A material pneumatic conveying system driven by a single piston sheath

A pneumatic conveying and single-piston technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of low safety, high matching degree of sample bottle and pipeline, and precipitation, etc., to ensure physical characteristics and accuracy, and pneumatic conveying Various methods, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

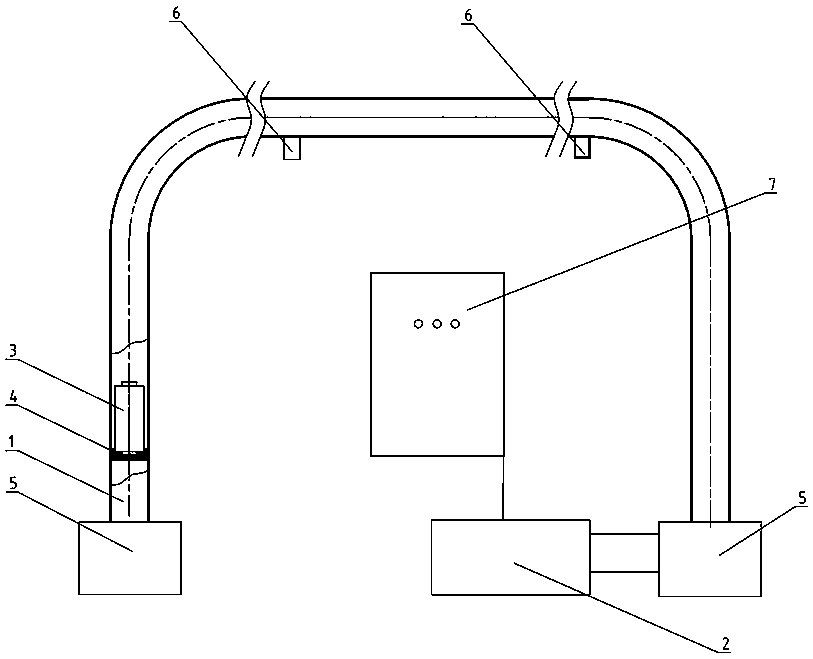

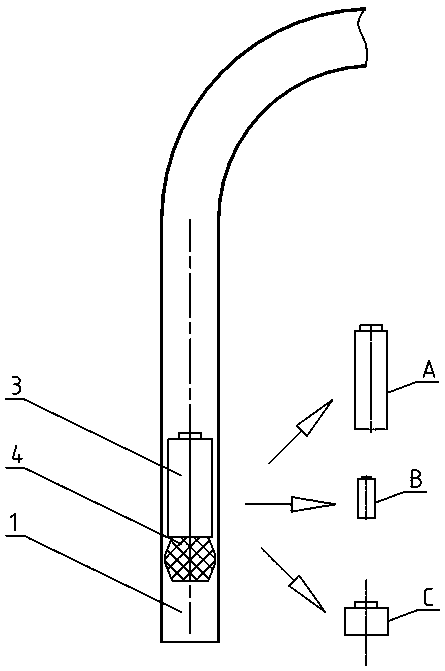

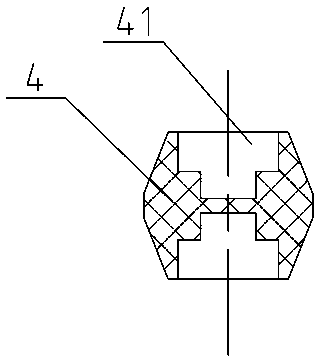

[0050] Specific embodiment 1: as image 3 As shown, in a preferred embodiment, the axial end surface of the piston sheath 4 is provided with a fixing portion 41 for fixing the object 3 to be conveyed. By arranging the fixing part 41, the piston sheath 4 can be arranged behind the object 3 to be conveyed for pushing the object 3 to be conveyed, and the piston sheath 4 can be arranged in front of the object 3 for conveying. Pulling the object to be conveyed 3 realizes the conveyance; by cooperating with the driving air source unit 2 capable of generating positive / negative air pressure in the conveying pipeline unit 1, the pneumatic conveying methods of the present invention are varied and flexible. In this preferred embodiment, the fixing part 41 includes a concave bracket arranged on the end surface of the piston sheath 4, and the object to be transported 3 such as figure 1 As shown, one end of it is clamped and fixed in the concave bracket.

[0051] Such a special design has...

specific Embodiment 2

[0052] Specific embodiment 2: as Figure 4 As shown, the fixed portion 41 includes a recessed protection cavity 44 arranged on one end of the piston sheath 4, the protection cavity 44 is used to carry the object to be conveyed 3 so that the object to be conveyed 3 does not contact the transmission pipeline unit 1, and the opening of the protection cavity 44 A matching guide part 45 is provided at the end. When the piston sheath 4 pushes the object 3 to be conveyed, the guide part 45 first contacts the object 3 to be conveyed and guides the object 3 to be conveyed into the protection cavity 44 under the action of thrust.

[0053] Through such an arrangement, there are the following advantages: First, because the object 3 to be conveyed is carried on the protection cavity 44 and does not contact the transmission pipeline unit 1, the piston sheath 4 forms a more comprehensive protection for the object 3 to be conveyed, further ensuring that the air pressure does not It will direc...

specific Embodiment 3

[0059] Specific embodiment 3: as Figure 5As shown, in this preferred embodiment, the axial ends of the piston sheath 4 are symmetrically tapered, so that the overall shape of the piston sheath 4 is a drum shape with thin ends and a thick middle, so that when the piston sheath 4 is stationary, Contact with the transfer pipe unit 1 is maintained only through the axial middle. Through such a special scientific design, first, the contact surface between the piston sheath 4 and the transmission pipeline unit 1 is small, reducing the friction between the piston sheath 4 and the transmission pipeline, and the transmission resistance is small; second, this special structure makes the piston sheath 4 4. During the high-speed pneumatic conveying in the conveying pipe unit 1, it can flexibly adapt to the direction of the pipe, and effectively prevent the piston sheath 4 from turning over and being stuck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com