FRP(fiberglass reinforced plastic) anchor rod capable of bearing high pretightening force and manufacture method thereof

A high preload, FRP technology, which is applied in the installation of bolts, earthwork drilling, textiles and paper making, etc., can solve the problems of insufficient torsional strength of FRP bolts, and achieve high overall processing strength and high prefabrication. The effect of tightness and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

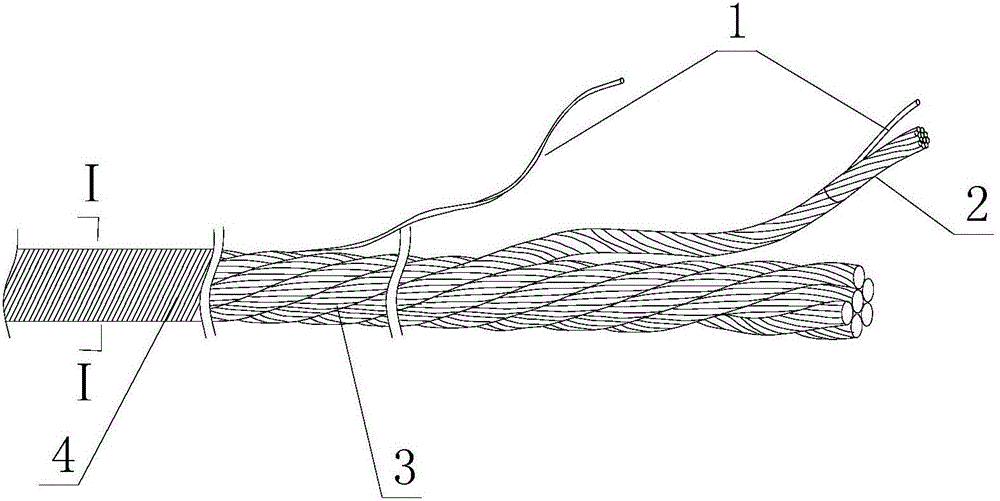

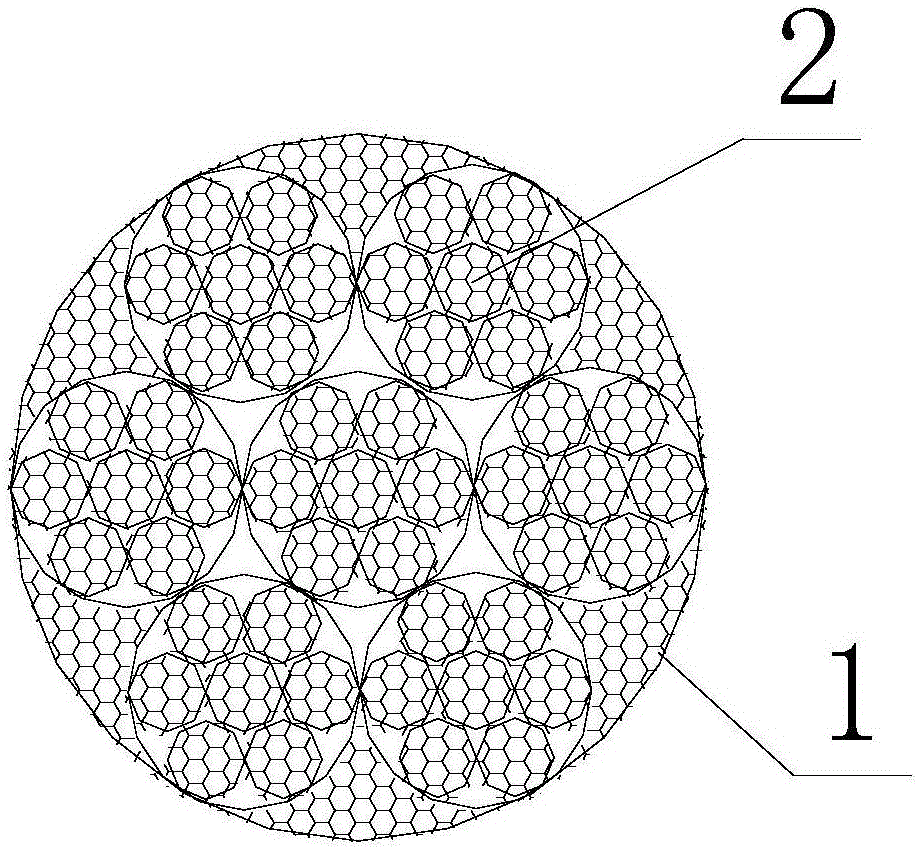

[0016] Such as figure 1 As shown, the fiberglass anchor rod capable of withstanding high preload of the present invention comprises a glass fiber bundle rope-like rod body 3 made of loose glass fiber yarns 1 first grouped and twisted into glass fiber bundles 2 and then twisted left-handedly. , the threaded grooves on the surface of the rope-shaped rod body 3 of the glass fiber yarn bundle are wound with loose glass fiber yarns filling up the threaded grooves, and the loose glass fiber yarns are bonded by resin to form an uncured anchor rod body 4. The forming die head 6 right-hand-molded the uncured anchor rod body 4 bonded with glass fiber yarn into a glass fiber reinforced plastic anchor rod body 5 .

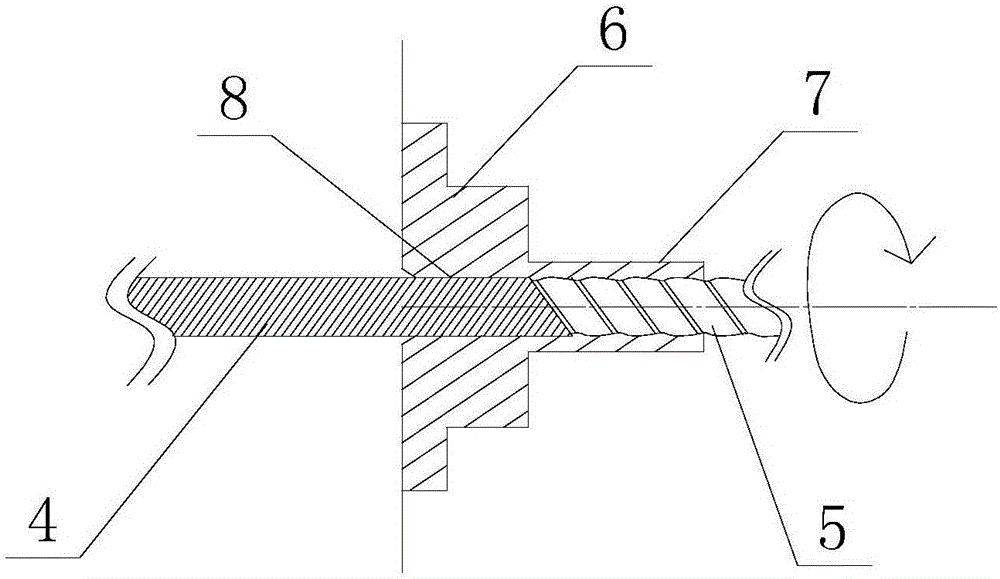

[0017] Such as figure 2 As shown, the forming die 6 includes a stepped die body, a guide hole 8 is opened in the middle of the stepped die body, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com