Plasma processing apparatus and protection ring thereof

A processing device and plasma technology, applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve problems such as back pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

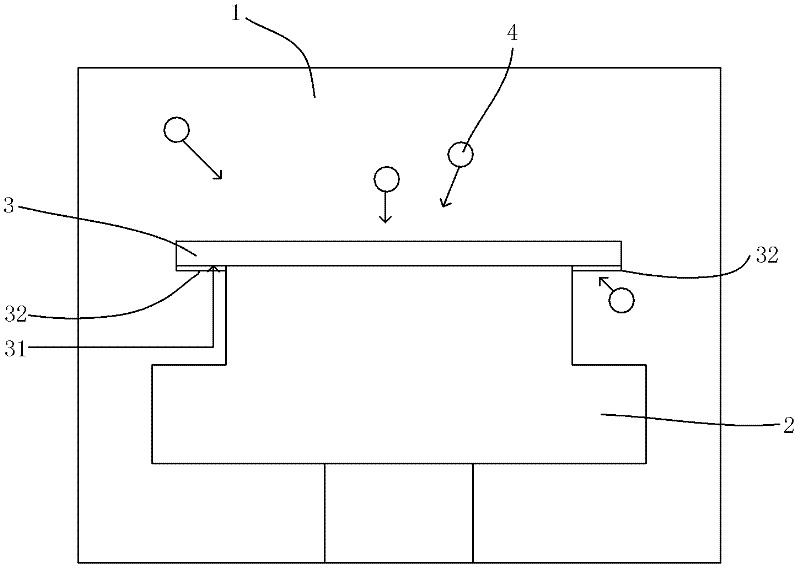

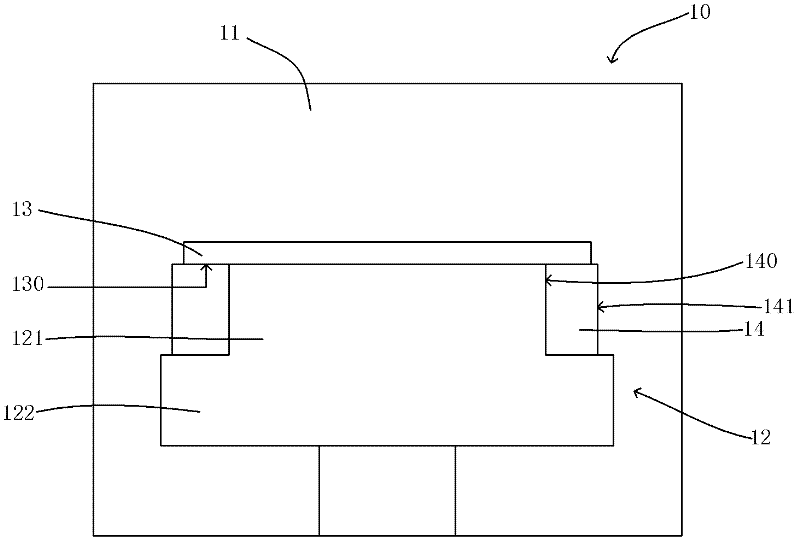

[0020] The problem to be solved by the present invention is: when the diameter of the wafer to be processed is larger than the outer diameter of the portion of the electrostatic chuck that absorbs the wafer, by setting a protective ring in the device, the problem of backside contamination of the wafer during plasma processing can be effectively improved.

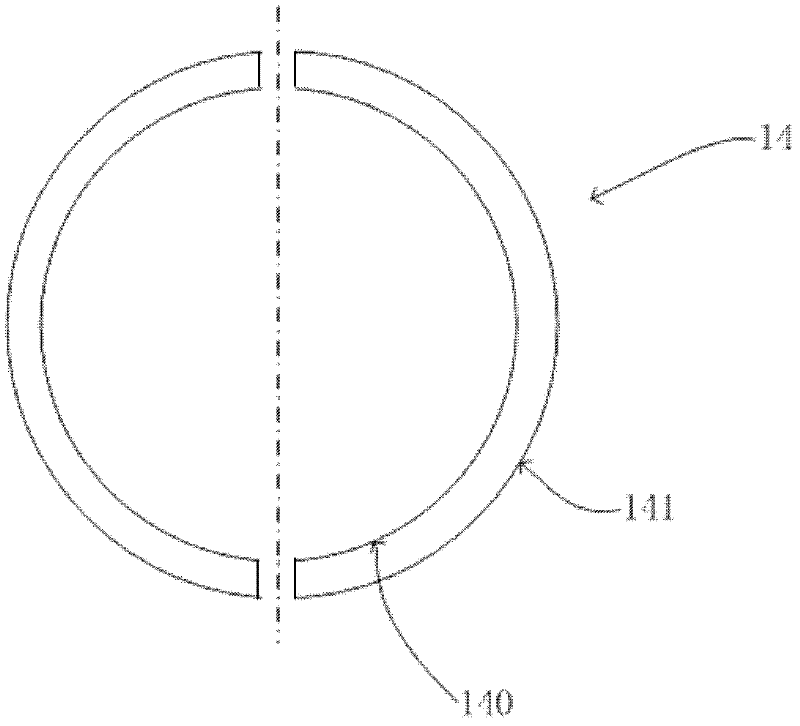

[0021] To solve this problem, the present invention sets a hollow annular protective ring in the plasma processing apparatus, which is installed on the electrostatic chuck to surround the electrostatic chuck and supports the wafer to be processed together with the electrostatic chuck. Therefore, the back side of the electrostatic chuck will not be exposed to the plasma in the processing chamber, so that the problem of contamination of the back side of the wafer during the plasma treatment process of the wafer can be improved. Moreover, the size of the guard ring can be flexibly adjusted according to the diameter of the wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com