Full-automatic one-time milling device for diesel engine body

A diesel engine, milling processing technology, applied in the direction of engine components, machines/engines, feeding devices, etc., can solve the problems of low processing efficiency, the uniformity of processing quality cannot be effectively guaranteed, and affect the overall quality of the diesel engine body, etc., to achieve High processing efficiency, high degree of automation, and the effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

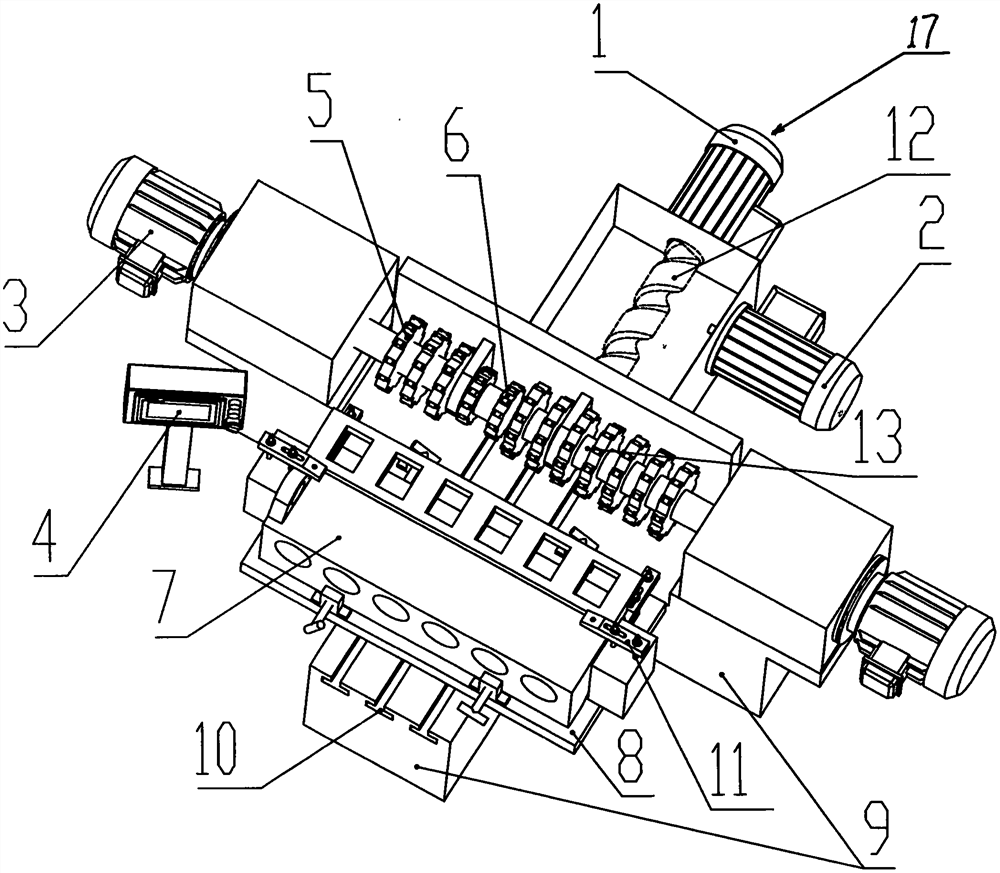

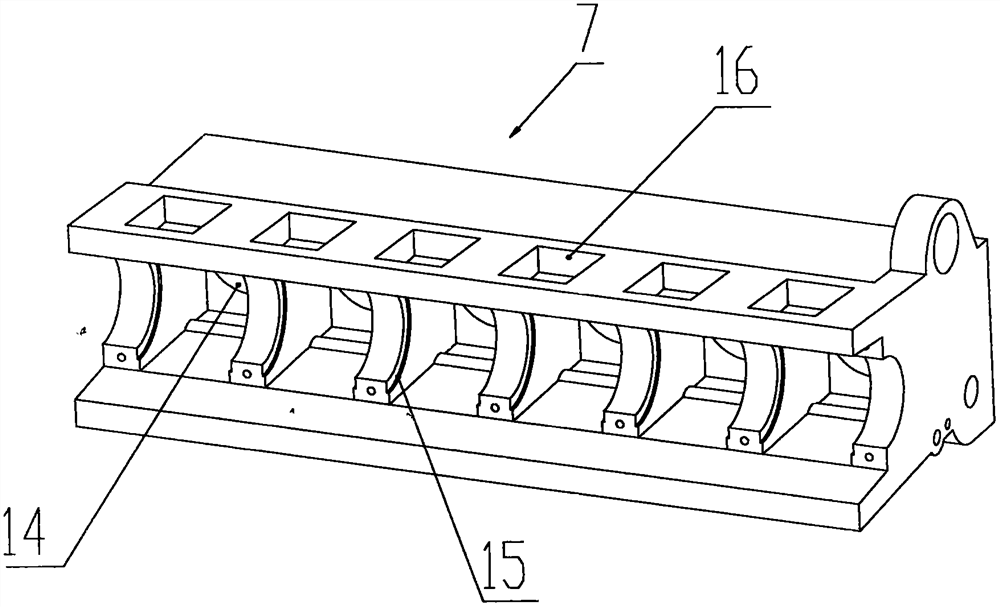

[0010] Such as figure 1 , figure 2 As shown, the fully automatic disposable milling processing device of the diesel engine body of the present invention includes a base 9 and a workbench 8. The workbench 8 is mounted on the front of the base 9 through a guide rail assembly 10, and the Organism fixture 11, described workbench 8 links to each other with mobile power source 17 through transmission assembly 12, all is equipped with milling power source 3 on the both sides of described base 9 (comprising left side, right side respectively, for milling Motor), described milling power source 3 is connected with milling rotating shaft 13 (comprising each piece of left side, right side, for being close to each other), on this milling rotating shaft 13, some milling cutters are housed.

[0011] Described milling cutter comprises large disc milling cutter 5, small disc milling cutter 6, and this small disc milling cutter 6 is in milling rotating shaft 13 (being a piece in left side or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com