A Classification Method for Processing Attributes of Threshing and Red-cured Tobacco Leaves

A technology of threshing, redrying, and attribute classification, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of quality loss, insufficient processing strength, and excessive processing strength of tobacco leaves, and achieves the improvement of adaptability and processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention, and further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0036] A method for classifying processing attributes of threshed red-cured tobacco leaves, comprising the following steps:

[0037] (1) Collect 658 grades of tobacco leaves allocated by the tobacco company within three years as tobacco leaf samples, select stem content rate, leaf surface density, tension, average moisture content, filling value, and 5 tobacco leaf physical quality indicators as characteristics, and take each tobacco leaf Each eigenvalue of the sample (corresponding eigenvalues already exist in the database of a general tobacco enterprise and does not need to be re-measured) is stored in a vector X, which is the tobacco leaf sample data.

[0038] Then according to formula 1. Standardize all data to obtain modeling sample data.

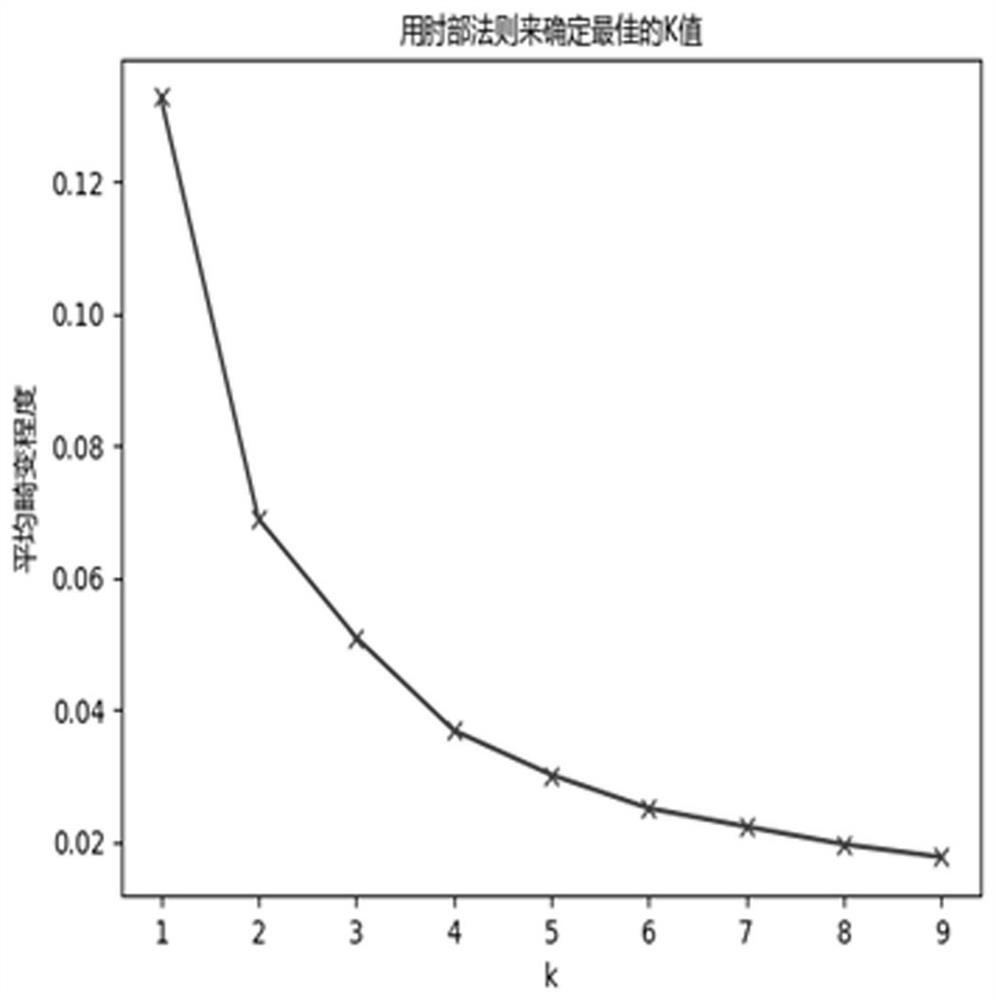

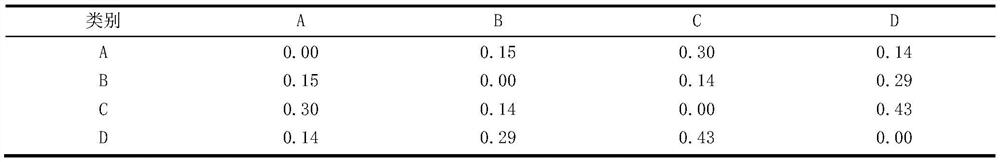

[0039] (2) The number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com