Impurity cleaning device for material pneumatic transmission system

A pneumatic transmission and cleaning device technology, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of complex electric warehouse opening structure, high maintenance cost, and pipeline wear, so as to eliminate the risk of high-altitude operations, and the overall The structure is simple and compact, and the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

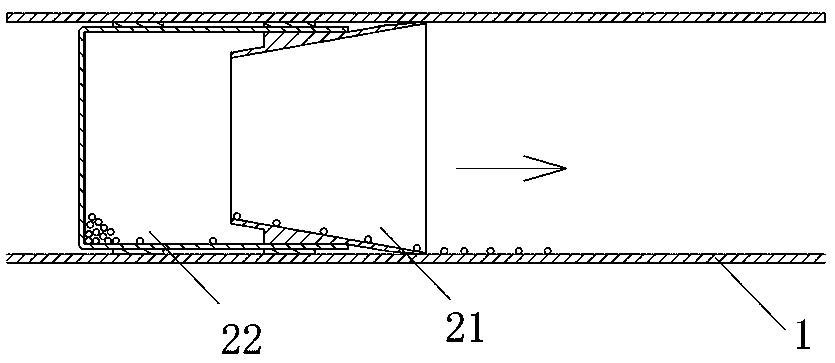

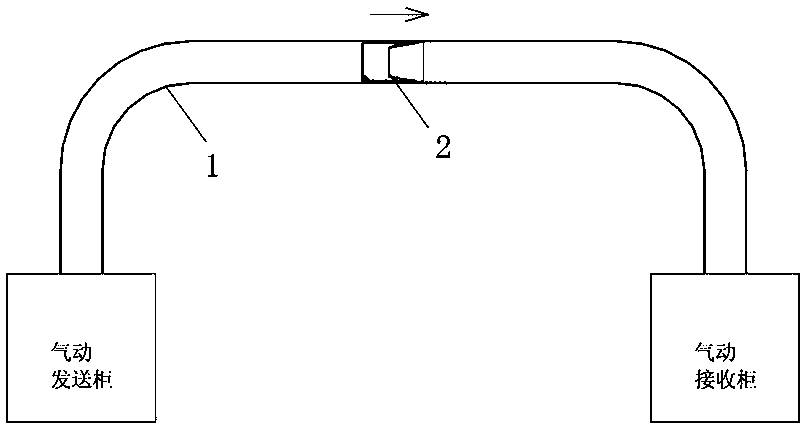

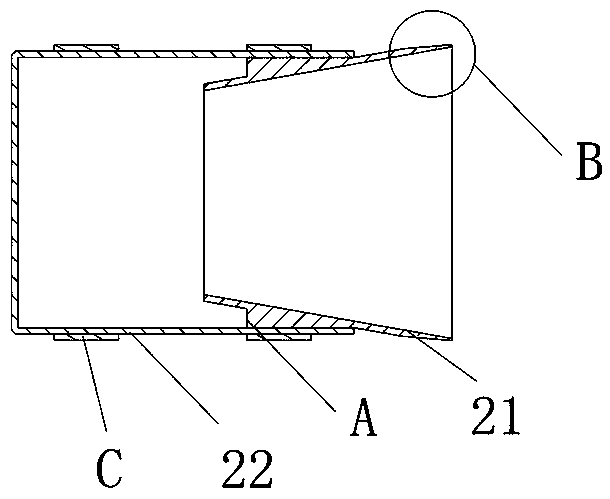

[0031] Such as Figure 1 to Figure 4 As shown, the present invention provides an impurity cleaning device for a material pneumatic conveying system, which includes a moving body 2 that can be pneumatically conveyed in a pneumatic conveying pipeline 1, and the length of the moving body 2 is not longer than 2 meters. At least one end opening of the mobile body 2 forms a shovel portion 21 for shoveling impurities in the pneumatic transmission pipeline 1 into the mobile body 2 for collection during transmission of the mobile body 2 . The specific implementation principle is as follows:

[0032] When the operator thinks it needs to be cleaned, he can put the impurity cleaning device directly into the pneumatic transmission pipeline 1 at any time, and then operate the pneumatic transmission system normally, so that the mobile body 2 is pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com