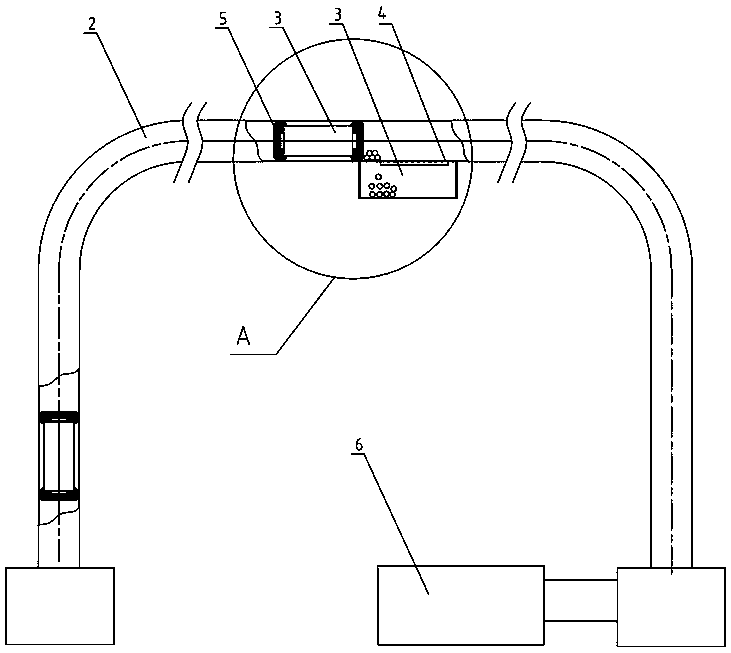

A material pneumatic conveying system with cleaning and collecting functions

A technology of pneumatic conveying and pneumatic transmission, applied in conveyors, transportation, packaging, packaging, etc., can solve the problems of increasing friction of objects to be conveyed, jamming of objects to be conveyed, high maintenance costs, and reducing the risk of breakage or blockage , Reduce the cost of use, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0048] Specific embodiment 1: as Figure 6 As shown, in this embodiment, a sealing flange assembly 37 is provided at both ends of the falling material collecting device 3 , and the falling material collecting device 3 is sealingly connected with the pneumatic transmission pipeline 2 at both ends through the sealing flange assembly 37 . The foreign matter settling part 4 is set in the falling material collection device 3, and the pneumatic transmission pipeline 2 at both ends of the falling material collecting device 3 is kept in transmission connection through the foreign matter settling part 4, that is, the object to be transported 1 or the piston sheath 5 is transferred from the pneumatic transmission pipeline 2 at one end. Enter the falling material collection device 3, pass through the foreign matter settlement part 4 in the falling material collecting device 3, and then output from the falling material collecting device 3, and then enter the pneumatic transmission pipeline...

specific Embodiment 2

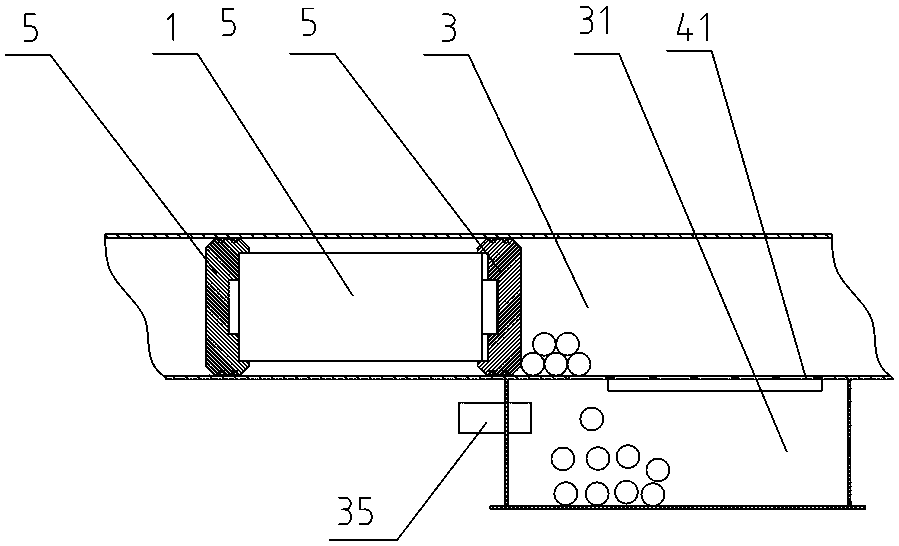

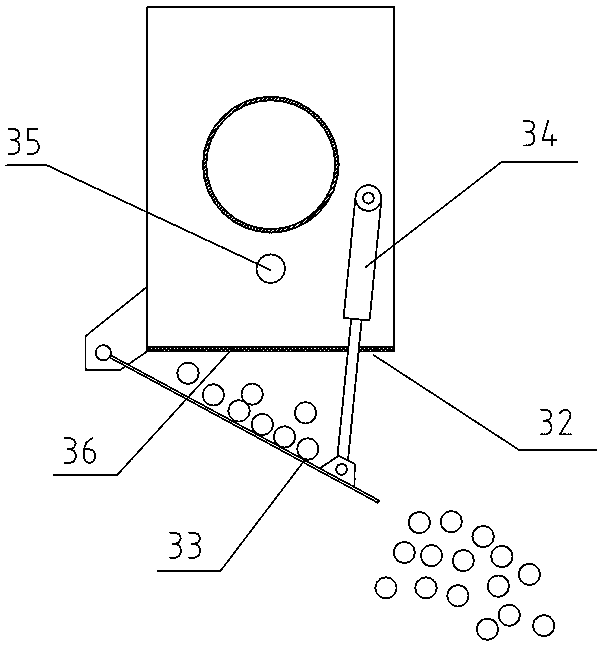

[0050] Specific embodiment 2: as Figure 7 As shown, in this embodiment, the falling material collection device 3 is arranged under the pneumatic conveying pipeline 2 , and the foreign matter settling part 4 is arranged on the bottom wall of the pneumatic conveying pipeline 2 . The top of the falling material collecting device 3 is provided with an opening. The staff does not need to disconnect the pneumatic transmission pipeline 2, but only needs to set the foreign matter settlement part 4 on the pipeline bottom wall of the pneumatic transmission pipeline 2 (a man-made one such as Figure 5 large-area settling holes 41 as shown, or use a Figure 4 The shown gasket with a plurality of settling holes 41 is placed on the opening of the bottom wall of the pneumatic transmission pipeline 2), and then the falling material collecting device 3 is sealed and fixed under the foreign matter settling part 4, so that the falling material collecting device 3 The top opening of the filter...

specific Embodiment 3

[0051] Specific embodiment 3: as Figure 8 As shown, in this embodiment, the falling material collection device 3 is arranged below the pneumatic transmission pipeline 2, and the foreign matter settlement part 4 is arranged on the top wall of the blanking material collection device 3 (only one such as Figure 5 Large-area settling holes 41 as shown, or set as Figure 4 A plurality of settling holes 41 are shown), and the bottom wall of the pneumatic transmission pipeline 2 at the foreign matter settling portion 4 is provided with an opening 21 that cooperates with the foreign matter settling portion 4 . The worker only needs to open an opening 21 on the bottom wall of the pneumatic transmission pipeline 2, then align the falling material collection device 3 with the foreign matter settlement part 4 with the opening 21, and install it under the pneumatic transmission pipeline 2 in a sealed manner. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com