Saw blade right-angle head

An angle head and right-angle technology, applied in the field of saw blade right-angle head, can solve the problems of cumbersome and complicated assembly process, increase processing time, strict assembly requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with a specific embodiment.

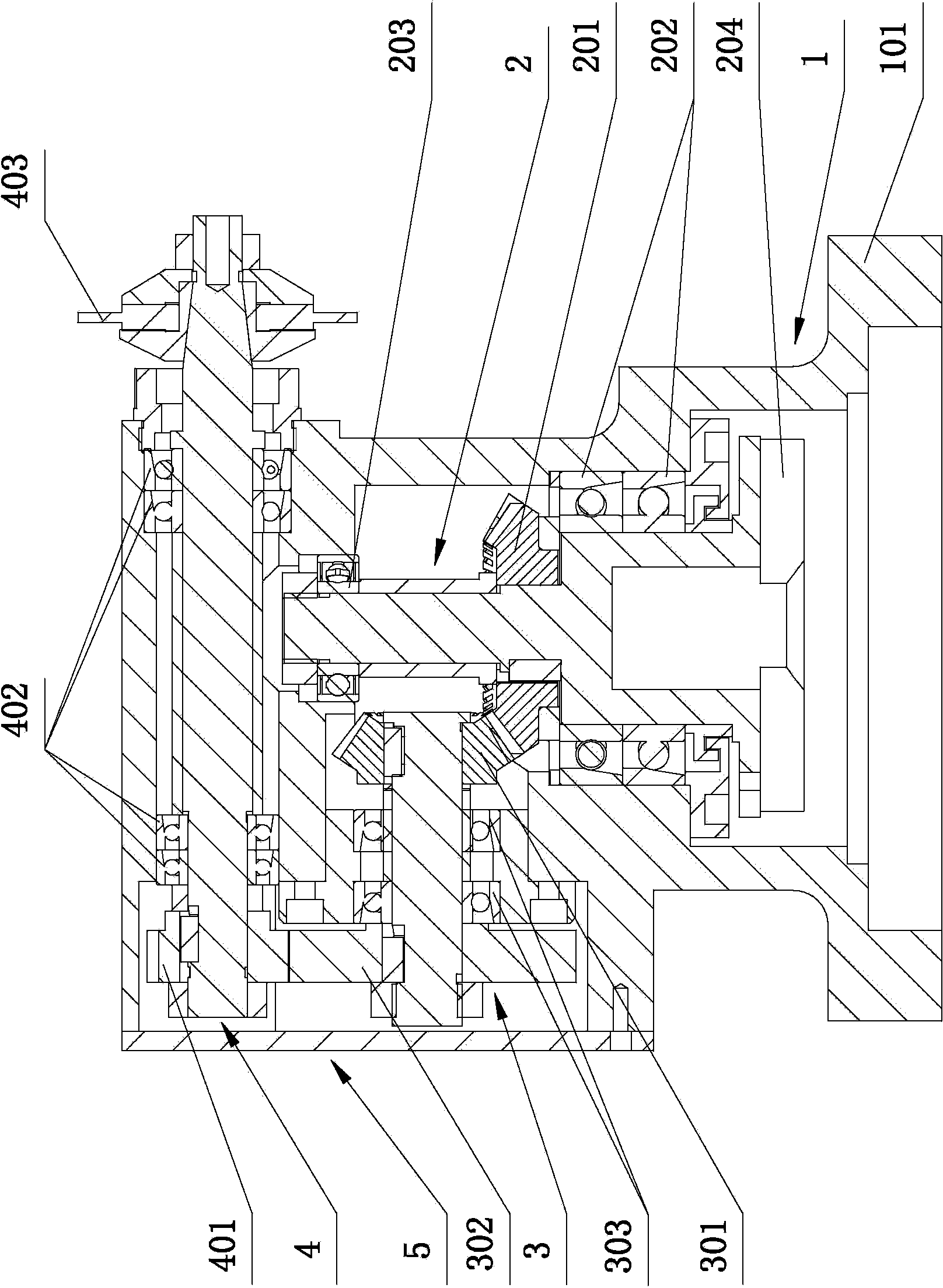

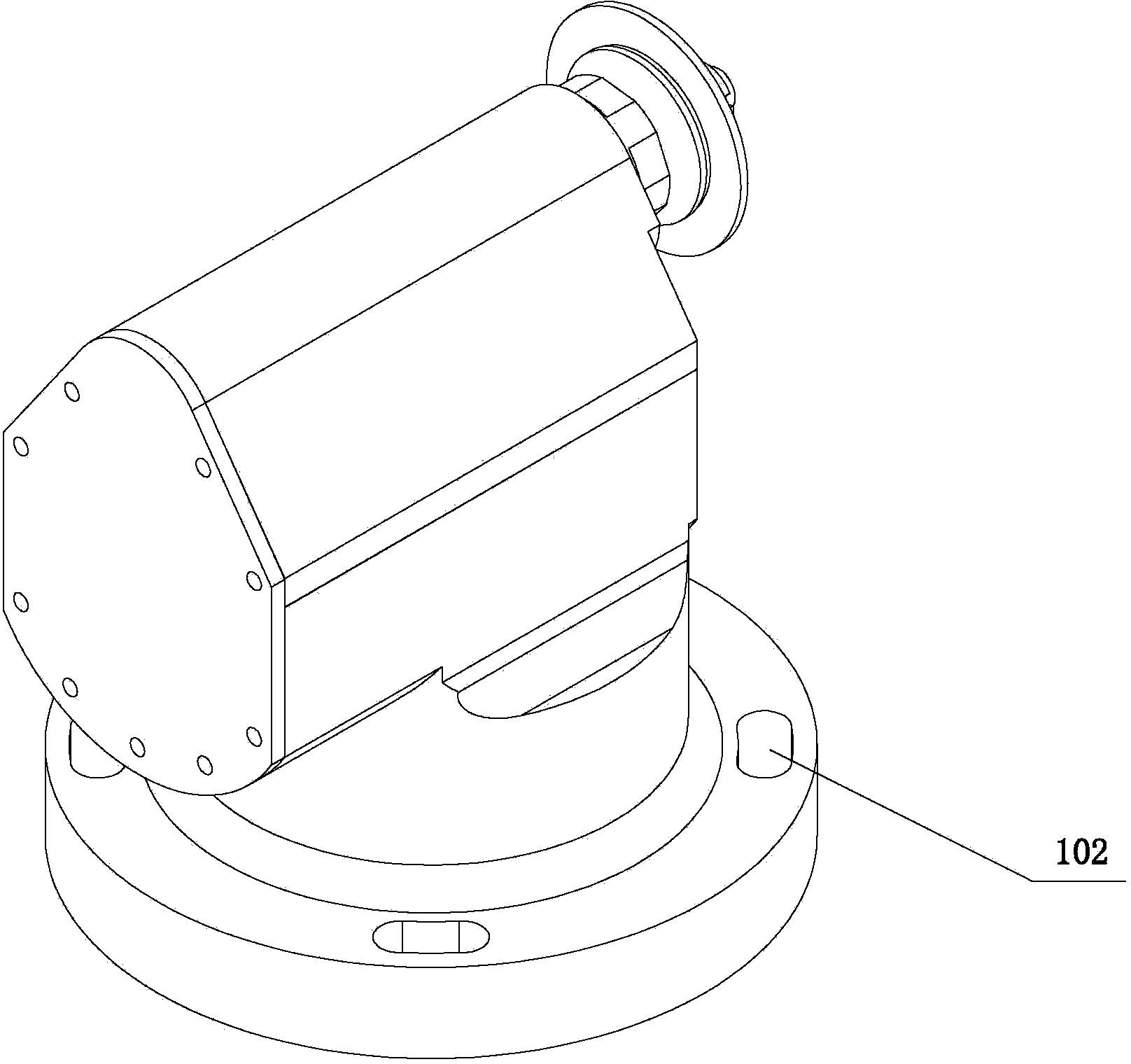

[0014] See attached figure 1 And attached image 3 As shown, this embodiment includes an angle head main body 1 , a driving shaft 2 , a driven shaft 3 , a saw blade shaft 4 , and an end cover 5 . When the angle head main body 1 is placed vertically, the driving shaft 2 is installed at the vertical center position of the lower part of the angle head main body 1 . Two angular contact ball bearings 202 are installed on the drive shaft 2 close to the chassis flange 101 , and the two angular contact ball bearings 202 are in contact and have the same installation direction. A deep groove ball bearing 203 is installed at a position away from the chassis flange 101 , and the three together ensure the centering of the drive shaft 2 inside the angle head main body 1 and the rigidity of the drive shaft 2 . A bevel gear 201 is installed between the deep groove ball bearing 203 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com