Method for controlling ultrafiltration element pollution in water treatment

A technology for ultrafiltration filter elements and pollution control, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as ultrafiltration membrane pollution and ultrafiltration filter element pollution, and achieve Large economic benefits, improved cleaning effect, and improved water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples.

[0038] When one of the following situations occurs, the ultrafiltration filter element needs to be cleaned:

[0039] 1. Under normal pressure, the permeate flow rate drops to 15-20% of the normal value;

[0040] 2. Normal water flow rate, water supply pressure increased by 10-15%;

[0041] 3. The water quality of the product decreases, and the bacteria increase by 10%;

[0042] 4. The operating pressure has increased by 10-15%.

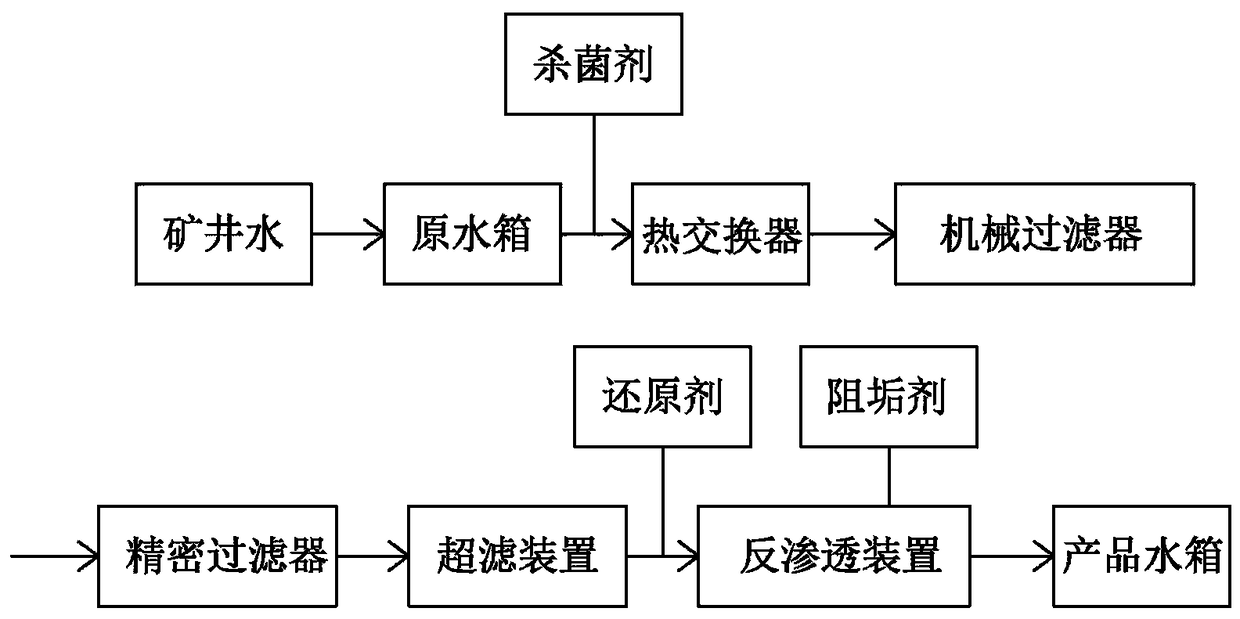

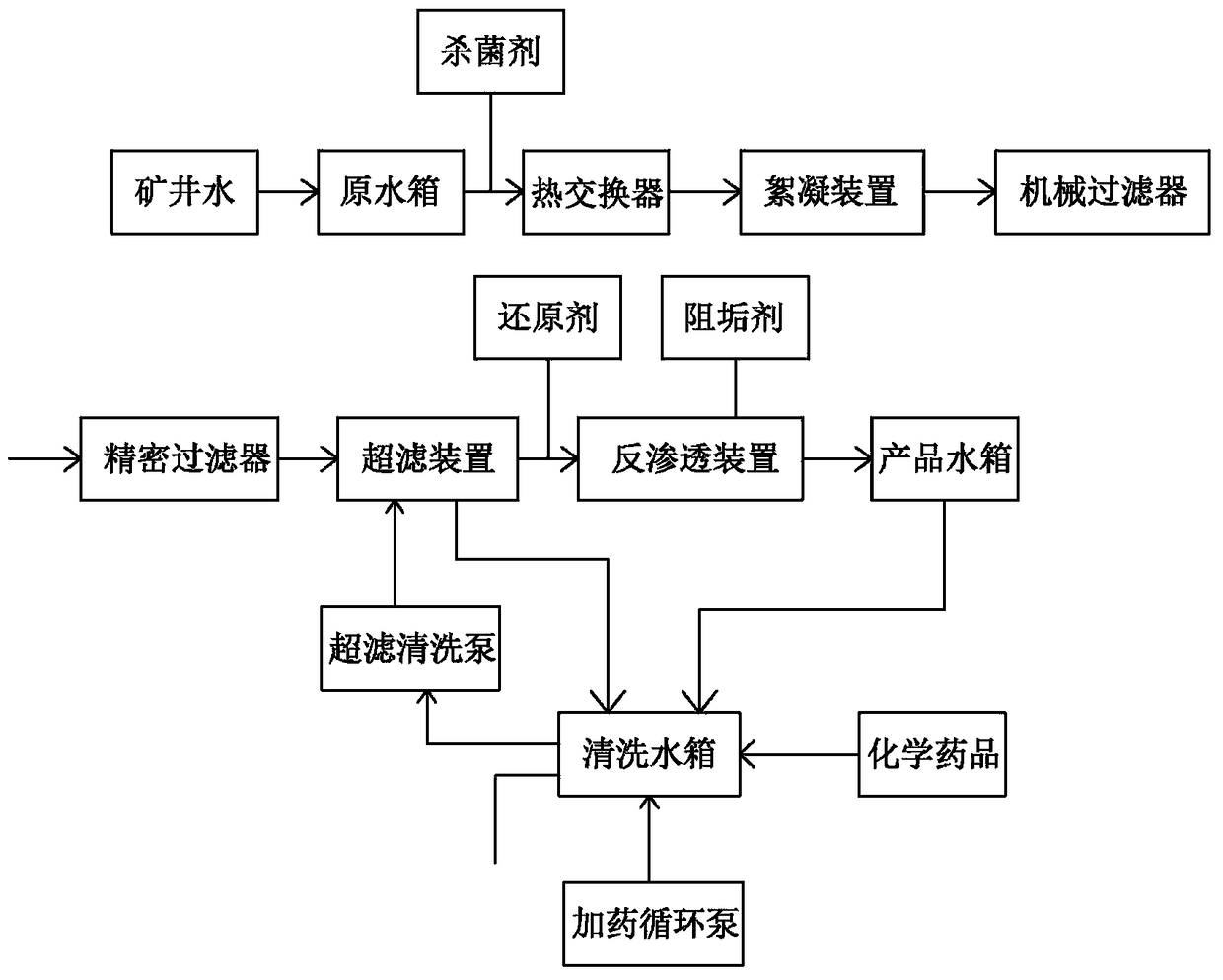

[0043] A method for controlling pollution of an ultrafiltration filter element in water treatment, comprising pretreatment before water filtration and membrane washing after pollution; as figure 2 As shown, the pretreatment is to add a flocculation device before the mechanical filter, and the raw water is treated with a flocculant in the flocculation device; the membrane flushing is to use a cleaning water tank arranged in parallel with the revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com