Split knotter

A split-type, knotter technology, applied in packaging, agricultural machinery and implements, applications, etc., can solve the problems of increasing the strength of parts, high requirements for assembly and machining accuracy, complex structure, etc., to reduce replacement costs, reduce Effects of manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

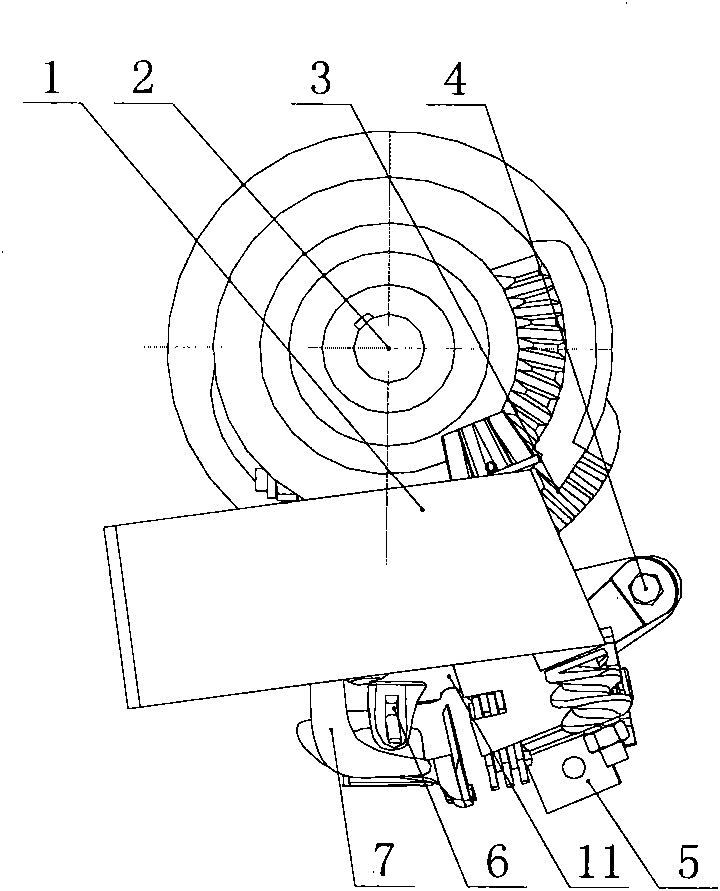

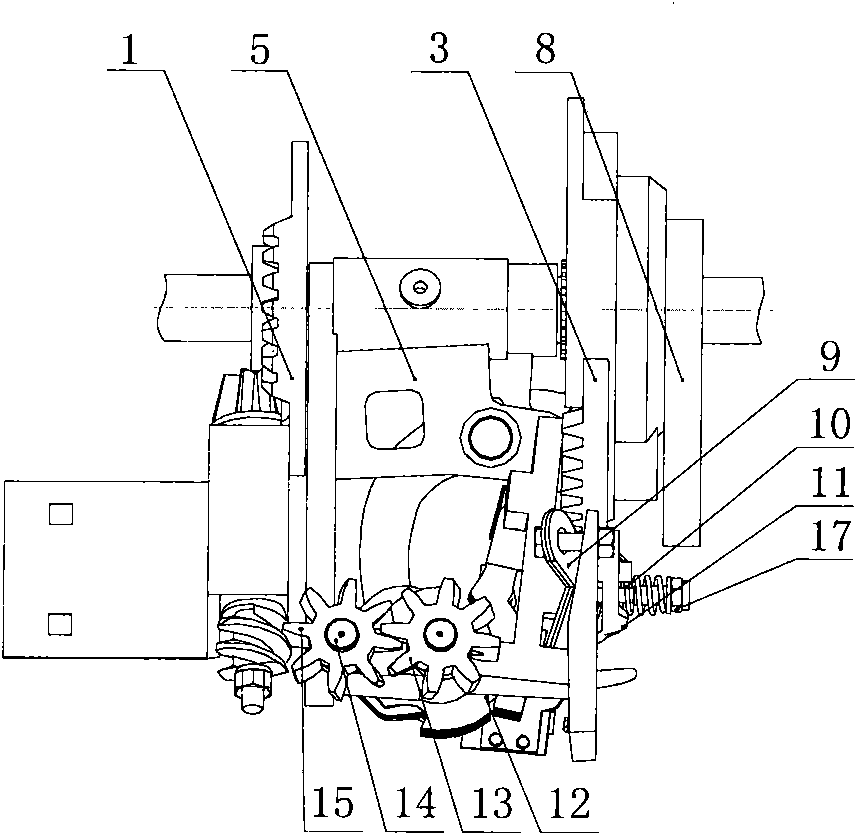

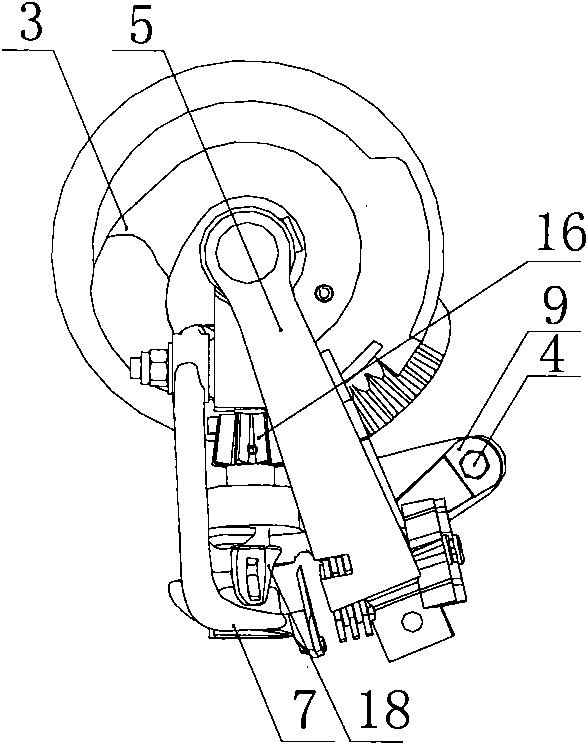

[0027] The present invention provides a split knotter, which will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] Figure 1 to Figure 1 0 is the overall assembly diagram, split mechanism diagram and parts diagram of the split knotter of the present invention, respectively. The main body mounting frame 5 of the split knotter mainly includes six shaft holes I, II, III, IV, V, and VI. The shaft hole II intersects with the shaft hole I, and the included angle is 90°-100°. III is perpendicular to shaft hole I, shaft hole IV, shaft hole V, and shaft hole VI are parallel to each other, and the intersection angle between shaft hole V and shaft hole II is less than 90°. The drive shaft 2 is installed in the shaft hole 1 of the main body mounting frame 5, the rope clamp drive mechanism 1 and the split drive disc mechanism 3 are coaxially installed at the two ends of the drive shaft 2, and the clamp rope drive mechanism 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com