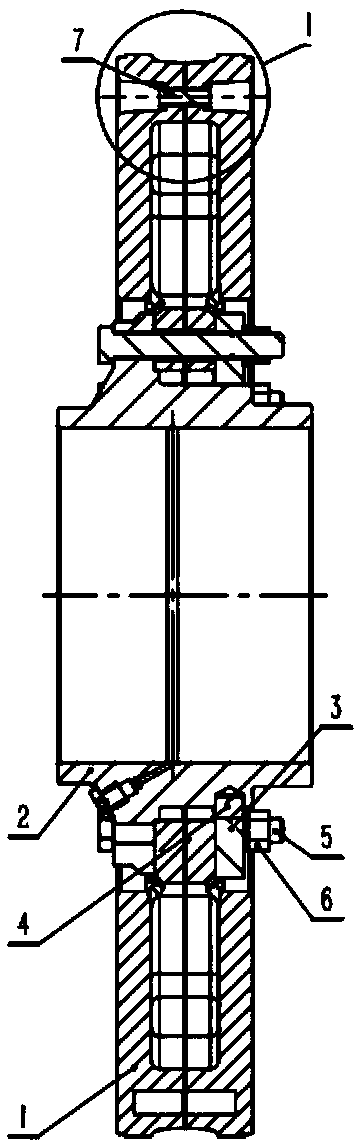

InactiveCN103506695ASmall heightImprove processing strengthMetal sawing accessoriesPositioning apparatusBall bearingDrive shaft

A saw blade right-angle head comprises an angle head body, a driving shaft, a driven shaft, a saw blade shaft and an end cover, wherein the driven shaft is arranged on the lower portion of the angle head body, the driving shaft is perpendicular to the driven shaft, and the driven shaft is parallel with the saw blade shaft; an angle gear of the driving shaft is matched with an angle gear assembled on the driven shaft, a straight gear of the driven shaft is matched with a straight gear of the saw blade shaft, the gravity center of the angle head body is inclined downwards, and kidney-shaped holes are formed in a base plate flange of the angle head body. An angular contact ball bearing and a deep groove ball bearing are arranged on the driving shaft, angular contact ball bearings are arranged on the driven shaft, the angular contact ball bearings of the driven shaft are arranged at certain intervals, and two angular contact ball bearings are arranged on the saw blade shaft. A key groove is formed in the bottom of the driving shaft and matched with a transmission key block of the driving shaft. The kidney-shaped holes are evenly distributed in the circumferential direction with the driving shaft as a center line. According to the saw blade right-angle head, the angle head body and the driving shaft are directly installed, the angle head is directly installed on a lathe, and the position of the angle head is adjusted through the kidney-shaped holes. The angle head can save assembling and replacing time and guarantee assembling accuracy.

Owner:佛山市永信模具有限公司

Low-loss high-strength microwave medium ceramic and preparing method thereof

The invention discloses low-loss high-strength microwave medium ceramic. The composition expression of the ceramic is xCaTiO3-ySmAlO3-(1-x-y)CaSmAlTiO6, wherein x, y and (1-x-y) each represent a molarratio, x is 0.6, y is larger than or equal to 0 and smaller than 0.4. The invention further discloses a preparing method of the low-loss high-strength microwave medium ceramic. In the microwave medium ceramic, SmAlO3 is partly or overall replaced with CaSmAlTiO6, and therefore the dielectric constant can be reduced, and the temperature stability can be improved; by increasing the sintering temperature, the processing intensity of the ceramic is increased; the CaSmAlTiO6 and the SmAlO3 have the similar dielectric constants, but the CaSmAlTiO6 has the resonant frequency temperature coefficientcloser to zero and the higher hardness, so the high-hardness ceramic material with the dielectric constant of about 35, the low loss and the resonant frequency temperature coefficient close to zero can be obtained by partly or overall replacing the SmAlO3 with the CaSmAlTiO6 and adjusting the ratio of the components.

Owner:无锡鑫圣慧龙纳米陶瓷技术有限公司

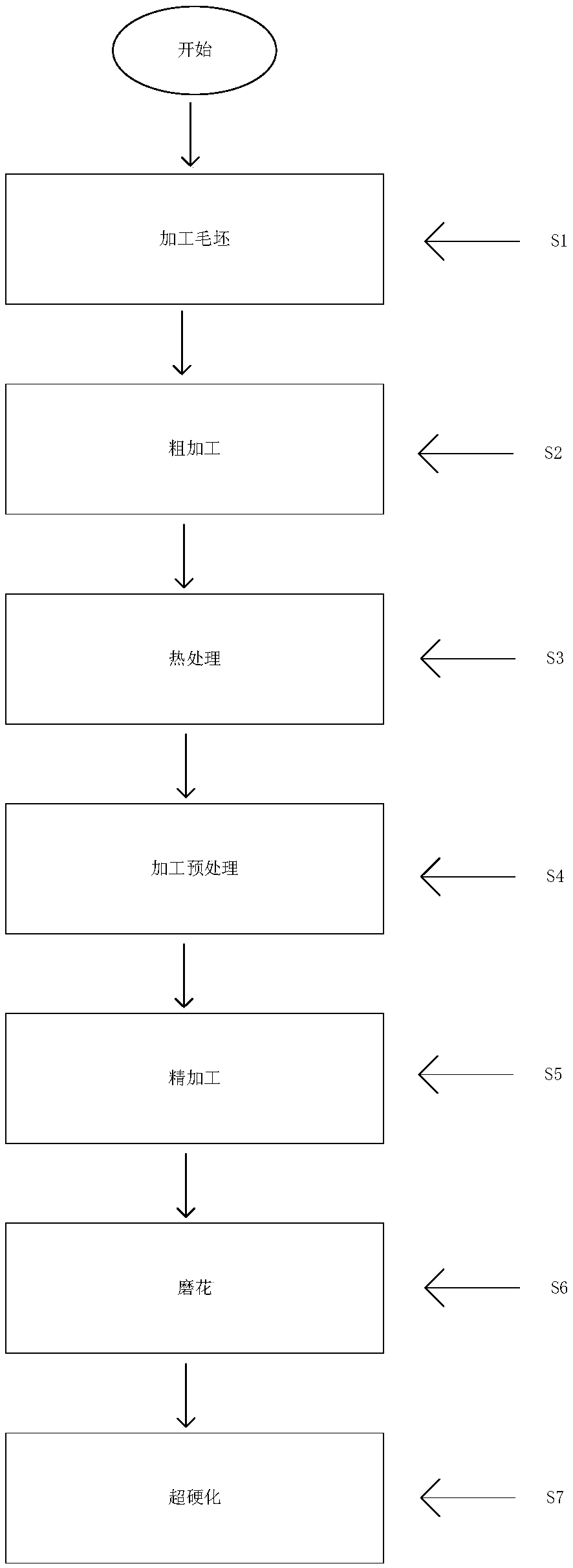

Mould machining process

InactiveCN108637616AImprove performanceImprove processing strengthThermal treatmentMachining process

The invention discloses a mould machining process. The mould machining process comprises the following steps of: blank machining; rough machining, thermal treatment; pretreatment of machining; fine machining; buffing; and hardening. According to the mould machining process, the traditional mould machining process is improved, thermal treatment is imported to improve the performance during blank machining, and hardening is imported to improve the later blank machining strength, so that moulds can be applied in a plurality of different fields through one process; and the mould machining processhas the advantages of being low in cost, short in working procedure time length and wide in application range.

Owner:无锡智高点技术研发有限公司

Plasma processing apparatus and protection ring thereof

InactiveCN102368467AFlexible size adjustmentImprove processing strengthElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProtection ring

The invention provides a plasma processing apparatus and a protection ring thereof. The plasma processing apparatus comprises the following parts: a processing cavity; a static sucker which is placed in the processing cavity and is applied to adsorb a wafer; a hollow protection ring which is provided on the static sucker in a mode of encircling the static sucker and supports the wafer with the static sucker together. The protection ring is provided on the static sucker and supports a wafer to be processed with the static sucker together. In a process of carrying out plasma processing on the wafer, a wafer back side pollution problem can be improved, and processing strength of the wafer can be increased. A dimension of the protection ring can be flexibly adjusted according to a diameter dimension of the wafer to be processed, and a same plasma processing apparatus can carry out plasma processing on wafers with a plurality of specification dimensions.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Cast-in excircleself-locking thread air cylinder sleeve and manufacturing technology thereof

InactiveCN109306915AImprove bindingImprove machining accuracyCylinder headsFoundry mouldsManufacturing technologySelf locking

Owner:ZYNP GRP ANHUI CO LTD

Urine detection test paper for reflecting human fatigue degree, and preparation method thereof

InactiveCN107340290AEasy to operateFast detection operationMaterial analysis by observing effect on chemical indicatorBiological testingComposite filmFiltration

The invention relates to the technical field of medical detection, particularly to a urine detection test paper for reflecting the human fatigue degree, and a preparation method thereof, wherein the urine detection test paper contains thiol protease, sodium dihydrogen phosphate, water-soluble polythiophene, chloroauric acid tetrahydrate, sodium hydroxide and polyvinyl alcohol, and the surface of the urine detection test paper is coated with a chitosan / titanium dioxide composite film. The preparation method comprises: immersing filtration paper in the mixed solution of a solution A and a solution B, and covering the surface of the filtration paper with a chitosan / titanium dioxide composite film, wherein the solution A contains water-soluble polythiophene, chloroauric acid tetrahydrate, sodium dihydrogen phosphate and sodium hydroxide, and the solution B contains polyvinyl alcohol and thiol protease. According to the present invention, the prepared urine detection test paper has advantages of strong hydrophilicity, convenient operation and high detection sensitivity, and can adsorb and permeate urine protein.

Owner:ARMY MEDICAL UNIV

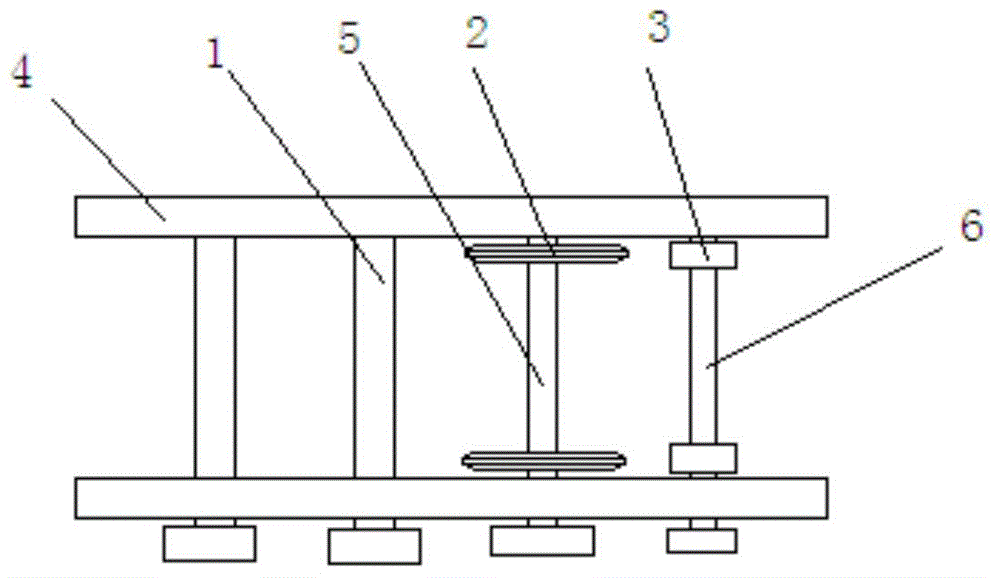

Fluoroplastic product calender

InactiveCN108724577APrevent delays in work efficiencyEmbody efficiencyMetal working apparatusMechanical engineeringElectric furnaces

The invention discloses a fluoroplastic product calender. The fluoroplastic product calender comprises a device main body, a heating electric furnace and a conveying device. The bottom end of the device main body is fixedly connected with a working platform, the middle part of the working platform is fixedly connected with a cutting device, the middle part of the working platform is tightly weldedwith a flattening wheel lifting column. The flattening wheel lifting column can adjust the height of a flattening wheel well, thereby changing the thickness of a rolled plastic product. By pressing an adjusting button, the flattening wheel can be raised and lowered, thereby changing the thickness of the rolled plastic product. The conveying device can transport the rolled plastic product to a safe position to avoid the collision between the rolled plastic product and a newly processed plastic product, thereby reflecting the safety of the plastic product calender. A transmission wheel can provide power to transport the rolled fluoroplastic product to a carrying area, embodying the high efficiency of the device, and is suitable for the use of the fluoroplastic product calender. The fluoroplastic product calender has broad development prospects in the future.

Owner:湖州博创氟材科技有限公司

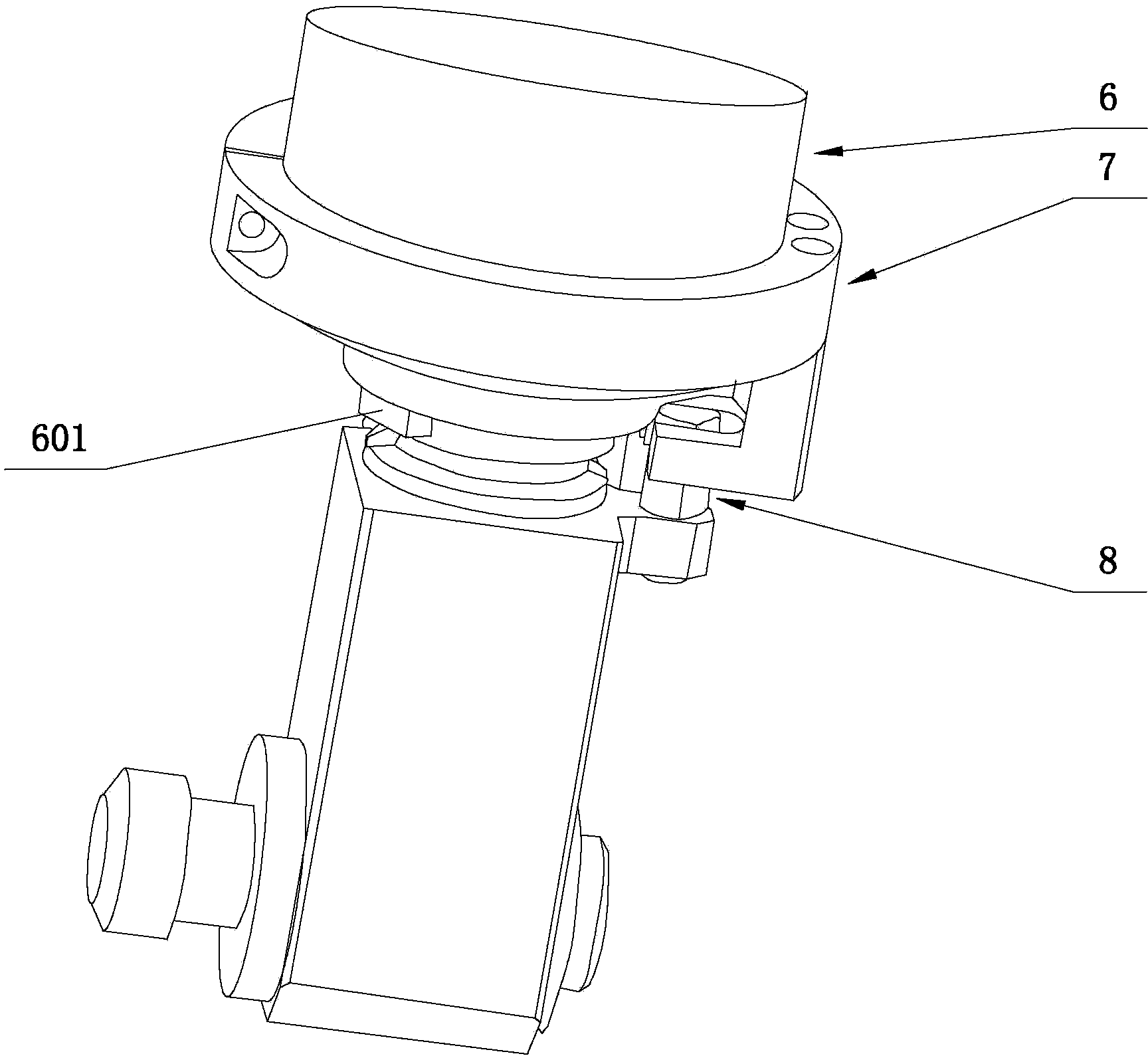

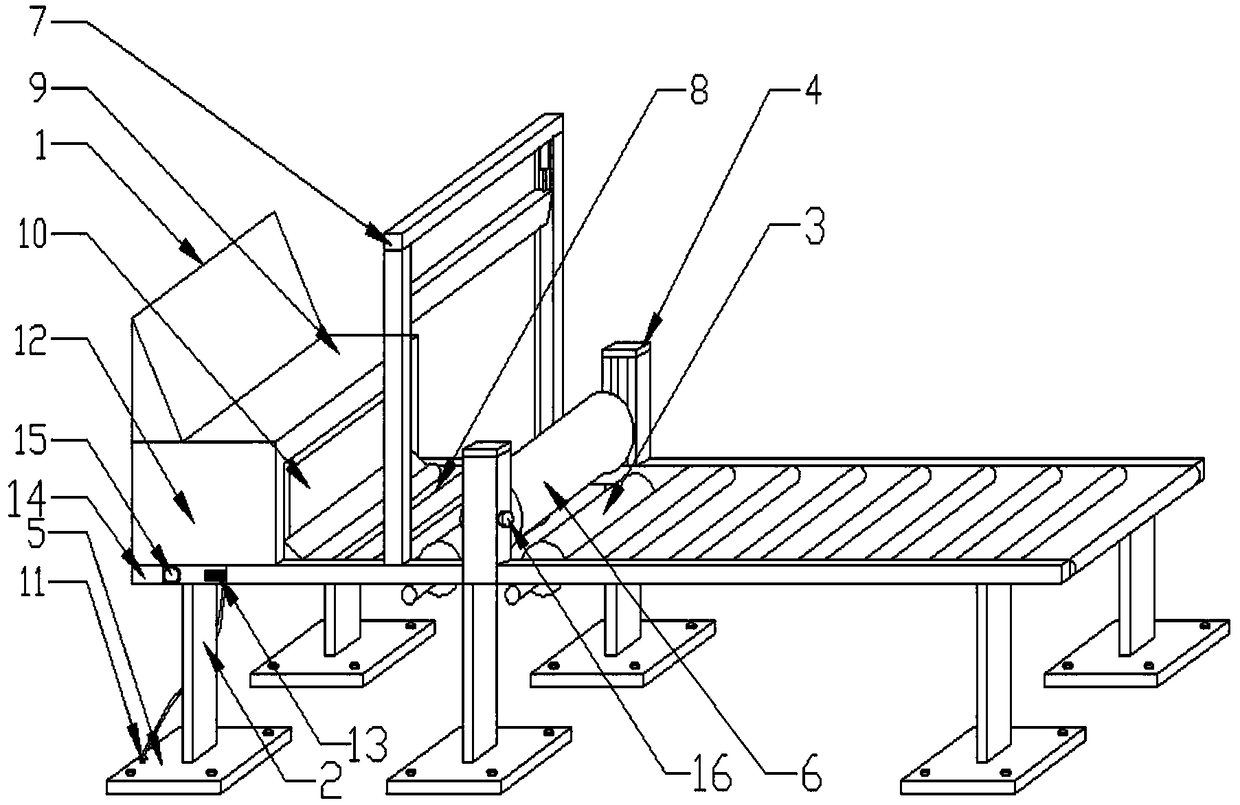

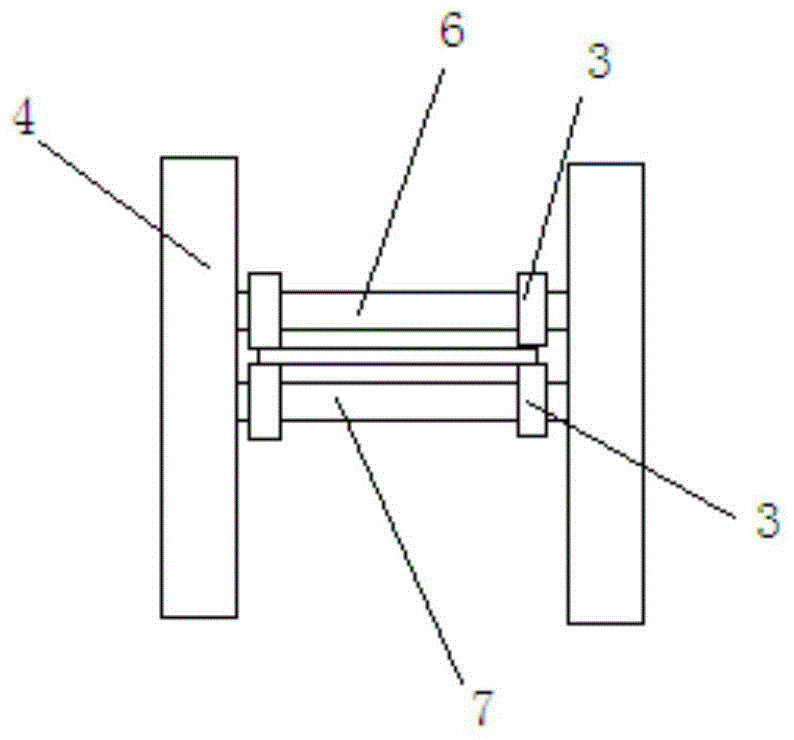

Full-automatic one-time milling device for diesel engine body

PendingCN113510282AImprove machining accuracy and strengthExtended service lifeCasingsMachines/enginesManufacturing engineeringDiesel engine

The invention discloses a full-automatic one-time milling device for a diesel engine body. The full-automatic one-time milling device comprises a base and a workbench, wherein the workbench is arranged in front of the base through a guide rail assembly, a machine body clamp is arranged on the workbench, the workbench is connected with a movable power source through a transmission assembly, milling power sources are arranged on two sides of the base and are connected with a milling rotating shaft, a plurality of milling cutters are arranged on the milling rotating shaft, the milling cutter comprises a large disc milling cutter and a small disc milling cutter, and the small disc milling cutter is positioned at the outer end part of the milling rotating shaft. According to the full-automatic one-time milling device, one-time synchronous milling finish machining is carried out on the multiple bearing seat assembly steps of a diesel engine body through the multiple milling cutters, and the machining precision and strength of the bearing seat assembly steps are improved; and the machining efficiency is high, the automation degree is high, the uniformity of machining quality is effectively guaranteed, and the overall quality of the diesel engine body is improved; and therefore, the engine runs more stably and reliably.

Owner:浙江东新卡特科技有限公司

Three-dimensional polymer and preparation method thereof

ActiveCN112537793AImprove processing strengthImprove processing efficiencyShaking/oscillating/vibrating mixersTransportation and packagingPolymer sciencePolymer

The invention discloses a three-dimensional polymer and a preparation method thereof, belonging to the technical field of inorganic chemistry. The three-dimensional polymer disclosed in the inventionhas a chemical formula of C30H22N4O8Cu2, and belongs to a monoclinic system. The invention discloses the preparation method for the three-dimensional polymer. According to the invention, through the design of a first stirring module, a second stirring module, a third stirring module and a fourth stirring module in a material mixing assembly, the single-mode stirring effect of traditional preparation equipment is changed into multi-mode stirring effect, and during stirring, the multiple stirring effects can be repeatedly and circularly carried out.

Owner:上海万狮环保科技有限公司

Edge trimming device for steel plate

InactiveCN105107905AGuaranteed process requirementsSimple structureEngineeringMechanical engineering

The invention provides an edge trimming device for a steel plate. The edge trimming device comprises a support and a workbench. A conveying mechanism, an edge cutting mechanism and a deburring mechanism are arranged on the support. The conveying mechanism is arranged on the workbench. The edge cutting mechanism comprises a first rotation shaft arranged in parallel to conveying rollers and two cutter discs. The deburring mechanism comprises a second rotation shaft and a third rotation shaft in parallel to the second rotation shaft. The second rotation shaft and the third rotation shaft are disposed on the two sides of the workbench respectively, and the two ends of the second rotation shaft and the two ends of the third rotation shaft are each provided with a deburring element. According to the edge trimming device for the steel plate, the structure is simple, and the operation is convenient; irregular edges of the steel plate are cut off rapidly through the cutter discs, burrs produced during cutting are removed through the deburring mechanism at the same time, and deburring and cutting are completed simultaneously; the process requirement of the steel plate is met, and the work efficiency is improved.

Owner:金迈思(天津)建筑工程技术有限公司

High-temperature lead-free solder wire and preparation method thereof

ActiveCN113441870AIncrease roughnessPrevent slidingWelding/cutting media/materialsSoldering mediaAlloySoldering

The invention relates to the field of brazing technologies, in particular to a high-temperature lead-free solder wire and a preparation method thereof. The problems that a lead-free solder wire is thin and soft, and is likely to slip when a worker holds the solder wire for soldering, and consequently the soldering efficiency of a workpiece is reduced are solved. The high-temperature lead-free solder wire comprises a shell made of tin alloy and an inner core made of soldering flux; and a plurality of spiral grooves are formed in the outer wall of the shell, and an anti-skid piece is arranged on the outer wall of the shell. The high-temperature lead-free solder wire has the advantages that the probability that the solder wire slips during soldering of workers is reduced, and the soldering efficiency is improved.

Owner:YIK SHING TAT SOLDER MFR KUNSHAN

Split knotter

The invention relates to a split knotter which belongs to the field of agricultural mechanical equipment. A drive shaft is installed in a shaft hole I of a main installation frame; a rope clamping drive mechanism and a split drive disk mechanism are coaxially installed at both ends of the drive shaft; a cam swinging rod is installed on a shaft hole III of the main installation frame, and the cam swinging rod and the split drive disk mechanism form a cam mechanism; the rope clamping mechanism and a rope clamping right helical gear are coaxial and are installed on a shaft hole V of the main installation frame; a rope clamping left helical gear is installed on a shaft hole VI of the main installation frame; an olecranon intermittent gear and an olecranon tongue are axially connected with an olecranon shaft respectively and installed on a shaft hole II of the main installation frame; and the olecranon tongue and the main installation frame form a small cam mechanism. Key mechanisms of theinvention are formed by combining split parts, thereby reducing the processing deformation of integrated parts and the manufacture and maintenance cost of a press baler, being beneficial to the adjustment of relative positions during assembly, overcoming the defect of replacing the whole part due to the damage of a structure, prolonging the service life of the knotter and enhancing the processingstrength of the parts.

Owner:CHINA AGRI UNIV

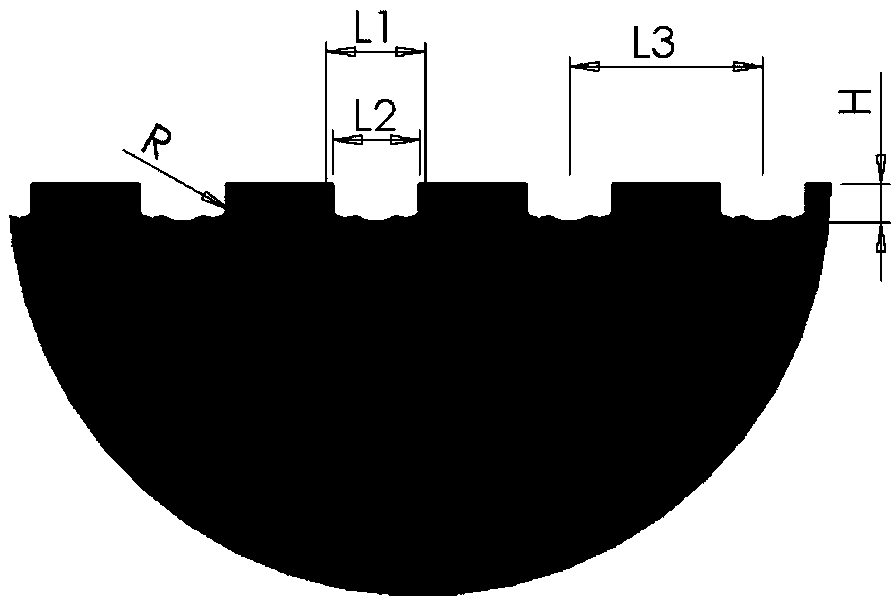

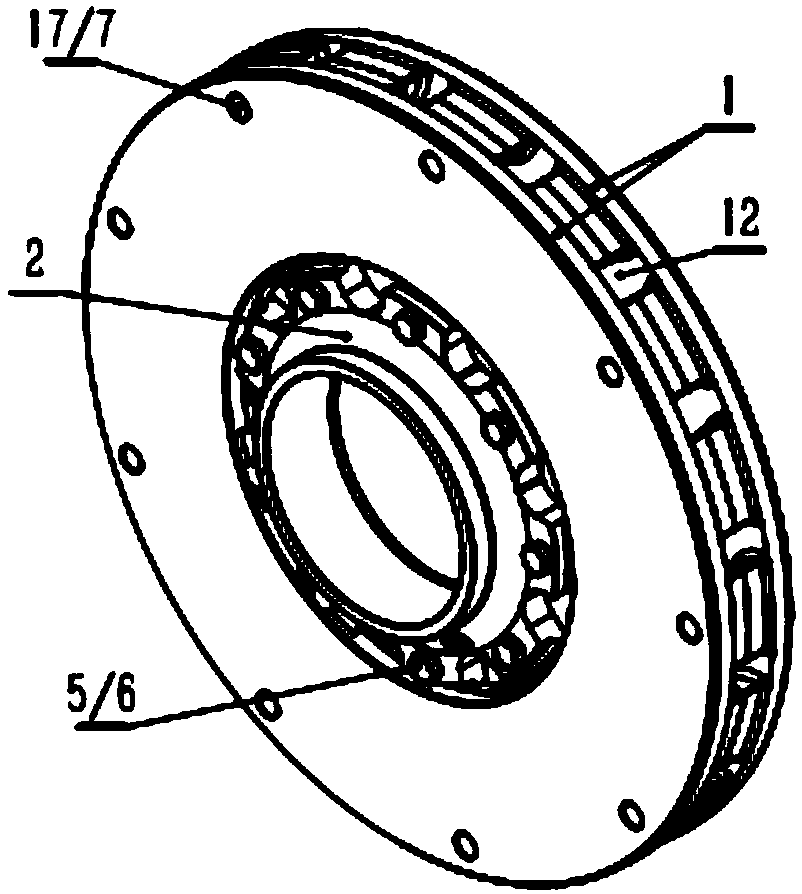

All-carbon ceramic axle-mounted brake disc

ActiveCN109236904AImprove antioxidant capacityImprove convenienceBraking discsFriction liningCeramic compositeUltimate tensile strength

The invention discloses an all-carbon ceramic axle-mounted brake disc. The brake disc includes a disc hub and a plurality of friction discs which are coaxially piled up, wherein the disc hub is sleeved with the friction discs. The friction discs are interlocked and connected through connecting structures into a whole and the friction discs and the disc hub are also interlocked and connected through connecting structures into a whole; the friction discs are made from carbon ceramic composite materials and composed of heat dissipation reinforcement bars with the disc surfaces and the rear surfaces are arranged in the radial direction, the heat dissipation reinforcement bars between the piled-up friction discs make contact in a one-to-one corresponding mode, axial heat dissipation channels are formed in the two sides of the heat dissipation reinforcement bars, and communication grooves communicated with the axial heat dissipation channels on the two sides are formed between the heat dissipation reinforcement bars. The all-carbon ceramic axle-mounted brake disc has the advantages that the structure is simple, the heat dissipation effect is excellent, connection is reliable, maintenanceis convenient, and the weight is low, and reliable braking is ensured while the energy consumption and maintenance cost of a transport tool are reduced.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

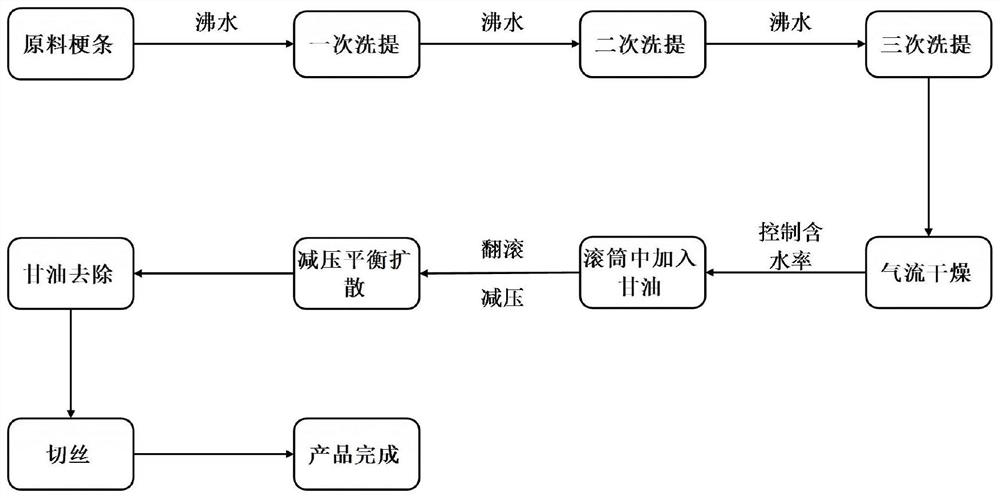

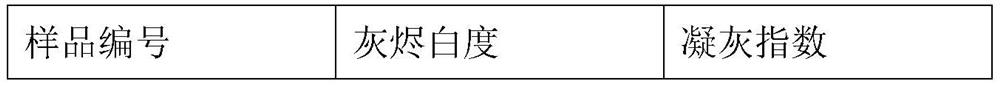

Cut stem preparation method capable of improving cigarette ash whiteness

ActiveCN112450482AReduce breakage rateReduce manufacturing costTobacco preparationTobacco treatmentBiotechnologyBiochemical engineering

The invention discloses a cut stem preparation method capable of improving cigarette ash whiteness. The cut stem preparation method comprises the following steps: (1) carrying out elution treatment onraw material tobacco stems; (2) repairing the eluted tobacco stems by adopting glycerol so as to recover the processing resistance of the tobacco stems; and (3) removing residual glycerol on the tobacco stems, and shredding the tobacco stems to obtain the tobacco stem shreds. After the stem shreds for the cigarettes are added into the cigarettes for use, the ash whiteness of the cigarettes can beobviously improved by 15-30 units, the ash coagulation index is reduced by 1-2 units, the sensory quality of the cigarettes is slightly changed, potential safety hazards are avoided, and compared with a common process for improving the ash whiteness of the cigarettes through stem shred treatment (the breakage rate is about 10-20%), according to the method, the crushing rate can be controlled within 2-3%, and the production cost is greatly reduced.

Owner:CHINA TOBACCO YUNNAN IND

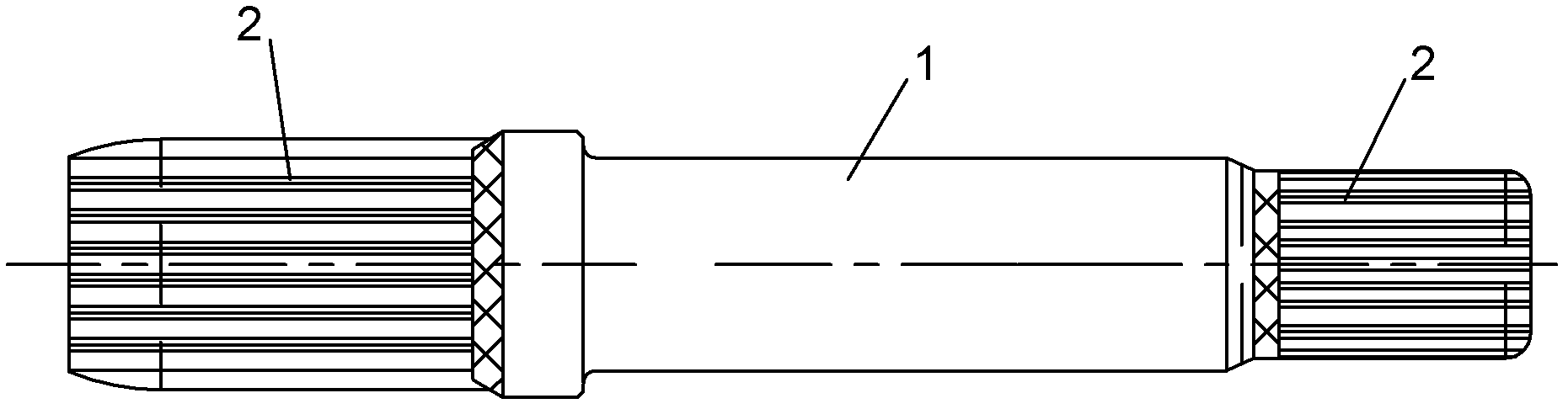

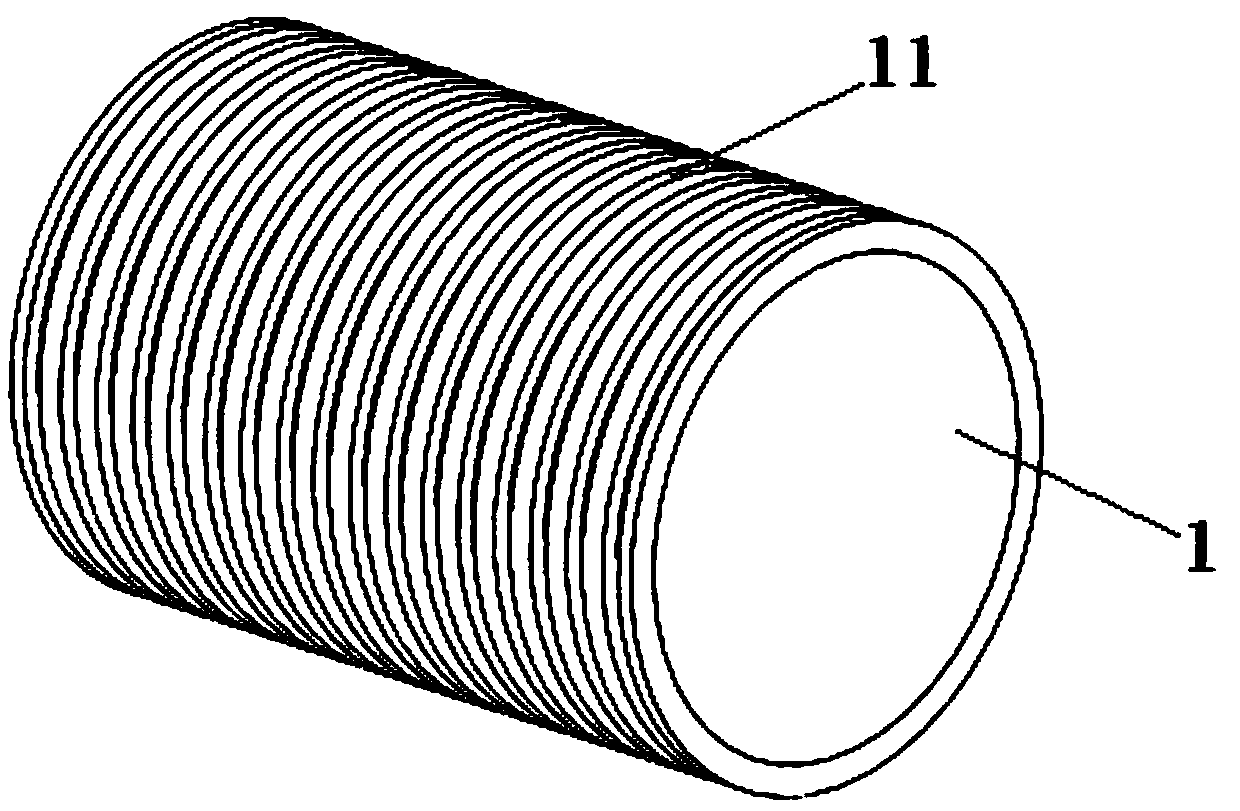

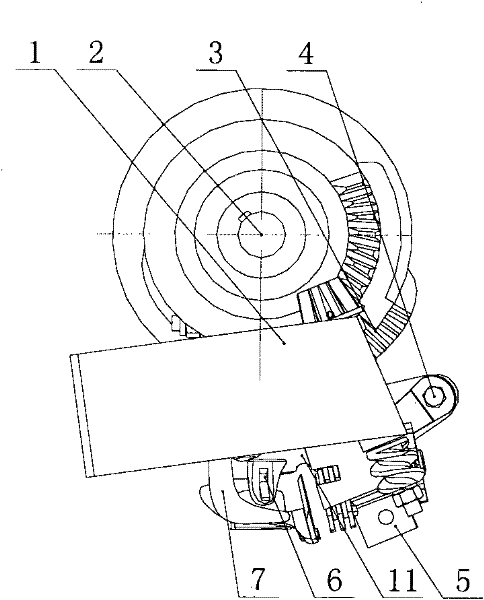

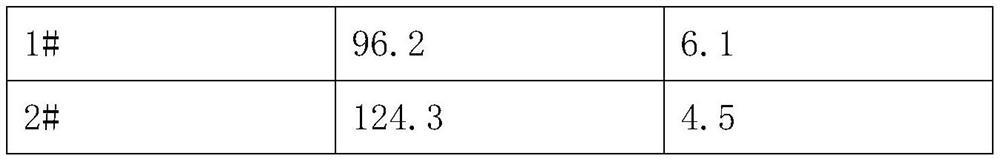

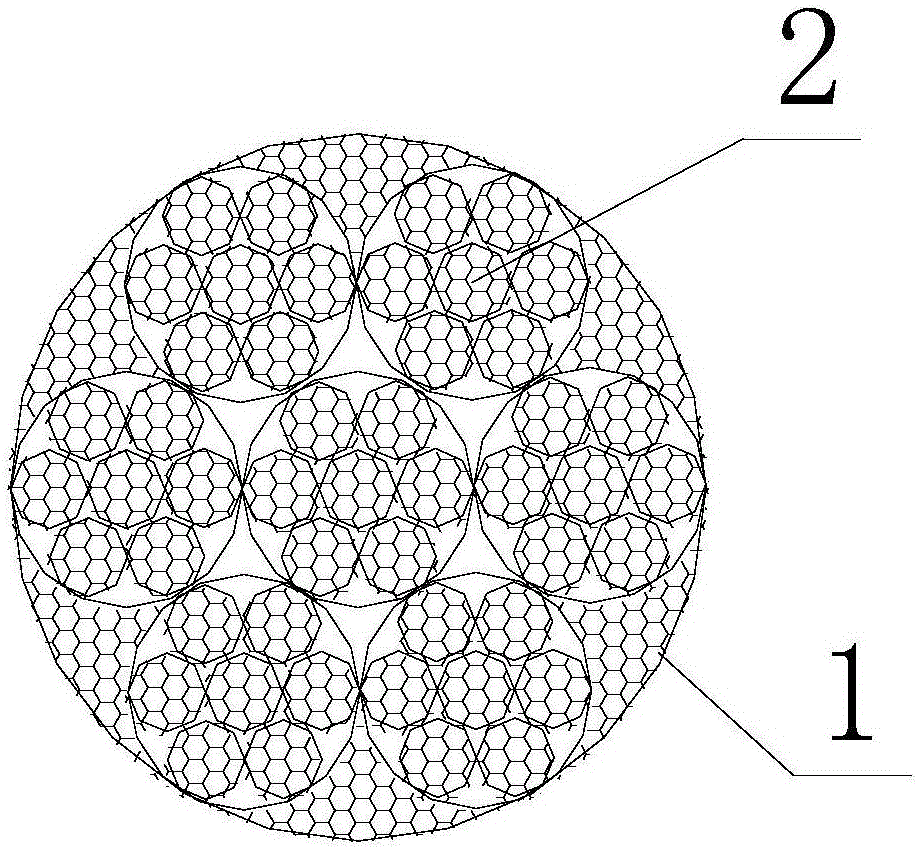

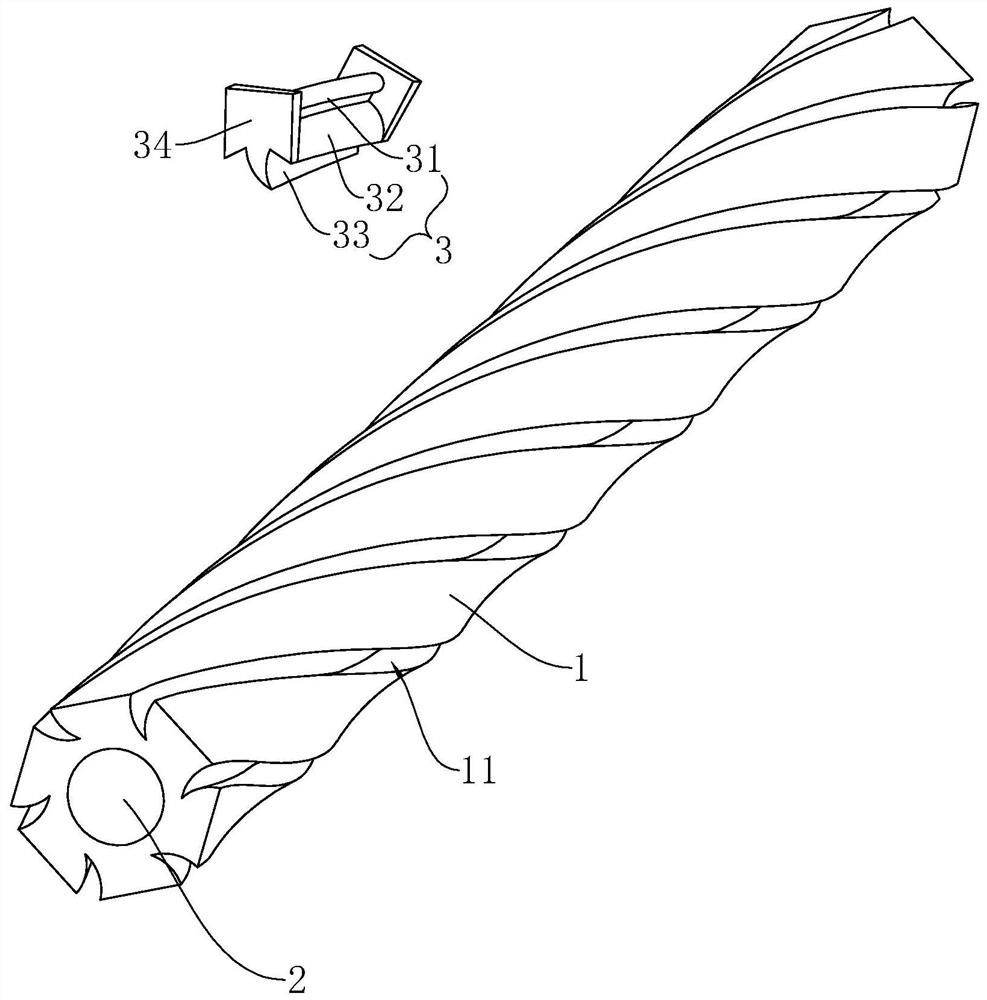

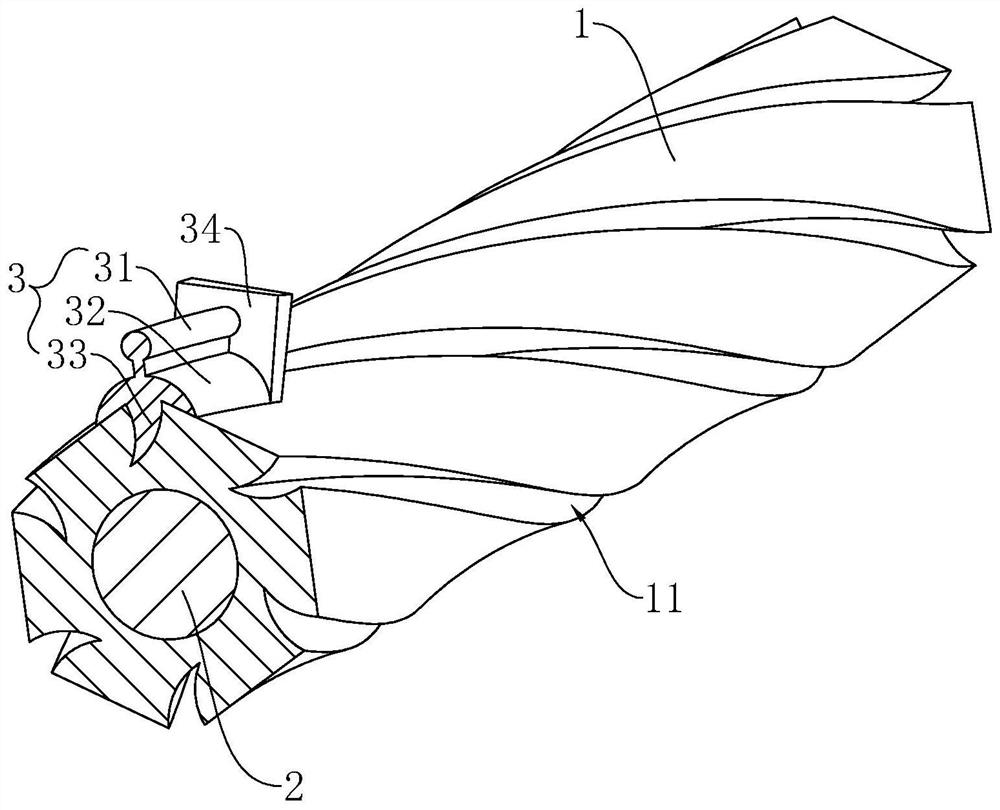

FRP(fiberglass reinforced plastic) anchor rod capable of bearing high pretightening force and manufacture method thereof

ActiveCN106555601AIncreased torsional strengthOverall high processing strengthTextile cablesAnchoring boltsYarnEngineering

The invention relates to an FRP(fiberglass reinforced plastic) anchor rod capable of bearing a high pretightening force and a manufacture method thereof. The anchor rod comprises a glass fiber yarn bundle rope-shaped rod body, bulk glass fiber yarns are twisted in a grouped manner to form glass fiber yarn bundles, and then are twisted in a sinistral manner to form the glass fiber yarn bundle rope-shaped rod body, thread grooves in the surface of the glass fiber yarn bundle rope-shaped rod body are wound by bulk glass fiber yarns which fill and level up the thread grooves, and after being bonded by a resin, the bulk glass fiber yarns are molded and cured. The bulk glass fiber yarns are twisted in the grouped manner to form several glass fiber yarn bundles, and then the glass fiber yarn bundle rope-shaped rod body is formed, the thread grooves in the surface of the glass fiber yarn bundle rope-shaped rod body are wound by the bulk glass fiber yarns which fill and level up the thread grooves, and then are impregnated with the resin, after the bulk glass fiber yarns are bonded by the resin, the rod body of the uncured anchor rod which is bonded with the glass fiber yarns is made to traverse a guide hole of a forming die head, and the uncured anchor rod is shaped into a dextral FRP anchor rod by means of an internal screw thread. By means of the sinistral winding manner of the glass fiber yarns, the tensile strength of the glass fiber yarns can be fully utilized, the torsional strength of the rod body is improved, the high pretightening force of the FRP anchor rod can be guaranteed, the problem that a relatively-large pretightening force cannot be applied to the FRP anchor rod can be well solved, and the usage effect of the FRP anchor rod is excellent.

Owner:CHINA UNIV OF MINING & TECH

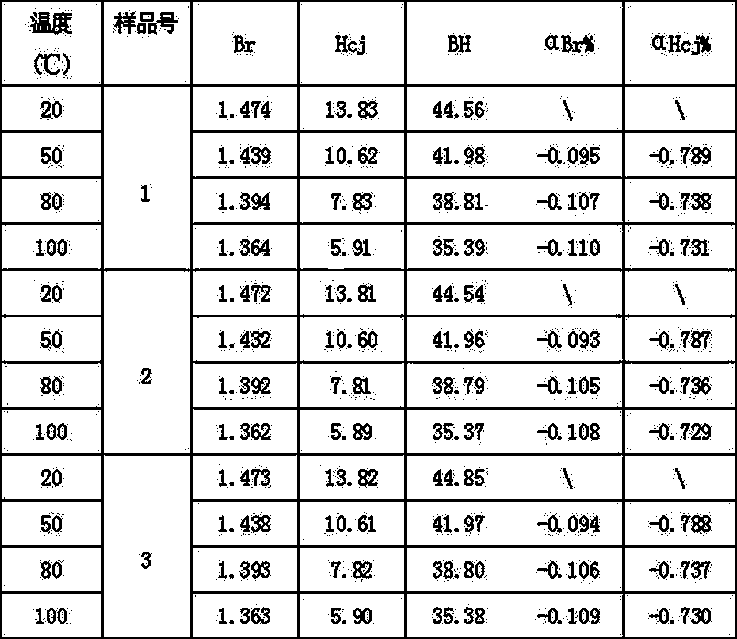

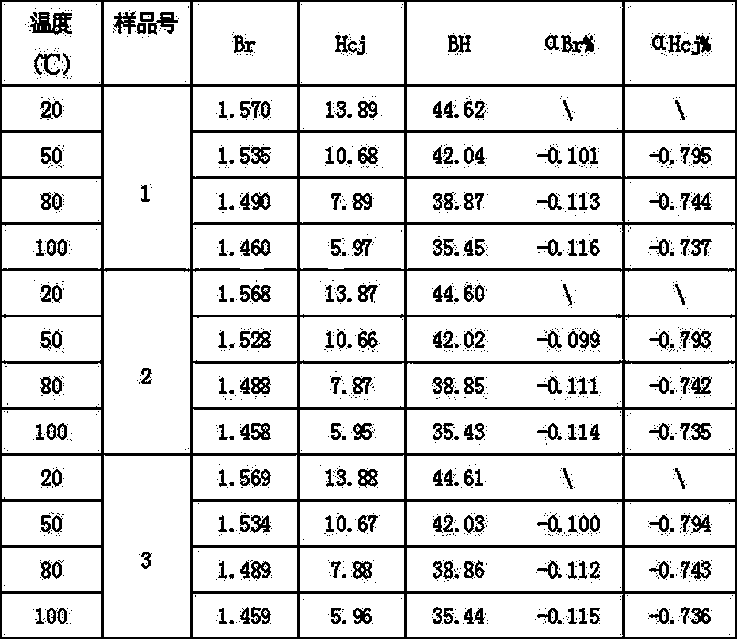

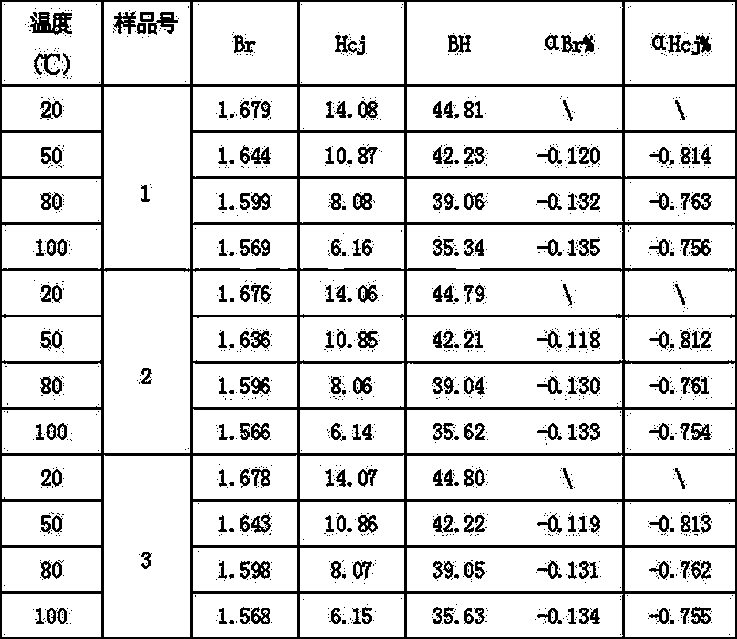

Dysprosium-iron-praseodymium-neodymium magnetic steel with high performance

InactiveCN103811142AExcellent magnetic propertiesImprove processing strengthMagnetic materialsDysprosiumAlloy

The invention discloses dysprosium-iron-praseodymium-neodymium magnetic steel with high performance. The dysprosium-iron-praseodymium-neodymium magnetic steel comprises the following components in percent by weight: more than or equal to 0.022% and less than or equal to 0.036% of C, less than or equal to 0.45% of Mn, more than or equal to 1.00% and less than or equal to 2.00% of Dy, more than or equal to 12.50% and less than or equal to 13.50% of Ni, more than or equal to 2.50% and less than or equal to 3.00% of Mo, more than or equal to 21.00% and less than or equal to 22.50% of Cr, more than or equal to 1.90% and less than or equal to 6.00% of Si, more than or equal to 0.30% and less than or equal to 0.50% of Al, more than or equal to 0.10% and less than or equal to 0.15% of Cu, less than or equal to 0.015% of P, less than or equal to 0.010% of S, more than or equal to 0.40% and less than or equal to 0.70% of Nb, less than or equal to 0.1% of Ga, 28-29% of praseodymium-neodymium alloy 1#, 10-20% of dysprosium-iron alloy 2# and the balance of Fe and other inevitable trace impurities. The dysprosium-iron-praseodymium-neodymium magnetic steel disclosed by the invention has the advantages that the praseodymium-neodymium alloy 1# and the dysprosium-iron alloy 2# are adopted for adjusting and controlling the content of dysprosium, praseodymium and neodymium in the magnetic steel, so that the quality and the quality stability of a magnetic-steel product are improved.

Owner:NINGBO HONGLEI MAGNETICS

A scroll compressor

ActiveCN105840504BImprove processing strengthIncrease the difficulty of the processRotary piston pumpsRotary piston liquid enginesScroll compressorBack pressure

The invention discloses a scroll compressor. The scroll compressor comprises an upper support and an upper cover, wherein the upper support and the upper cover are connected. A movable scroll plate is arranged in the upper support and in the upper cover. A static scroll plate is coaxially arranged on the side, close to the upper cover, of the movable scroll plate. An elastic circular ring is coaxially arranged on the side, close to the upper support, of the movable scroll plate. The upper support is provided with an inner supporting part and an outer supporting part, wherein the inner supporting part and the outer supporting part are matched with the elastic circular ring. A suspended part is formed between the inner supporting part and the outer supporting part. A back pressure sealing groove is formed in the bottom face of the suspended part. A back pressure sealing ring tightly attached to the elastic circular ring is arranged in the back pressure sealing groove. A back pressure cavity and an air sucking cavity which communicate with the suspended part are formed in the upper support. An exhaust cavity communicating with the back pressure cavity is formed in the upper cover. A compression cavity communicating with the air sucking cavity and the exhaust cavity is formed between the movable scroll plate and the static scroll plate. The scroll compressor is sufficient and reliable in sealing effect, and the technology difficulty of a sealing structure of the scroll compressor is low.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

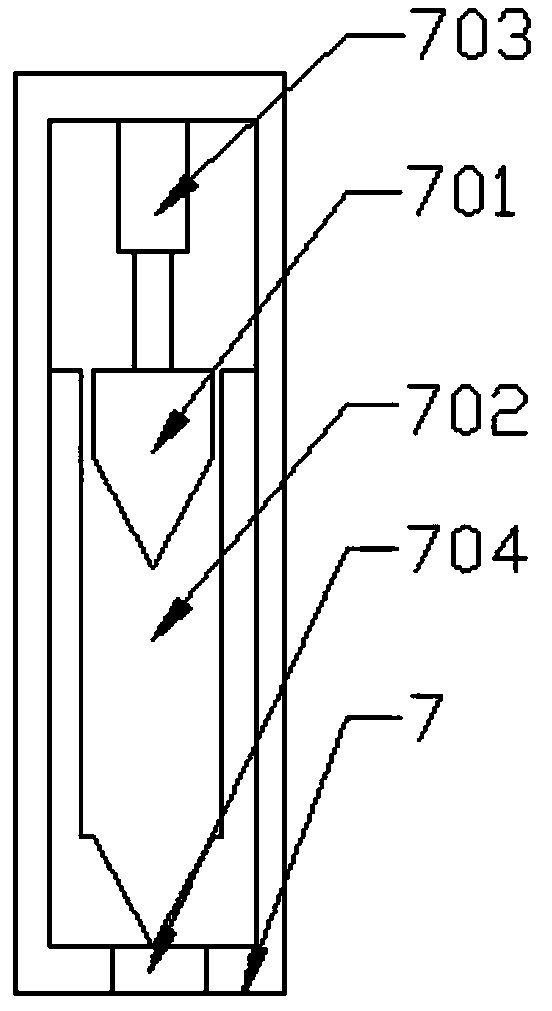

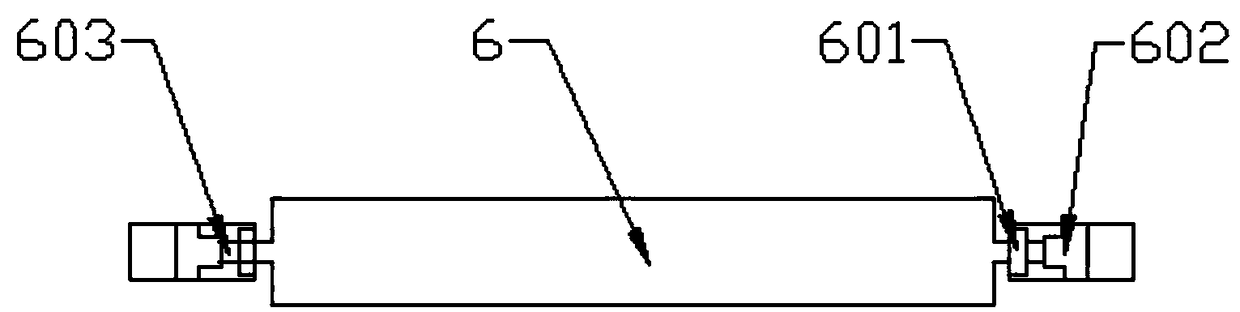

An ultra-high-strength fastener and its manufacturing process and device

ActiveCN111941007BReduce extrusion buildupAvoid crush wearMetal-working feeding devicesScrew-threads articlesProcess engineeringScrew thread

The invention discloses an ultra-high-strength fastener and its manufacturing process and device. The processing technology in this scheme includes a raw material treatment, b cold heading treatment, c thread processing cold treatment, and d surface treatment, wherein the thread processing cold treatment is applied to the device The thread rolling processing assembly is connected with an oil cooling assembly for cold processing of bolts, and one side of the thread rolling processing assembly is connected with a transfer assembly for processing and transporting the processed bolts one by one. Processing, since the thread rolling processing in this scheme includes the transfer components used to transfer the bolts one by one, it is convenient to process the processed bolts one by one, which reduces the extrusion accumulation during bolt processing and avoids the gap between the bolt and the nut. The extrusion wear improves the processing strength between the bolt and the nut. At the same time, the oil cooling component is used to facilitate the oil cooling treatment during the thread processing, so as to avoid the wear of the outer ring thread and the thread processing mechanism during thread processing.

Owner:宁波神川新材料有限公司

Mud scraping process for fluorescent lamp head

InactiveCN106090675AAvoid affecting light transmission performanceImprove uniformitySemiconductor devices for light sourcesTransmittanceEngineering

The invention aims to provide a mud scraping process for a fluorescent lamp head. The mud scraping process comprises the steps that 1, material matching is conducted, specifically, welding mud is prepared according to process requirements, and the prepared welding mud is stirred fully until the welding mud has certain fluidity; and 2, mud scraping and smearing processing is conducted, specifically, the prepared and stirred welding mud is poured into a mud scraper, then the inner wall of an aluminum cap of the led lamp head is subjected to mud scraping and smearing processing, and smearing processing of the aluminum cap is conducted in a rotation mode. The uniformity of mud scraping is improved by improving the mud scraping process for the lamp head, the processing strength is improved, the influence of mud falling of parts on light transmittance performance is avoided, the yield is increased, and the production cost is reduced.

Owner:ANHUI SHILIN LIGHTING

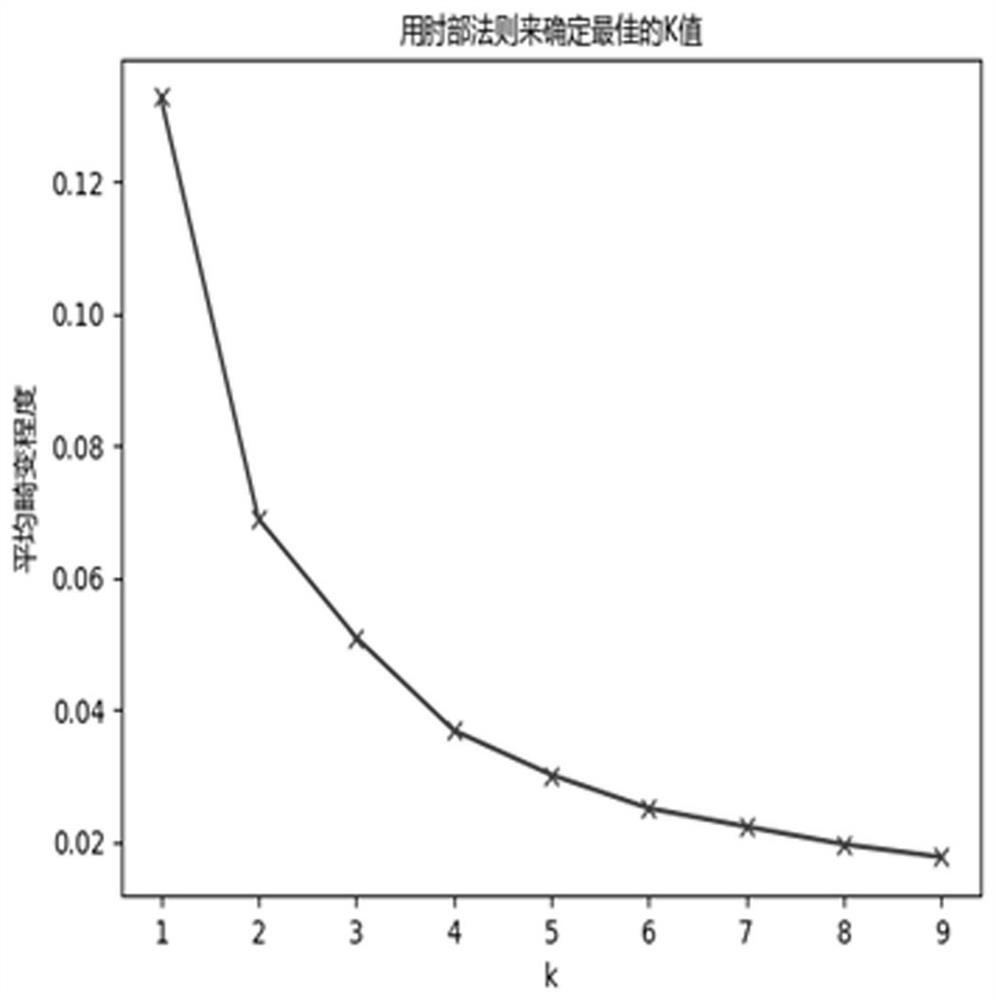

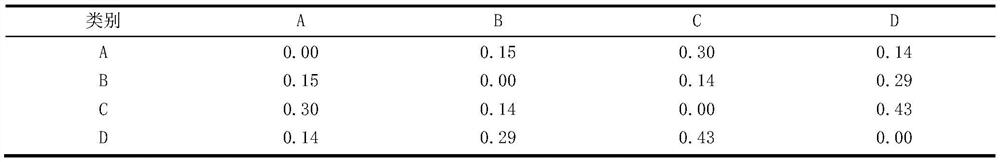

A Classification Method for Processing Attributes of Threshing and Red-cured Tobacco Leaves

ActiveCN111671128BImprove adaptabilityImprove processing strengthTobacco preparationAlgorithmGenetics

The invention relates to the technical field of tobacco leaf processing, in particular to a method for classifying processing attributes of threshed and recured tobacco leaves. The method includes the following steps: selecting the physical quality index of tobacco leaves as a feature, measuring the characteristic data of the tobacco leaf samples to be classified; determining the number K of clusters; selecting K tobacco leaf samples as initial cluster centers; calculating the relationship between other tobacco leaf samples and the cluster centers Euclidean distance, according to the criterion of the closest distance, classify all tobacco leaf samples into the category corresponding to the nearest cluster center; calculate the mean value of each feature of all tobacco leaf samples in the same category, and use it as the new clustering center of the category Cluster center: Repeat the above two steps until the set number of iterations is reached or until the mean is consistent with the cluster center. Through the application, not only the efficiency of threshing and redrying is improved, but also the matching degree of processing intensity and tobacco leaf processing properties is improved.

Owner:CHINA TOBACCO JIANGSU INDAL

High-speed scale scrap drill bit

InactiveCN105642967AImprove drilling effectImprove processing strengthTransportation and packagingTrepanning drillsUltimate tensile strengthMachining

Disclosed is a high-speed scale scrap drill bit. The high-speed scale scrap drill bit comprises a drill bit body provided with upright-shaped cutting edges. The cutting edges are provided with a scrap breaking cutting opening which is formed by the two cutting edges in a mutually intersecting mode. The scrap breaking cutting opening is of an asymmetrical and inclined structure. A cylindrical connection handle is arranged behind the drill bit body. The cutting edges are arranged to be in the upright shape so that the drilling ability of the drill bit can be enhanced, and the machining strength of the drill bit is promoted. The cutting edges are provided with the scrap breaking cutting opening so that scrap iron can be cut off and removed conveniently, and accordingly the scrap iron is prevented from blocking a machining hole. Therefore, the next step of machining can be conducted smoothly through the drill bit, and the machining efficiency of the drill bit is improved. A transition component is provided with locating pins so that the drill bit can be located on a drilling machine more firmly. The locating pins are provided with abrasion-resistant layers, so that the abrasion resistance of the locating pins is promoted, and accordingly the locating pins are located in locating holes more firmly.

Owner:江苏万金工具有限公司

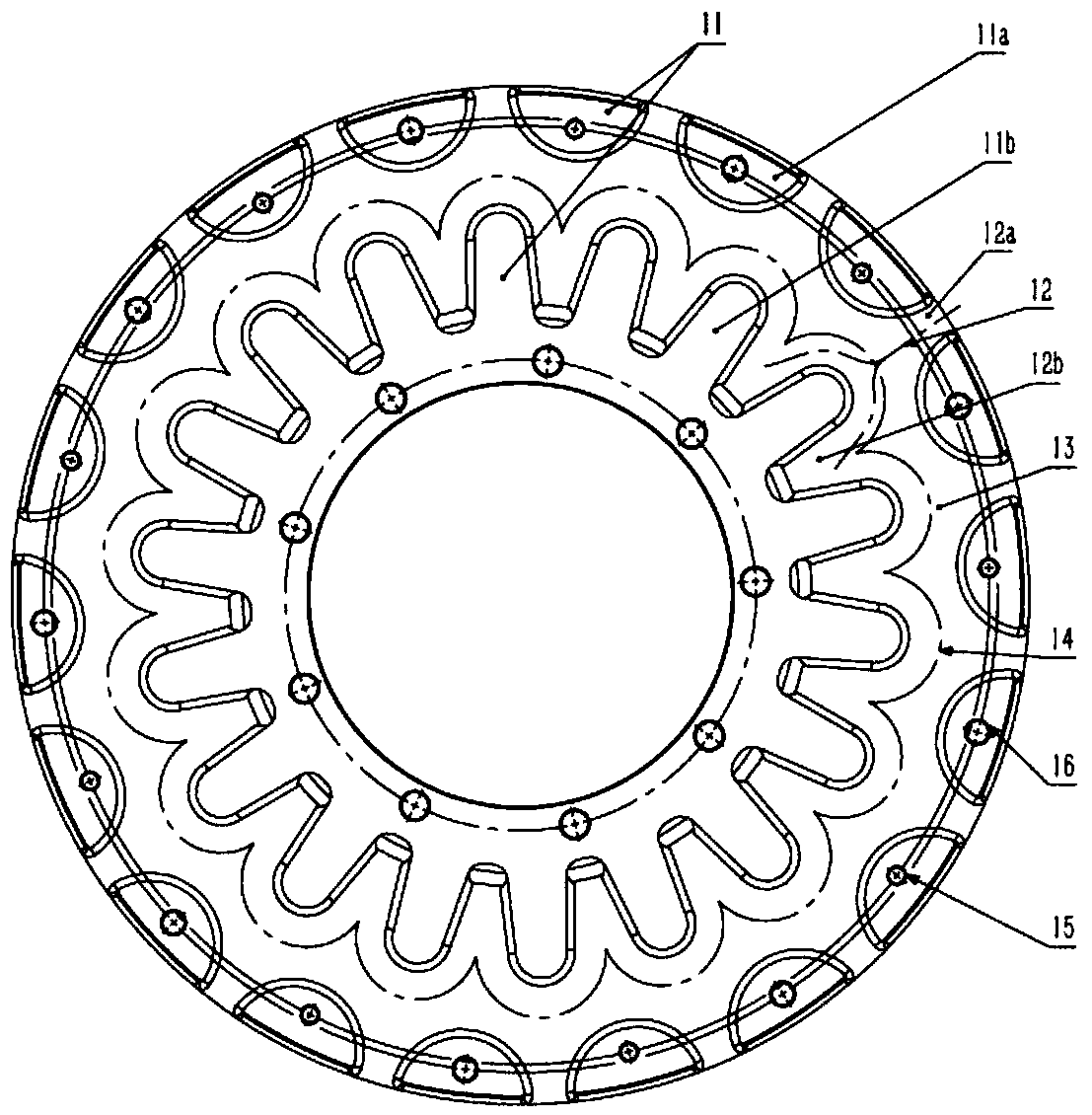

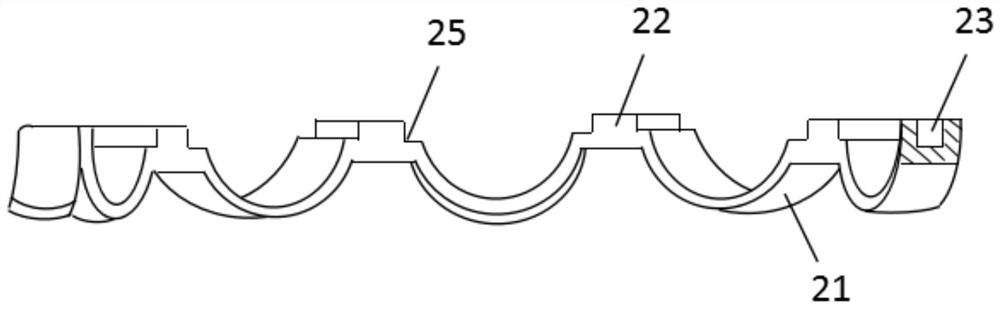

Wave-shaped ball bearing retainer structure made of engineering plastics and connecting method

PendingCN114110023ASimple structureReduce coefficient of frictionBearing componentsBall bearingEngineering plastic

The invention provides a wave-shaped ball bearing retainer structure made of engineering plastics and a connecting method, a retainer comprises an annular upper retainer and an annular lower retainer, the annular upper retainer and the annular lower retainer are respectively provided with a semicircular ball pocket and a connecting part which are symmetrical to each other along the circular ring direction, and the connecting part of the upper retainer and the connecting part of the lower retainer are respectively provided with a cylindrical pin and a circular blind hole which are matched with each other; the top of the cylindrical pin is provided with a cone protruding outwards. The connecting method of the retainers comprises the steps that firstly, the balls, the upper retainer and the lower retainer are pre-assembled between the bearing inner ring and the bearing outer ring, the upper retainer and the lower retainer are pressed through a mold connected with an ultrasonic generating device, cylindrical pins are inserted into blind holes, and the ultrasonic generating device works in the pressing process; the cone accumulates energy to generate high temperature, so that the cylindrical pin and the blind hole are fused and welded into a whole. The retainer structure can be connected in an ultrasonic fusion welding mode, and compared with an existing engineering plastic retainer which is connected in a buckling mode, a riveting mode and the like, the machining precision and the retainer strength are effectively improved, and the machining efficiency is higher.

Owner:QINGDAO TAIDE AUTOMOBILE BEARING

A kind of high-temperature lead-free solder wire and its preparation method

ActiveCN113441870BIncrease roughnessPrevent slidingWelding/cutting media/materialsSoldering mediaAlloyHigh heat

This application relates to the field of brazing technology, in particular to a high-temperature lead-free solder wire and its preparation method, which solves the problem that the lead-free solder wire is thin and soft, and the staff tends to slip off when holding the solder wire for welding, resulting in a reduction in the welding efficiency of the workpiece. The problem, which includes a shell formed of tin alloy and an inner core formed of flux, the outer wall of the shell is provided with a plurality of spiral grooves, and the outer wall of the shell is provided with anti-skid parts. The application has the effects of reducing the probability of the solder wire slipping off when workers are welding, and improving the welding efficiency.

Owner:YIK SHING TAT SOLDER MFR KUNSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com