Dysprosium-iron-praseodymium-neodymium magnetic steel with high performance

A high-performance technology of dysprosium, iron and praseodymium, which is applied in the field of rare earth permanent magnets, can solve the problems of difficulty in controlling the production cost of magnet steel, ensuring product quality stability, and controlling the accuracy of the addition of related rare earth elements, etc., so as to improve the use performance and environmental adaptability, reduce the difficulty of smelting, and improve the effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

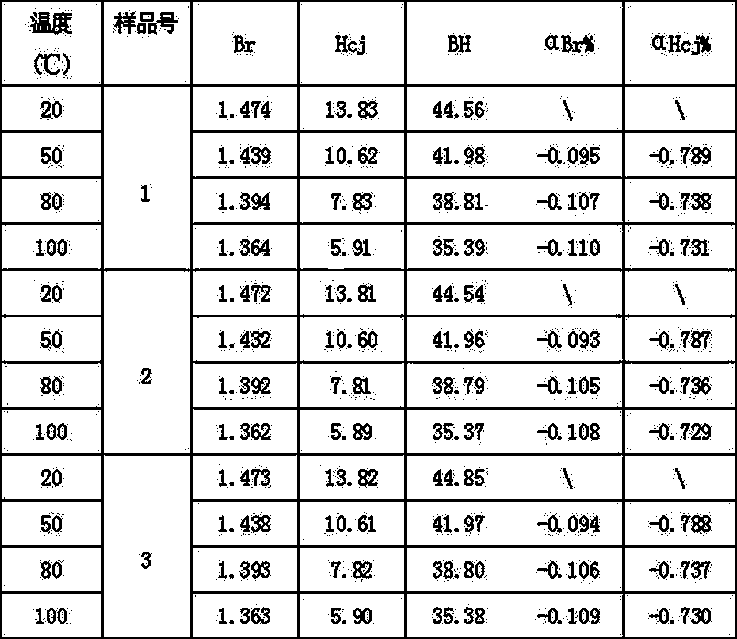

Embodiment 1

[0031] Steel slabs are produced by continuous casting. After the slabs are heated at 1400°C, they are hot-rolled and finished into 2.4mm steel plates, wherein the weight fraction of each component in the slabs is C: 0.025%; Mn: 0.20% ;P: 0.010%; S: 0.010%; Dy: 1.00%; Ni: 12.80%; Mo: 2.60%; ; Ga: 0.10%; praseodymium neodymium alloy 1#: 28.00%; dysprosium iron alloy 2#: 20.00%, the balance is Fe and other unavoidable trace impurities. Wherein the composition weight fractions of praseodymium-neodymium alloy 1# are Pr: 6.50%, Nd: 24.00%, and the balance is Fe and other unavoidable trace impurities; the composition weight fractions of dysprosium-iron alloy 2# are Dy: 10.00%, remainder The amount is Fe and other unavoidable impurities. During the smelting process of the billet, the content of praseodymium, neodymium and dysprosium in the magnetic steel alloy is adjusted by adjusting the addition amount of praseodymium neodymium alloy 1# and dysprosium iron alloy 2#, so as to achiev...

Embodiment 2

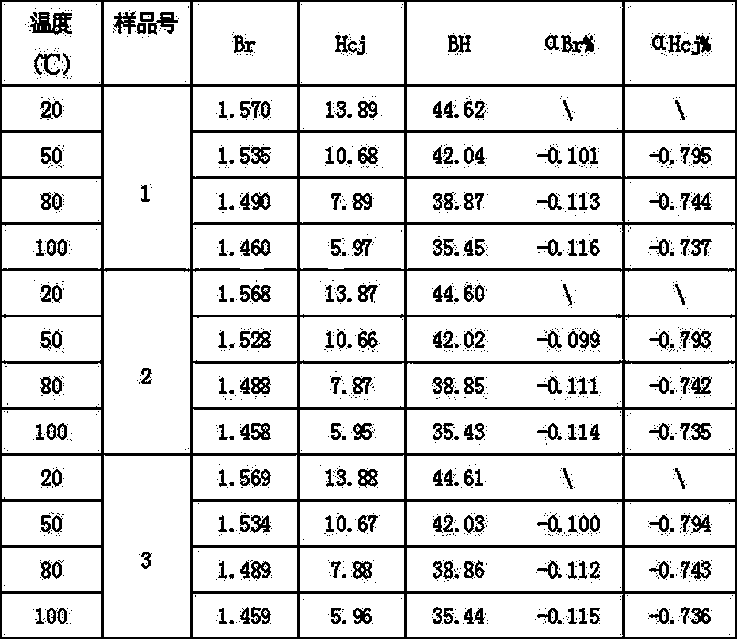

[0036] Steel slabs are manufactured by continuous casting. After the slabs are heated at 1400°C, they are hot-rolled and finished into 2.4mm steel plates, wherein the weight fraction of each component in the slabs is C: 0.027%; Mn: 0.30% ; P: 0.008%; S: 0.0080%; Dy: 1.50%; Ni: 12.90%; Mo: 2.70%; ; Ga: 0.080%; praseodymium neodymium alloy 1#: 28.50%; dysprosium iron alloy 2#: 15.00%, the balance is Fe and other unavoidable trace impurities. Wherein the composition weight fraction of praseodymium neodymium alloy 1# is Pr: 7.50%, Nd: 25.00%, the balance is Fe and other unavoidable trace impurities; each composition weight fraction of dysprosium-iron alloy 2# is Dy: 10.00%, remainder The amount is Fe and other unavoidable impurities. During the smelting process of the billet, the content of praseodymium, neodymium and dysprosium in the magnetic steel alloy is adjusted by adjusting the addition amount of praseodymium neodymium alloy 1# and dysprosium iron alloy 2#, so as to achiev...

Embodiment 3

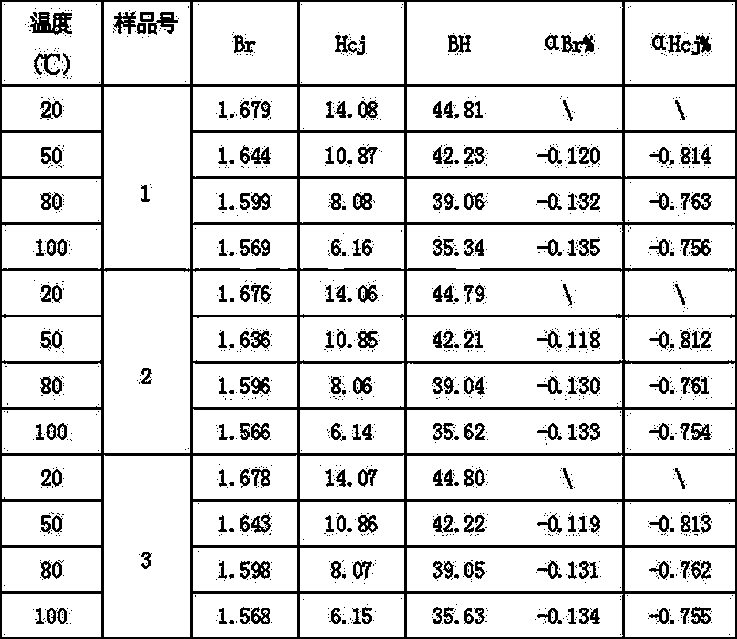

[0041] Steel slabs are produced by continuous casting. After the slabs are heated at 1400°C, they are hot-rolled and finished into 2.4mm steel plates, wherein the weight fraction of each component in the slabs is C: 0.030%; Mn: 0.35% ;P: 0.006%; S: 0.0040%; Dy: 2.00%; Ni: 13.00%; Mo: 2.80%; ; Ga: 0.06%; praseodymium neodymium alloy 1#: 29.00%; dysprosium iron alloy 2#: 10.00%, the balance is Fe and other unavoidable trace impurities. Wherein the composition weight fraction of praseodymium neodymium alloy 1# is Pr: 8.50%, Nd: 26.00%, the balance is Fe and other unavoidable trace impurities; each composition weight fraction of dysprosium-iron alloy 2# is Dy: 10.00%, remainder The amount is Fe and other unavoidable impurities. During the smelting process of the billet, the content of praseodymium, neodymium and dysprosium in the magnetic steel alloy is adjusted by adjusting the addition amount of praseodymium neodymium alloy 1# and dysprosium iron alloy 2#, so as to achieve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com