Cast-in-situ dado structure for manually excavated pile and construction method

A technique for manually digging piles and wall structures, which is applied in foundation structure engineering, sheet pile walls, buildings, etc. It can solve problems such as inconsistent construction methods, achieve high strength and stability of retaining walls, and overcome the need for transportation and hoisting of prefabricated retaining walls in mountainous areas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

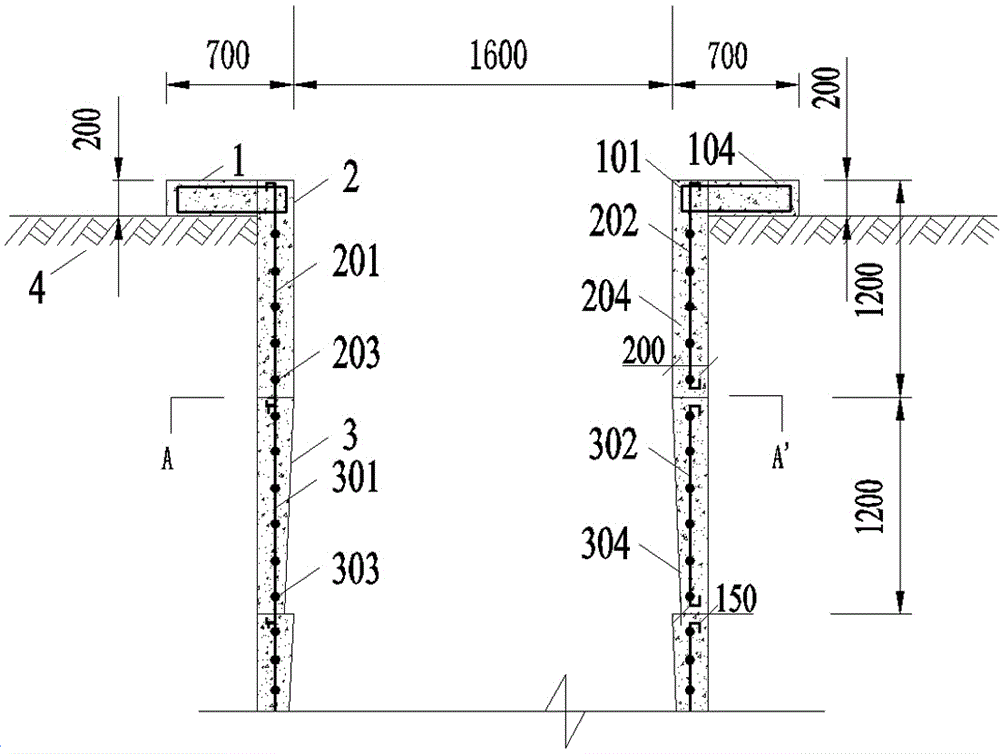

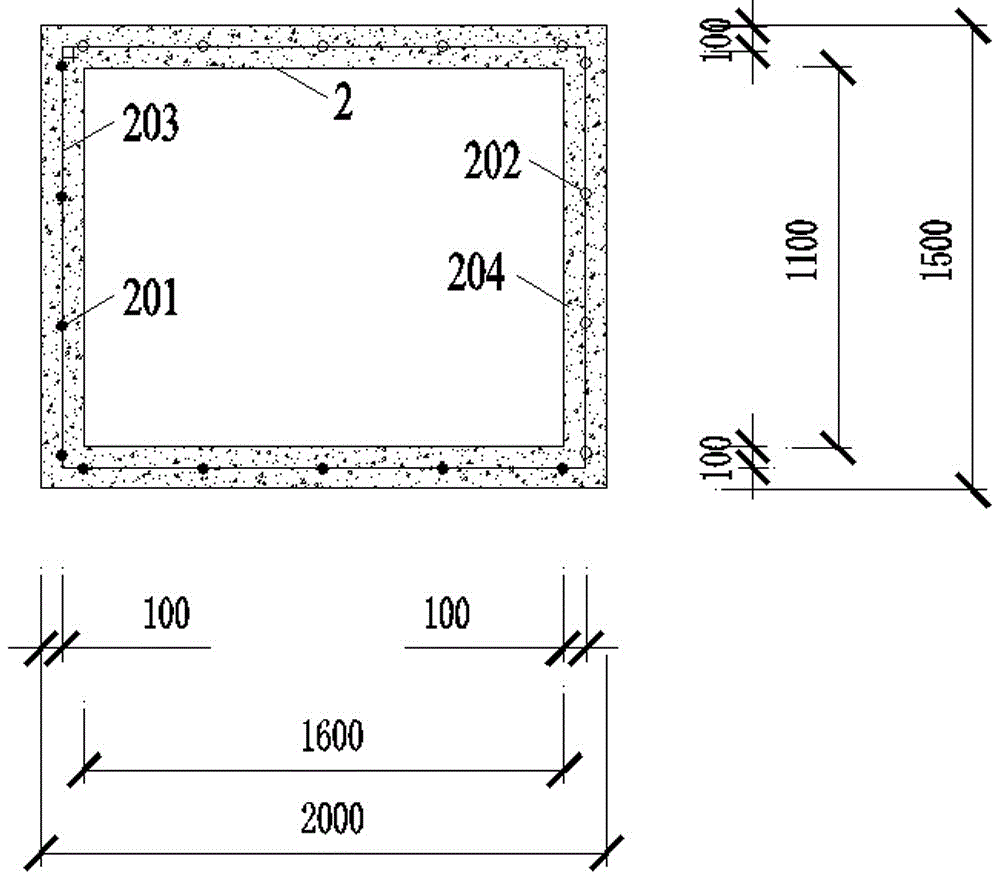

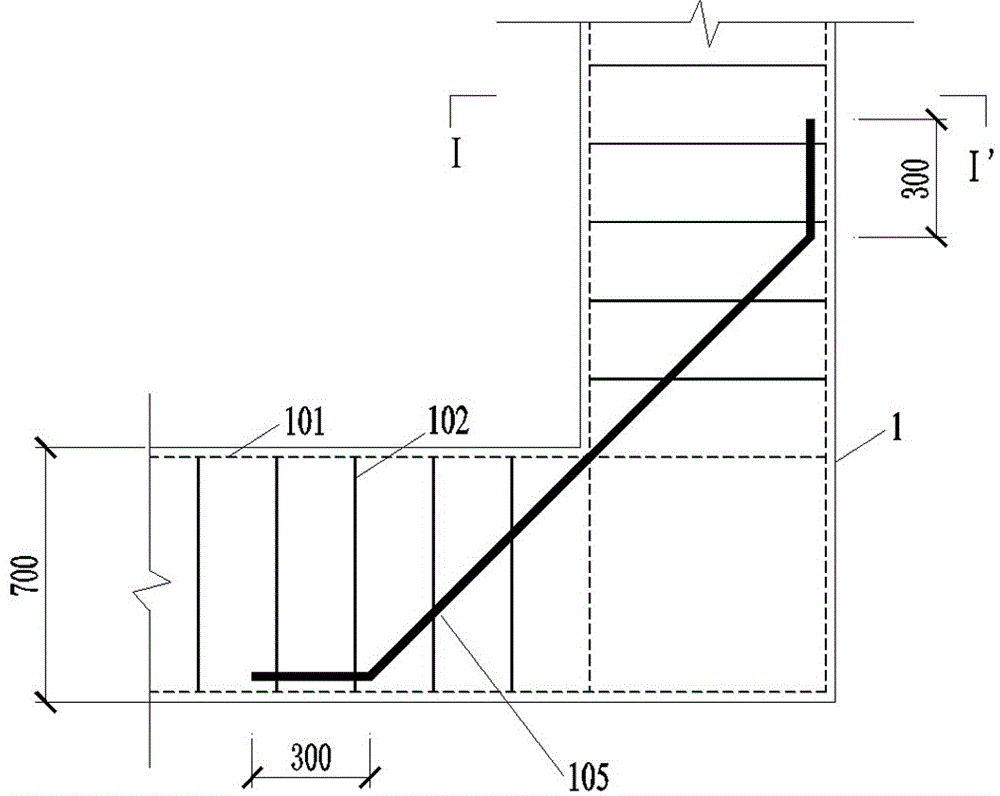

[0026] Hereinafter, the specific content of the present invention will be described in detail in conjunction with the accompanying drawings by taking the manual hole-digging pile with a horizontal section of 1.1 m in width and 1.6 m in length as an example.

[0027] The retaining wall system includes a lock beam 1 on the horizontal plane of the soil body 4 of the hole and a retaining wall on the side wall of the pile.

[0028] The material of the locking beam 1, the orifice connection section retaining wall 2 and the hole inner section retaining wall 3 is reinforced concrete, and the steel bars adopted are Class I steel bars, and the pouring concrete is C25 concrete.

[0029] The bottom surface of the locking beam 1 closely fits the horizontal plane of the soil body 4, and the upper surface is parallel to the bottom surface. It is flush with the upper surface of the orifice connecting section retaining wall 3 .

[0030] The longitudinal section shape of the orifice connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com