A kind of high-temperature lead-free solder wire and its preparation method

A lead-free solder and solder wire technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of reduced welding efficiency and easy slippage of workpieces, and achieve the effect of improving processing strength, improving stability, and facilitating promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

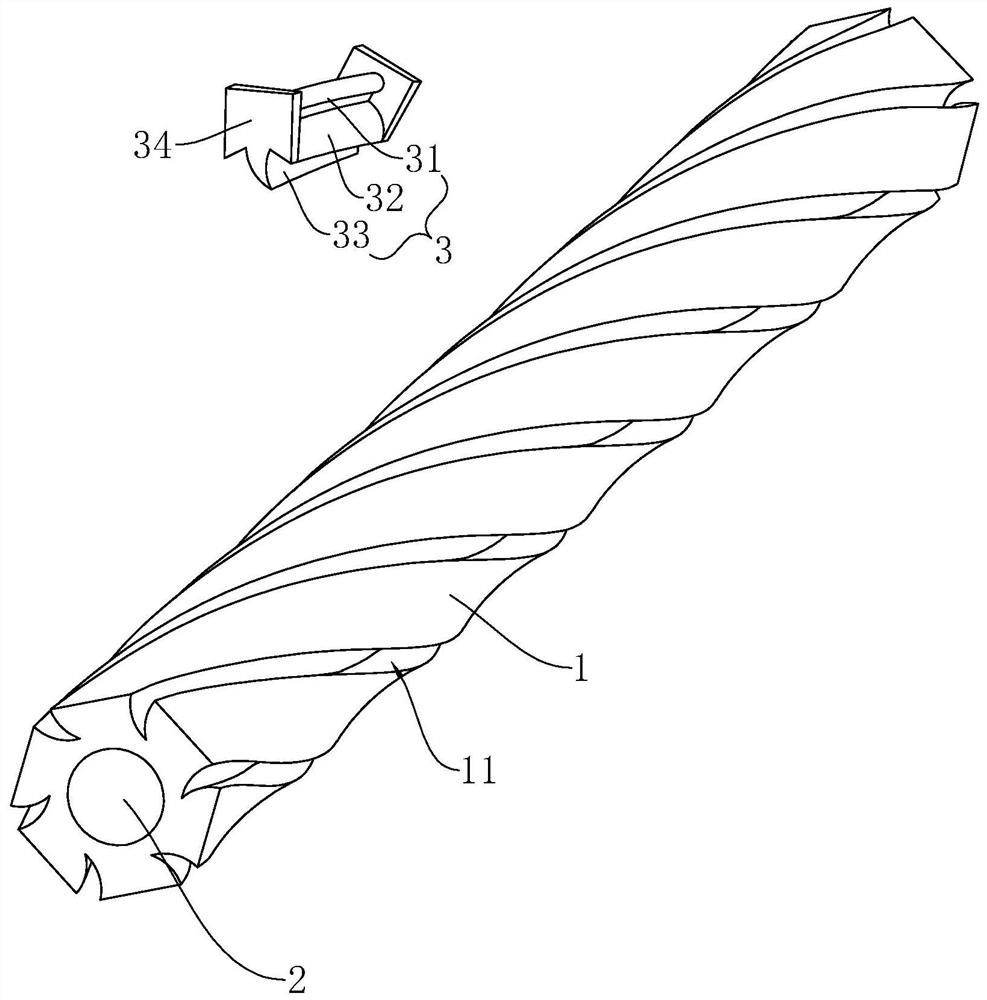

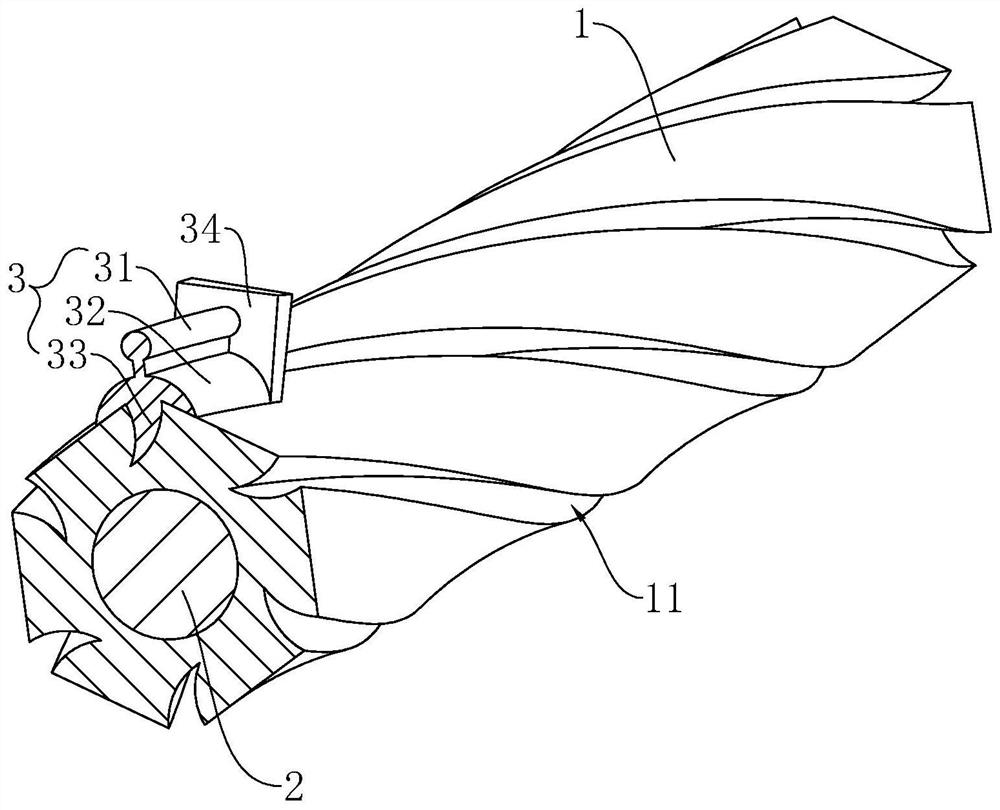

[0040] The embodiment of the present application discloses a high-temperature lead-free solder wire. refer to figure 1 and figure 2 , a high-temperature lead-free solder wire, including a shell 1 and an inner core 2, the inner wall of the shell 1 is bonded to the cylindrical inner core 2, the outer wall of the shell 1 is in the shape of a spiral hexagonal column, and the outer wall of the shell 1 is along the spiral hexagonal column There are grooves 11 on the six edges of the solder wire, which improves the roughness of the outer wall of the solder wire, improves the stability of the staff holding the solder wire, and facilitates the staff to rotate the solder wire, quickly separate the soldering point from the solder wire, and The excess melted solder is accommodated in the groove 11 to prevent sharp ends or sticking of the solder joints. The grooves 11 are arranged obliquely to the plane where the radius of the inner core 2 lies, and the width of the grooves 11 gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com