Patents

Literature

45results about How to "Will not affect normal transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

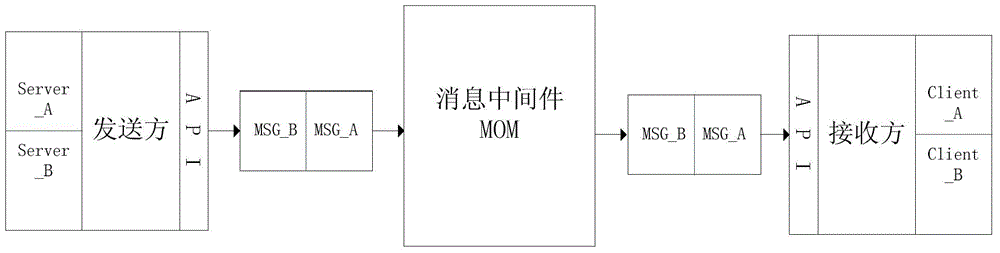

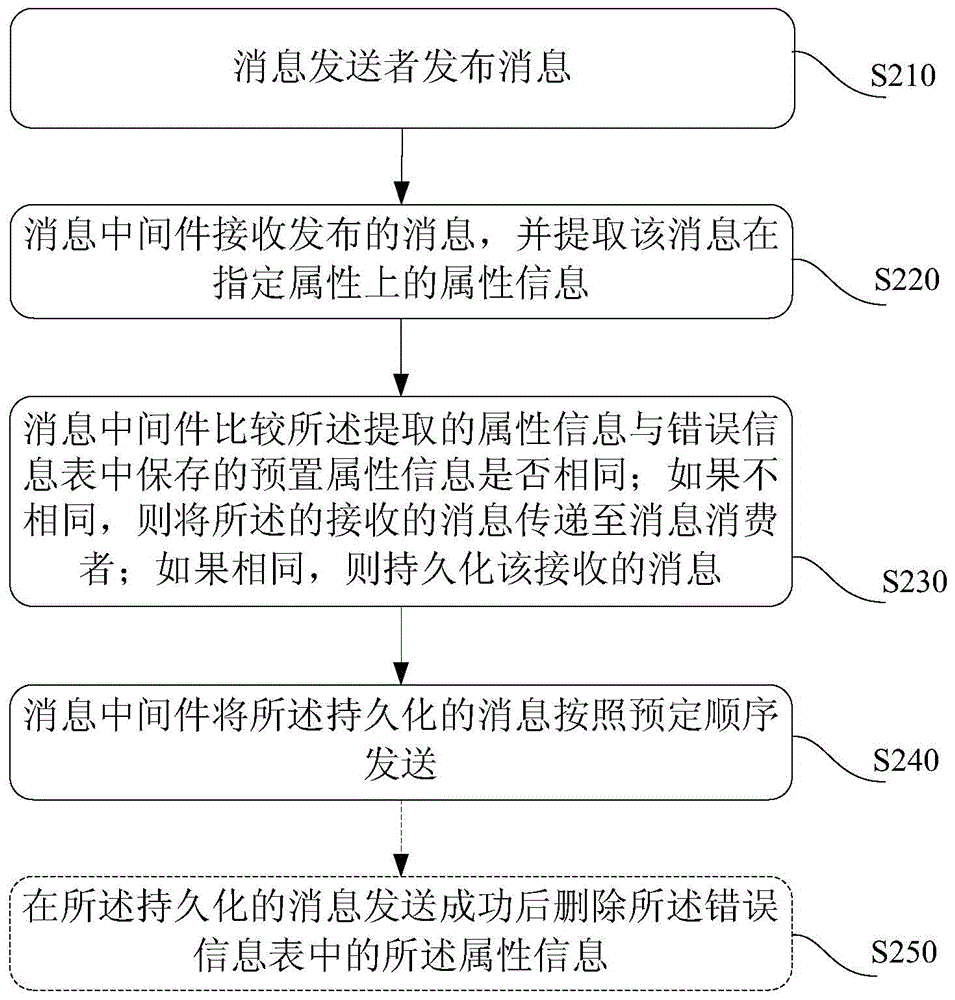

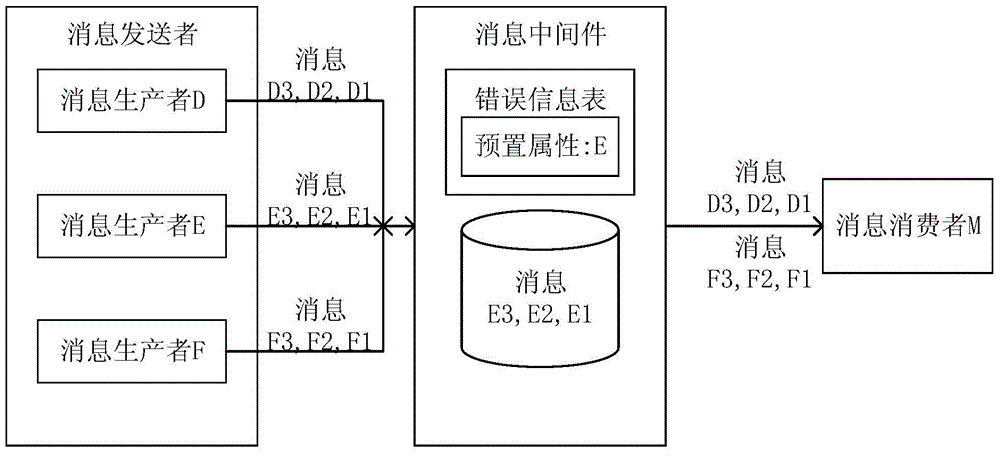

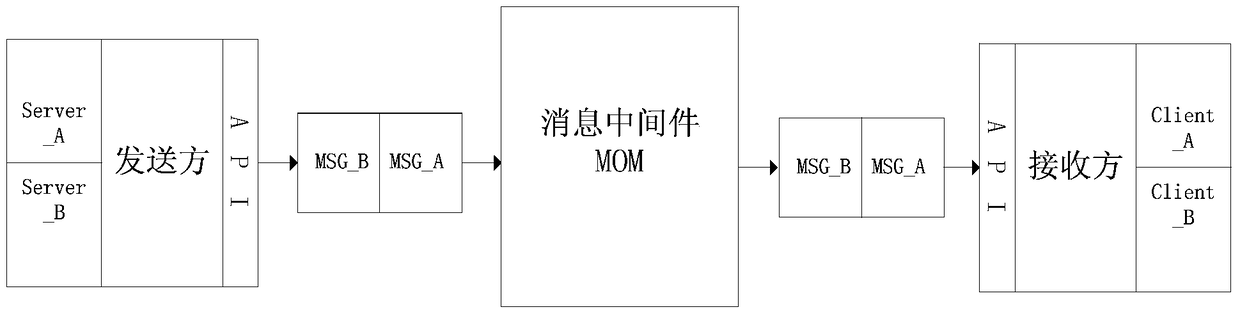

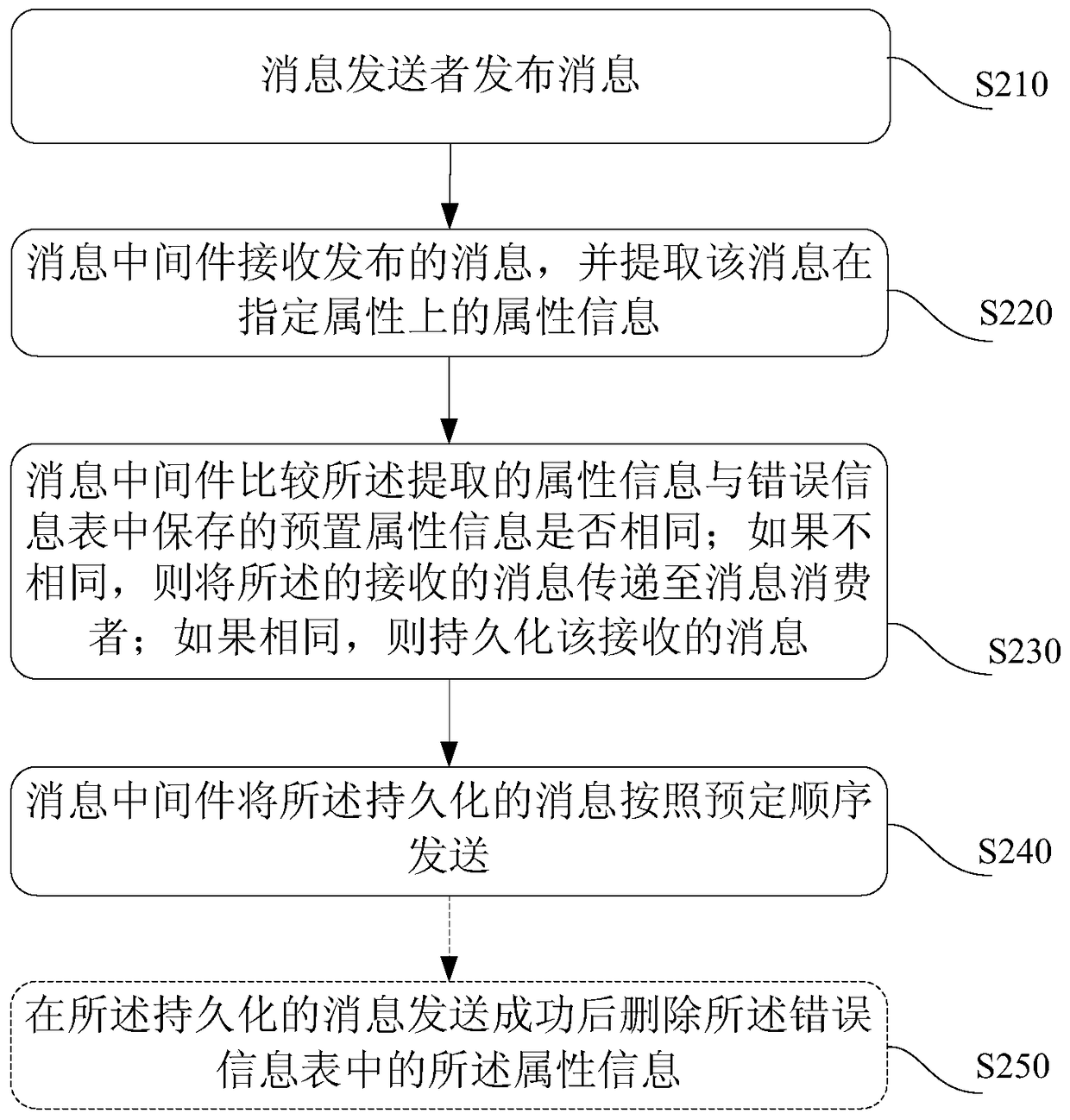

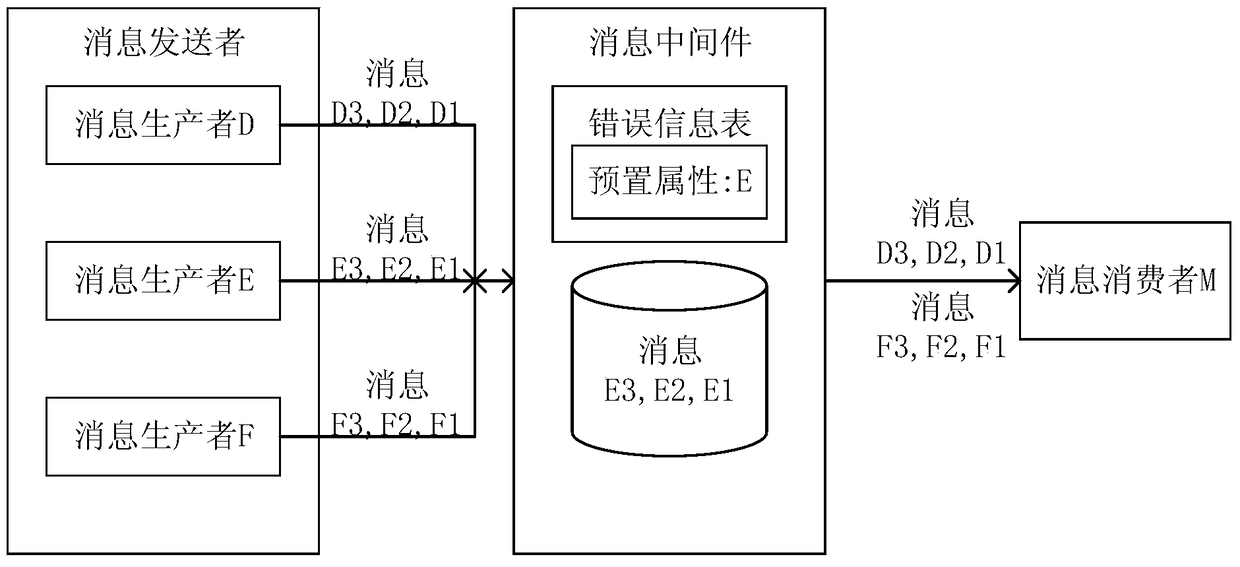

Message transmission method and system and message-oriented middleware

ActiveCN104980450AGuaranteed stabilityGuaranteed correctnessTransmissionMessage passingMessage-oriented middleware

The invention provides a message transmission method and system and a message-oriented middleware. The message transmission method comprises: a message sender issues messages with different attribute information; the message-oriented middleware receives the issued messages and extracts the attribute information of the messages on an appointed attribute; the message-oriented middleware determines whether the extracted attribute information is the same as preset attribute information saved in an error information table; if not, the message-oriented middleware transfers the received messages to a message consumer or maintains the received messages; if yes the message-oriented middleware sends the maintained messages according to a predetermined sequence. By means of the embodiments of the invention, improvements in the orderliness and the stability of message transmission are facilitated.

Owner:ALIBABA GRP HLDG LTD

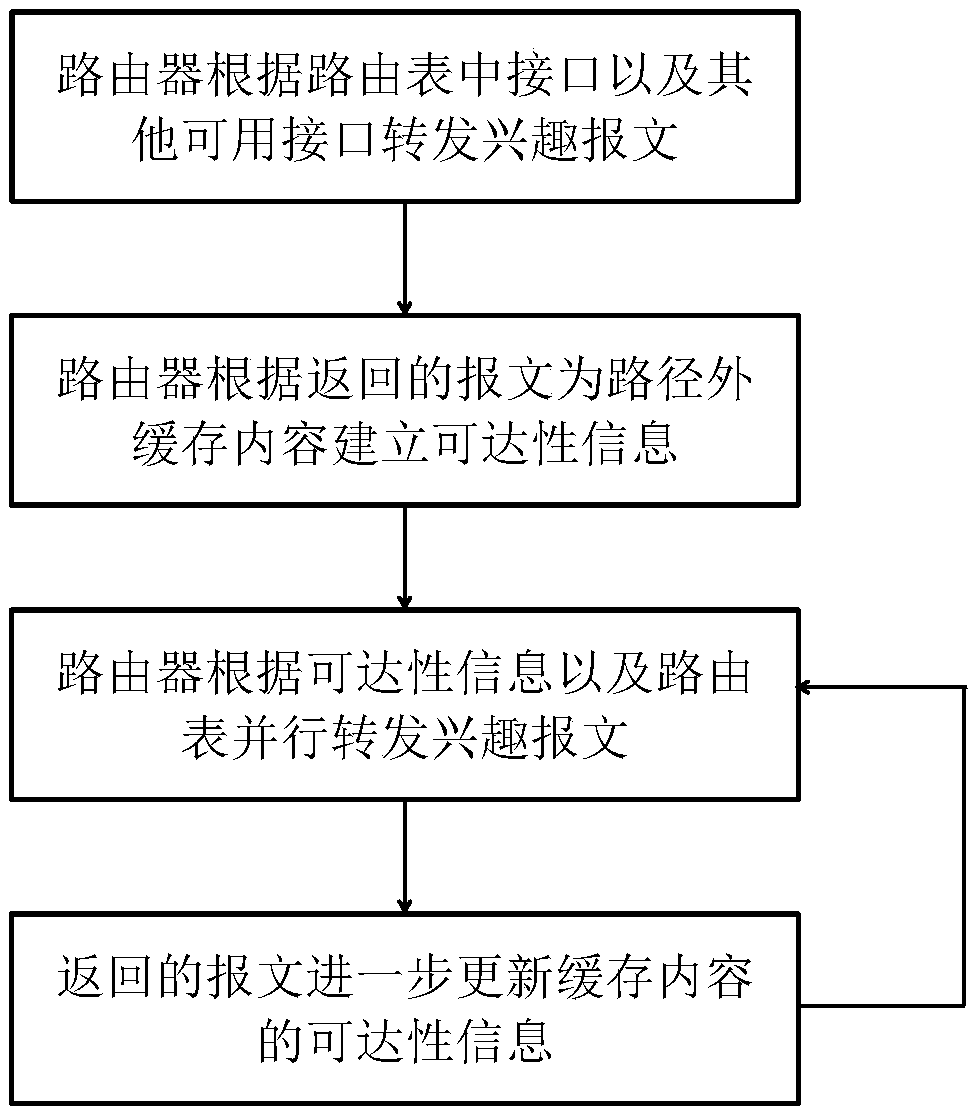

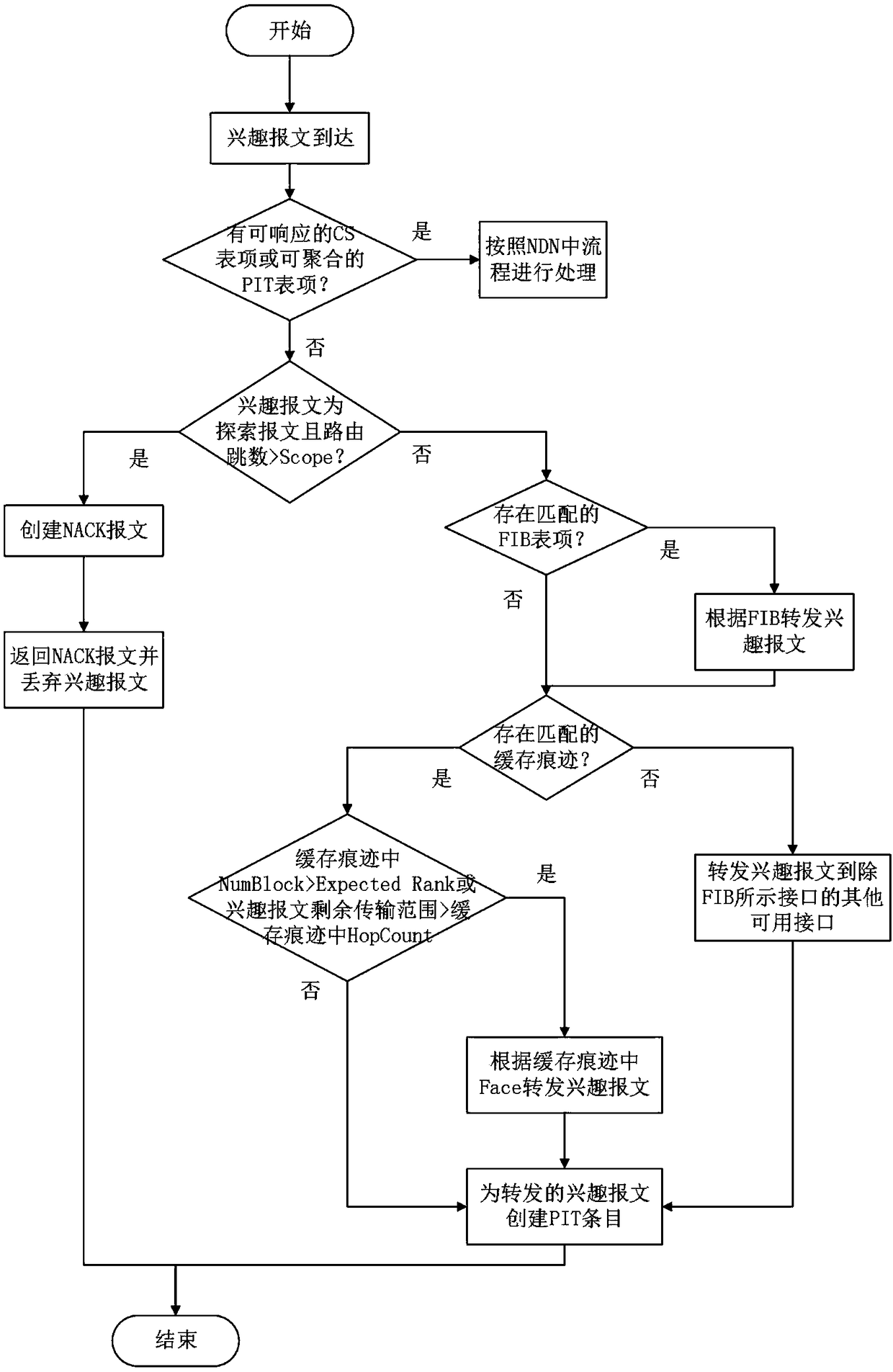

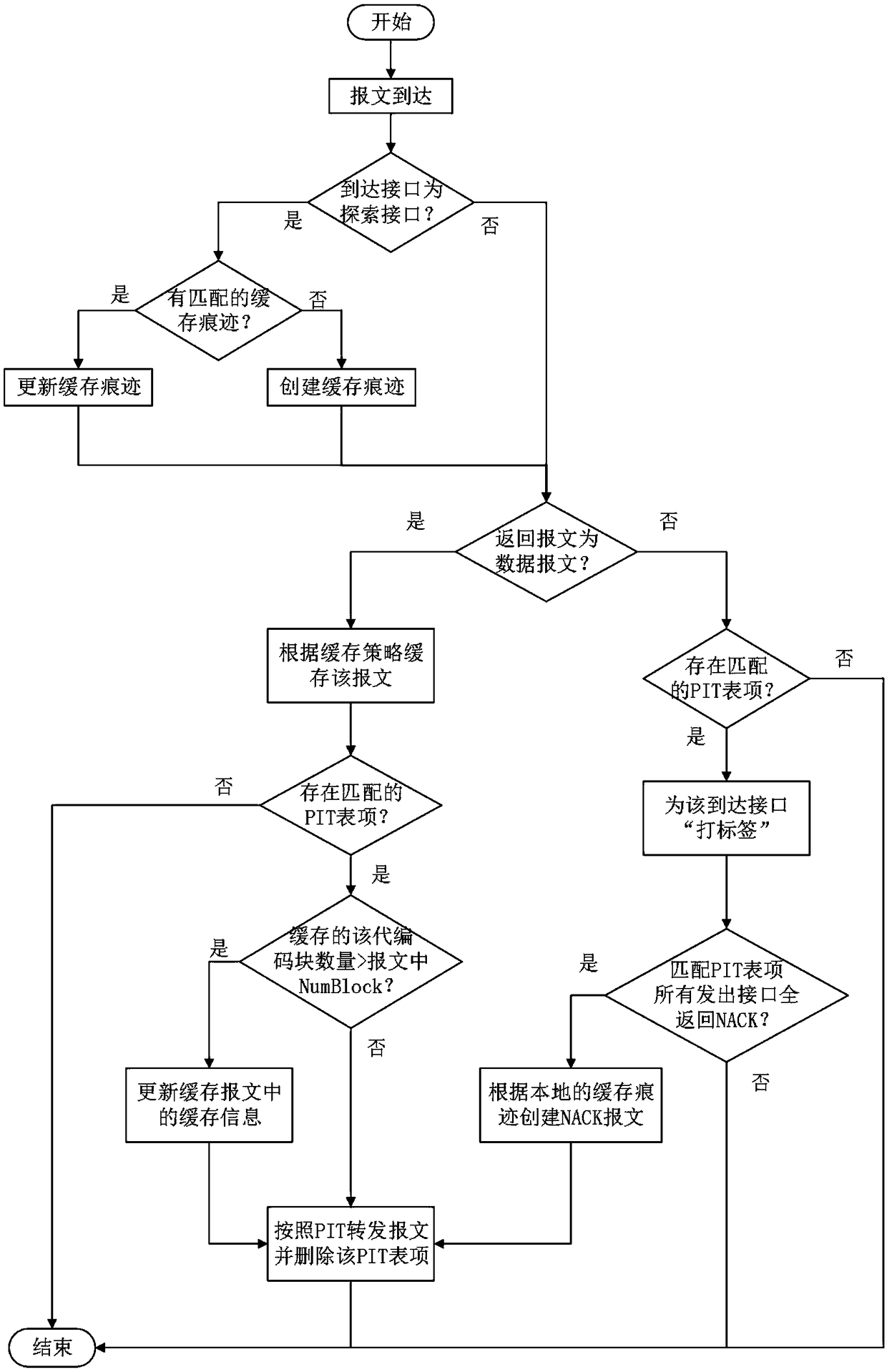

Multipath forwarding method in named data networking based on network coding

ActiveCN109347983AReduce overheadReduce maintenance overheadError prevention/detection by using return channelData switching networksData contentNetwork code

The invention discloses a multipath forwarding method in a named data networking based on network coding. The method comprises two phases of exploring cache content outside the path and utilizing thecache content outside the path. In an initial exploring phase of obtaining a data content generation, a routing table forwards interest messages normally and also forwards the interest messages to other available interfaces, thereby initiatively exploring availability of the generation of data content cached by network nodes outside the path, and reachability information is established for the cache content outside the path according to returned messages. A router forwards the interest messages to an original data source according to the routing table and also forwards the interest messages tocache nodes outside the path according to the reachability information of the cache content outside the path established in the exploring phase, thereby searching response, and the returned messagesare further used for updating the reachability information of the cache content. According to the method, through utilization of the cache content outside the path, the advantages of multipath transmission and in-networking cache of the named data networking are exerted sufficiently, so transmission performance of the networking is improved.

Owner:SOUTHEAST UNIV

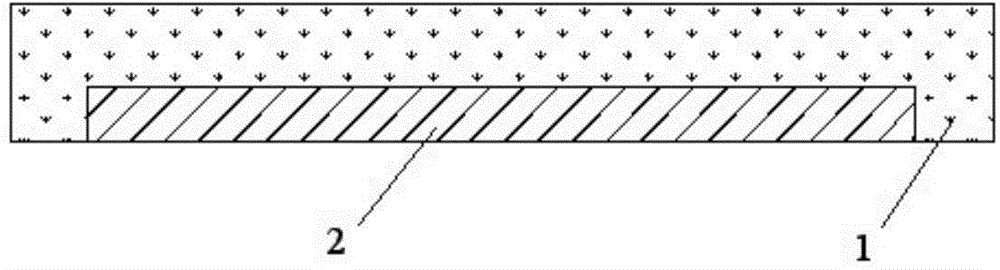

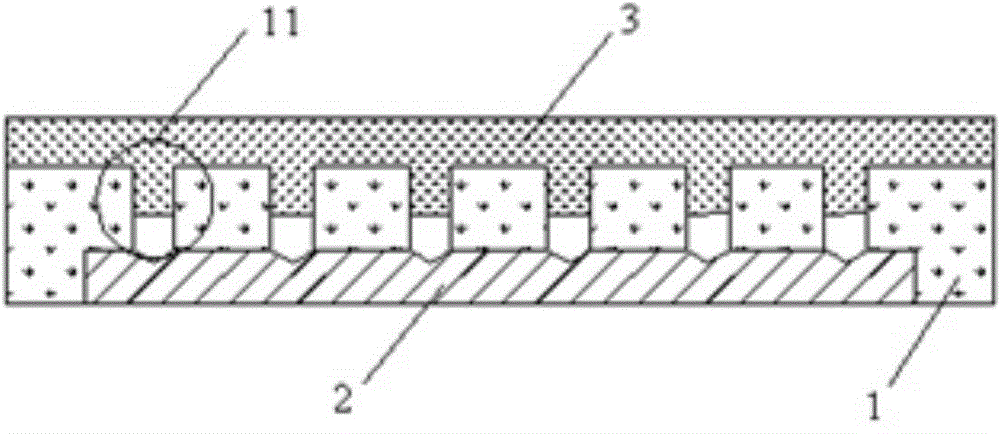

Communication equipment metal shell and preparation method thereof

InactiveCN105530782AImprove processing strengthImprove the decorative effectMetal casingsMetal layered productsEngineeringMetal substrate

The invention discloses a communication equipment metal shell and a preparation method thereof. The communication equipment metal shell comprises a metal substrate, slits and a plastic support layer, wherein the plastic support layer covers at least one part of the inner surface of the metal substrate; the slits run through the metal substrate and do not run through the plastic support layer; and the section shapes of the parts, located on the plastic support layer, of the slits are one or more of an inverted cone, an arc shape, a rectangle and an inverted trapezoid. The slits of the communication equipment metal shell disclosed by the invention do not deform and the communication equipment metal shell has smooth consistency in appearance.

Owner:BYD CO LTD

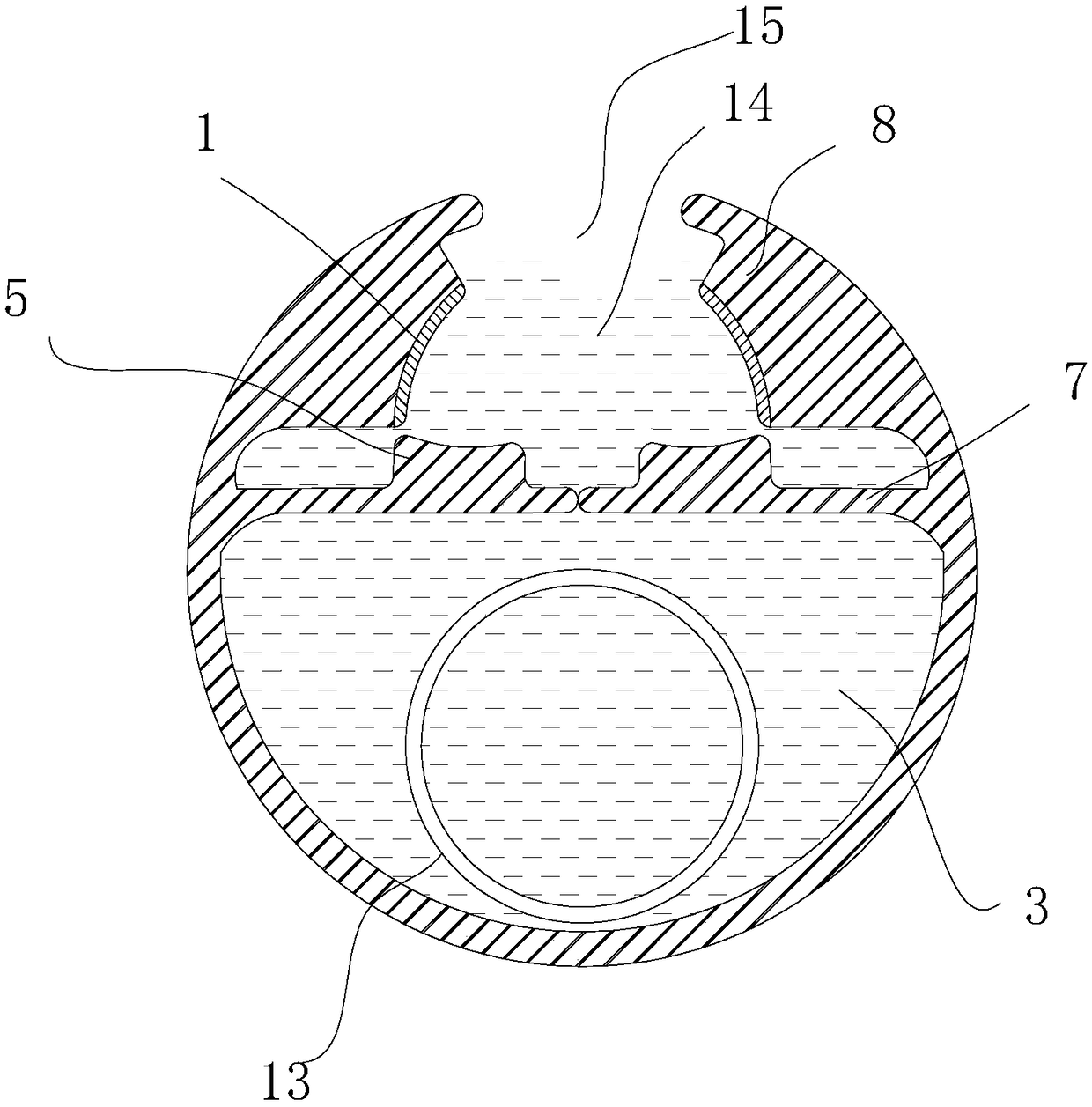

Drainage pipeline

ActiveCN108758111ARealize separate cavity dischargeReduce CooldownPipe heating/coolingRigid pipesEngineeringShear force

The invention discloses a drainage pipeline. The drainage pipeline comprises a pipeline body. The top of the pipeline body is provided with an opening. Two partition boards are arranged in the middleportion of the pipeline body. The opposite faces of the two partition boards make contact with each other for sealing. The other ends of the two partition boards are integrally connected with the pipeline body. The two partition boards cut off a drainage channel in the middle of the pipeline body. A bottom drainage cavity is formed below the two partition boards. A clamping cavity is formed at theupper ends of the partition boards. An intermediate pipe is arranged in the clamping cavity. The middle of the intermediate pipe is provided with an independent drainage channel. The drainage pipeline can realize respective cavity discharge of two kinds of liquid simultaneously. The whole pipeline can be opened in the shearing process, water in the pipeline is discharged to give an effective warning. When shear force is large, the intermediate pipe can be pressed into the bottom drainage cavity below the partition boards to be protected. The drainage pipeline has good buffering performance and protective performance, also has the good warning effect and achieves the effect of high-efficiency liquid discharge.

Owner:山东泷瑞源电气科技有限公司

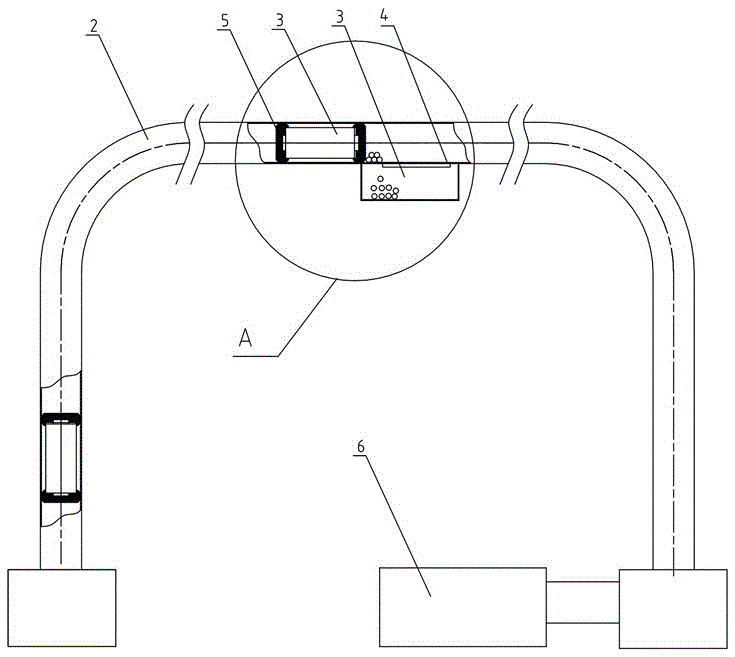

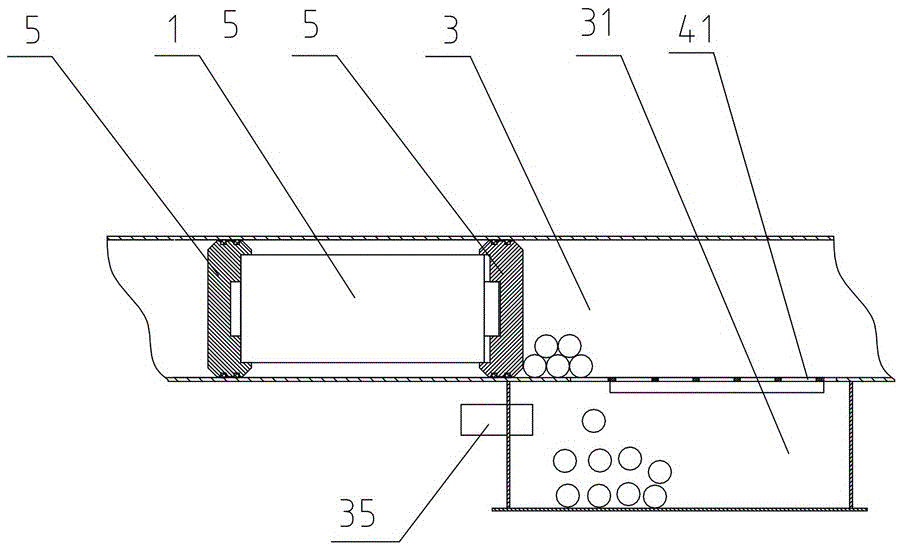

Pneumatic material conveying system with functions of sweeping and collecting

The invention discloses a pneumatic material conveying system with functions of sweeping and collecting. The pneumatic material conveying system comprises a pneumatic transmission pipeline used for transmitting materials to be conveyed, and more than one blanking collection device connected with the pneumatic transmission pipeline in a sealing way, wherein each blanking collection device is provided with a blanking collection cavity used for collecting a foreign matter in the pneumatic transmission pipeline; a foreign matter settling part used for enabling the foreign matter to settle is arranged between each blanking collection cavity and a pipeline cavity of the pneumatic transmission pipeline; the blanking collection cavities are communicated with the pipeline cavity of the pneumatic transmission pipeline by the foreign matter settling parts; when the foreign matter moving in the pneumatic transmission pipeline passes through the blanking collection devices, the foreign matter settles in the foreign matter settling parts and then drops into the blanking collection cavities. The pneumatic material conveying system has the advantages of being capable of collecting the foreign matter in the pneumatic transmission pipeline in time, maintaining the interior of the pneumatic transmission pipeline to be clean, and being easy to maintain.

Owner:HUNAN SUNDY SCI & TECH DEV

Cotton-thread production technology

ActiveCN107488902AReduce processing timeAvoid downtimePiercing arrangementsMechanical engineeringCotton thread

The invention belongs to the field of spinning, and discloses a cotton-thread production technology. The cotton-thread production technology includes the following steps that 1, a cotton thread is sequentially wound around all guiding wheels to penetrate out of a winding part; 2, a movable base is moved, and the distance between an upper pressing plate and a lower pressing plate is adjusted to be maximum; 3, the cotton thread is tightened through all the guiding wheels, the tightened cotton thread pulls a triggering wheel, and a stretchable rod is located in the extension stage; 4, when the thread breaking condition of the cotton thread appears, pull applied to the triggering wheel through the cotton thread disappears, and the triggering wheel is pulled by a pulling spring to move towards a pressing plate provided with the stretchable rod; 5, the triggering wheel presses the cotton thread wound around the triggering wheel on the pressing plate, and meanwhile the triggering wheel presses a pressing switch; 6, a motor connected with the pressing switch drives the movable base to move, the movable base enables the upper pressing plate and the lower pressing plate to oppositely move through two pulling rods, and a redundant cotton thread wound around the winding part is released out of an outlet of the winding part. By means of the cotton-thread production technology, the thread breaking condition can be discovered in time.

Owner:ZUNYI TIANYUN TEXTILE CO LTD

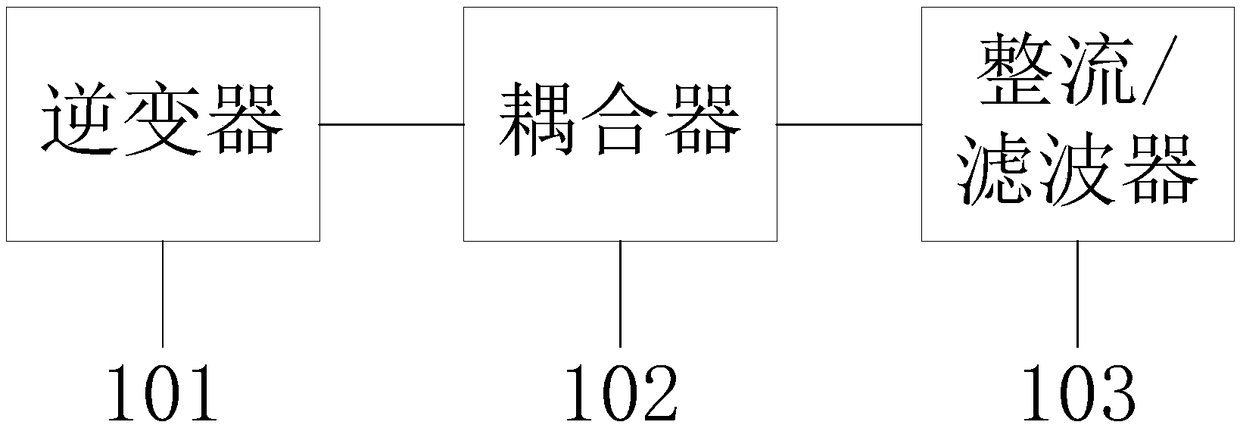

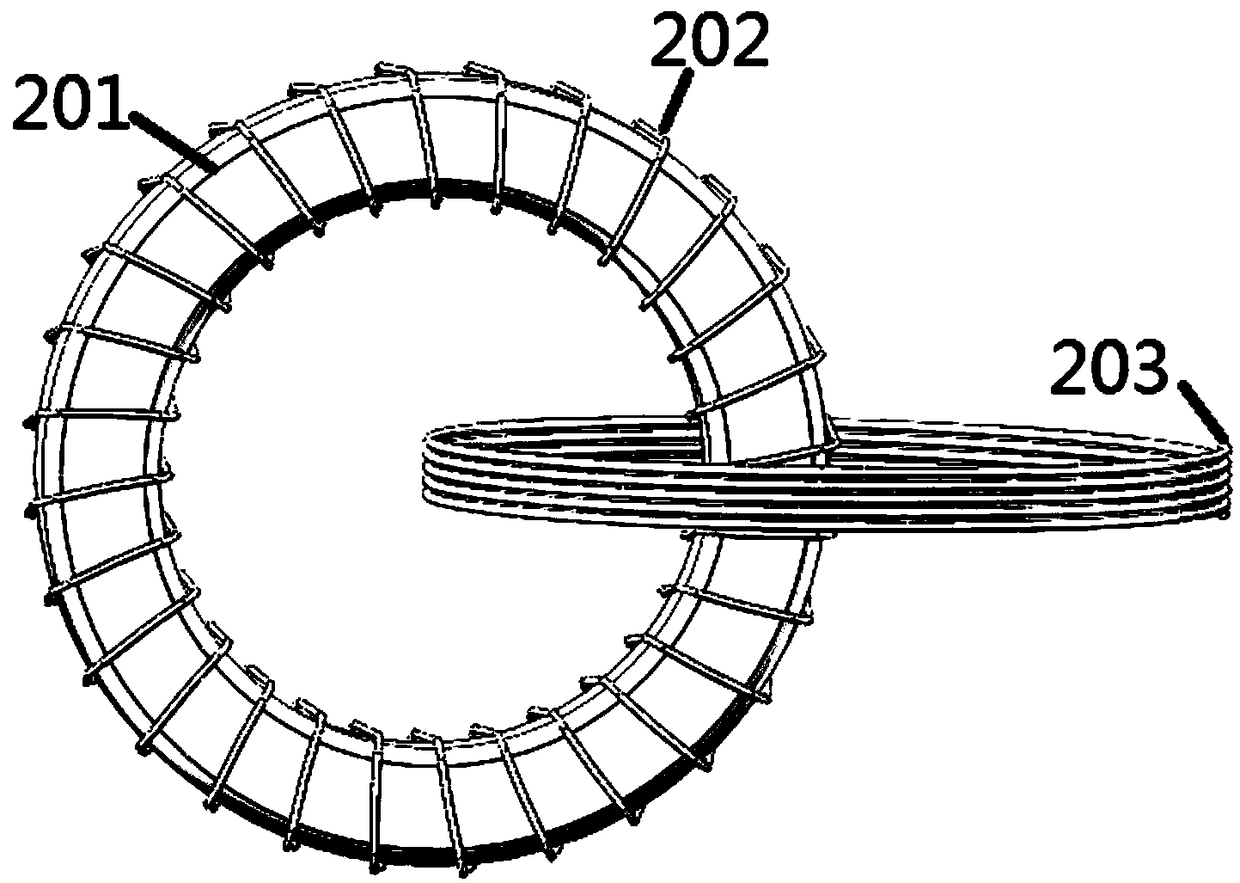

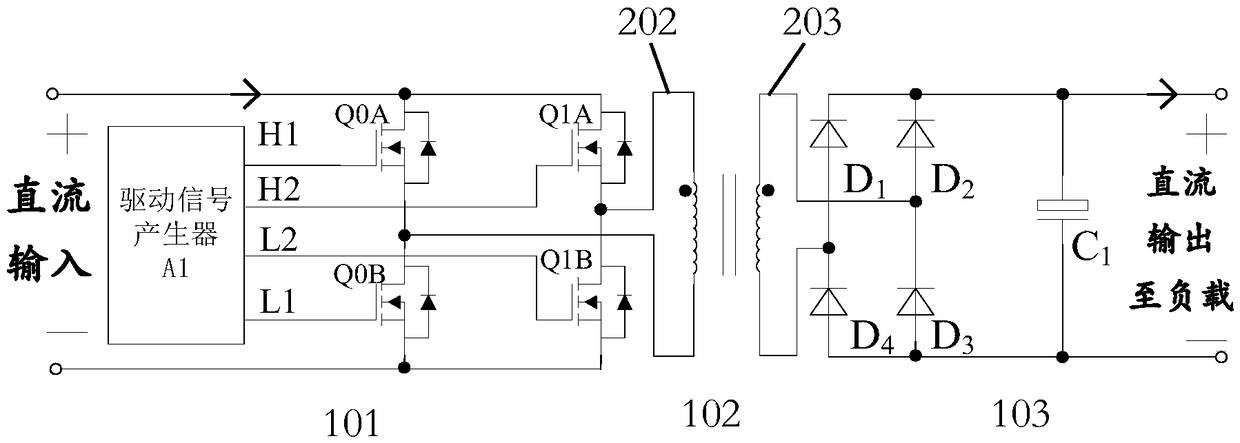

Non-contact type power transmission device capable of canceling electromagnetic force

InactiveCN108879983AEasy to useNo mechanical wearAc-dc conversion without reversalCircuit arrangementsElectromagnetic interferenceContact type

The invention discloses a non-contact type power transmission device capable of canceling electromagnetic force. The non-contact type power transmission device is composed of an inverter, a coupler and a rectifier / filter. The non-contact type power transmission device capable of canceling the electromagnetic force has high reliability, a long service life, vibration isolation, no electromagnetic force and no abrasion and is free from the influence of impurities.

Owner:XIDIAN UNIV

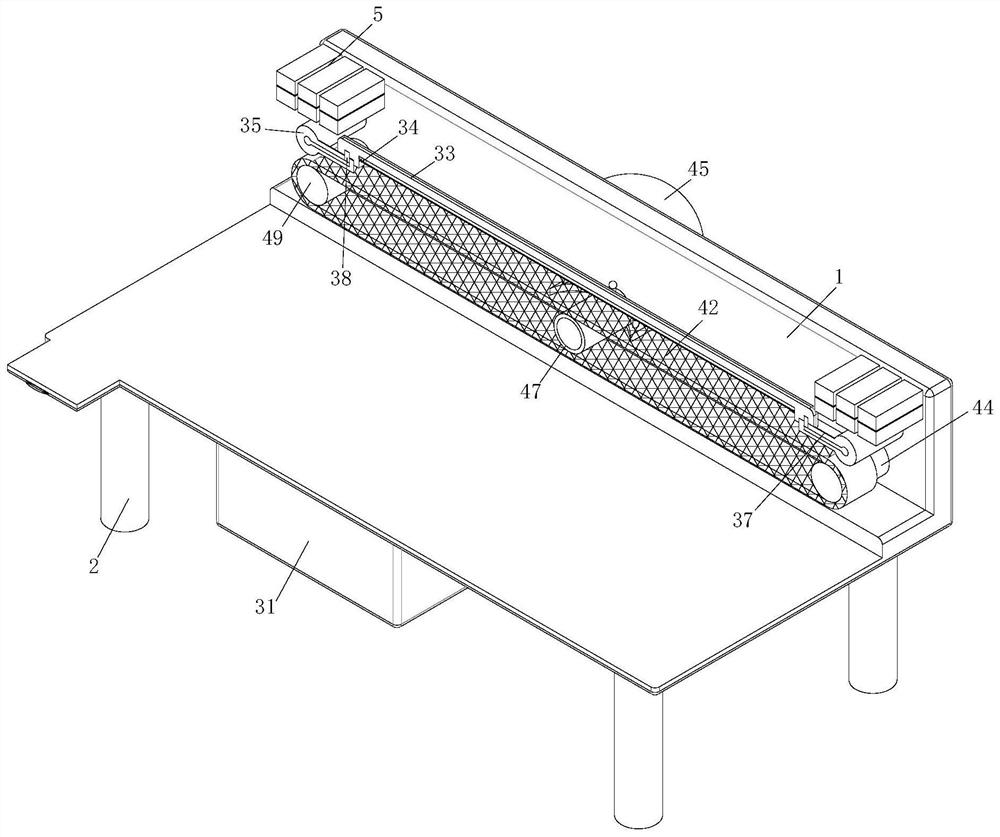

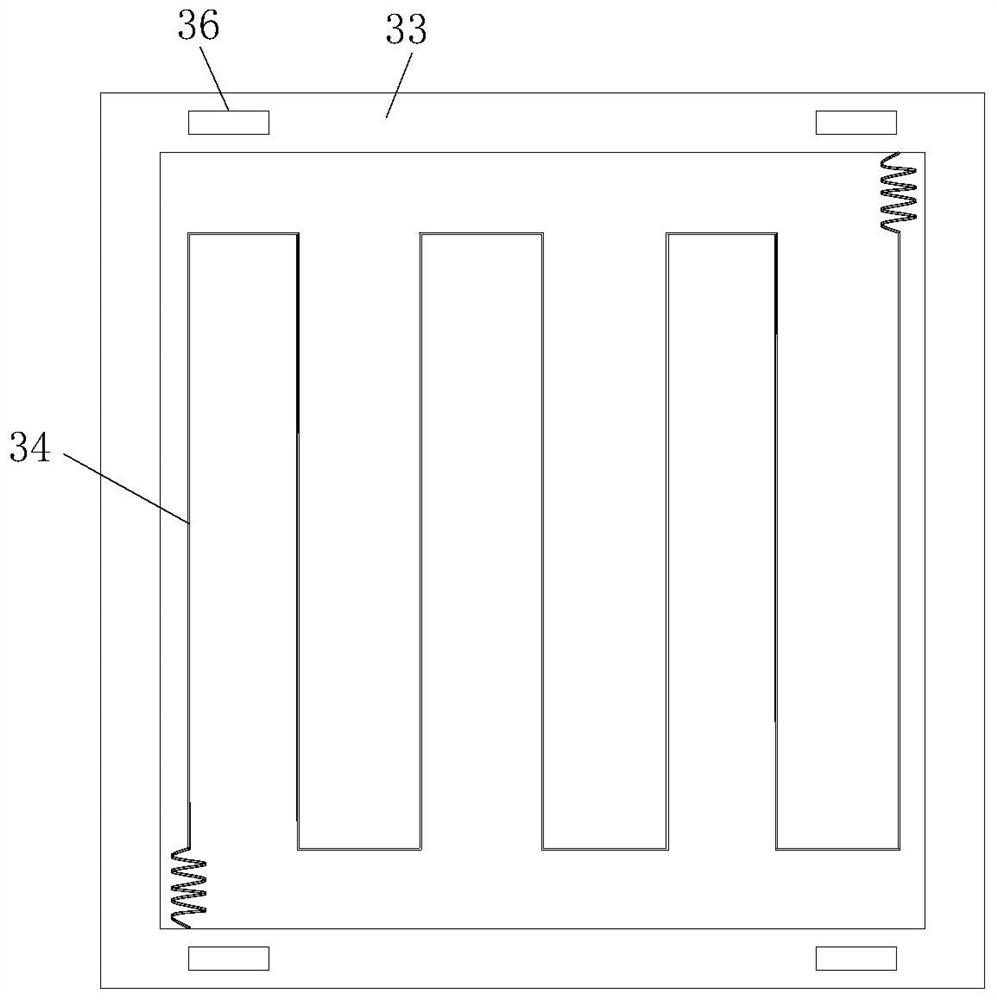

Novel environment-friendly and efficient transport equipment in underground coal mine

InactiveCN107187793AImprove transmission efficiencyAddressing coal slippageConveyorsEarth drilling and miningCoalEngineering

The invention discloses novel environment-friendly and efficient transport equipment in an underground coal mine. The equipment comprises a coal belt conveyor and a baffle block. A plurality of rows of electromagnetic blocks are uniformly distributed and embedded in a conveying belt of the coal belt conveyor. The thickness of each electromagnetic block is equal to that of the conveying belt. The embedded electromagnetic blocks do not affect smooth conveying of the conveying belt on rollers of the coal belt conveyor. Connecting line poles of the electromagnetic blocks are arranged on one side of the conveying belt. An electric brush is arranged on the connecting line poles on a coal conveying section of the conveying belt. A baffle block pushing device is arranged at the position, corresponding to the conveying belt, of the lower end of the coal belt conveyor and pushes the baffle block onto the conveying belt. The baffle block is in attraction connection with the electrified electromagnetic blocks. By arranging the baffle block with a circulating separation function on the conveying belt of the coal belt conveyor, the conveying efficiency of the coal belt conveyor can be quadrupled, and the problem that coal is prone to slipping off is well solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

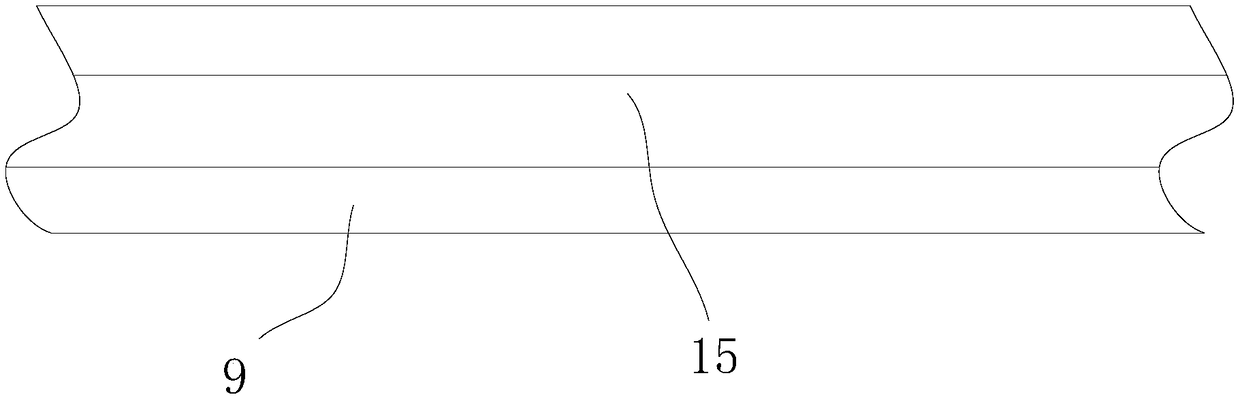

Guiding band with deviation correcting device, of cloth dryer

The invention discloses a guiding band with a deviation correcting device, of a cloth dryer. The guiding band disclosed by the invention comprises a guiding band, wherein two deviation correcting mechanisms are symmetrically arranged on two sides of the guiding band; each of the deviation correcting mechanisms comprises a clamping unit and a pulling unit, wherein each clamping unit comprises an upper clamping roller, a lower clamping roller, an upper center shaft, a lower center shaft and a rotating screw rod; the upper clamping rollers are positioned over an edge of the guiding band, and the lower clamping rollers are positioned under the edge of the guiding band; each of the upper clamping rollers sleeves the corresponding upper center shaft in an inserting manner, and each of the lower clamping rollers sleeves the corresponding lower center shaft in an inserting manner; each of the rotating screw rods is sequentially in screw connection to the corresponding upper center shaft and the corresponding lower center shaft; each pulling unit comprises an inserting and connecting ring, an inserting and sleeving ring and a pulling air cylinder, wherein each inserting and connecting ring is molded on the outer side wall of the corresponding upper clamping roller; each inserting and sleeving ring is molded on the outer side wall of the corresponding lower clamping roller; an annular inserting and connecting groove is formed in the outer side wall of the circumference of each inserting and sleeving ring, and an annular through groove is formed in each inserting and sleeving ring; one end of a piston rod of each pulling air cylinder penetrates through the corresponding through groove and a limiting block is molded at the corresponding penetrated end. Through the adoption of the guiding band disclosed by the invention, the deviated guiding band can be pulled into a correct operating orbit, and the transporting of the guiding band is not influenced.

Owner:浙江嘉业印染有限公司

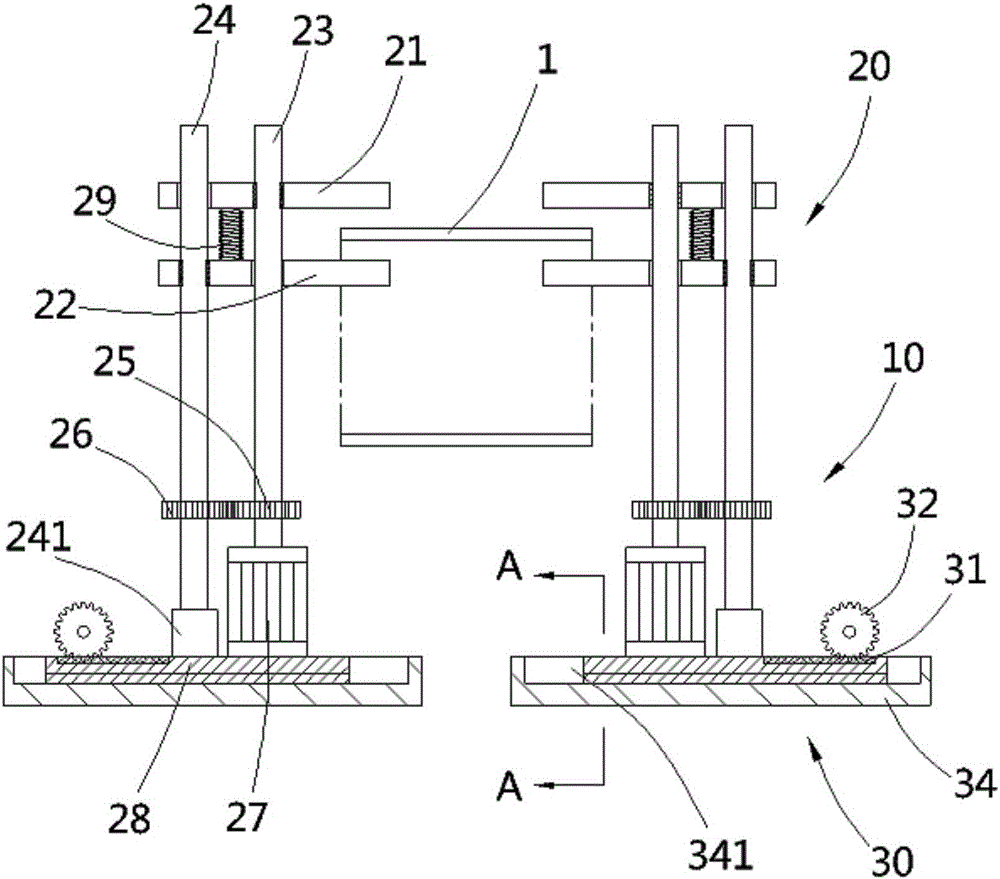

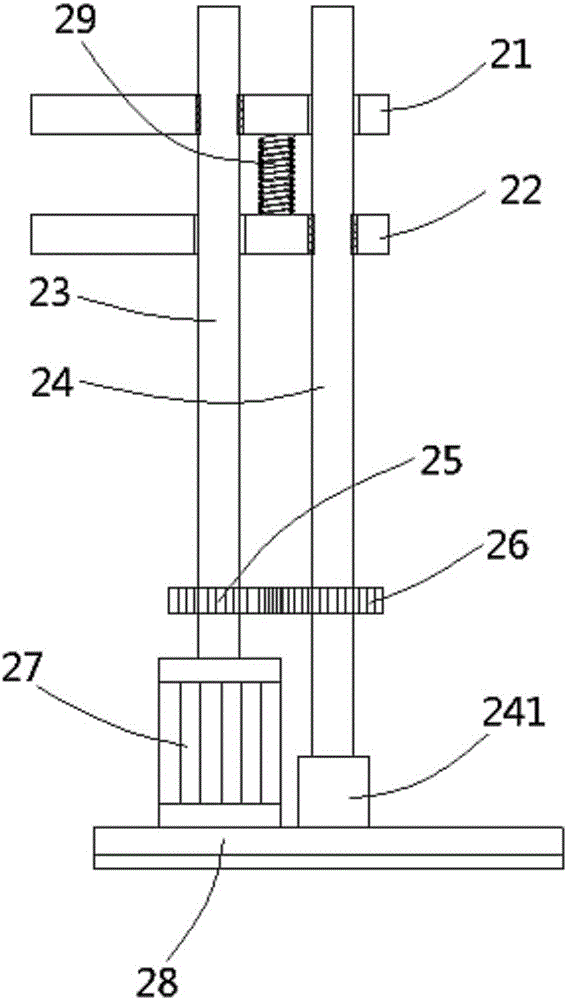

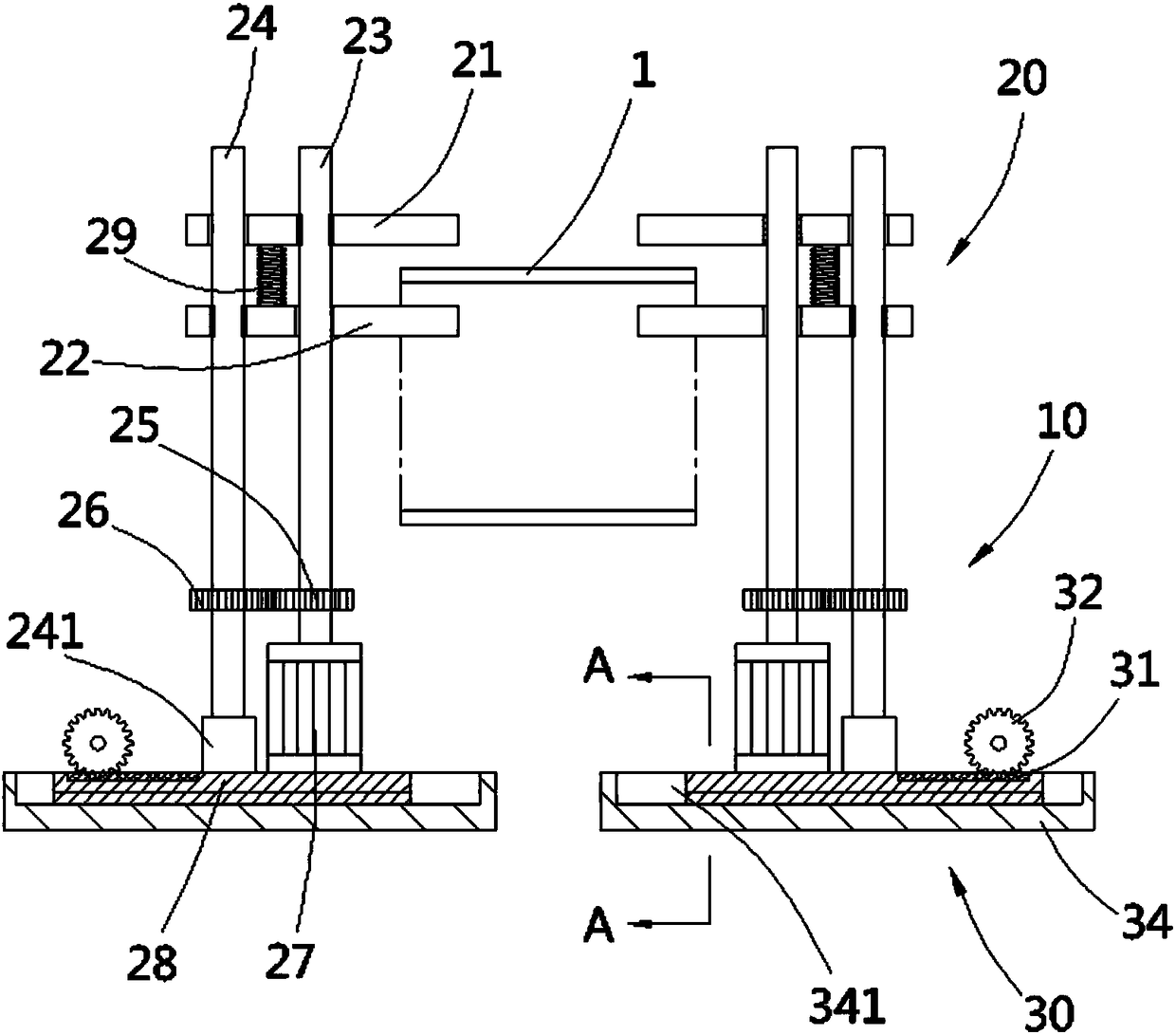

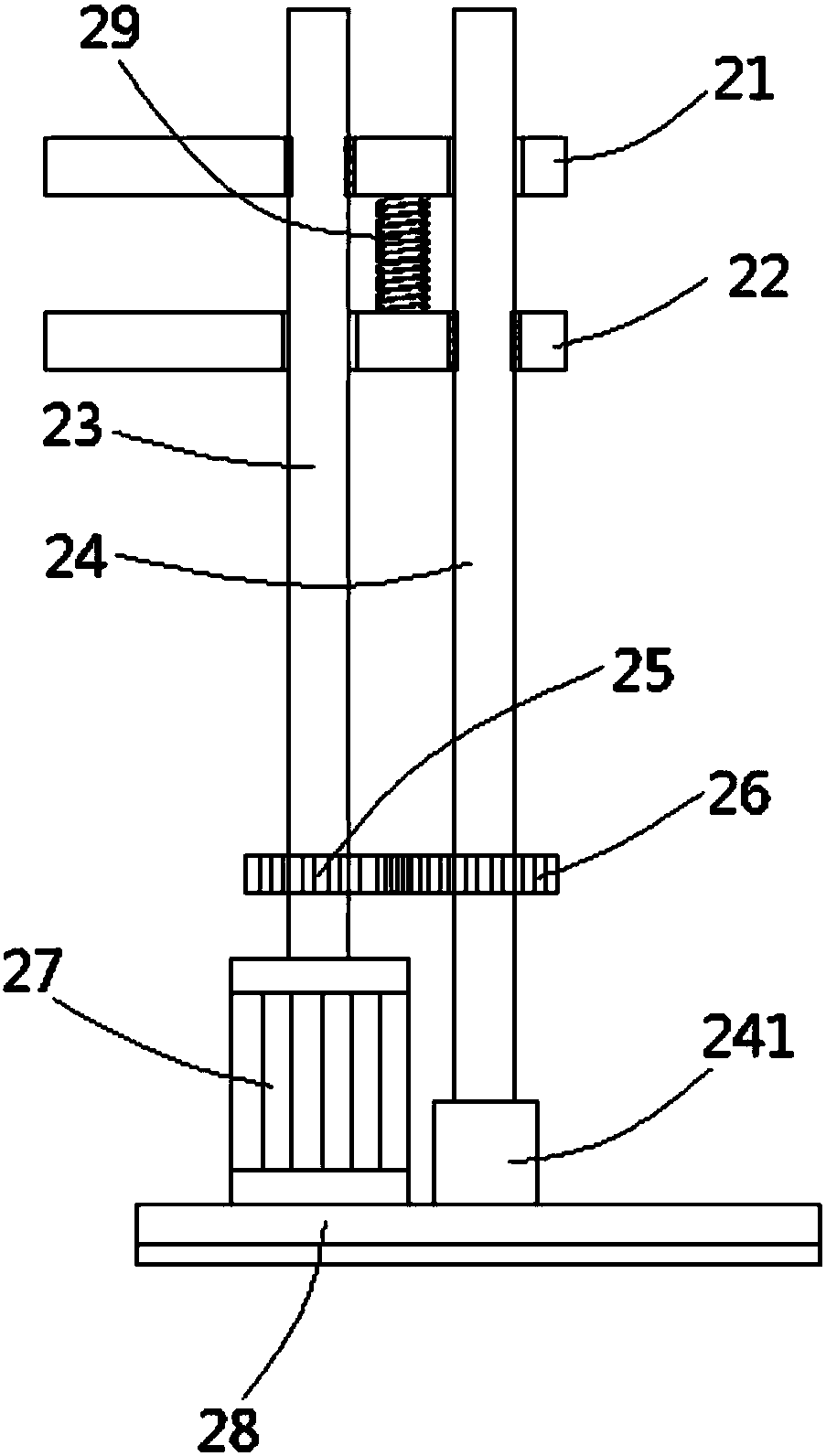

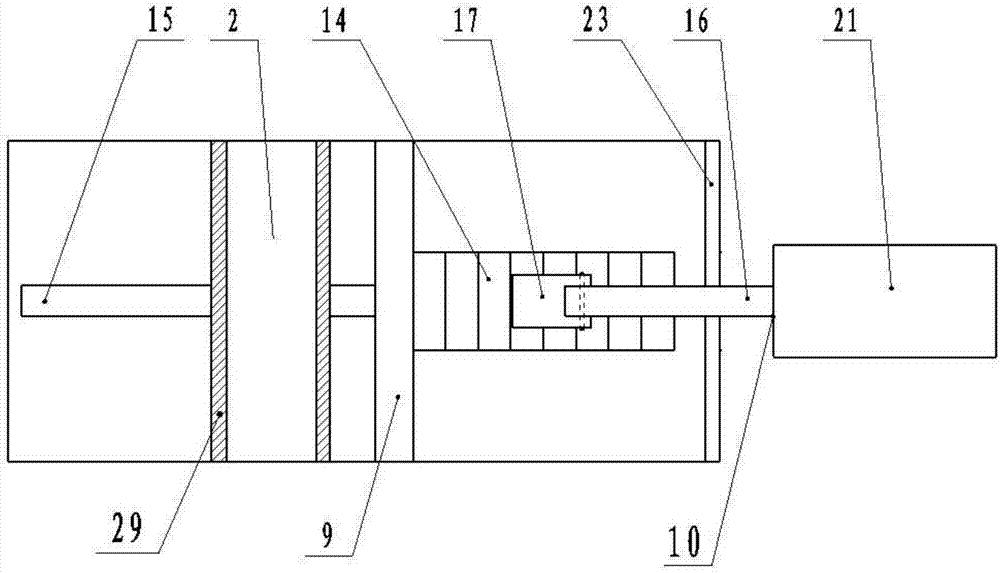

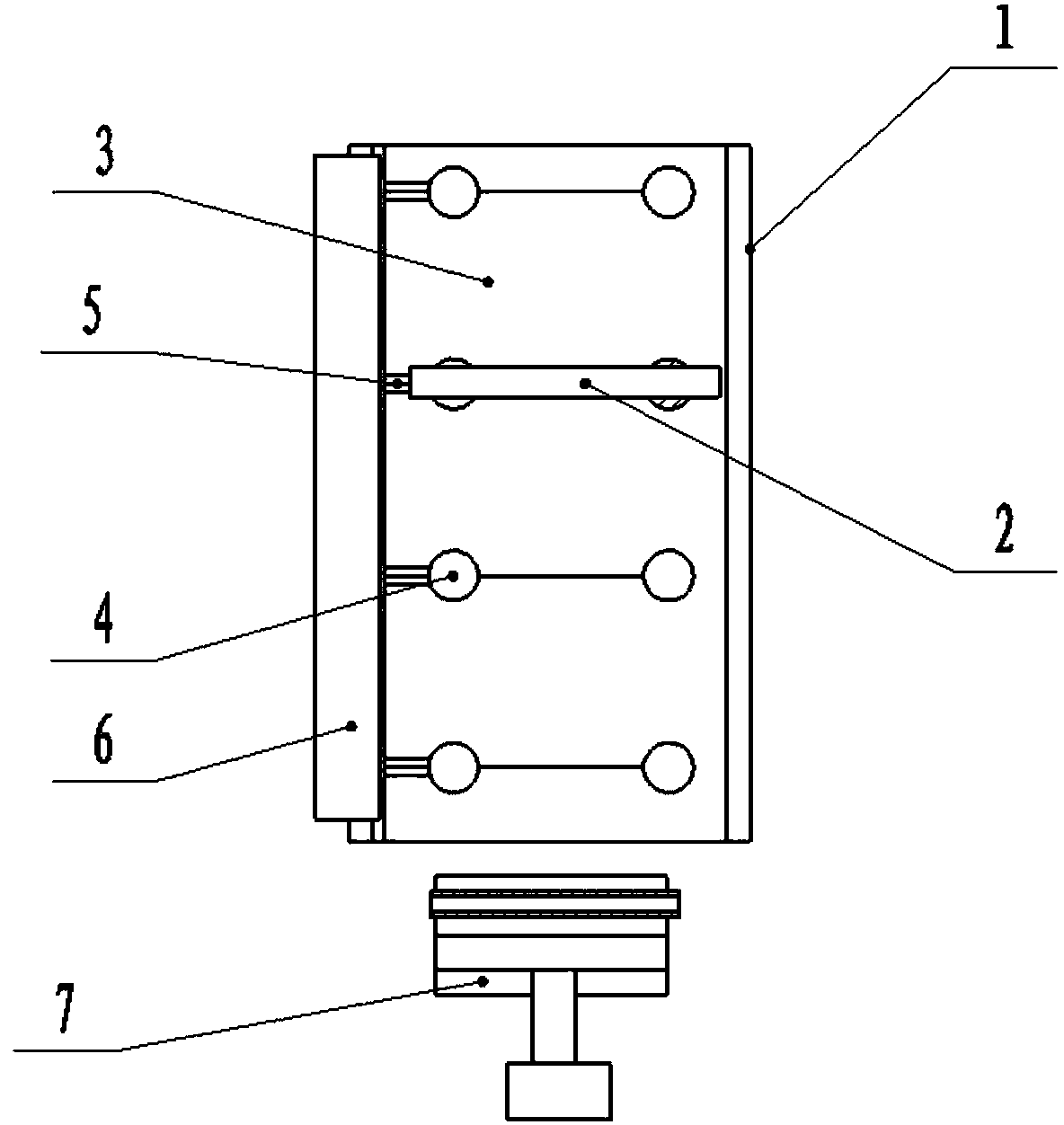

Deviation correcting device for guiding belt of cloth drying machine

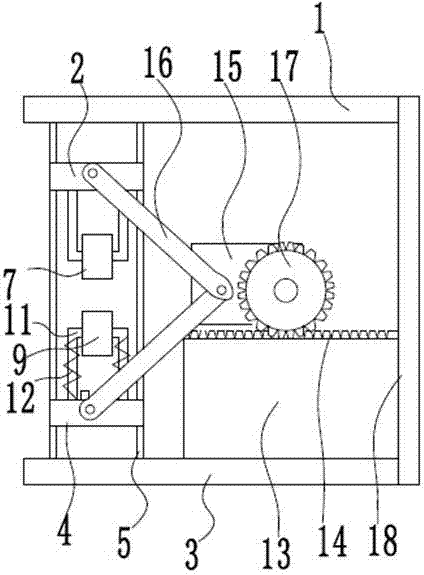

InactiveCN105890337AGuaranteed uptimeWill not affect normal transmissionDrying solid materialsEngineeringDrive motor

The invention discloses a deviation correcting device for a guiding belt of a cloth drying machine. The deviation correcting device comprises two deviation correcting mechanisms which are symmetrically arranged on the two sides of the guiding belt, and each deviation correcting mechanism comprises a clamping unit and a pulling unit; each clamping unit comprises an upper clamping plate, a lower clamping plate, an upper rotating screw, a lower rotating screw, an upper rotating gear, a lower rotating gear, a driving motor and a base plate, wherein the upper clamping plate and the lower clamping plate are located above and below the edge of the guiding belt respectively, the upper rotating screw and the lower rotating screw are vertically connected to the upper clamping plate and the lower clamping plate in a screwed mode respectively, the upper rotating gear and the lower rotating gear are fixedly arranged on the upper rotating screw and the lower rotating screw in a sleeving mode respectively and meshed with each other, and an output shaft of the driving motor is fixedly connected with the lower end of the upper rotating screw; each pulling unit comprises a long-strip-shaped rack part formed on the upper end face of the base plate, a gear meshed with the rack part and a motor used for driving the gear to rotate. According to the device, the deviated guiding belt can be pulled to a correct operating track, and normal conveying of the guiding belt cannot be influenced.

Owner:杉华纺织(苏州)有限公司

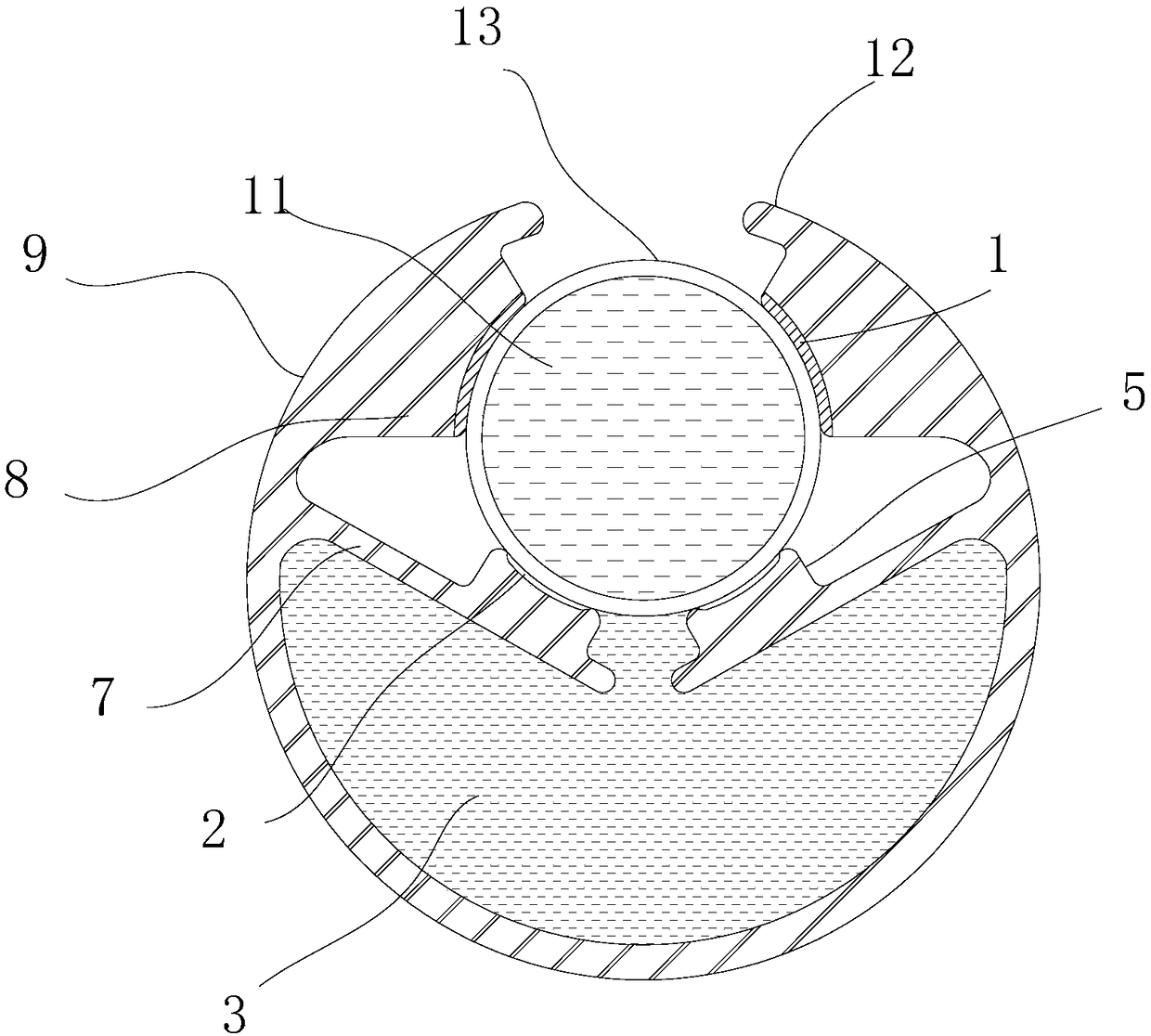

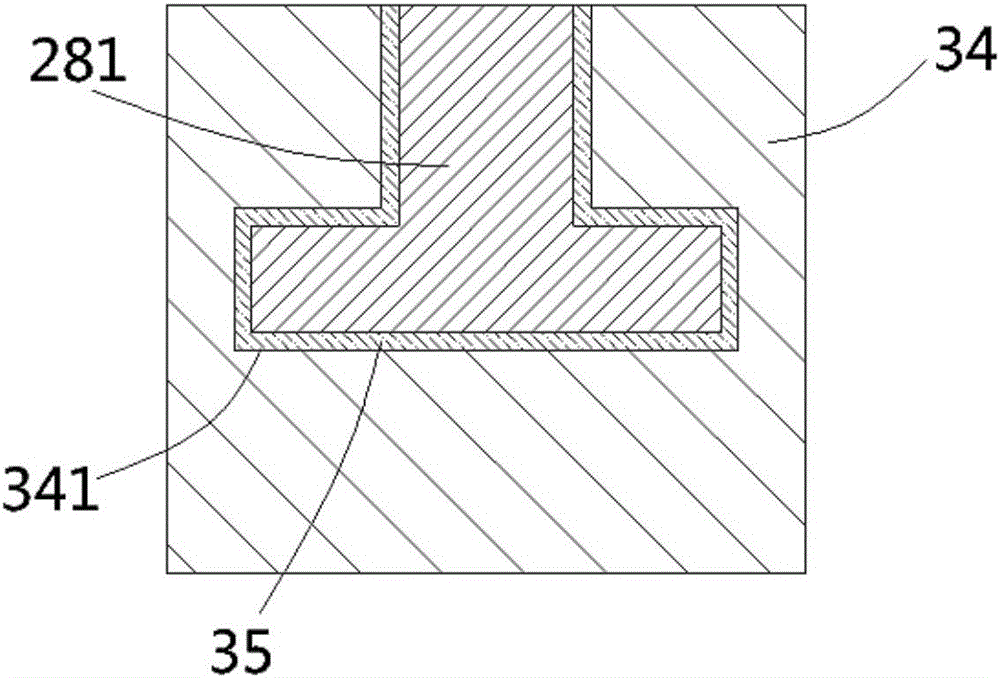

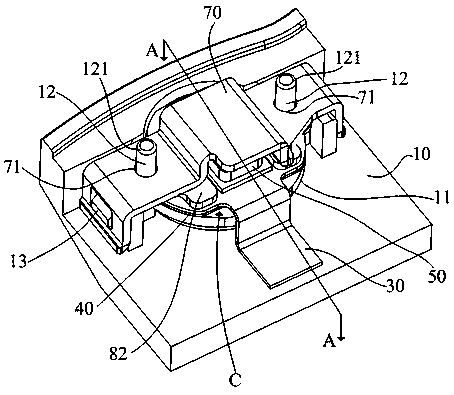

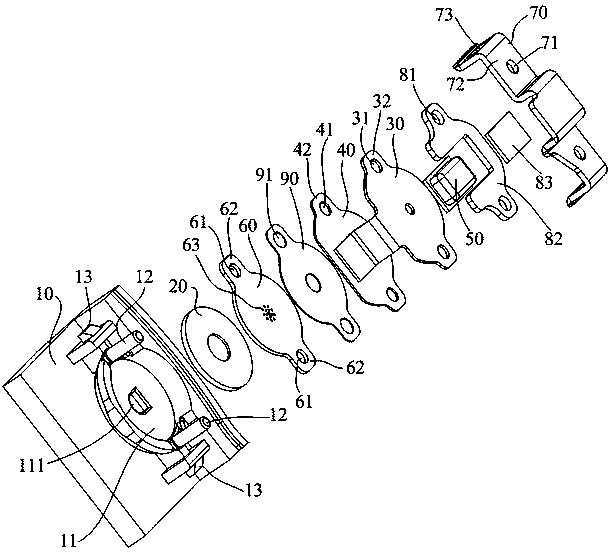

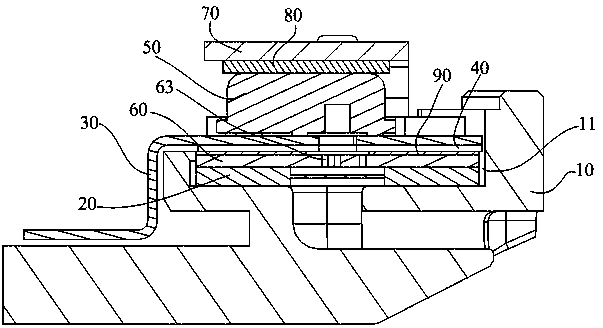

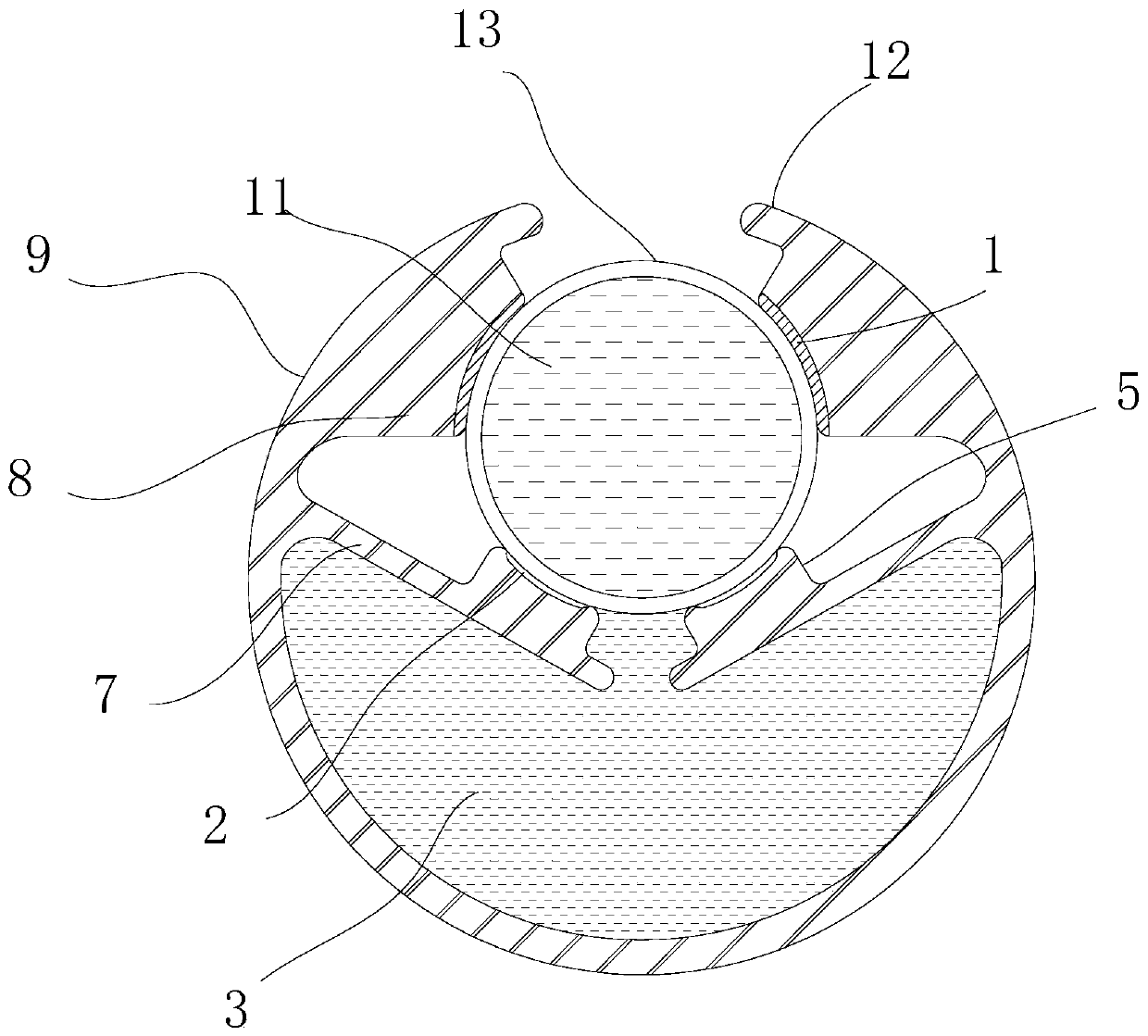

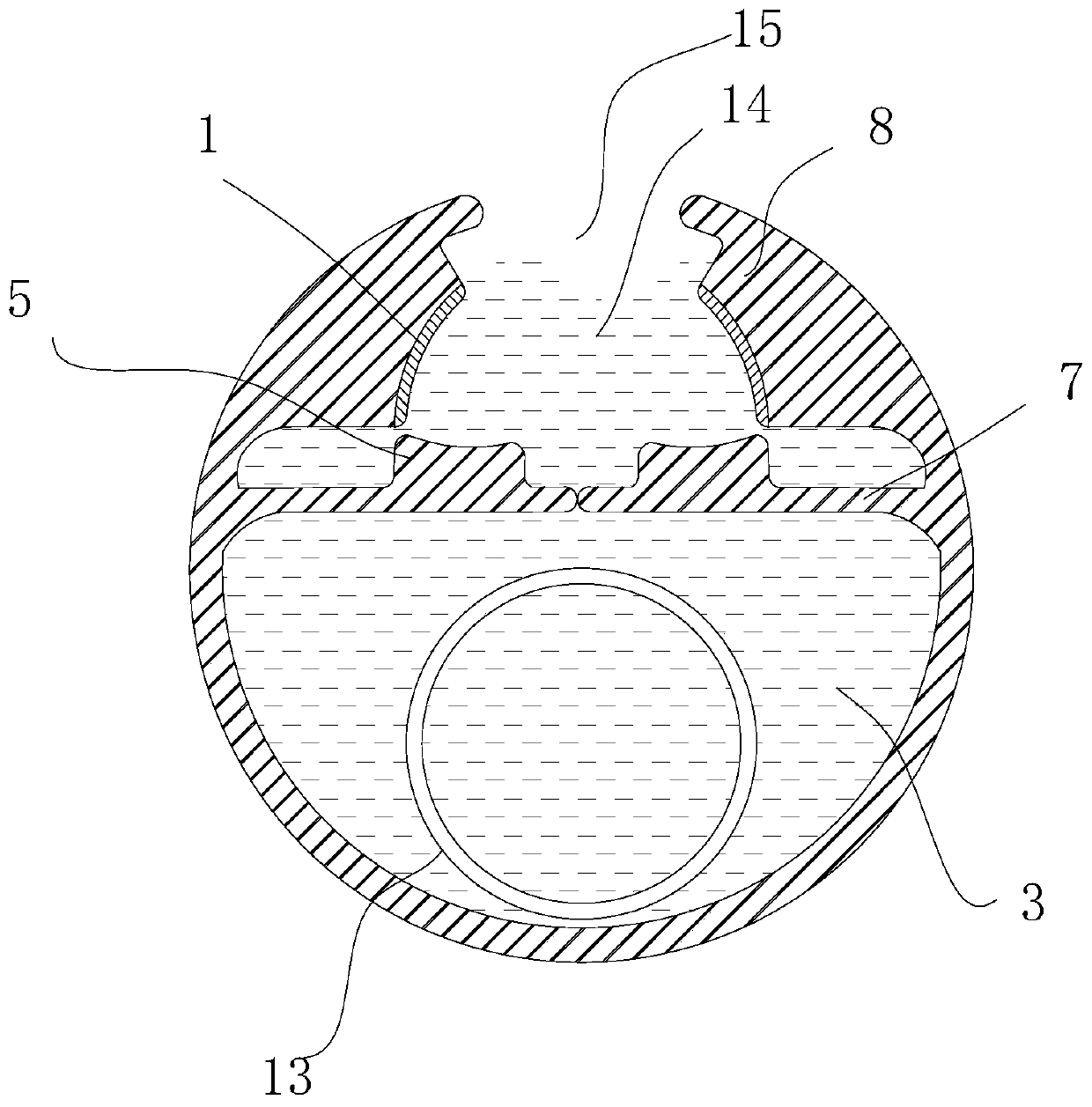

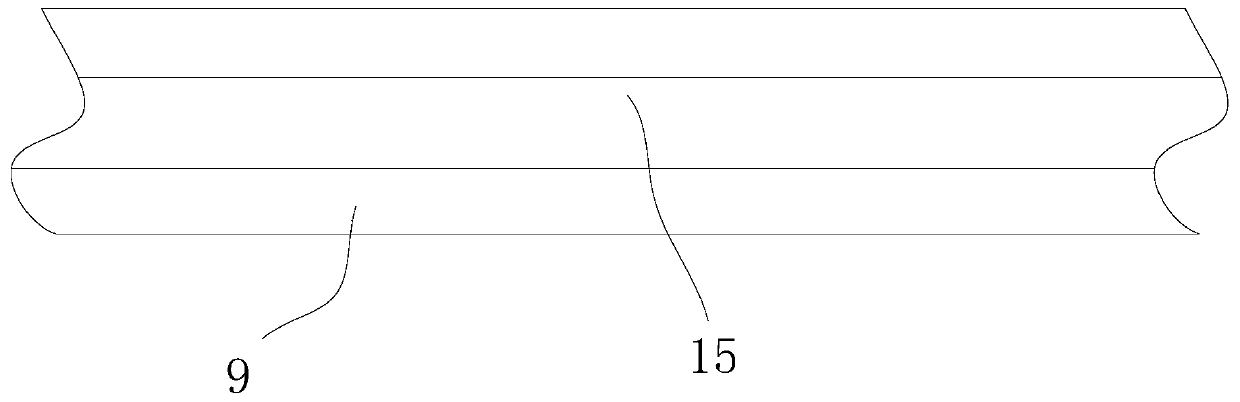

Microphone waterproof mounting structure and intelligent electronic product

InactiveCN109982180AAct as supportAvoid deformationMouthpiece/microphone attachmentsAgricultural engineeringTransmission performance

The invention provides a microphone waterproof installation structure and an intelligent electronic product, the microphone waterproof installation structure comprises a shell, a waterproof film, a reinforcing plate, a circuit board and a microphone, the microphone waterproof installation structure also comprises a waterproof film reinforcing plate and a pressing plate, and the waterproof film reinforcing plate is located between the waterproof film and a circuit board assembly and is bonded with the waterproof film and the circuit board assembly in an attached manner; the pressing plate is fixedly connected with the shell, and the waterproof membrane, the waterproof membrane reinforcing plate and the circuit board assembly are clamped between the pressing plate and the shell; at least twopositioning columns are further formed on the shell, positioning holes are correspondingly formed in the waterproof film reinforcing plate, the circuit board assembly and the pressing plate, and thewaterproof film reinforcing plate, the circuit board assembly and the pressing plate are arranged on the positioning columns in a sleeving mode through the positioning holes. The protection effect onthe waterproof film is further enhanced, the waterproof film is prevented from deforming to cause water drainage failure, the sound transmission performance and the waterproof performance are furtherimproved, and an intelligent electronic product with the microphone waterproof installation structure can be normally used in a deep water environment.

Owner:GEER TECH CO LTD

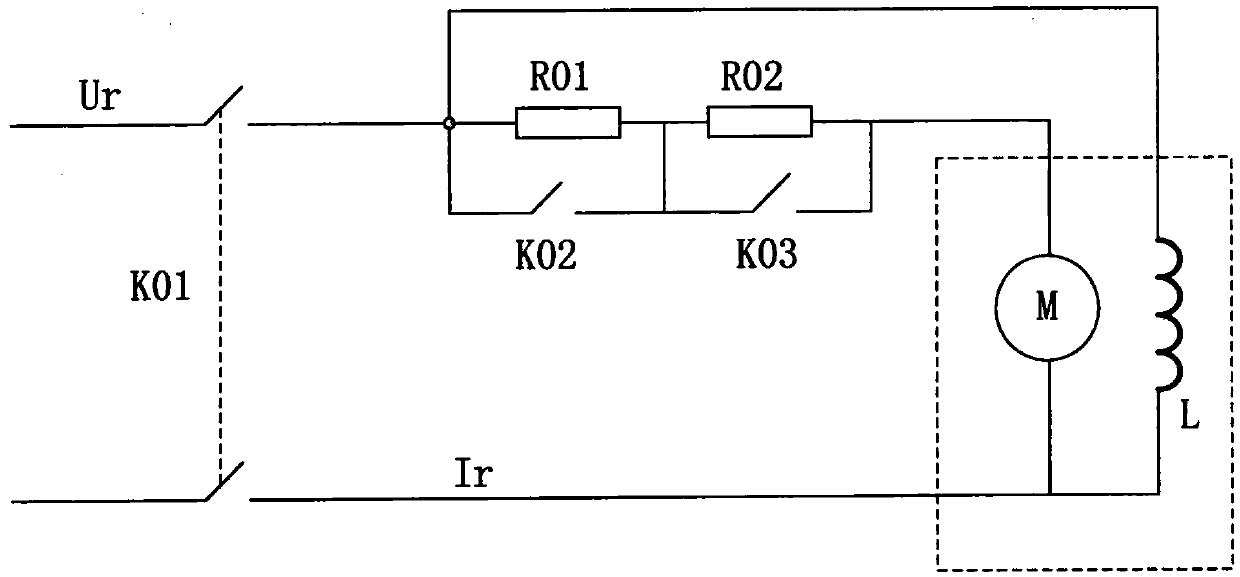

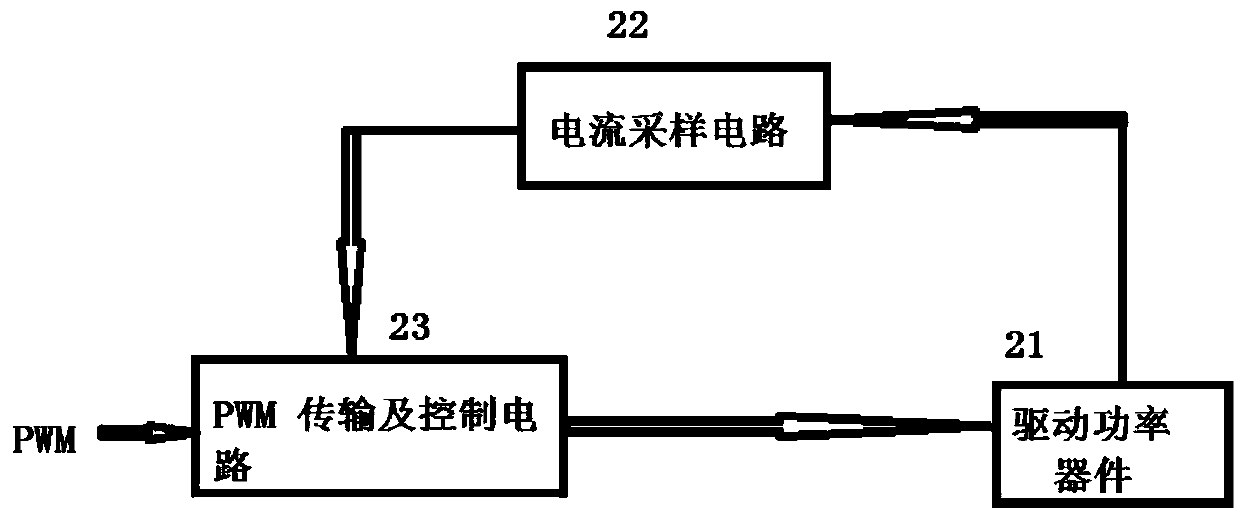

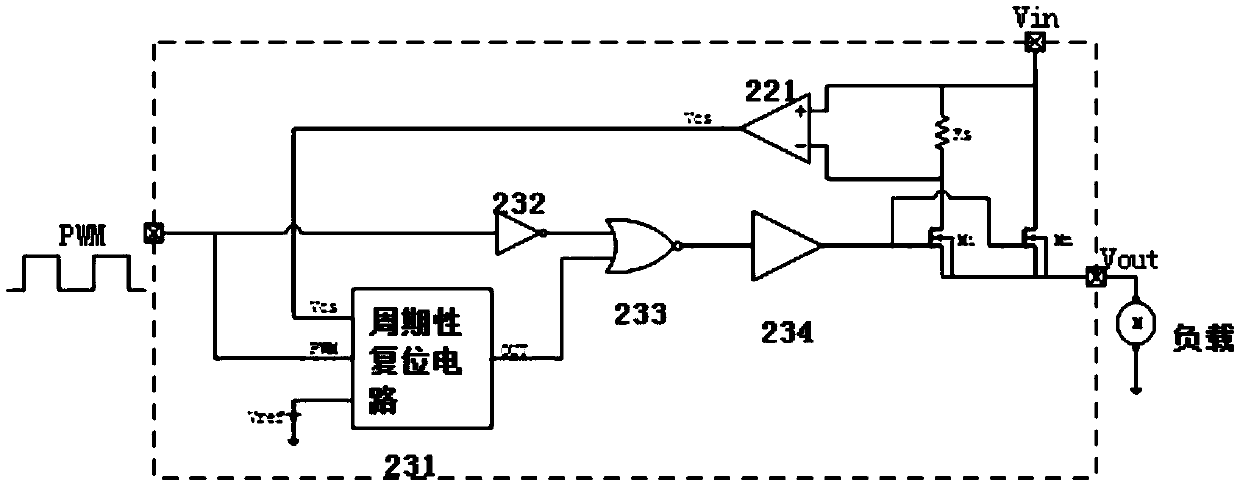

Current-limiting protection device and motor driving chip

ActiveCN111262228AReduce drive lossRealize the current limit start functionAc motor stoppersEmergency protective arrangements for limiting excess voltage/currentControl signalElectric machine

A current-limiting protection device comprises a current sampling circuit which is connected with a driving power device and is used for sampling the current of a load and converting a sampling current signal into a sampling output voltage signal, and a PWM signal transmission and control circuit which is in signal connection with the current sampling circuit and the PWM and is used for controlling the driving power device to be turned on or turned off according to a comparison result of the sampling output voltage and a reference voltage. According to the scheme of the invention, the current-limiting protection device is integrated in the motor driving chip, peripheral elements such as an armature series resistor and a switching tube for starting the motor are omitted, and the developmentcost and the motor driving loss are reduced. Moreover, the starting current is controlled by sampling the current of the power tube cycle by cycle, the current-limiting starting function of the motorcan be realized without changing the duty ratio of the preset PWM signal, and the current-limiting function of the device is automatically stopped after the motor is started, so that the normal transmission of the preset PWM control signal is not influenced.

Owner:小华半导体有限公司

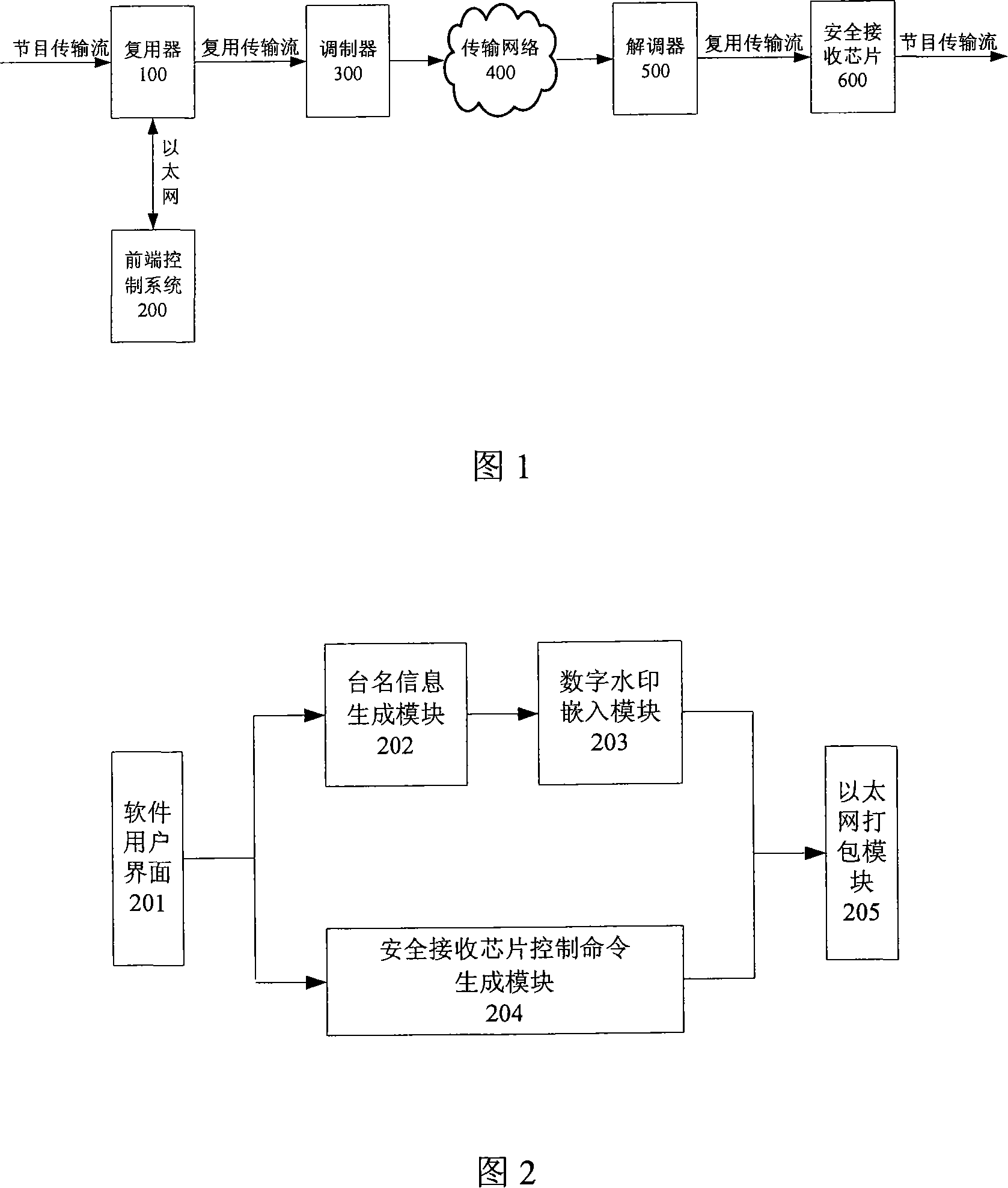

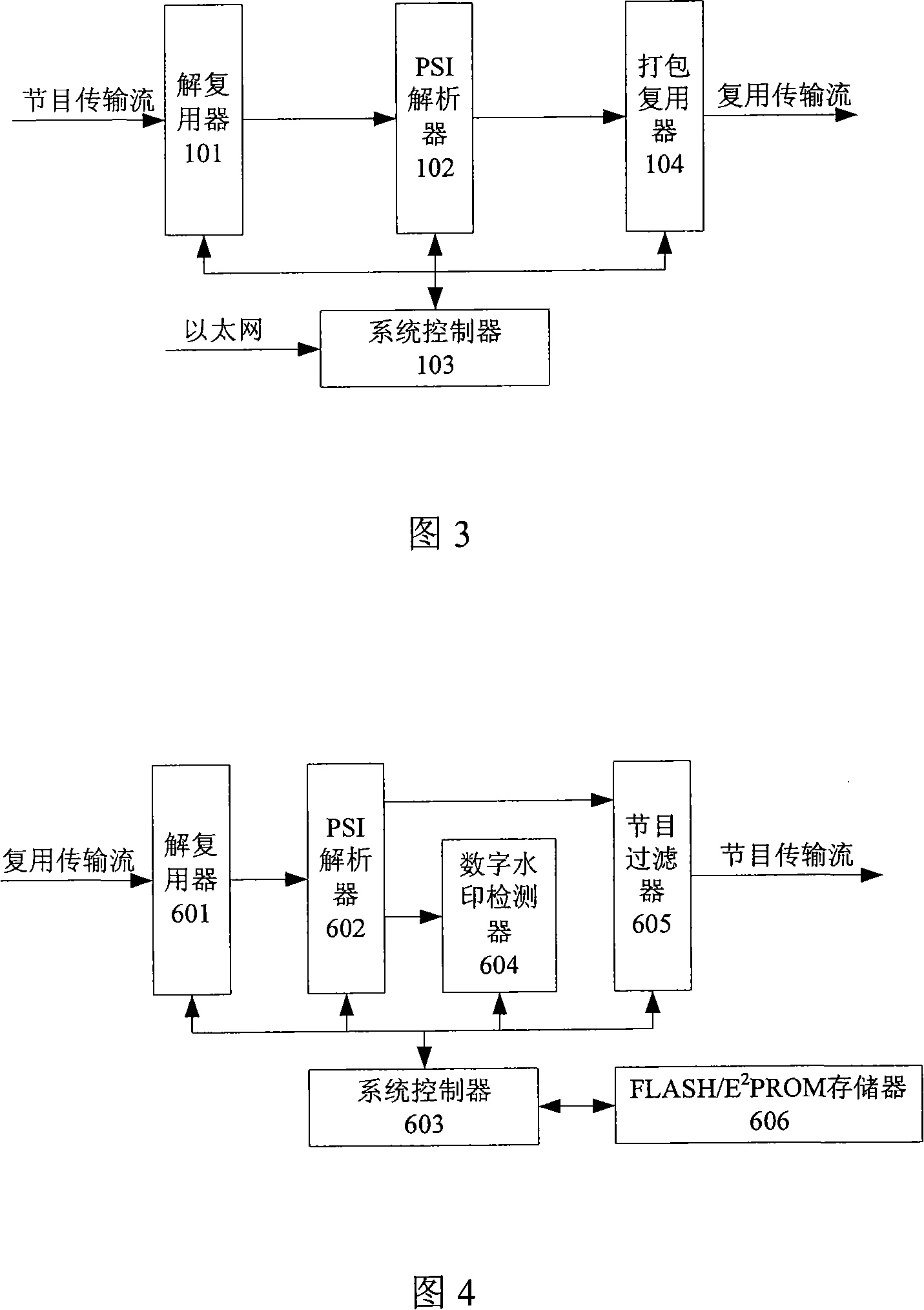

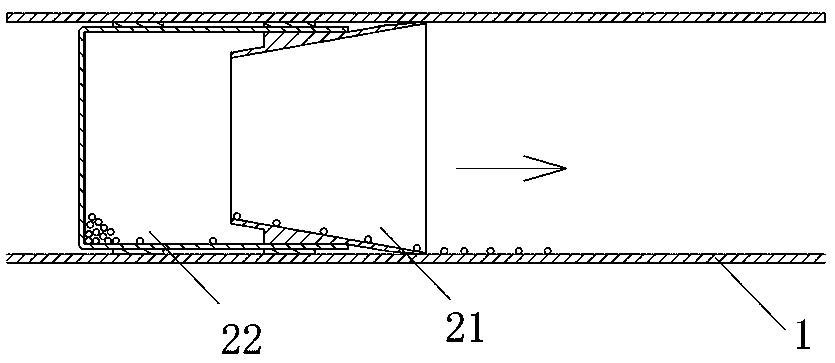

Method for authenticating upgrade information with digital watermark

ActiveCN101123713AWill not affect normal transmissionEasy to operatePulse modulation television signal transmissionAnalogue secracy/subscription systemsSatelliteDigital watermarking

The invention discloses a method that upgrading information is identified by a digital watermark and relates to a digital information processing technology used to improve information reliability of satellite digital television in communication field. According to the existing related standard and technology of satellite digital television, a front-end control system of the invention embeds the digital watermark into station name upgrading information, and the invention sends a corresponding order to a safety receiving chip and controls the safety receiving chip to detect digital watermark in upgrading information. With the method, the invention has the advantages that the invention can control and operate identification operation of upgrading information in upflowing system, prevent the station name upgrading information from being tampered, improve reliability of the station name upgrading information, and ensure normal upgrading. Therefore, the invention can further enhance management and control on satellite digital television broadcasting.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

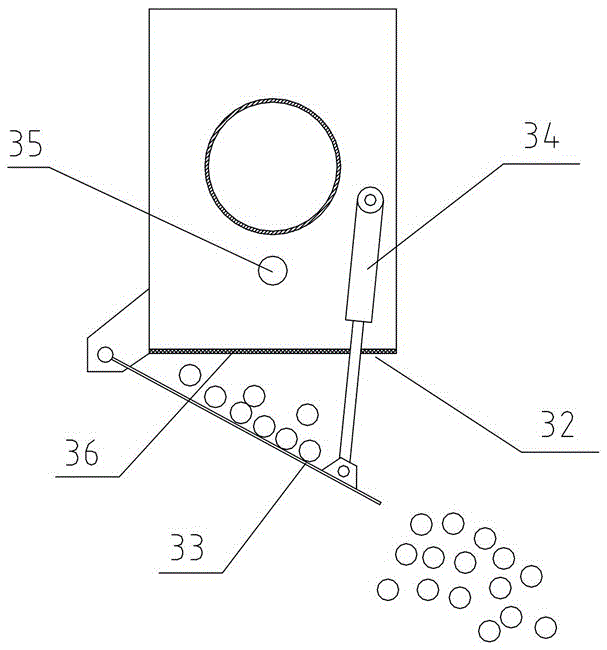

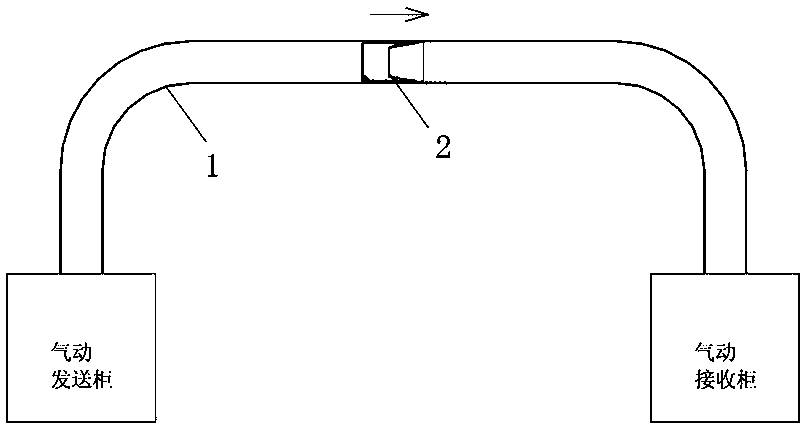

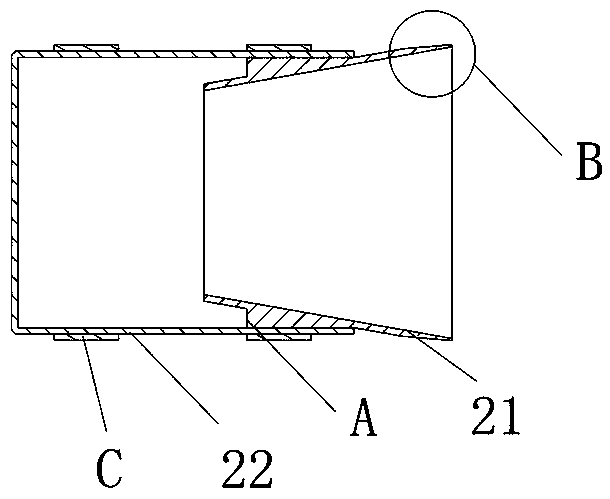

Impurity cleaning device for material pneumatic transmission system

PendingCN111498507AWill not affect normal transmissionGuaranteed delivery effectBulk conveyorsForeign matterShovel

The invention discloses an impurity cleaning device for a material pneumatic transmission system. A moving body capable of conducting pneumatic transmission in a pneumatic transmission pipeline is included. At least one end of the moving body is opened to form a shovel barrel part so that during transmission of the moving body, the shovel barrel part can be used for shoveling impurities in the pneumatic transmission pipeline into the moving body for collection. The impurity cleaning device has the advantages that the structure is simple and compact, the manufacturing cost is low, operation iseasy, foreign matter in the pneumatic transmission pipeline can be collected in time, the interior of the pneumatic transmission pipeline is kept clean, and maintaining is easy.

Owner:HUNAN SUNDY SCI & TECH DEV

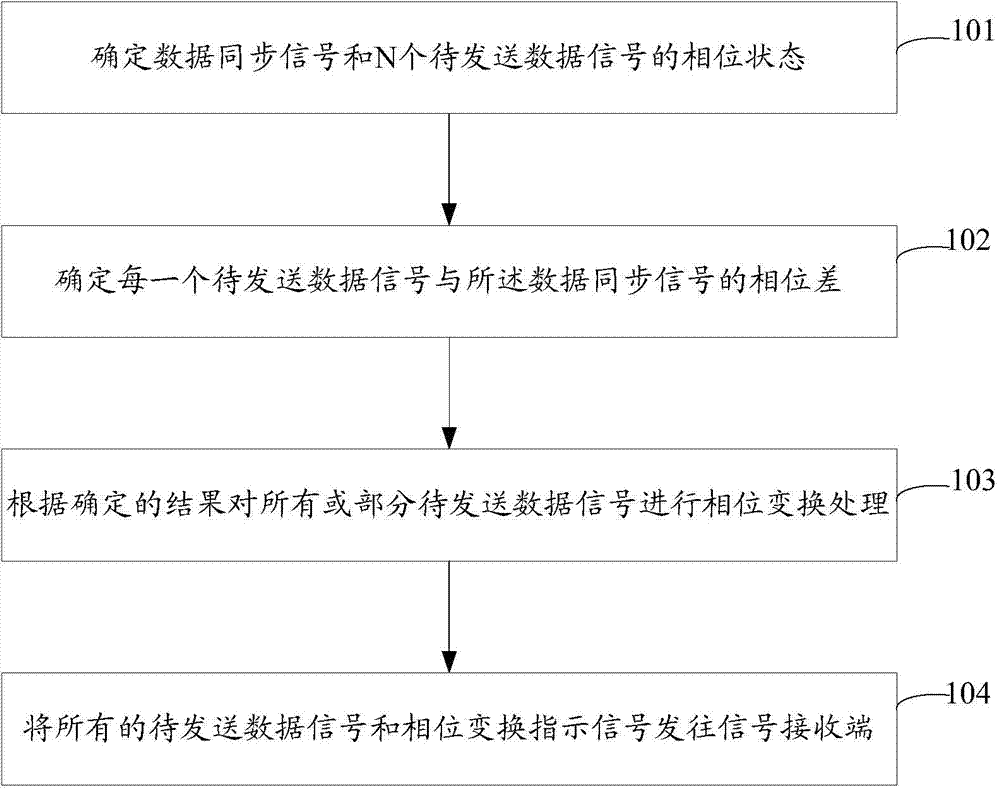

Signal processing method and device

ActiveCN104714902AWill not affect normal transmissionReduce distractionsSynchronisation transmittersSynchronisation signal speed/phase controlData synchronizationPhase difference

The present invention discloses a signal processing method and apparatus. According to the signal processing method, phase change processing can be performed on to-be-sent data signals according to a phase status of a data synchronization signal and phase statuses of the to-be-sent data signals, so that phase differences between a majority of to-be-sent data signals in the processed to-be-sent data signals and the data synchronization signal meet a certain condition, thereby reducing a volume of coupling crosstalk, generated by the to-be-sent data signals, on the data synchronization signal and further reducing impact of SSN on a system.

Owner:HUAWEI TECH CO LTD

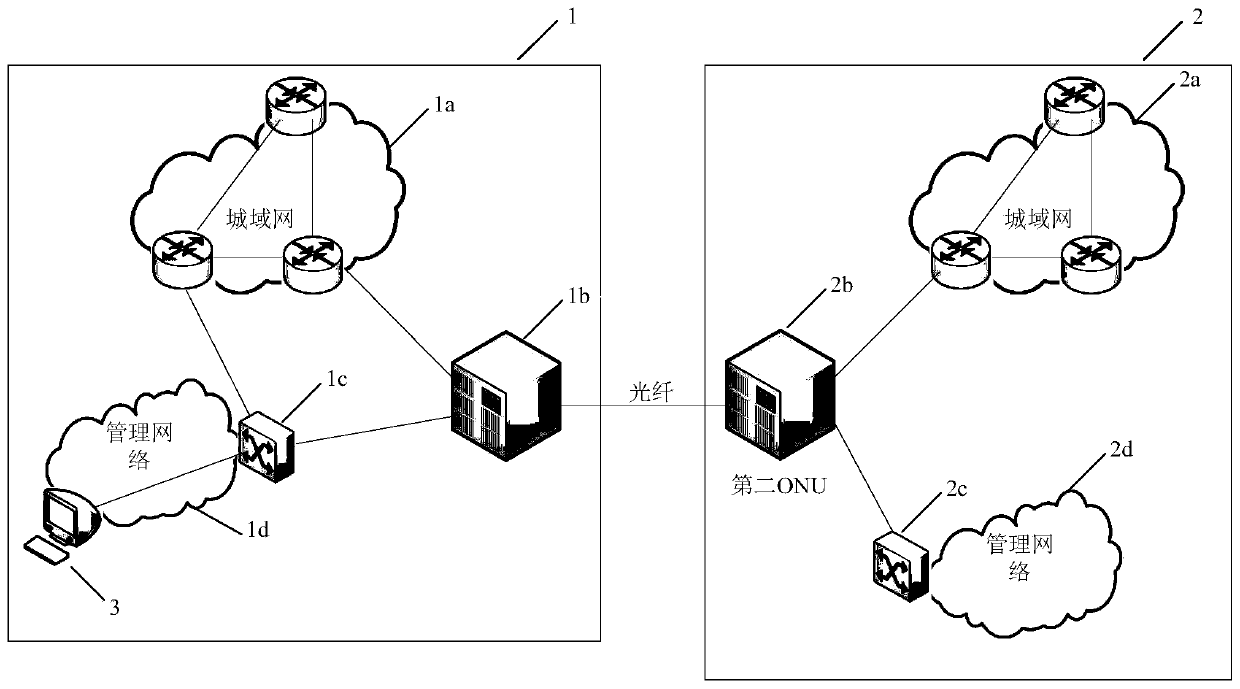

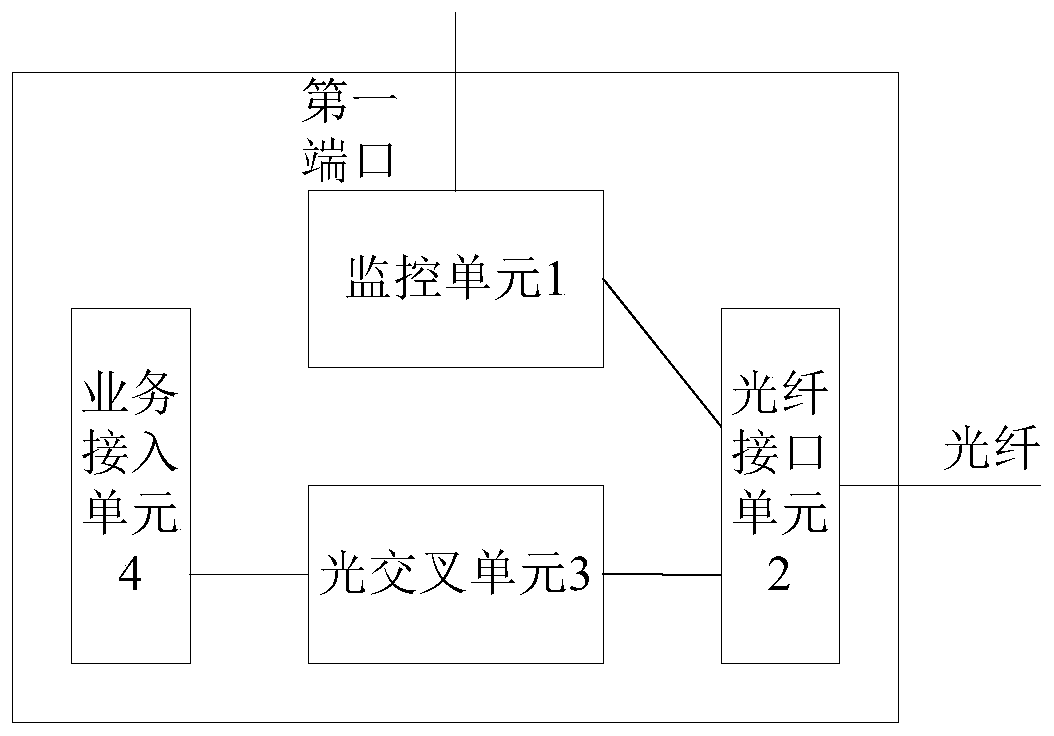

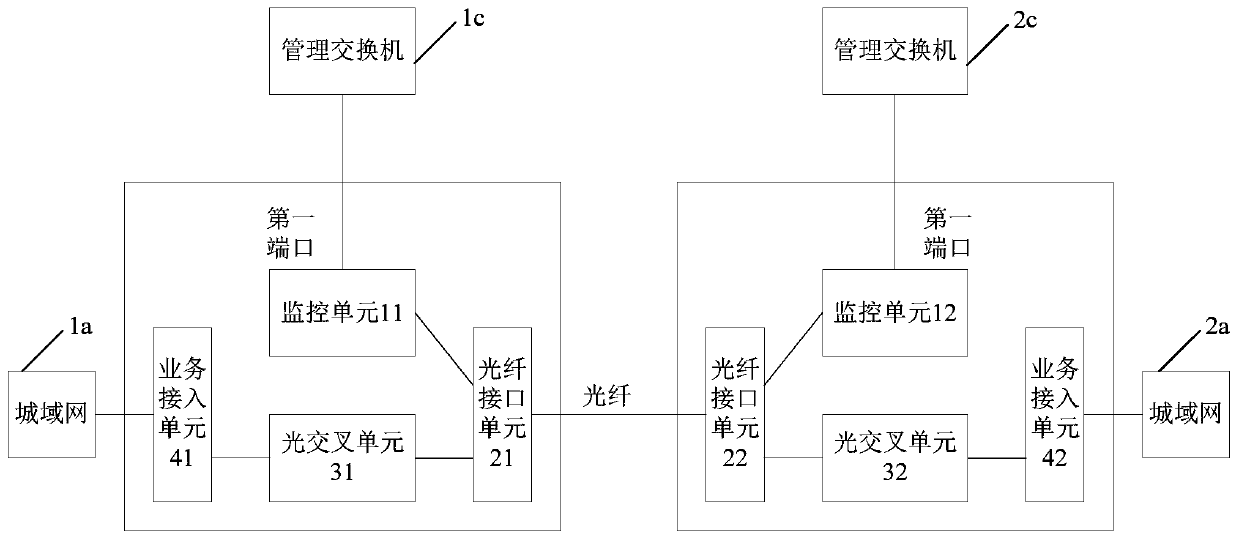

Communication method, device and system

ActiveCN111447036AWill not affect normal transmissionWavelength-division multiplex systemsNetworks interconnectionComputer networkEngineering

The invention discloses a communication method, device and system, and belongs to the field of communication. The method comprises the steps that: a first optical network node (ONU) receives a management message from a management network through a first port included in the first ONU and receives a service message from a metropolitan area network through a second port included in the first ONU, the management message belonging to a management service, and the service message belonging to a user service; the first ONU generates a data frame, wherein the data frame comprises message data in themanagement message; the first ONU converts the data frame into a first optical signal with a first wavelength and converts the service message into a second optical signal with a second wavelength, wherein the first wavelength is different from the second wavelength; and the first ONU sends the first optical signal and the second optical signal to a second ONU. The normal transmission of the management service can be prevented from being influenced.

Owner:HUAWEI TECH CO LTD

A rectifying device for the guide belt in the cloth dryer

InactiveCN105890337BGuaranteed uptimeWill not affect normal transmissionDrying solid materialsEngineeringDrive motor

The invention discloses a deviation correcting device for a guiding belt of a cloth drying machine. The deviation correcting device comprises two deviation correcting mechanisms which are symmetrically arranged on the two sides of the guiding belt, and each deviation correcting mechanism comprises a clamping unit and a pulling unit; each clamping unit comprises an upper clamping plate, a lower clamping plate, an upper rotating screw, a lower rotating screw, an upper rotating gear, a lower rotating gear, a driving motor and a base plate, wherein the upper clamping plate and the lower clamping plate are located above and below the edge of the guiding belt respectively, the upper rotating screw and the lower rotating screw are vertically connected to the upper clamping plate and the lower clamping plate in a screwed mode respectively, the upper rotating gear and the lower rotating gear are fixedly arranged on the upper rotating screw and the lower rotating screw in a sleeving mode respectively and meshed with each other, and an output shaft of the driving motor is fixedly connected with the lower end of the upper rotating screw; each pulling unit comprises a long-strip-shaped rack part formed on the upper end face of the base plate, a gear meshed with the rack part and a motor used for driving the gear to rotate. According to the device, the deviated guiding belt can be pulled to a correct operating track, and normal conveying of the guiding belt cannot be influenced.

Owner:杉华纺织(苏州)有限公司

A material pneumatic conveying system with cleaning and collecting functions

The invention discloses a pneumatic material conveying system with functions of sweeping and collecting. The pneumatic material conveying system comprises a pneumatic transmission pipeline used for transmitting materials to be conveyed, and more than one blanking collection device connected with the pneumatic transmission pipeline in a sealing way, wherein each blanking collection device is provided with a blanking collection cavity used for collecting a foreign matter in the pneumatic transmission pipeline; a foreign matter settling part used for enabling the foreign matter to settle is arranged between each blanking collection cavity and a pipeline cavity of the pneumatic transmission pipeline; the blanking collection cavities are communicated with the pipeline cavity of the pneumatic transmission pipeline by the foreign matter settling parts; when the foreign matter moving in the pneumatic transmission pipeline passes through the blanking collection devices, the foreign matter settles in the foreign matter settling parts and then drops into the blanking collection cavities. The pneumatic material conveying system has the advantages of being capable of collecting the foreign matter in the pneumatic transmission pipeline in time, maintaining the interior of the pneumatic transmission pipeline to be clean, and being easy to maintain.

Owner:HUNAN SUNDY SCI & TECH DEV

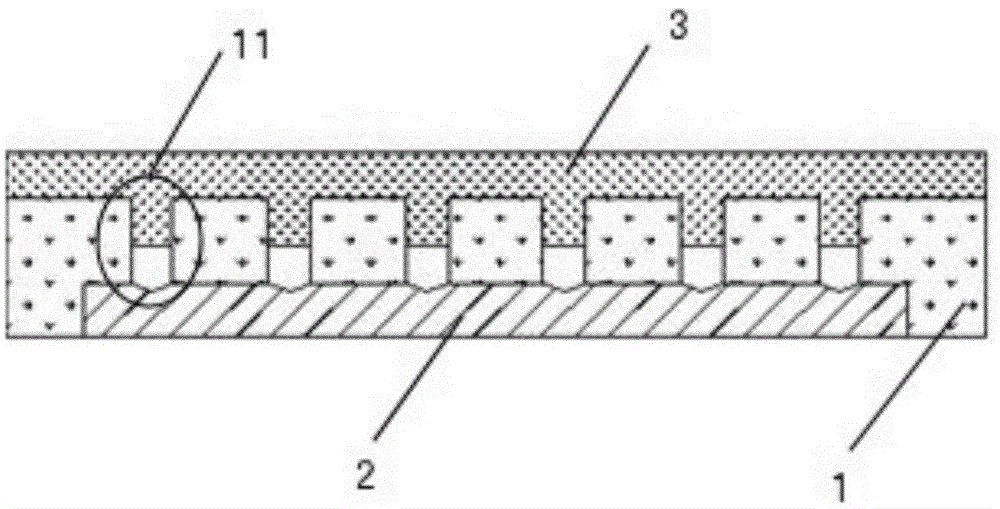

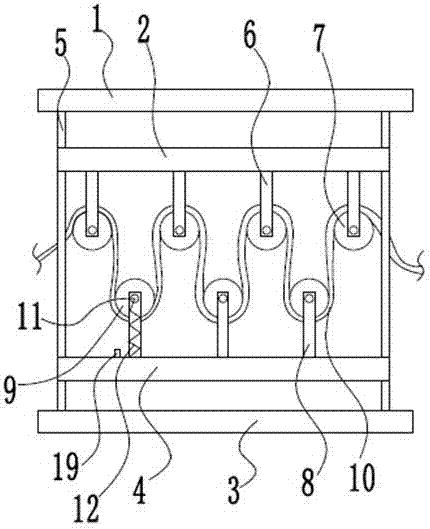

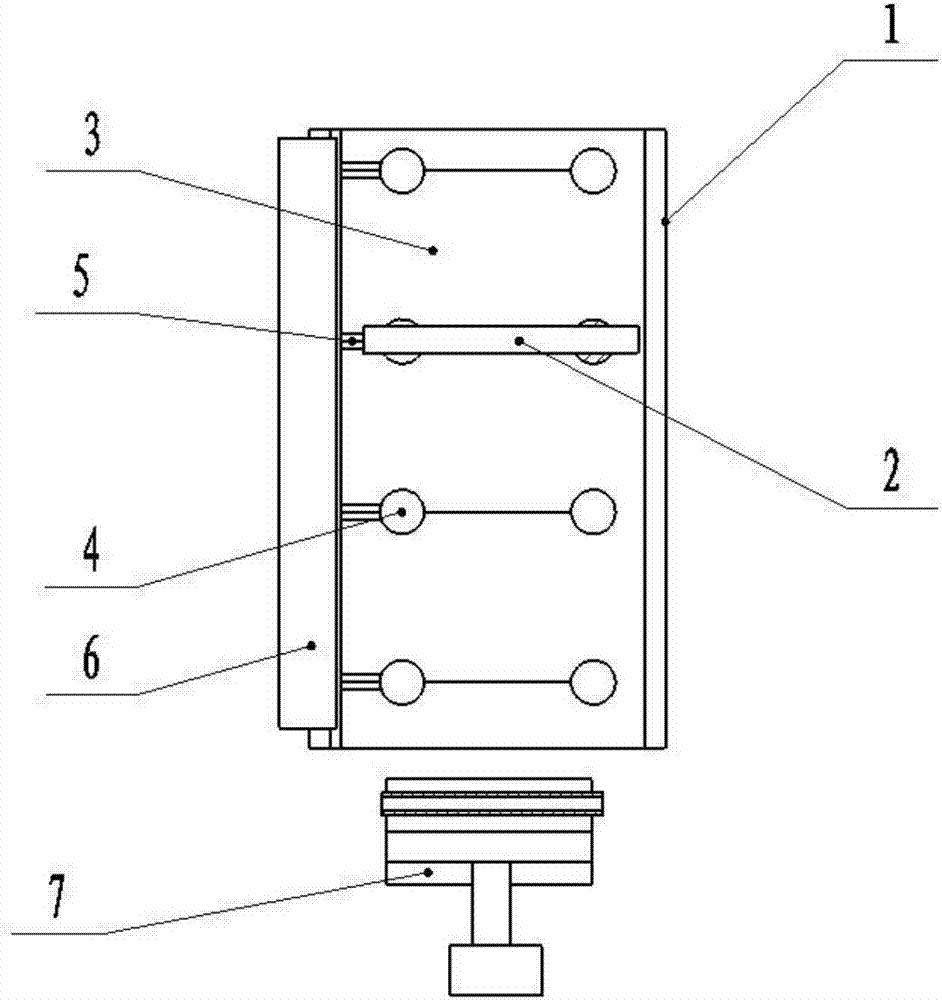

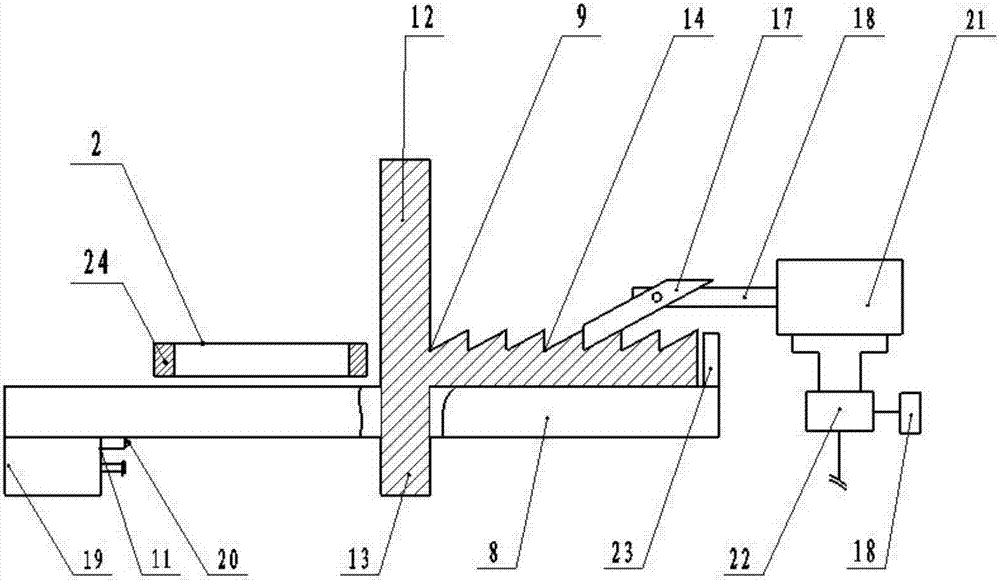

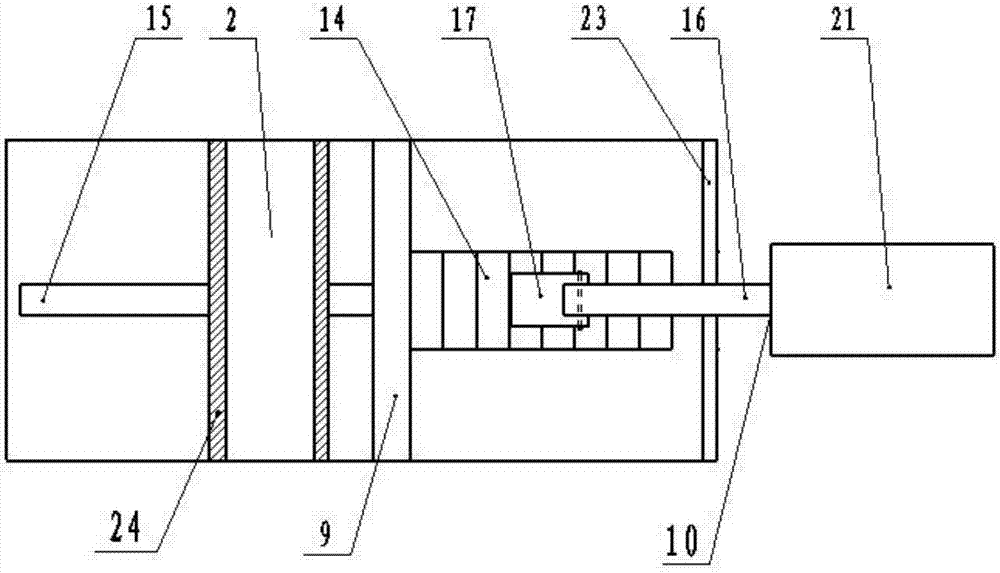

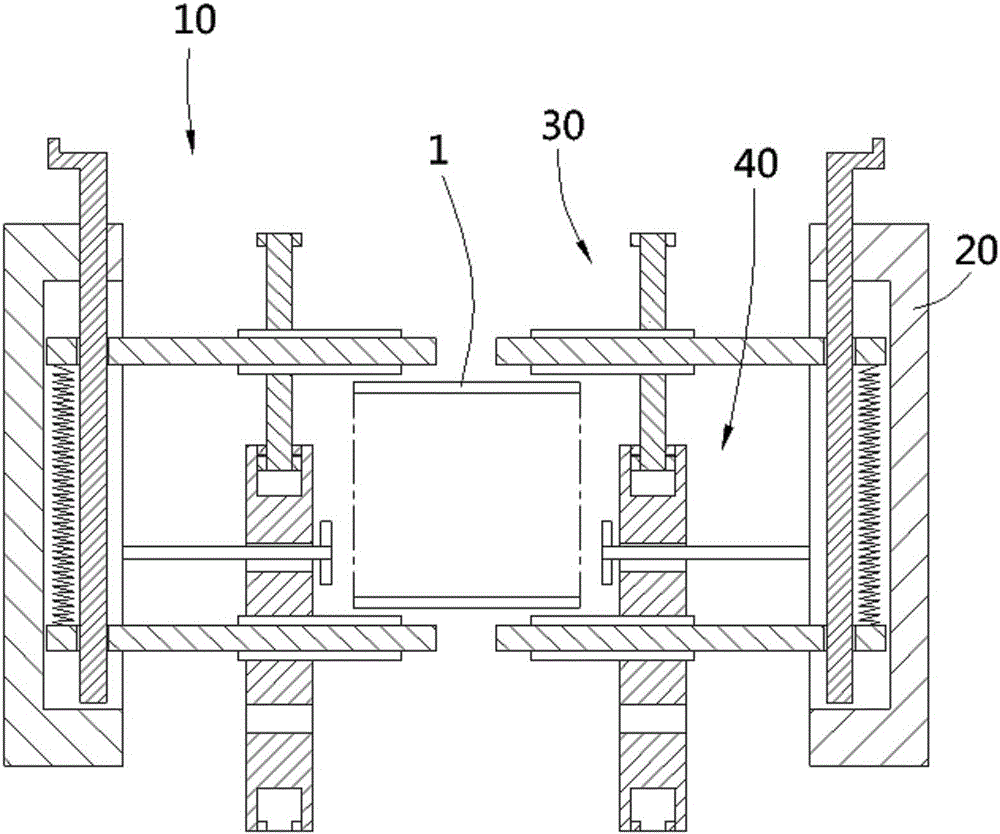

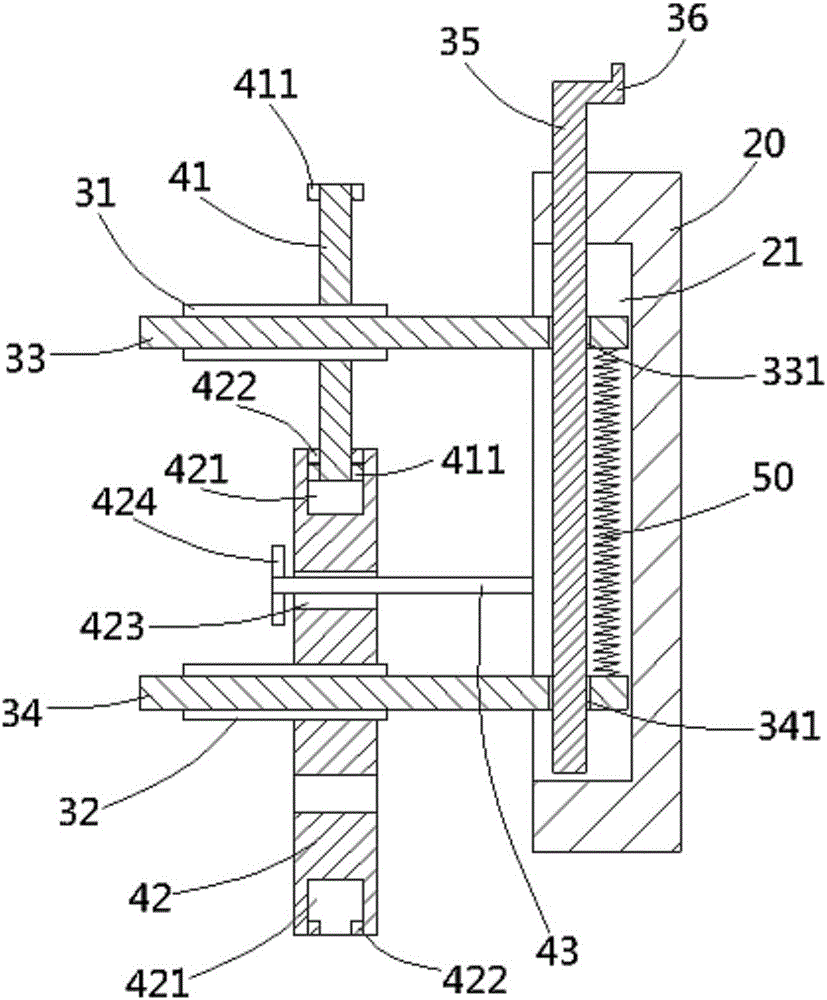

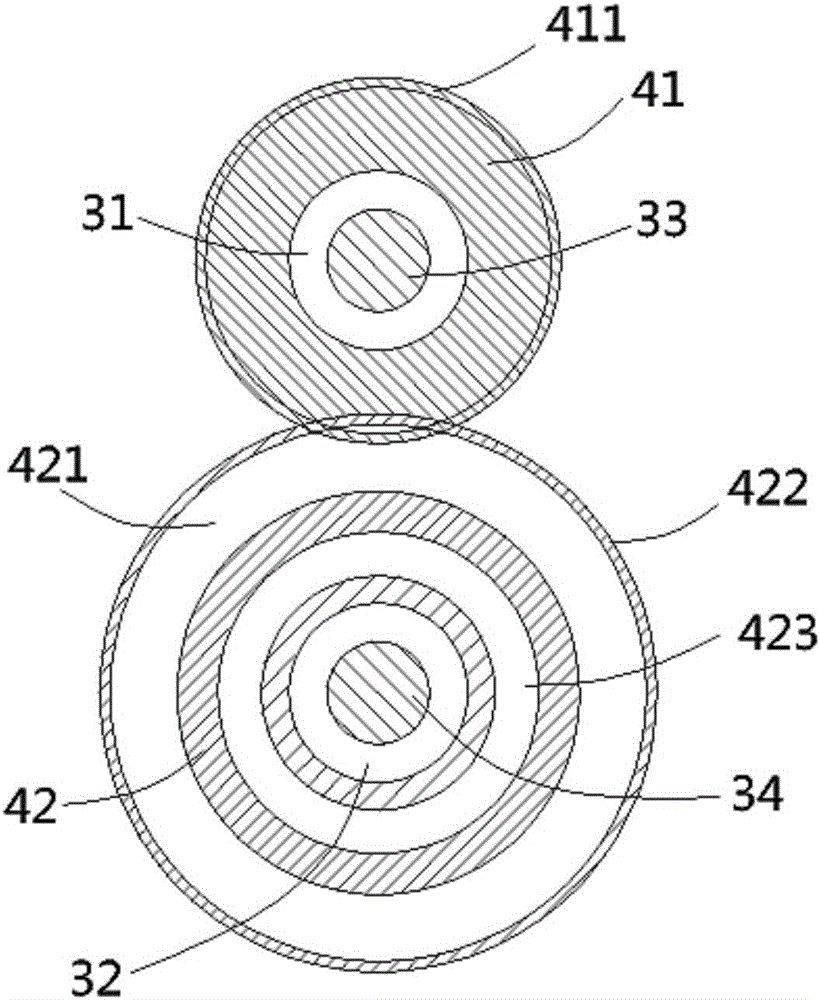

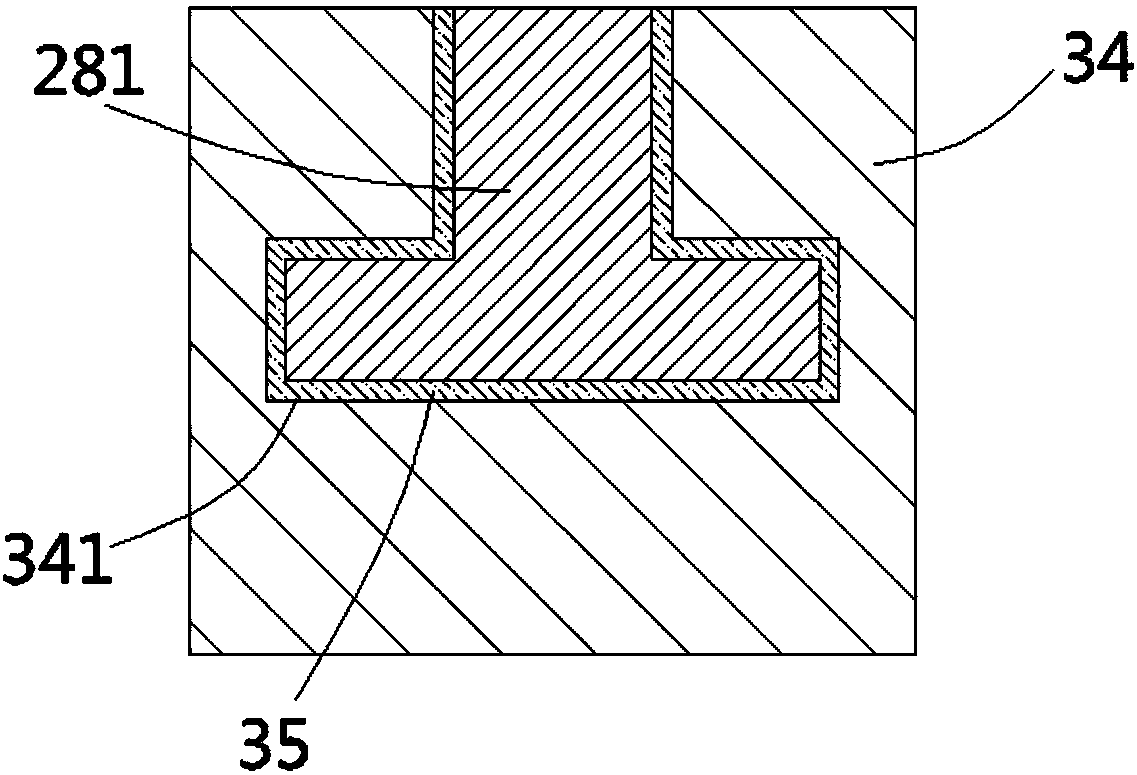

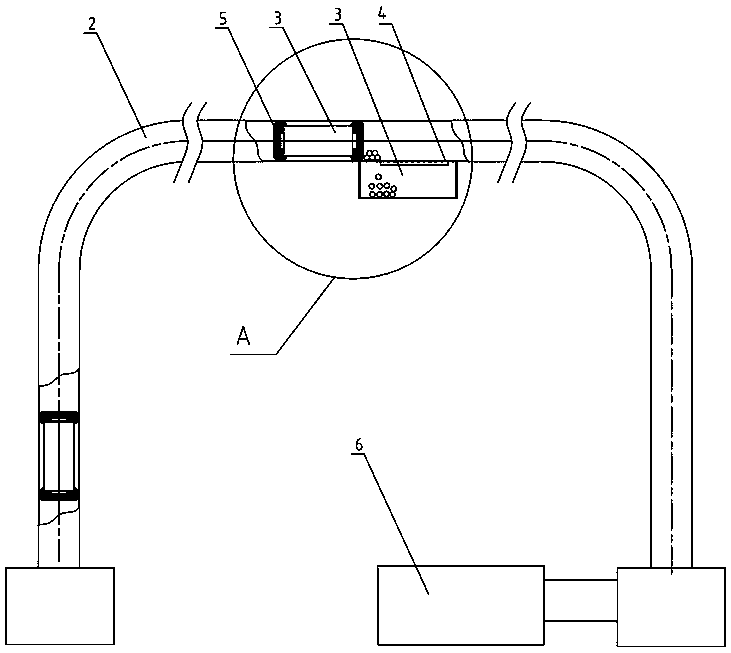

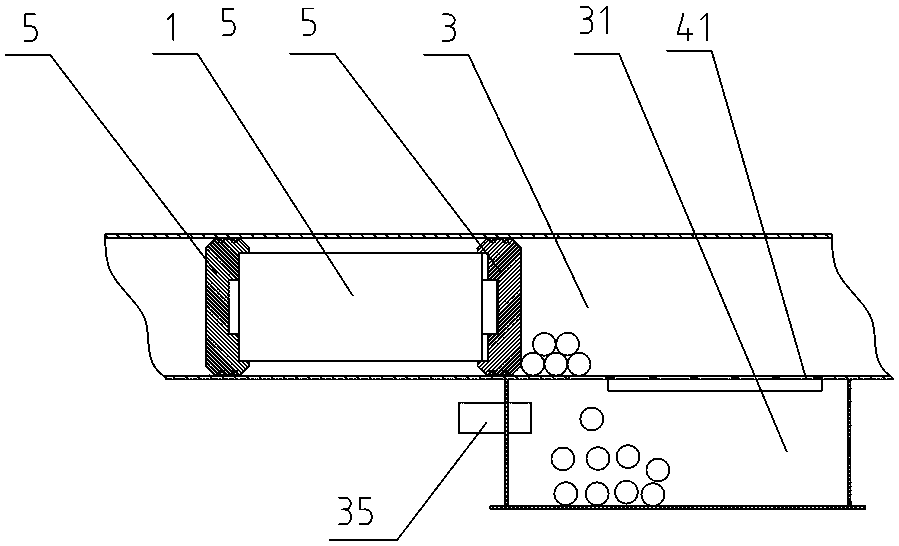

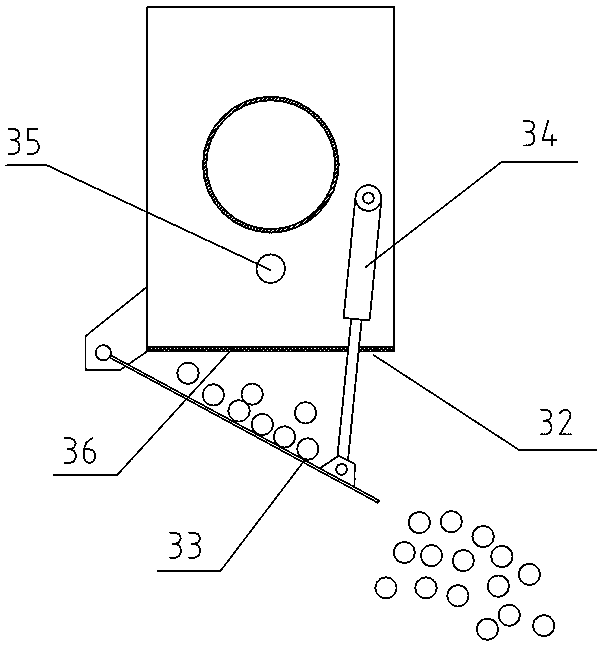

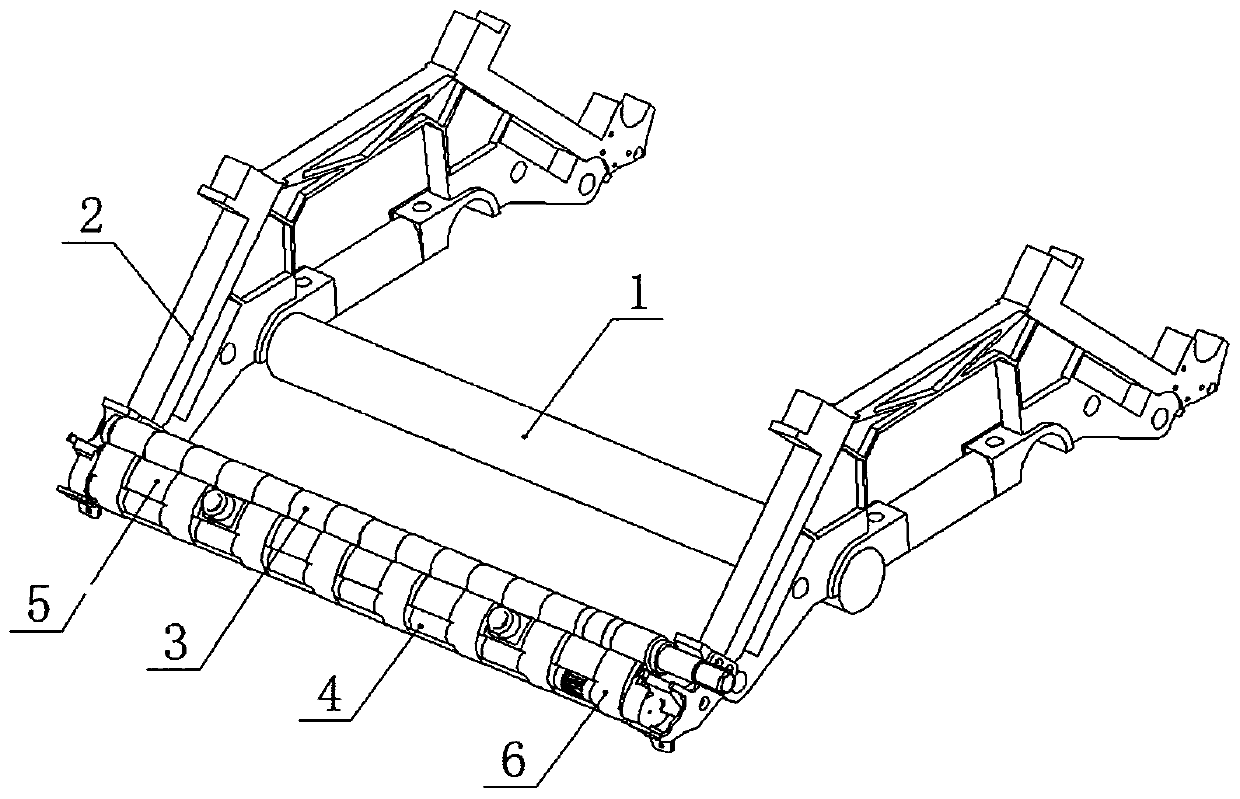

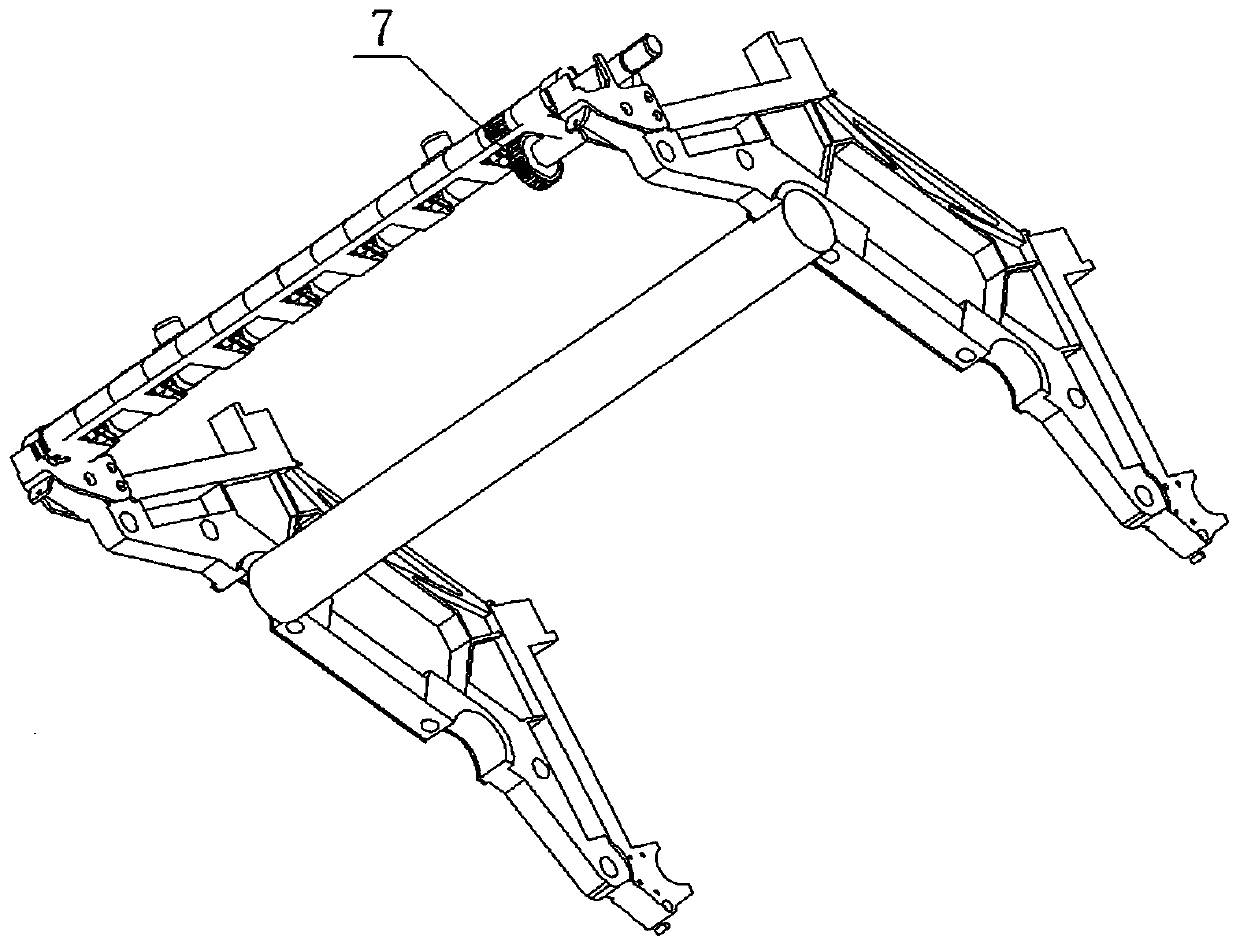

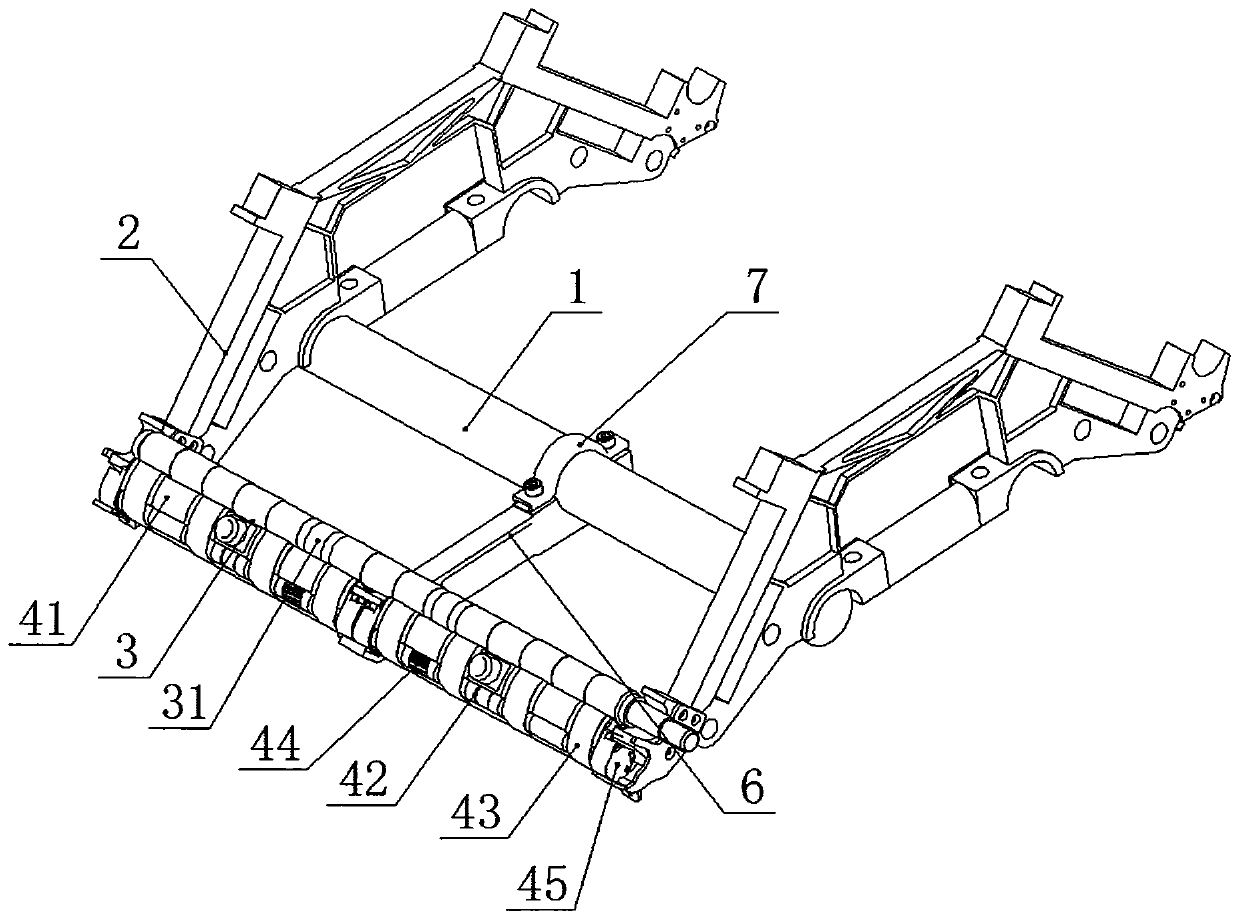

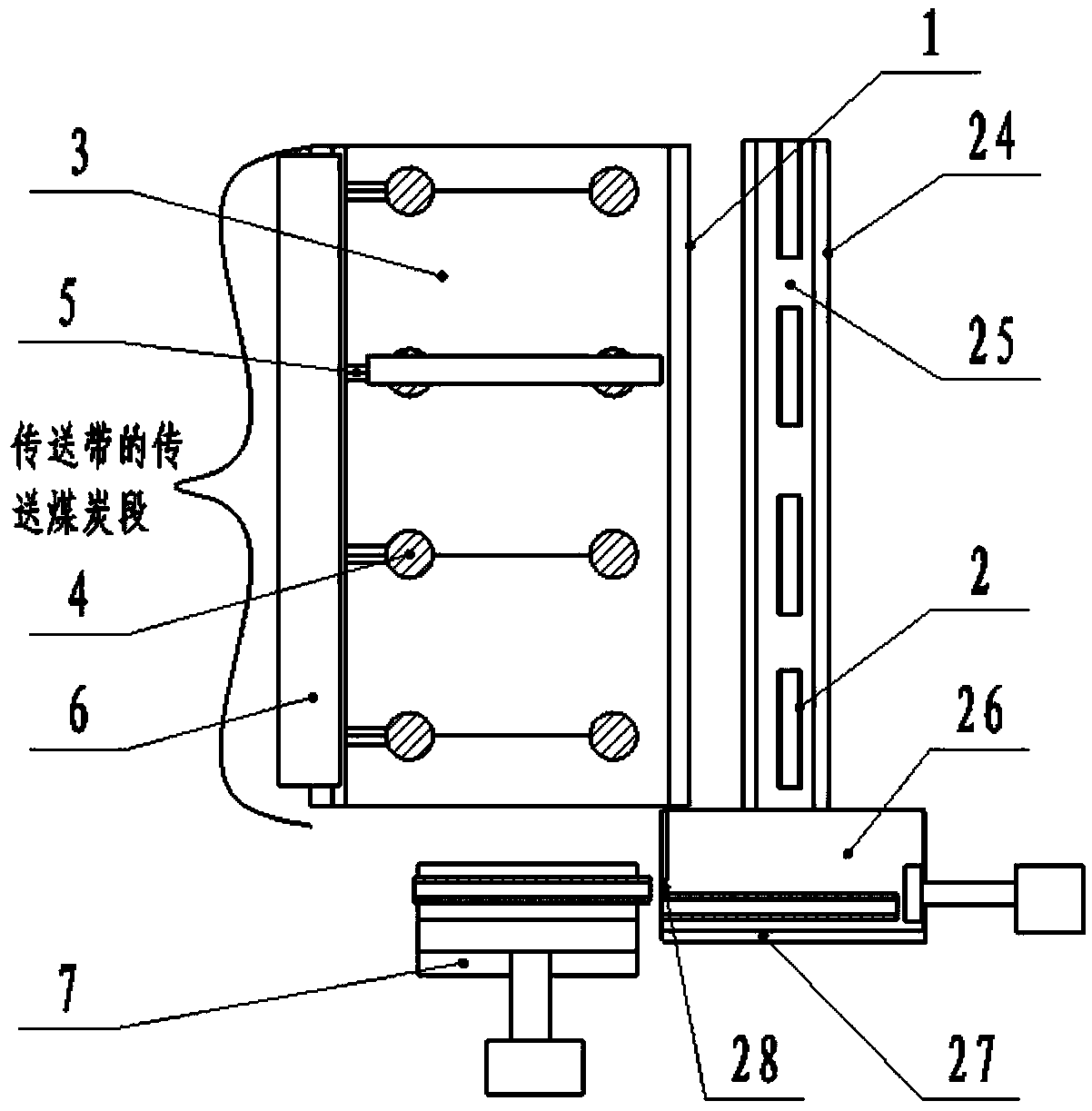

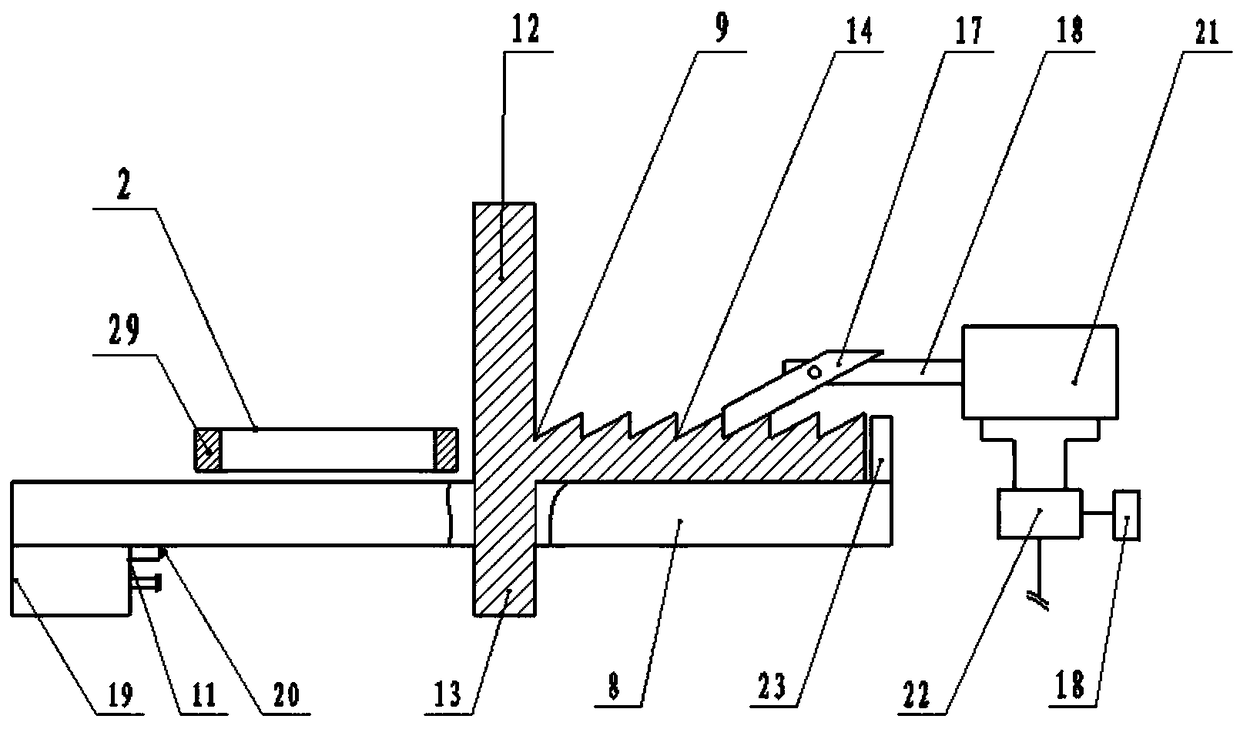

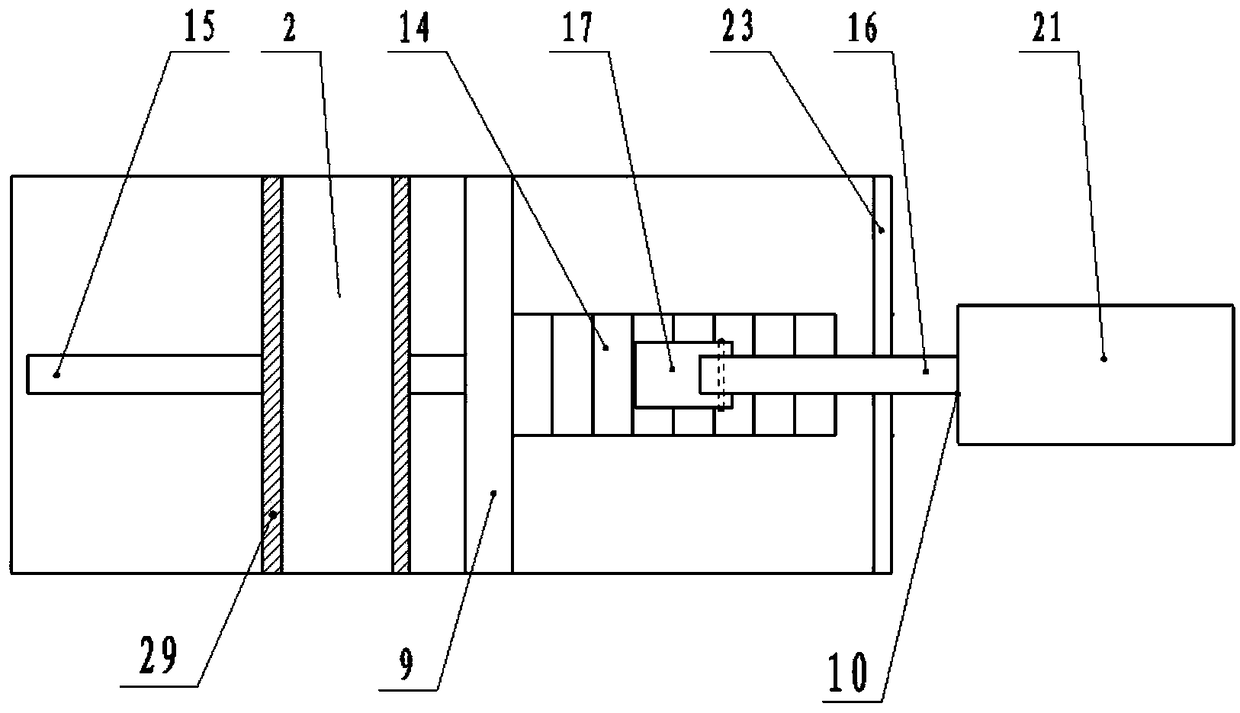

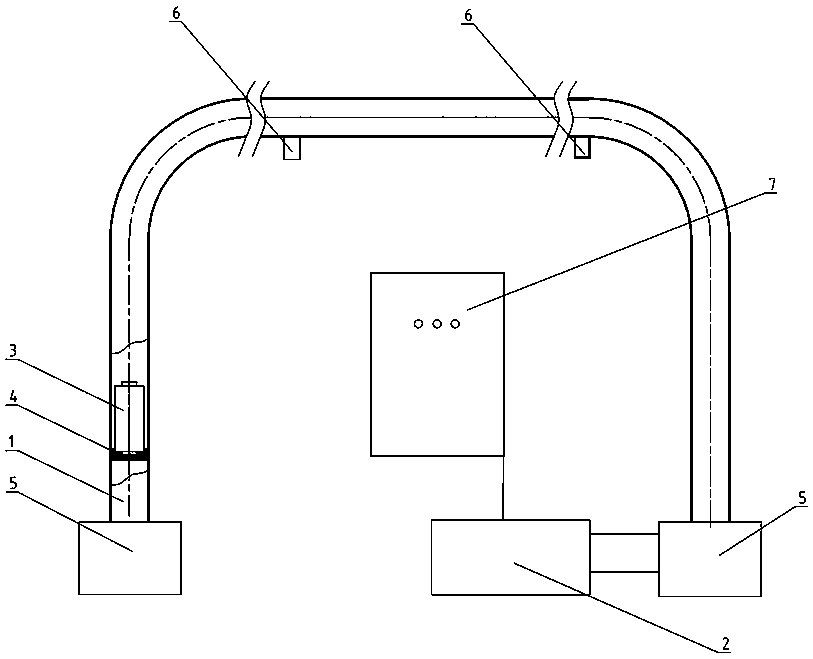

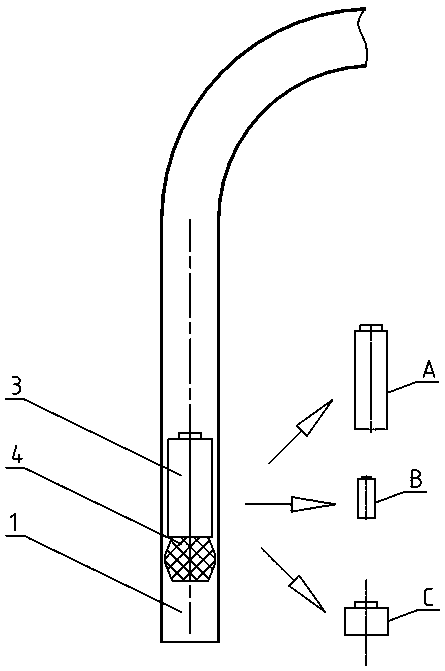

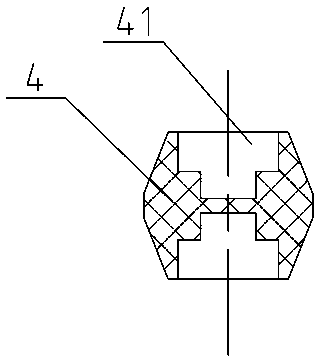

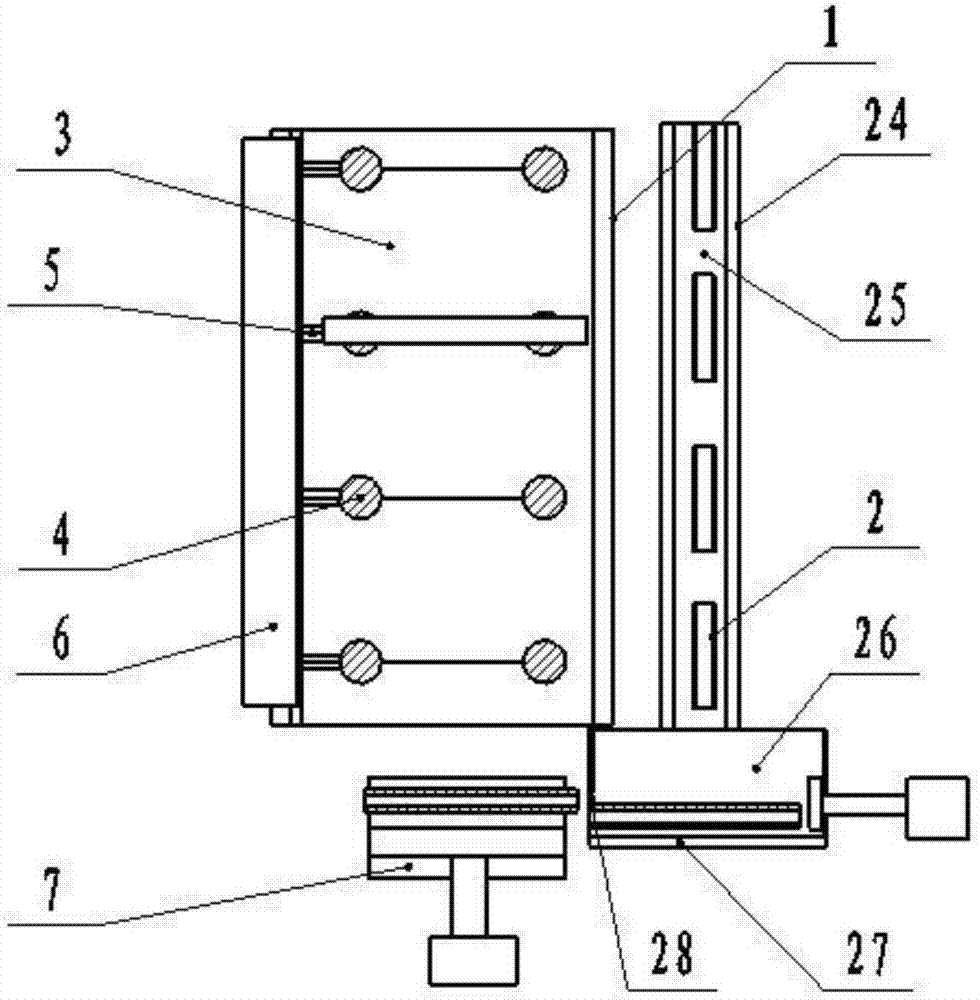

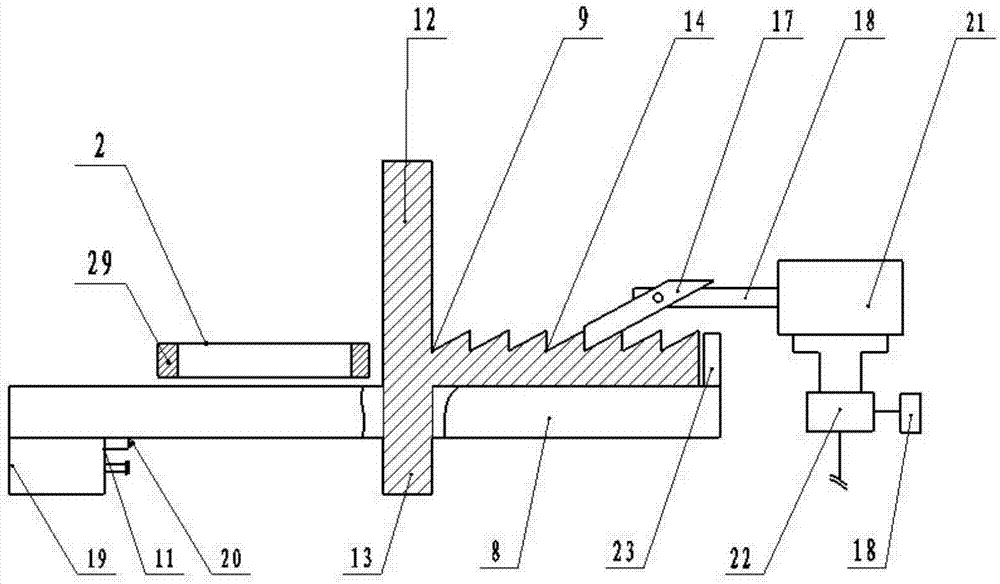

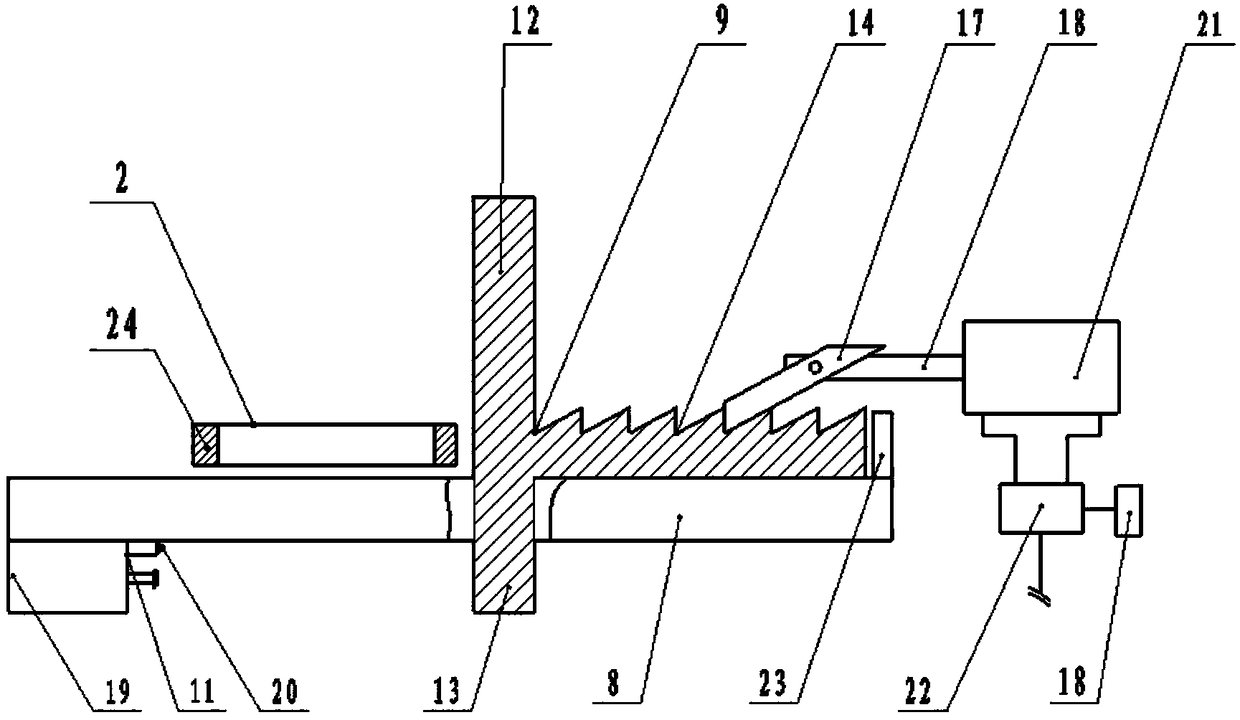

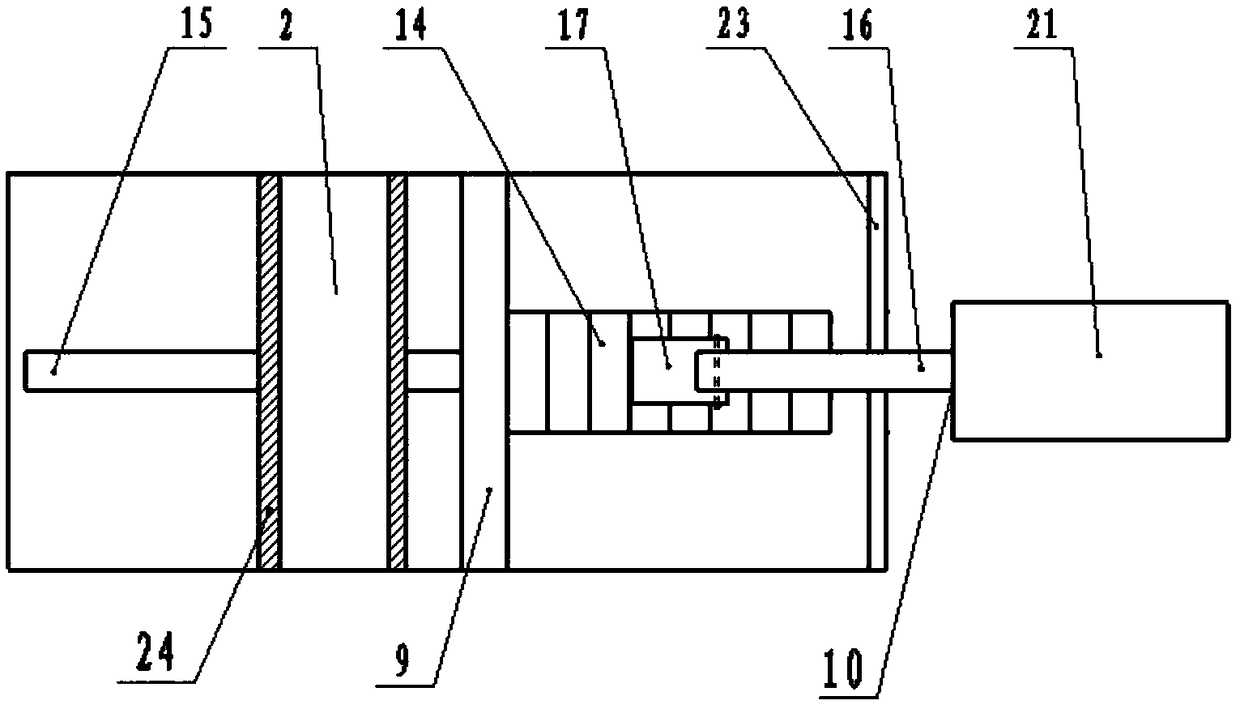

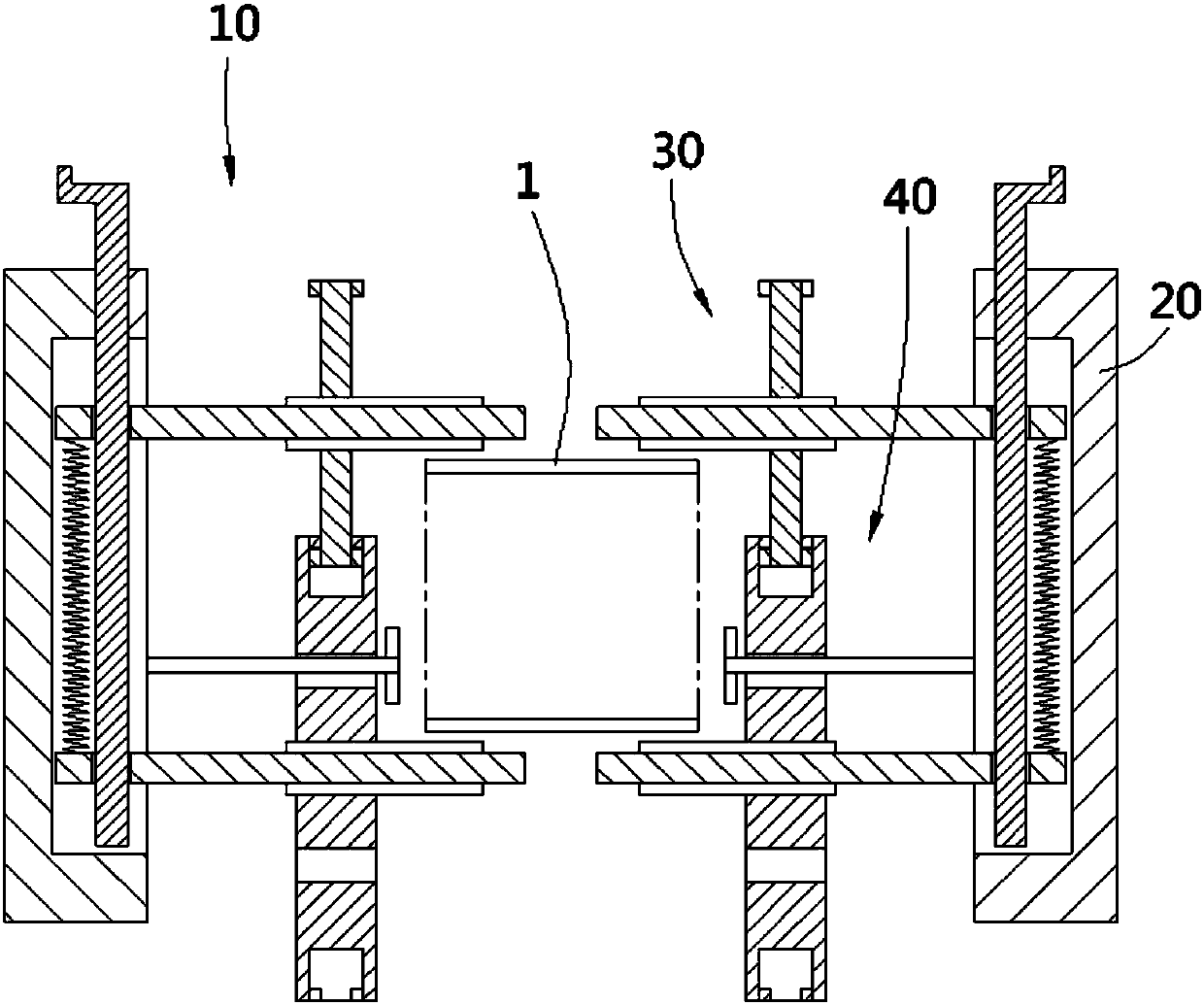

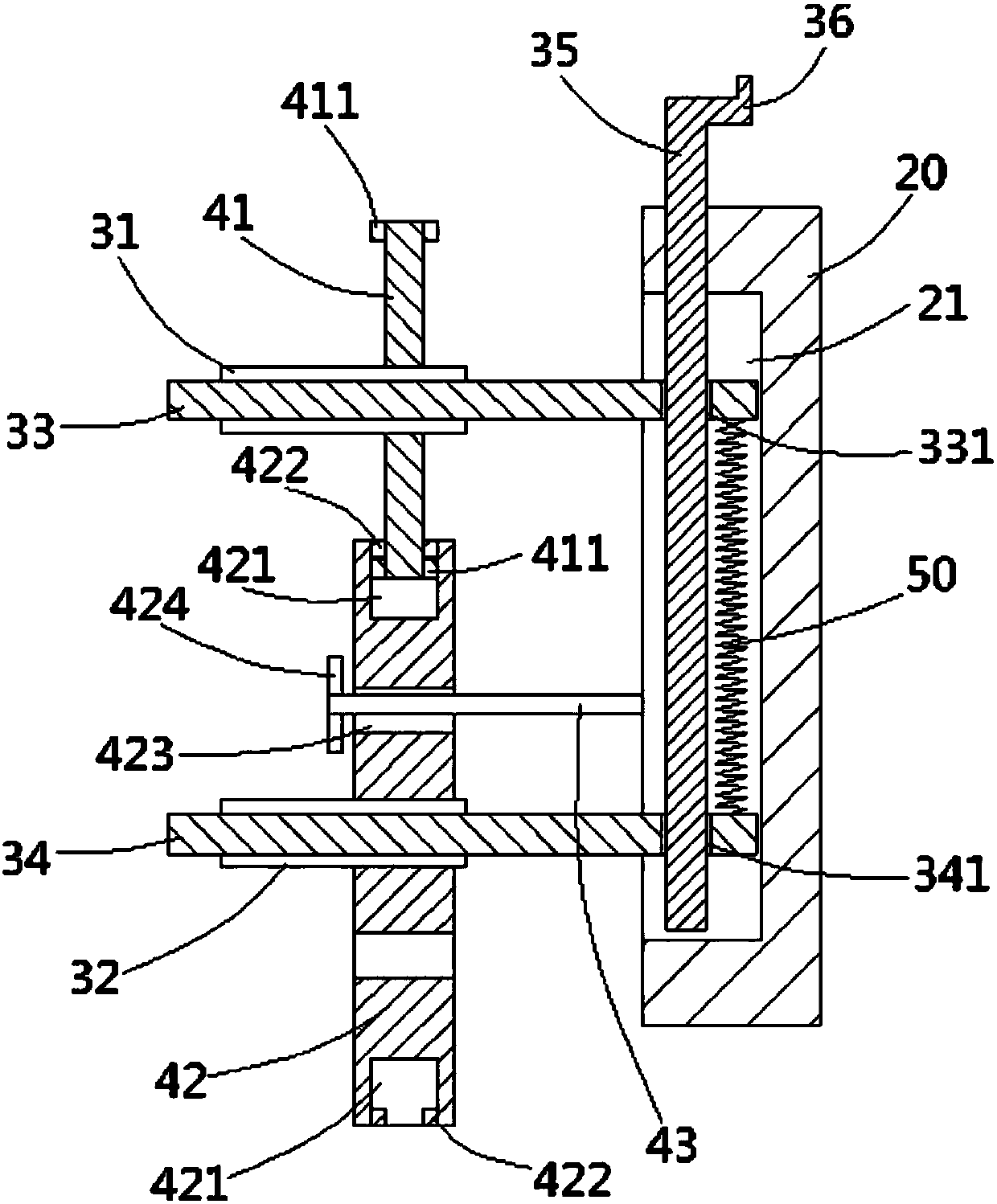

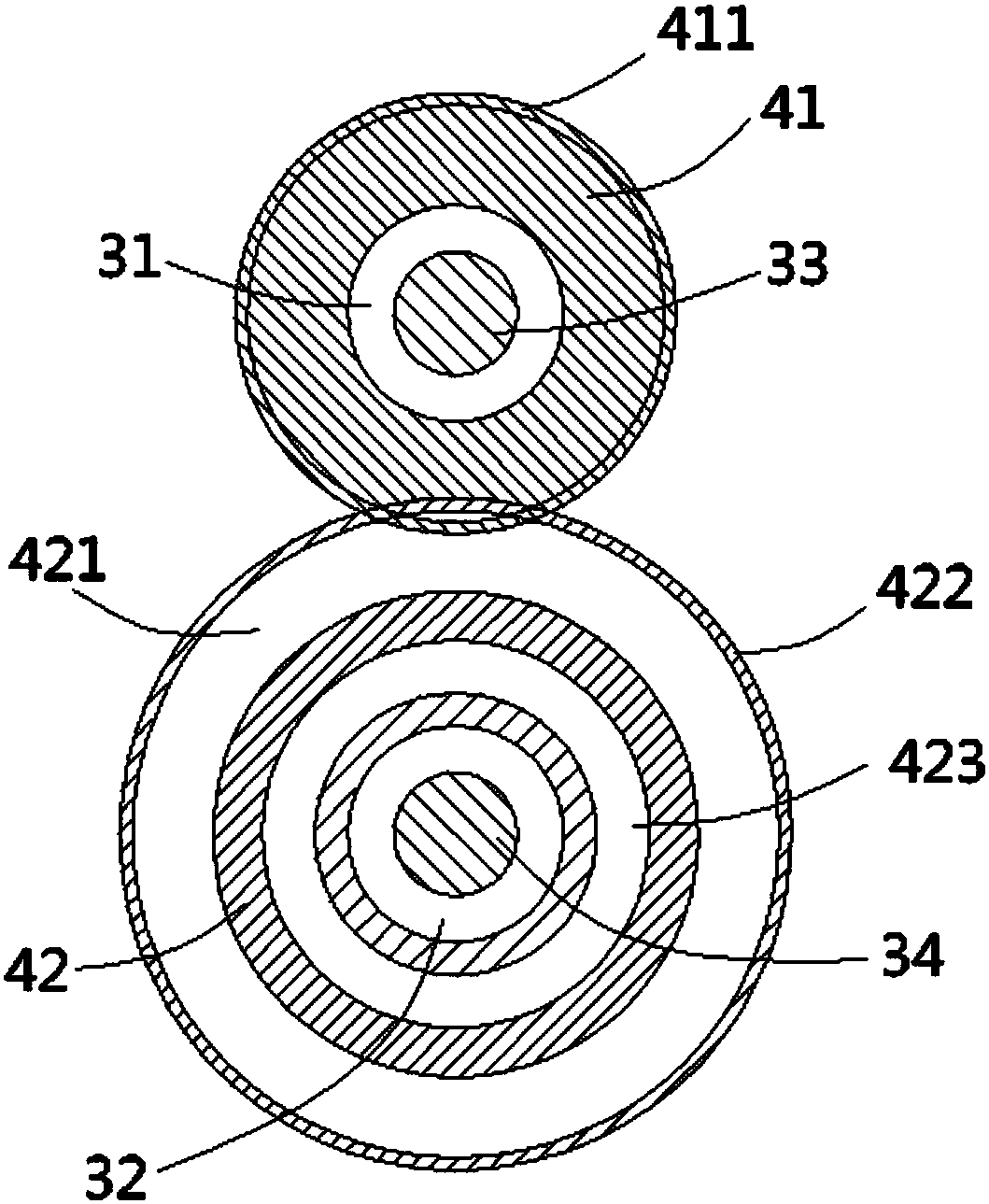

Transmission supporting mechanism for compact spinning carrier gear

InactiveCN111005100AEliminate manufacturing errorsReduce manufacturing costPortable liftingDrafting machinesYarnSpinning

The invention relates to a transmission supporting mechanism for a compact spinning carrier gear. The transmission supporting mechanism comprises a circular machine beam (1), wherein the circular machine beam (1) is provided with left and right roller seats (2); a front roller (3) is arranged between the front portions of the left and right roller seats (2); left and right gathering mechanisms (4)are arranged below the front roller (3); a support arm (6) is arranged in the middle of the circular machine beam (1) forwardly; one end of the gathering mechanism (4) is placed at the front end of the support arm (6), and the other end of the gathering mechanism (4) is arranged at the front part of the left roller seat or the right roller seat (2). The front roller drives left and right gathering small rollers through the left and right compact spinning carrier gears respectively, so that the load borne by the compact spinning carrier gear is greatly reduced, the compact spinning carrier gear is not prone to being damaged, the service life is greatly prolonged, the maintenance cost of a user is reduced, stable transmission is ensured, and the yarn quality is effectively guaranteed.

Owner:江阴市华方新技术科研有限公司

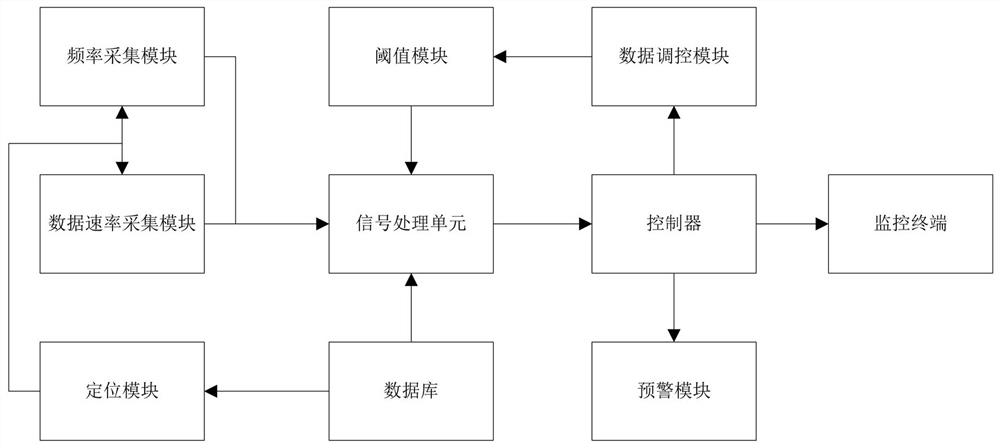

Smart park network monitoring system based on Internet of Things

InactiveCN113179196AWill not affect normal transmissionAvoid false alarmsData switching networksInstrumentsThe InternetData acquisition

The invention discloses a smart park network monitoring system based on the Internet of Things, and the system comprises a frequency collection module, a data rate collection module, a positioning module, a signal processing unit, and a database. When the instantaneous data volume of data acquisition points and equipment control points of the smart park monitoring system is too large, a controller controls a data regulation and control module to regulate a data transmission channel in time, the data regulation and control module controls threshold information sent by a threshold module according to the regulated data transmission channel, and when three-channel network transmission is carried out, the data regulation and control module controls the corresponding data acquisition point or equipment control point to send information in a delayed mode to adjust the state that the instantaneous data volume of each data acquisition point and equipment control point is too large in time.

Owner:深圳市利申和科技有限公司

Method and system for message delivery and message processing device

ActiveCN104980450BGuaranteed stabilityGuaranteed correctnessTransmissionMessage processingMessage passing

The invention provides a message transmission method and system and a message-oriented middleware. The message transmission method comprises: a message sender issues messages with different attribute information; the message-oriented middleware receives the issued messages and extracts the attribute information of the messages on an appointed attribute; the message-oriented middleware determines whether the extracted attribute information is the same as preset attribute information saved in an error information table; if not, the message-oriented middleware transfers the received messages to a message consumer or maintains the received messages; if yes the message-oriented middleware sends the maintained messages according to a predetermined sequence. By means of the embodiments of the invention, improvements in the orderliness and the stability of message transmission are facilitated.

Owner:ALIBABA GRP HLDG LTD

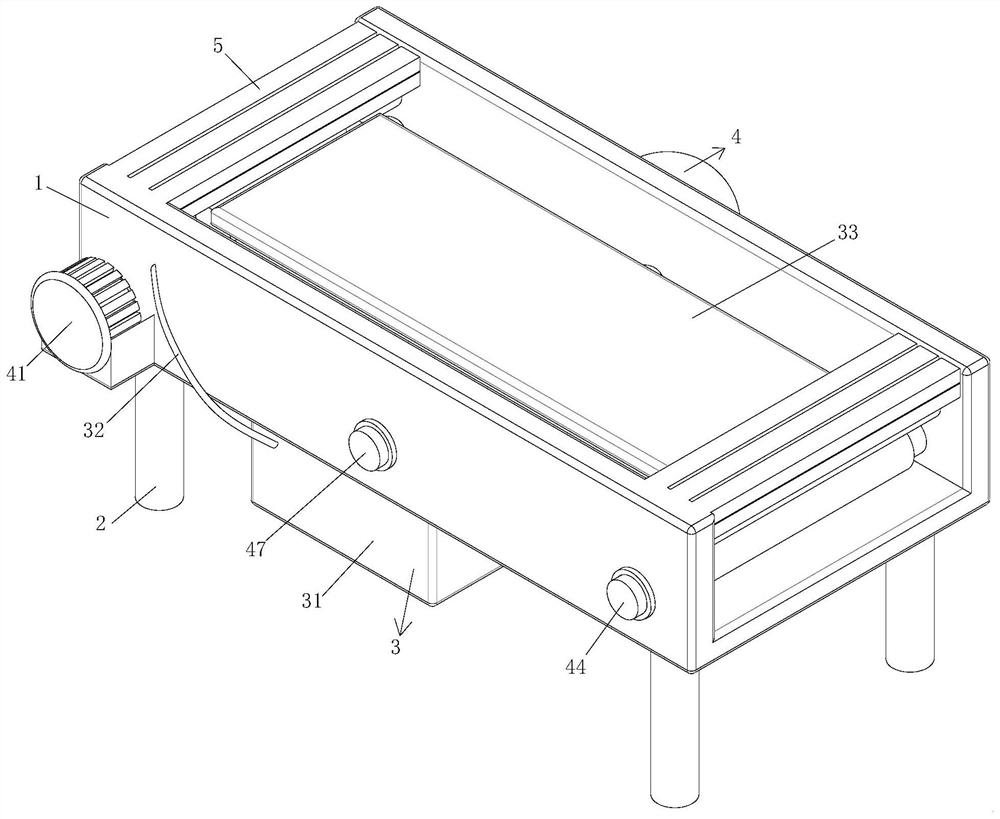

A conveyor belt electret machine based on molybdenum wire to add static electricity to the mask

ActiveCN111663322BWill not affect normal transmissionEasy to addMechanical cleaningPressure cleaningEngineeringConveyor belt

The invention provides a transmission belt electret machine for adding static electricity to a mask based on molybdenum wire, including a body, support legs for supporting the body, an electrostatic electret mechanism for carrying out electrostatic electret to the mask, and an electrostatic electret mechanism for transferring the mask to The stretching mask transmission mechanism at the electrostatic electret mechanism, the support legs are fixedly connected to the bottom of the body, the surface of the body is concave, and the inner wall of the body is fixedly connected with a reinforcing support rod, which relates to the field of electret machines. The conveyor belt electret machine based on molybdenum wire to add static electricity to the mask is designed according to the existing mask stacking and overlapping problem of the electret machine that adds static electricity to the hole mask, and designs a special structure that can quickly add static electricity without slowing down, so that It solves the problem that the transmission speed of the general electret machine that adds static electricity to the mask is easily affected by the light weight and multi-fold nature of the mask itself. If the transmission is too fast, the inertia will cause the mask to stack or even flip, which will affect the efficiency of adding static electricity to the mask. question.

Owner:江苏索盈节能环保设备有限公司

A method for improving underground coal mining transmission efficiency

The invention discloses a method for improving underground cold mining conveying efficiency. A coal belt conveyor and baffle blocks are adopted. A plurality of rows of electromagnet blocks are evenly embedded to a conveyor belt of the coal belt conveyor, the thickness of each electromagnet block is equal to that of the conveyor belt, and smooth transmission of the conveyor belt on rollers of the coal belt conveyor cannot be affected by embedding of the electromagnet blocks. Connection line poles of the electromagnet blocks are arranged on one side of the conveyor belt. Connection lines poles of a coal conveying segment of the conveyor belt are provided with electric brushes. A baffle block pushing device is arranged at the position, corresponding to the conveyor belt, of the lower end of the coal belt conveyor, the baffle block pushing device pushes the baffle blocks to the conveyor belt, and the baffle blocks are connected with the powered-on electromagnet blocks in an attraction manner. The conveyor belt of the coal belt conveyor is provided with the baffle blocks which are circularly separated, the conveying efficiency of the coal belt conveyor can be improved by three times, and the phenomenon that coal slides easily is solved well.

Owner:CHONGQING VOCATIONAL INST OF ENG

A material pneumatic conveying system driven by a single piston sheath

ActiveCN105600452BLess likely to get stuckLower matching requirementsConveyorsEngineeringAtmospheric pressure

The invention discloses a pneumatic material conveying system capable of driving by utilizing a single piston sheath. The pneumatic material conveying system comprises a transmission pipeline unit and a driving air source unit, wherein the transmission pipeline unit is internally provided with a material to be conveyed; the driving air source unit is communicated with the transmission pipeline unit, so that positive / negative air pressure is generated in the transmission pipeline unit; the transmission pipeline unit is also internally provided with the piston sheath matched with a transmission pipeline; the axial end of the piston sheath is in contact with the material to be conveyed; the piston sheath makes movement in the transmission pipeline unit under the action of the driving air source unit so as to complete the pneumatic conveying of the material to be conveyed. The pneumatic material conveying system has the advantages of being good in compatibility, low in use cost, convenient and fast in delivery and high in safety, and being capable of guaranteeing the physical properties and accuracy of a sample.

Owner:HUNAN SUNDY SCI & TECH DEV

Efficient transmission device for underground coal mining

InactiveCN107117429AEasy to recycleWill not affect normal transmissionConveyorsEarth drilling and miningCoal miningElectromagnet

The invention discloses an efficient transmission device for underground coal mining. The device comprises a coal belt conveyor and a baffle plate; multiple rows of electromagnets are uniformly inlaid in a conveying belt of the coal belt conveyor; the electromagnets are as thick as the conveying belt; the inlaying of the electromagnets cannot influence smooth transmission of the conveying belt on a roller of the coal belt conveyor; connecting wire poles of the electromagnets are arranged on one side of the conveying belt; electric brushes are arranged on the connecting wire poles of a coal conveying section of the conveying belt; a baffle plate pushing device is arranged at the lower end, opposite to the conveying belt, of the coal belt conveyor; the baffle plate pushing device pushes the baffle plate onto the conveying belt; and the baffle plate is connected with the electrified electromagnets in an absorption manner. The baffle plate capable of circularly separating is arranged on the conveying belt of the coal belt conveyor, so that the conveying efficiency of the coal belt conveyor can be improved by three times, and the phenomenon of easy slip of coals is preferably solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

A green and efficient transportation equipment for underground coal mines

InactiveCN107187793BWill not affect normal transmissionSolve the phenomenon of slippingConveyorsEarth drilling and miningCoalBelt conveyor

The invention discloses novel environment-friendly and efficient transport equipment in an underground coal mine. The equipment comprises a coal belt conveyor and a baffle block. A plurality of rows of electromagnetic blocks are uniformly distributed and embedded in a conveying belt of the coal belt conveyor. The thickness of each electromagnetic block is equal to that of the conveying belt. The embedded electromagnetic blocks do not affect smooth conveying of the conveying belt on rollers of the coal belt conveyor. Connecting line poles of the electromagnetic blocks are arranged on one side of the conveying belt. An electric brush is arranged on the connecting line poles on a coal conveying section of the conveying belt. A baffle block pushing device is arranged at the position, corresponding to the conveying belt, of the lower end of the coal belt conveyor and pushes the baffle block onto the conveying belt. The baffle block is in attraction connection with the electrified electromagnetic blocks. By arranging the baffle block with a circulating separation function on the conveying belt of the coal belt conveyor, the conveying efficiency of the coal belt conveyor can be quadrupled, and the problem that coal is prone to slipping off is well solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

A guide belt of a cloth dryer with a deviation correcting device

The invention discloses a guiding band with a deviation correcting device, of a cloth dryer. The guiding band disclosed by the invention comprises a guiding band, wherein two deviation correcting mechanisms are symmetrically arranged on two sides of the guiding band; each of the deviation correcting mechanisms comprises a clamping unit and a pulling unit, wherein each clamping unit comprises an upper clamping roller, a lower clamping roller, an upper center shaft, a lower center shaft and a rotating screw rod; the upper clamping rollers are positioned over an edge of the guiding band, and the lower clamping rollers are positioned under the edge of the guiding band; each of the upper clamping rollers sleeves the corresponding upper center shaft in an inserting manner, and each of the lower clamping rollers sleeves the corresponding lower center shaft in an inserting manner; each of the rotating screw rods is sequentially in screw connection to the corresponding upper center shaft and the corresponding lower center shaft; each pulling unit comprises an inserting and connecting ring, an inserting and sleeving ring and a pulling air cylinder, wherein each inserting and connecting ring is molded on the outer side wall of the corresponding upper clamping roller; each inserting and sleeving ring is molded on the outer side wall of the corresponding lower clamping roller; an annular inserting and connecting groove is formed in the outer side wall of the circumference of each inserting and sleeving ring, and an annular through groove is formed in each inserting and sleeving ring; one end of a piston rod of each pulling air cylinder penetrates through the corresponding through groove and a limiting block is molded at the corresponding penetrated end. Through the adoption of the guiding band disclosed by the invention, the deviated guiding band can be pulled into a correct operating orbit, and the transporting of the guiding band is not influenced.

Owner:浙江嘉业印染有限公司

drain pipe

ActiveCN108758111BRealize separate cavity dischargeReduce CooldownPipe heating/coolingRigid pipesEngineeringShear force

The invention discloses a drainage pipeline. The drainage pipeline comprises a pipeline body. The top of the pipeline body is provided with an opening. Two partition boards are arranged in the middleportion of the pipeline body. The opposite faces of the two partition boards make contact with each other for sealing. The other ends of the two partition boards are integrally connected with the pipeline body. The two partition boards cut off a drainage channel in the middle of the pipeline body. A bottom drainage cavity is formed below the two partition boards. A clamping cavity is formed at theupper ends of the partition boards. An intermediate pipe is arranged in the clamping cavity. The middle of the intermediate pipe is provided with an independent drainage channel. The drainage pipeline can realize respective cavity discharge of two kinds of liquid simultaneously. The whole pipeline can be opened in the shearing process, water in the pipeline is discharged to give an effective warning. When shear force is large, the intermediate pipe can be pressed into the bottom drainage cavity below the partition boards to be protected. The drainage pipeline has good buffering performance and protective performance, also has the good warning effect and achieves the effect of high-efficiency liquid discharge.

Owner:山东泷瑞源电气科技有限公司

Method and system for constructing frequency domain reflecting fiber grating sensing network of bus topological structure

InactiveCN102589590BIncrease the measurement distanceLarge capacityConverting sensor output opticallyFiberGrating

Owner:WUHAN UNIV OF TECH

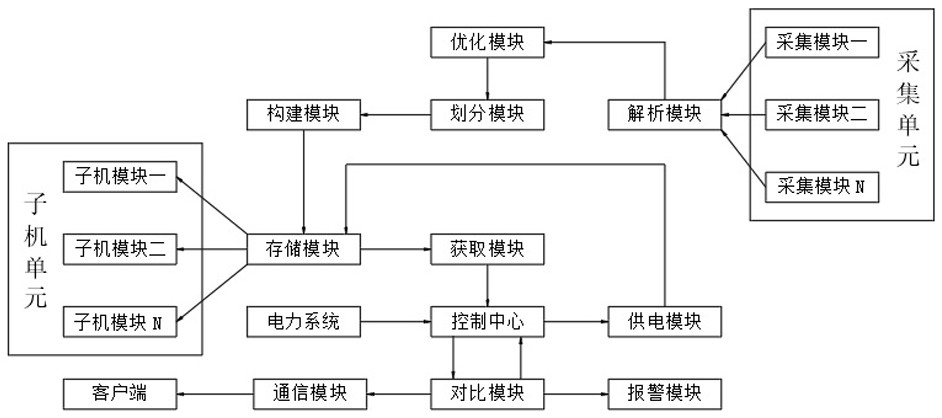

Distributed storage system with power failure protection function

PendingCN113946296AWill not affect normal transmissionReduce loss rateInput/output to record carriersDigital data information retrievalCurrent electricBusiness data

The invention relates to the technical field of storage systems, and discloses a distributed storage system with a power failure protection function, an acquisition unit is used for acquiring electric energy metadata, acquiring keywords under the current electric energy metadata and fields corresponding to the keywords, and sending the acquired electric energy metadata to an analysis module; and the analysis module is used for analyzing the electric energy metadata acquired by the acquisition unit and generating business data. The system is provided with a plurality of groups of sub-machine modules, so that a traditional storage mode is optimized, information to be stored can be uniformly dispersed to different storage spaces for storage, overload operation of single equipment is avoided, the overall operation of the storage system is more stable, and in the data storage process, comparison is carried out in a data comparison mode and a comparison result is generated, so that when a power failure or power failure phenomenon occurs, the power failure or power failure phenomenon can be inquired and emergently supplied, normal transmission of data is not affected, and the probability of data damage and local file loss is reduced.

Owner:蜂巢科技(南通)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com