A method for improving underground coal mining transmission efficiency

A technology of transmission efficiency and conveyor, which is applied in the field of coal mining, can solve the problems of coal slippage and low transmission efficiency of coal mining belt, and achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

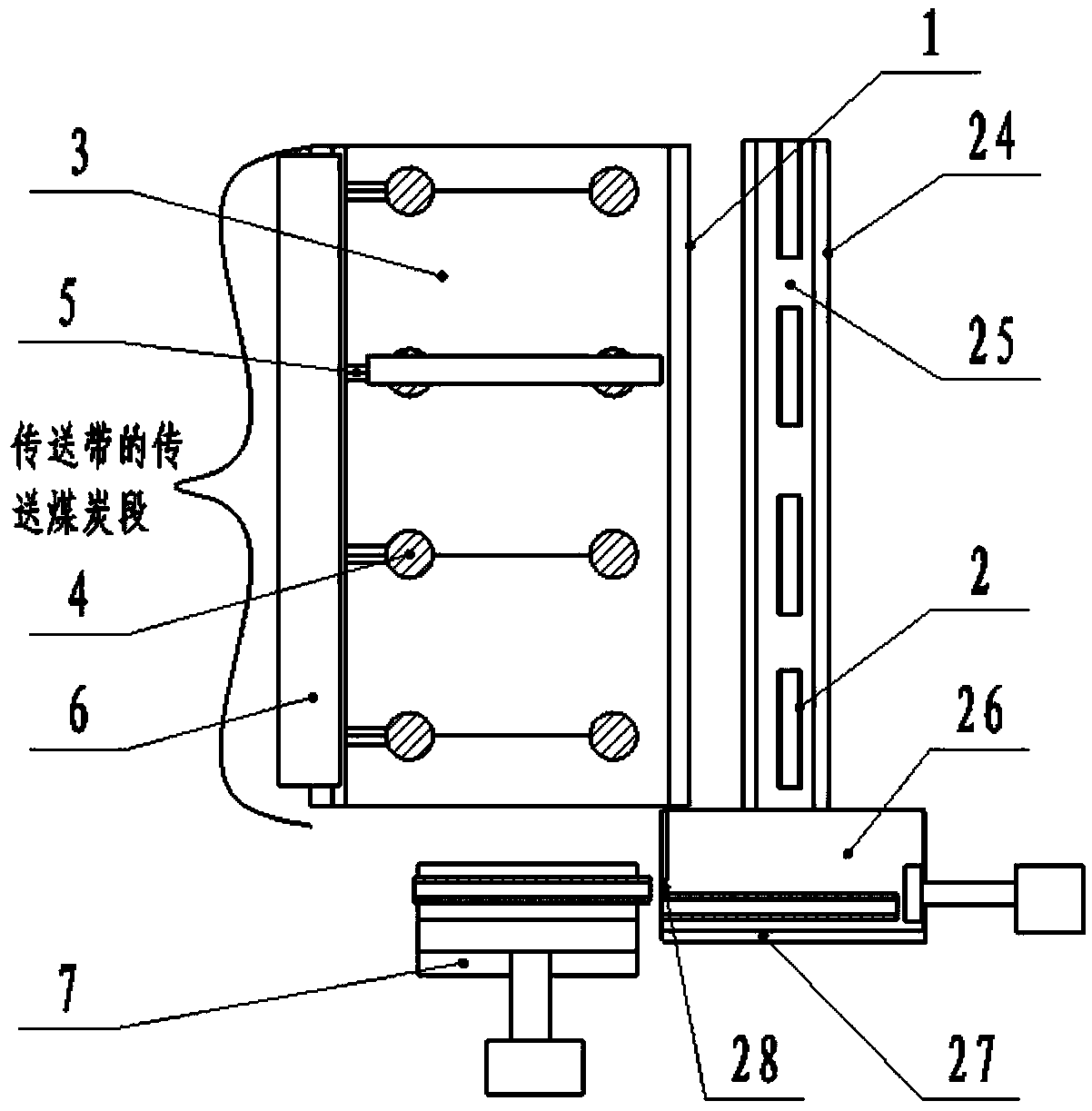

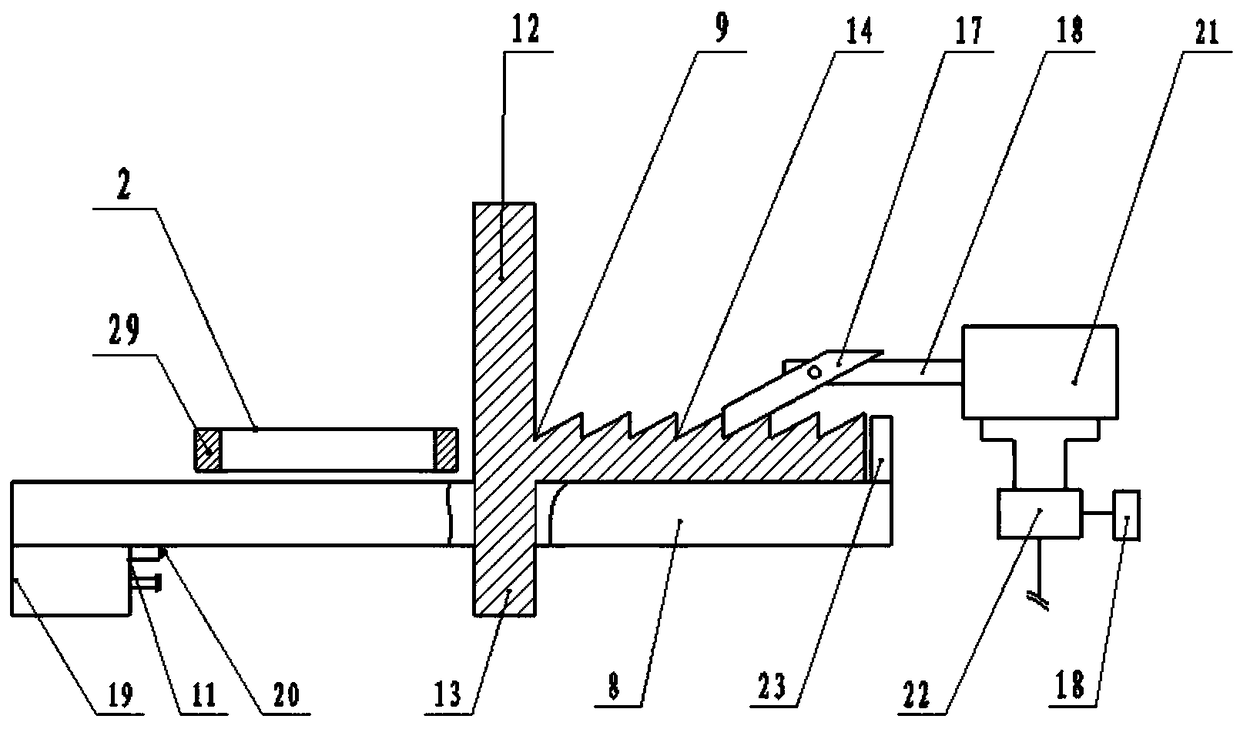

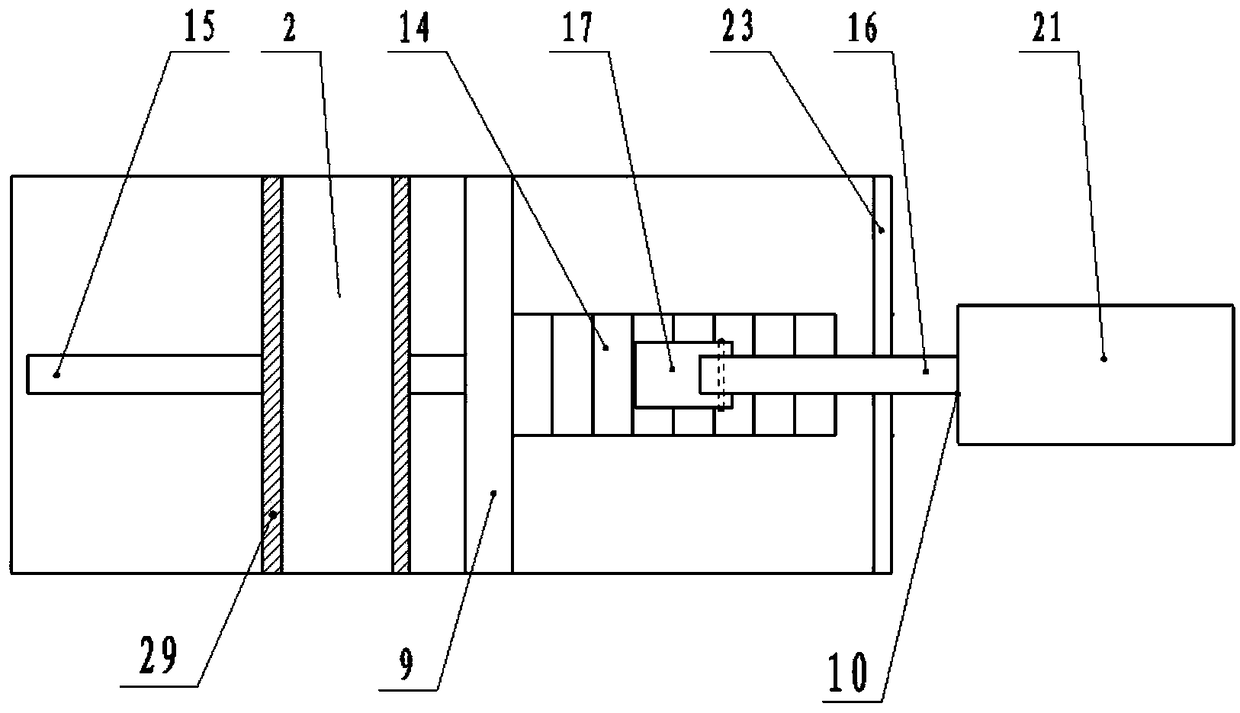

[0033] like figure 1 As shown, a method for improving underground coal mining transmission efficiency of the present invention includes a coal belt conveyor 1 and a baffle plate 2, and the coal belt conveyor 1 can adopt a fixed general-purpose belt conveyor of the Jinding Coal Machine DTII (A) type: DTⅡ(A) general-purpose new series general-purpose belt conveyor is an updated series after the first revision after optimization and absorption of domestic and foreign advanced technologies on the basis of DTⅡ general-purpose series. Widely used in coal, mining, metallurgy, port, power station, building materials, petroleum, chemical industry, light industry and other industries. It only needs to further improve the transmission belt of the DTⅡ(A) type fixed universal belt conveyor, which is convenient to implement, low in cost and high in efficiency.

[0034] The conveyor belt 3 of the coal belt conveyor 1 is uniformly inlaid with multiple rows of electromagnet blocks 4, the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com