Machining method for small-diameter positioning pin hole

A processing method and technology for positioning pin holes, which are used in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of low processing accuracy and large surface roughness of small-diameter positioning pin holes, and improve the processing quality. and strength, reduce surface roughness, and improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

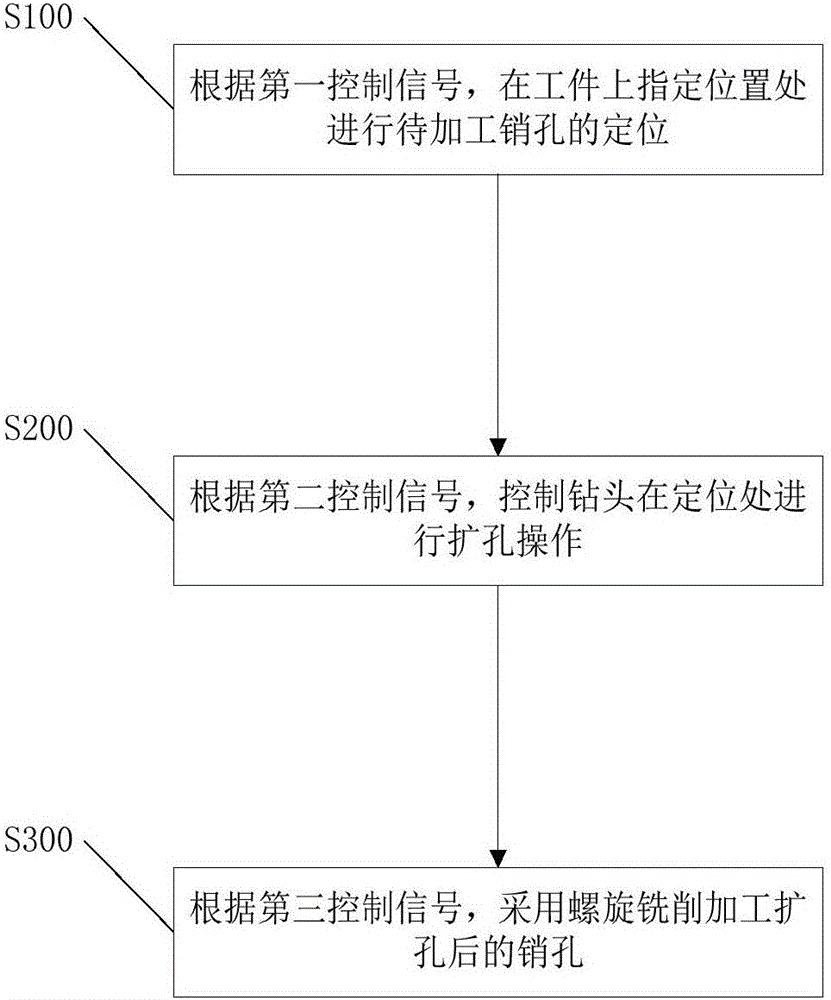

[0027] like Figure 4 As shown, an embodiment of the present invention provides a method for processing a small-diameter locating pin hole, comprising the following steps:

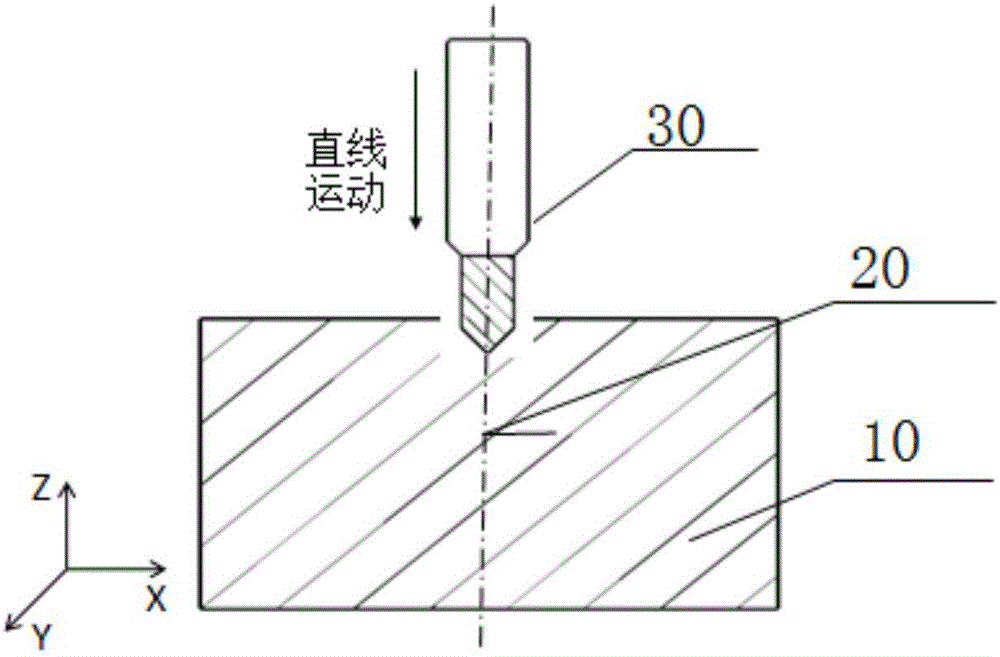

[0028] Step S100, according to the first control signal, perform positioning of the pin hole 20 to be machined at a designated position on the workpiece 10;

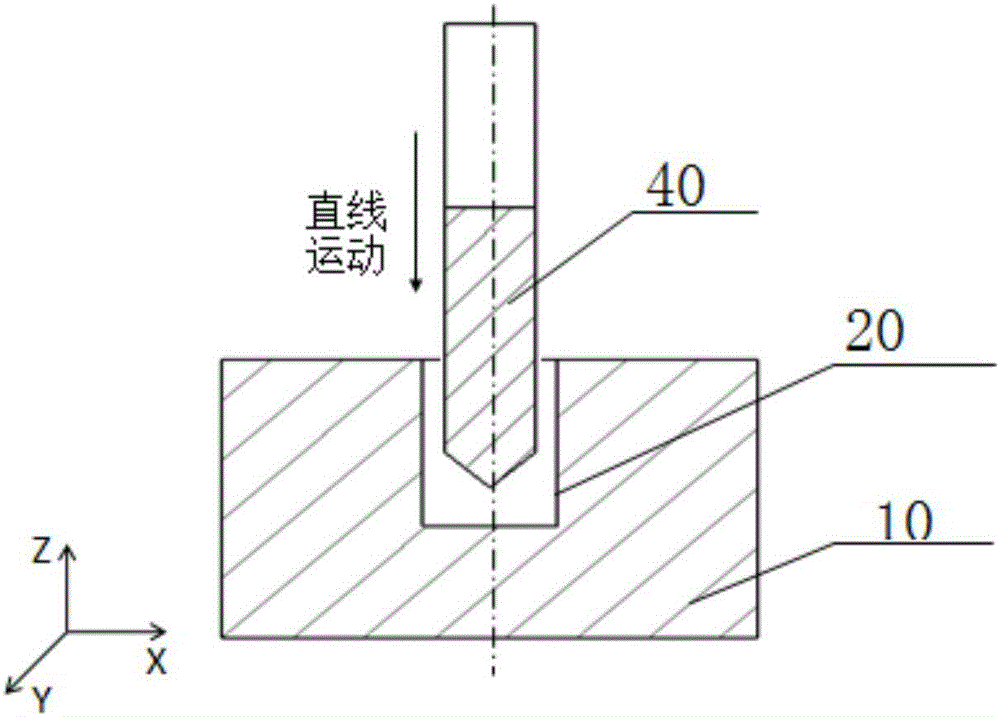

[0029] Step S200, according to the second control signal, control the drill bit 40 to perform a hole reaming operation at the location;

[0030] Step S300 , according to the third control signal, the pin hole 20 after the hole expansion is processed by helical milling.

[0031] The above-mentioned first control signal, second control signal and third control signal can be realized by programming respectively, and the programmed program is input into the automatic numerical control machine tool to complete the contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com